Effect of Processing Conditions and Die Design on Die Drool Phenomenon for HDPE Polymer Melt¶

Martin Zatloukal1,2, Jan Musil1,2

1 Polymer Centre, Faculty of Technology, Tomas Bata University in Zlín, nám. T. G. Masaryka 275,

762 72 Zlín, Czech Republic

2 Centre of Polymer Systems, Tomas Bata University in Zlín, nám. T. G. Masaryka 5555,

760 01 Zlín, Czech RepublicAbstract

In this work, the die drool phenomenon analysis has

been performed for HDPE polymer melt by using specific

type of experimental set-up. It has been revealed that the

thermally induced degradation occurring inside the

processing equipment may leads to HDPE melt

viscosity/elasticity enhancement, which promotes

unwanted material accumulation at the end of the

extrusion die. It has been found that for particular

processing conditions, shaped die, flared die or the use of

hard chrome instead of stainless steel can reduce die drool

phenomenon for HDPE.

Introduction

Die drool, also called die build-up, die bleed or plateout,

is undesirable spontaneous accumulation of polymer

melt at the exit edges or open faces of extrusion die during

melt extrusion of polyolefins, PVC, or filled polymers.

This unwanted phenomenon can occur in all common

extrusion processes (film blowing, pipe or profile

extrusion, fiber spinning, film casting etc.) and after it

arises, the productivity of extrusion line rapidly decreases

from following basic reasons. Firstly, small amount of

accumulated and usually degradated material sticks to the

extrudate at the die exit region which cause depreciation

of the final product. In the case of film casting or

extrusion of solid profiles is possible to solve this problem

only by strip the accumulated material from the die exit

region. However, in the case of film blowing, pipe, cored

profile extrusion or wire sheathing the die drool arises not

only at the outer exit region but also at the inner one

thereby the first clean opportunity is impossible.

Therefore, in these cases the extrusion line is necessary to

periodically switch off and after cleaning the die which is

uneconomical and time consuming.

The fundamental problem of die drool phenomenon is

to understand and describe the formation principle of this

phenomenon. In the open literature, several factors have

been found to support the formation of this instability.

They include pressure fluctuations in screw [1], volatitilies, low molecular fractions of the polymer, fillers,

poor dispersion of pigments [2], die swell [1, 3],

processing near degradation temperature [4], dissimilar

viscosities in blends [5], die design [6, 7, 8] etc.

At the present time, two basic types of die drool

phenomenon are known: external and internal. It has been

recently found that the external type of die drool

phenomenon for metallocene type of LLDPE polymer is

predominantly driven by the extrudate free surface rupture

and suction effect due to negative pressure generated at

the die exit region [9, 10] which can be suppressed by the

die exit angle modification [9, 10]. On the other hand, the

internal type of die drool phenomenon can be caused by

the flow induced fractionation occurred before the

polymer melt leave the extrusion die which is not fully

understood yet [11]. Thus, the effect of processing

conditions and die design on this unwanted flow

phenomenon has been investigated in this work for unfiled

HDPE extrusion through annular extrusion die.

Experimental

Material characterization

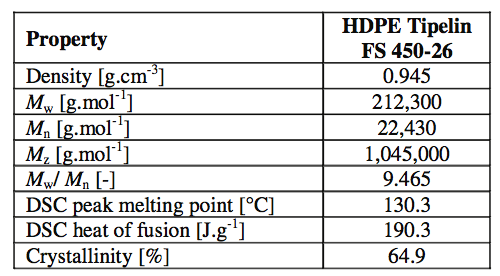

In this work, HDPE Tipelin FS 450-26 (TVK,

Hungary) polymer, widely used in the film extrusion was

chosen for the experimental research. The basic material

characteristics are provided in Table 1 and [12]. In order

to evaluate the HDPE polymer thermal stability, firstly,

polymer pellets were added and melted in the Rosand

RH7-2 control speed capillary rheometer equipped by

capillary die having 16mm length and 1mm radius. After

each 10 minutes of the rest, the constant shear rate (80 s

-1)

has been applied and the equilibrium capillary pressure

drop has been measured. This procedure was repeated 30

times to cover 5 hour degradation time period after which

the extruded polymer has been collected. This procedure

was applied for two different melt temperatures T = 210

oC and T = 260

oC. Effect of processing temperature and time

on the extrusion pressure for the tested HDPE sample is

provided in Figure 1. It is clearly visible that the extrusion

pressure rise occurs during the time suggesting that

temperature induced degradation leads to molecular weight increase of the tested polymer and the effect is

much more pronounced for the higher temperature.

Die drool measurements

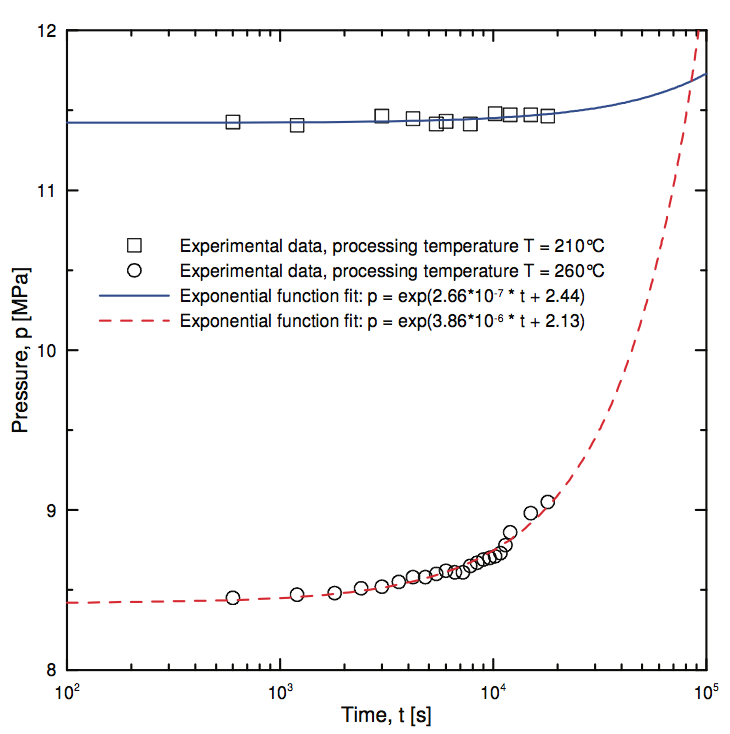

The die drool experiments were carried out on a

conventional Brabender Plasti – Corder 2000 single-screw

extruder with diameter D = 30 mm and L = 25 D (standard

single-thread screw with compression ratio 4:1, and

lengths of zones: feed L

1 = 10D, compression L

2 = 3D, metering L

3 = 12 D) which was included in the laboratory extrusion line. The schematic view of laboratory extrusion

line is depicted in Figure 2. This line consists of extruder

with four heating zones, transition annular part, specially

designed extrusion die, which is introduced in [9, 10],

photo camera placed near the die exit, and draw-off

mechanism. In our experiments, two different processing

conditions were used. In the first case, the extruder zones

(from the hopper to the die) were heated to

T

1 = 80°C, T

2 = 200°C, T

3 = 240°C and

T

4 = 260°C whereas in the

second case, third and fourth extruder zone temperatures

were decreased to T

3 = T

4 = 210°C by keeping the annular

tube (connecting die and extruder) and die exit

temperature in both cases constant, T

5 = T

6 = 150°C. Die

drool accumulation has been investigated for both

temperature profiles along the screw and constant mass

flow rate (1.1 kg.hr

-1). In this study, following extrusion

dies were utilized: straight die, shaped die, flared die

manufactured from stainless steel and straight die

manufactured from hard chrome material (see Figure 5 for

more detail). For each individual test, barrel, screw and all

parts of the die have been perfectly cleaned to ensure the

reproducibility of the performed measurements.

Results and discussion¶

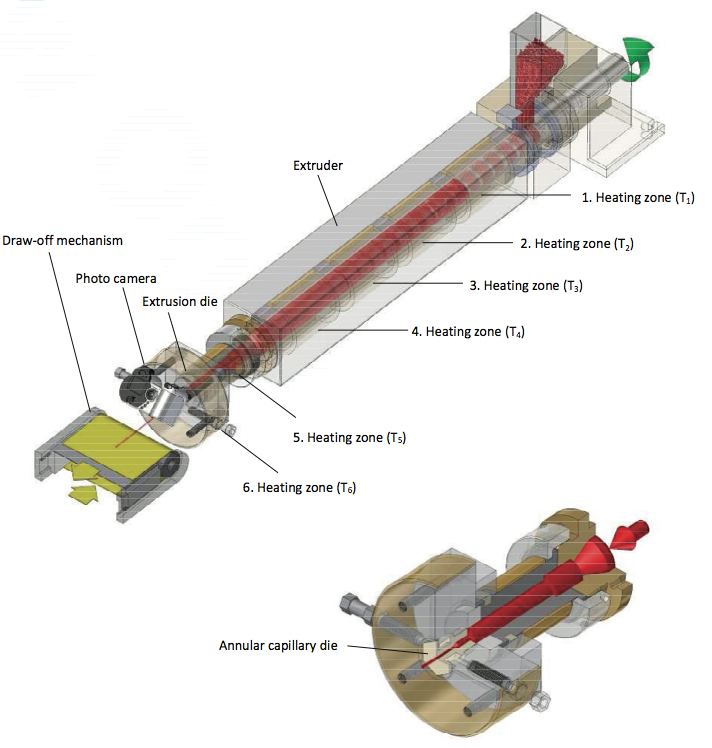

The character of the die drool phenomenon for HDPE

within the time has been investigated for the following

processing conditions at which the die drool intensity was

found to be the highest: temperature profile along the

screw: T

1 = 80°C, T

2 = 200°C, T

3 = 240°C, T

4 = 260°C;

annular tube (connecting die and extruder) and die exit

temperature T

5 = T

6 = 150°C; mass flow rate = 1.1 kg.hr

-1.

The obtained results are depicted in Figure 3. It is clearly

visible that the accumulated material takes a torus shape

along the exrudate surface rather than flakes or powder as

in the case of external mLLDPE die drool phenomenon

[9-10]. Moreover, no surface defects occur during the

HDPE die drool accumulation which lead us to the

conclusion that rupture of the extrudate free surface at the

die exit is not driving factor in this case (unlike for

mLLDPE [9-10]).

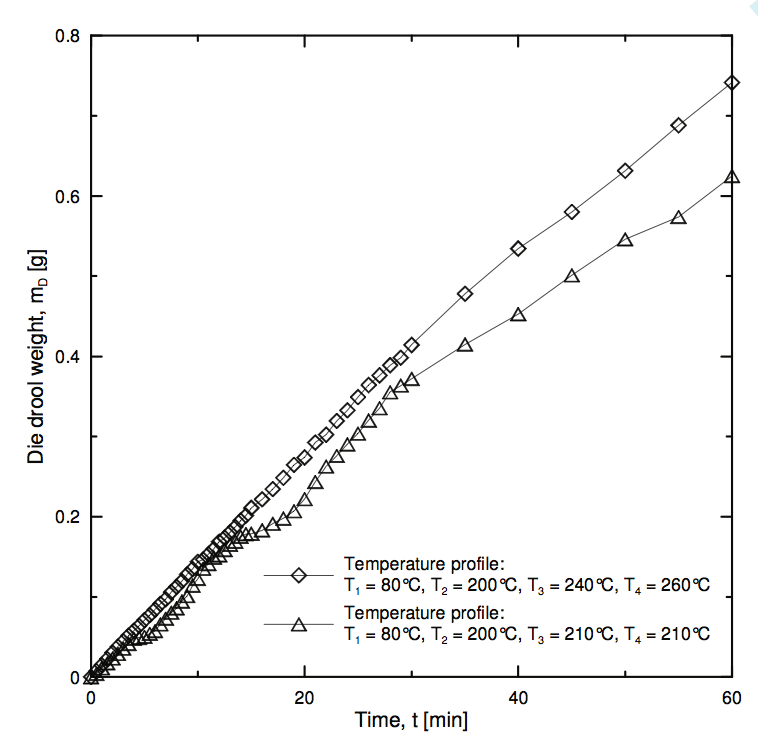

The effect of temperature profile along the screw

channel on the die drool intensity is visualized in Figure 4

for constant mass flow rate. It is nicely visible that the last

two screw zone temperature increase from 210°C to 260°C causes significant die drool intensity increase even if the

annular tube (connecting die and extruder) and die exit

temperatures remains to be unchanged, equal to 150°C.

This behavior can be explained by the increased

HDPE melt viscosity/elasticity due to thermally induced

degradation (as showed in the performed rheological

analysis) promoting flow induced fractionation of low

molecular weight component of HDPE, which is in good

correspondence with recent work on molecular weight

fractionation during polymer processing [11] and

theoretical study of internal die drool phenomenon [10]. In

more detail, the studied die drool phenomenon can be

understood through originally Busse’s hypothesis [13]

stating that during the flow, larger (highly elastic) chains

acquire more elastic energy near the wall than small

molecules which generates thermodynamic force tending

to increase the concentration of small molecules at the

wall (area of the high stress), and of the larger chains at

the centerline (area of the low stress). In the light of this

hypothesis, (where die drooled material can be viewed as

the low molecular weight component of HDPE), increased

die drool phenomenon through melt elasticity

enhancement can be explained by the increased

thermodynamic force driving molecular weight

fractionation intensity during the flow.

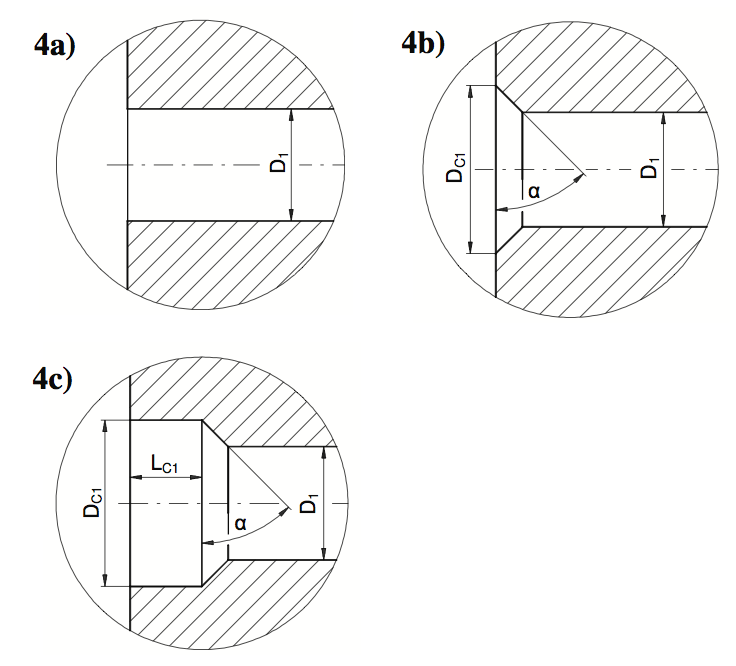

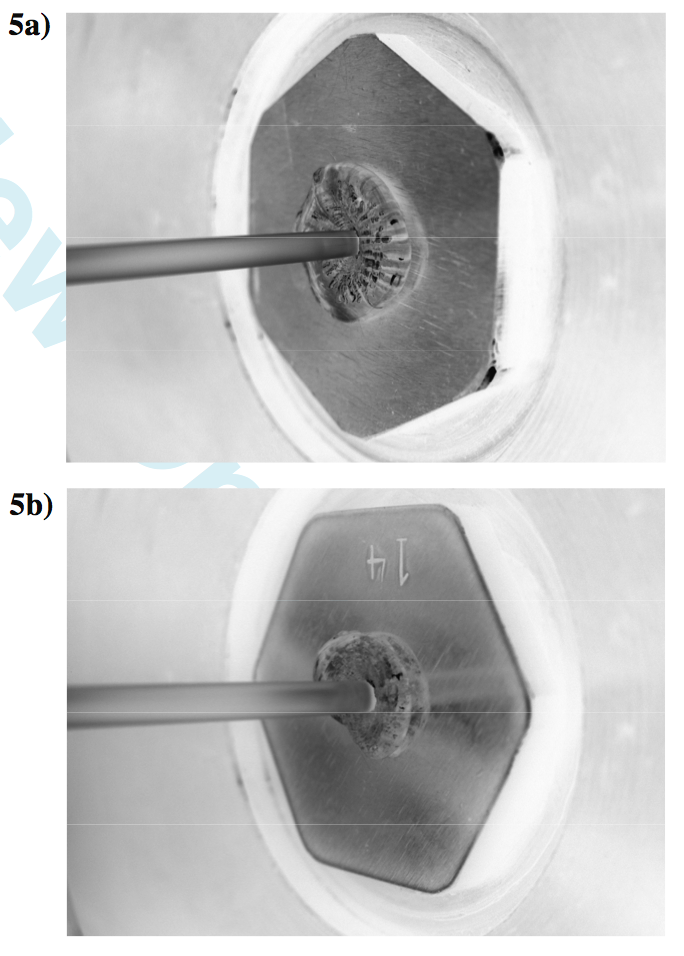

The effect of die design and die material on the die

drool phenomenon for HDDPE polymer melt has also

been investigated in this work. It was found that for the

particular processing conditions and given time period, the

stainless steel shaped die (22.2% die drool reduction),

stainless steel flared die (46% die drool reduction) or the

use of hard chrome straight die (20.2% die drool

reduction) reduces die drool phenomenon with respect to

reference stainless steel straight die. Die drool shape for

the reference stainless steel straight die and the most

stabilizing flared die is visualized in Figure 6.

Conclusion

In this work, the die drool phenomenon analysis has

been performed for HDPE polymer melt by using specific

type of experimental set-up. It has been revealed that the

temperature increase at the end of the extruder, by keeping

annular tube (connecting die and extruder) and die exit

temperature unchanged, leads to die drool intensity

increase. It has been proved that this type of the internal

die drool phenomenon is caused by the thermally induced

HDPE degradation enhancing melt elasticity and thus

promoting the flow induced fractionation of the HDPE

melt. It has also been found that for particular processing

conditions, shaped die, flared die or the use of hard

chrome instead of stainless steel can reduce die drool

phenomenon for HDPE.

Acknowledgement

The support of the projects by the Ministry of

Education CR (KONTAKT ME08090, MSM

7088352101) are gratefully acknowledged.

References

1. I. Klein, Plastics World, 112 – 113, (May 1981).

2. S. J. Kurtz, and S. R. Szaniszlo, U.S. Patent 5,008,056

(1991).

3. T. A. Hogan, P. Walia and B. C. Dems, Polym. Eng.

Sci. 49, 333-343 (2009).

4. D. A. Holtzen and J. A. Musiano, SPE RETEC, St.

Louis, (1996).

5. D. E. Priester, SPE ANTEC Tech. Papers, 40, 2059

(1994).

6. J. D. Gander and J. Giacomin, Polym. Eng. Sci. 37,

1113-1126 (1997).

7. F. Ding, L. Zhao, A.J. Giacomin and J. D. Gander,

Polym. Eng. Sci. 40, 2113-2123 (2000).

8. P. K. Dhori, R. S. Jeyaseelan, A. J. Giacomin and J. C.

Slattery, J. Non-Newtonian Fluid Mech.71, 231-243

(1997).

9. K. Chaloupkova and M. Zatloukal, Polym. Eng. Sci. 47,

871-881 (2007).

10. K. Chaloupkova and M. Zatloukal, J. Appl. Polym.

Sci. 111, 1728-1737 (2009).

11. M.D. Shelby, G.B. Caflisch, Polym. Eng. Sci. 44(7),

1283-1294 (2004).

12. R. Pivokonsky, M. Zatloukal, P. Filip, J. NonNewtonian

Fluid Mech., 150(1), 56-64 (2008).

13. W.F. Busse, Physics Today, 50, 32-41 (September

1964).

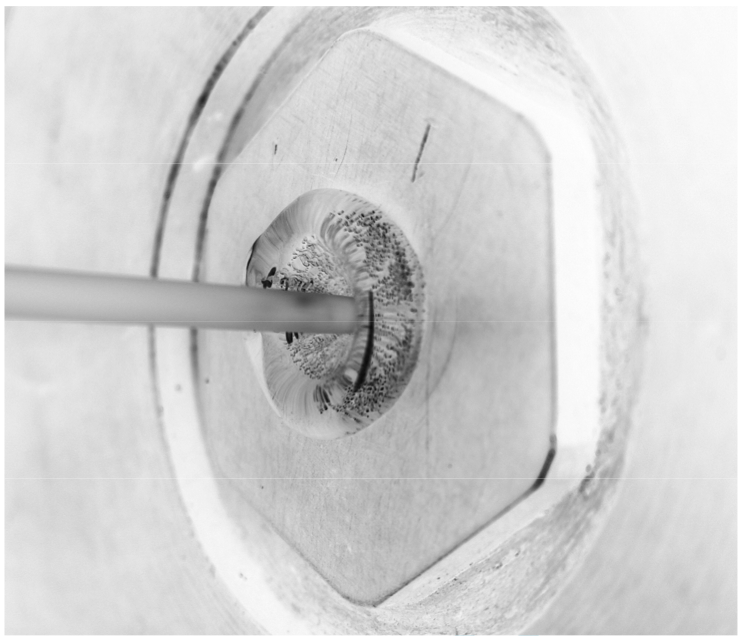

Table 1: Basic characterization of chosen polymer.

Figure 1. Effect of processing temperature on the time dependent extrusion pressure for tested HDPE Tipelin FS 450-26 sample.

Figure 2. 3D sketch of laboratory extrusion line (top) together with detail view of the extrusion die (bottom).

Figure 3. Die drool visualization at the die exit for the tested HDPE sample after 15 min of extrusion (temperature profile along the screw: T

1 = 80

oC, T

2 = 200

oC, T

3 = 240

oC, T

4 = 260

oC; annular tube (connecting die and extruder) and die exit temperature T

5 = T

6 = 150

oC; mass flow rate = 1.1 kg.hr

-1).

Figure 4. Die drool amount as a function of time for two different temperature profiles along the screw; mass flow rate = 1.1 kg.hr

-1, annular tube (connecting die and extruder) and die exit temperature T

5 = T

6 = 150

oC.

Figure 4. Investigated capillary dies, D

1=1.6mm, alpha=45°. 4a) Straight die; 4b) Shaped die, D

C1=2mm; 4c) Flared die, D

C1=2mm , L

C1=12mm.

Figure 5. Visualization of die drool phenomenon at the die exit after 10 minutes of extrusion. 5a) Stainless steel straight die; 5b) Stainless steel flared die (temperature profile along the screw: T

1 = 160

oC, T

2 =165

oC, T

3 =170

oC, T

4 = 170

oC; annular tube (connecting die and extruder) and die exit temperature T

5 = T

6 = 170

oC; mass flow rate = 0.9 kg.hr

-1).

Return to

Paper of the Month.