Investigation of Die Drool Phenomenon for Linear HDPE Polymer Melts Having Identical Polydispersity Index but Different MZ and MZ+1 Average Molecular Weights¶

Martin Zatloukal1,2, Jan Musil1,2

1 Centre of Polymer Systems, University Institute, Tomas Bata University in Zlin,

Nad Ovcirnou 3685, 760 01 Zlin, Czech Republic

2 Polymer Centre, Faculty of Technology, Tomas Bata University in Zlin,

TGM 275, 762 72 Zlin, Czech RepublicAbstract

In this work, die drool phenomenon, for two linear

HDPE polymers having identical polydispersity index

(M

w/M

n) but different M

z and M

z+1 molecular weight

averages, has been experimentally investigated. It has

been revealed that increase in linear HDPE chain length

promotes the die drool phenomenon.

Introduction

During the extrusion process, there is a tendency for

some polymers to adhere at the extrusion die lips.

The deposited material builds up into a large mass which

frequently breaks away from the die, completely

(or partly) encloses the extruded product, adheres

perseveringly onto extruded product surface and thus

damages it. This effect is in extrusion art defined as

undesirable spontaneous accumulation of polymer melt at

the die exit face and it is termed like “die drool”,

“drooling”, “die lip build-up”, “die bleed”, “die plateout”,

“die deposit”, “die drip” or “die moustache” and

the accumulated material is generally named “drool”.

It has been found by Klein [1] in 1981 that there are two

different die drool types; the first, which is related to a die

(polymer deposit builds up at slow stable rate) and the

second, which is related to the screw (die remains clean

for a period of time and the polymer deposit rises

suddenly). If this phenomenon takes place during the

extrusion process for particular polymer system, it is

necessary to periodically switch off the extrusion line in

order to complete die cleaning which is uneconomical and

also time consuming. In 1997, Gander and Giacomin [2]

published the overview about the die drool phenomenon.

They have concluded that die drool is a complex problem

having several minor sources, each of them playing

different role according to particular extrusion techniques,

processing conditions and polymer materials used. In the

open literature, several factors have been found to support

the formation of die drool phenomenon. They include

pressure fluctuations in screw [1], volatiles, low molecular fractions of the polymer, fillers, poor dispersion

of pigments [3], die swell [1, 4], processing near

degradation temperature [4-6], dissimilar viscosities in

blends [7], improper die design and die material [2, 8-

10], negative pressure at the die exit [11], utilization of

linear rather than branched polymers [12], high polymer

melt elasticity [13], etc.

In order to more deeply understand the die drool

phenomenon, two carefully prepared linear HDPE

polymers having identical polydispersity index (Mw/Mn)

but different M

z and M

z+1 molecular weight averages,

have been experimentally investigated.

Experimental

Material characterization

In this work, two linear and well stabilized HDPE

extrusion grades (HDPE 1 – HDPE Liten FB 29 E2009

3220 4479 and HDPE 2 – HDPE Liten FB 29 E2009 5498

7937) from Unipetrol RPA, Czech Republic were used.

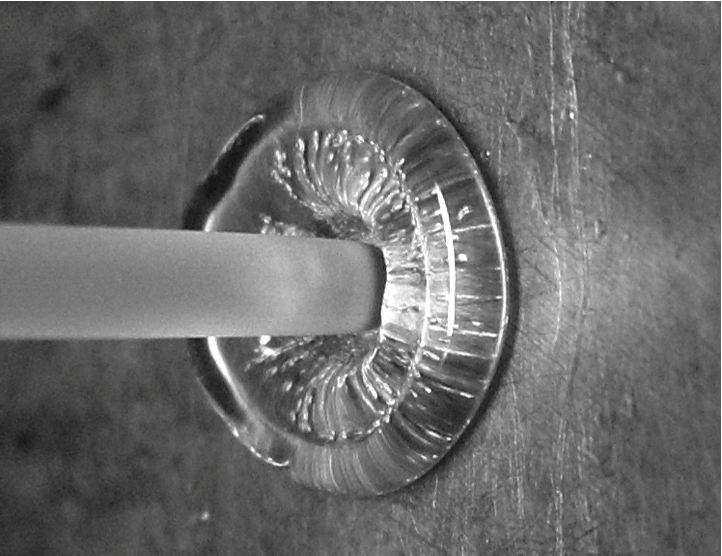

The basic characteristics for both samples are summarized

in Table 1. As can be seen, polymers having identical

polydispersity index (M

w/M

n) but different M

z and M

z+1

molecular weight averages (see definition bellow).

where ni is the fraction of molecules having the molecular

weight, M

i, in a blend of monodisperse species described

by the set of number [n

i, M

i].

Die drool measurements

Die drool experiments were performed on a

conventional Plasti – Corder 2000 model (Brabender,

Germany) single-screw extruder with diameter

D = 30 mm and L = 25D (standard single-thread screw

with compression ratio 4:1, and lengths of zones: feed

L1 = 10D, compression L2 = 3D, metering L3 = 12D).

The extrusion line consists of extruder with four

electrically heated zones, transition annular part, specially

designed annular extrusion die, which was introduced and used in [5, 11, 12 and 14], photo camera Dimage Z3

model (Konica Minolta, Japan) with resolution of 4 Mpx

placed near the die exit for die drool visualization,

nitrogen gas vessel with hosepipe supplying N

2 to a die

exit vicinity in order to prevent thermal/oxidative

degradation of collected die drool samples and finally

draw-off mechanism.

Extruder zones (from the hopper to the die) were

heated to T

1 = 150°C, T

2 = 155°C, T

3 = 160°C and

T

4 = 160°C, respectively by keeping the annular tube

(connecting die and extruder) and die exit temperature

constant, T

5 = T

6 = 160°C ensuring that no sample

degradation takes place. Furthermore, total mass flow rate

of extruded polymer melt ( m ) was varied from

0.075 kg.hr

-1 up to 0.725 kg.hr

-1 (i.e. from 68 s

-1 up to

652 s

-1 in terms of apparent shear rate). After 10 minutes

of extrusion at given m, the extruder was stopped and the

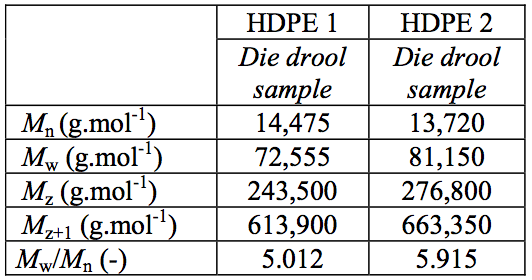

accumulated material (see Figure 1 for the example) was

manually removed from the die lip by a tweezer, weighted

on a sensitive analytical balance and the procedure was

repeated again for the higher m. Moreover, this technique

was applied three times at each m to prove the

reproducibility of such testing method. Before each set of

three independent 10 minutes tests (at one m), barrel,

screw and all parts of the die have been perfectly

manually cleaned.

Die drool intensity has been expressed in

dimensionless form through buildup ratio BR (firstly

introduced by Gander and Giacomin in [2]):

where m is defined above and B means buildup rate:

where B is the mass of accumulated

die drool material at

the die exit face and t

e is the total extrusion time of each

test (10 minutes in this case).

Results and Discussion¶

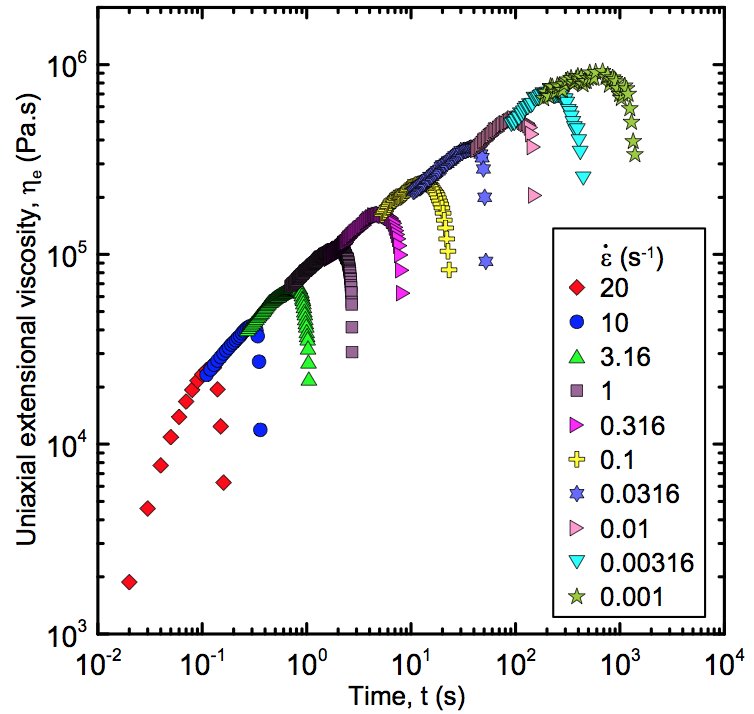

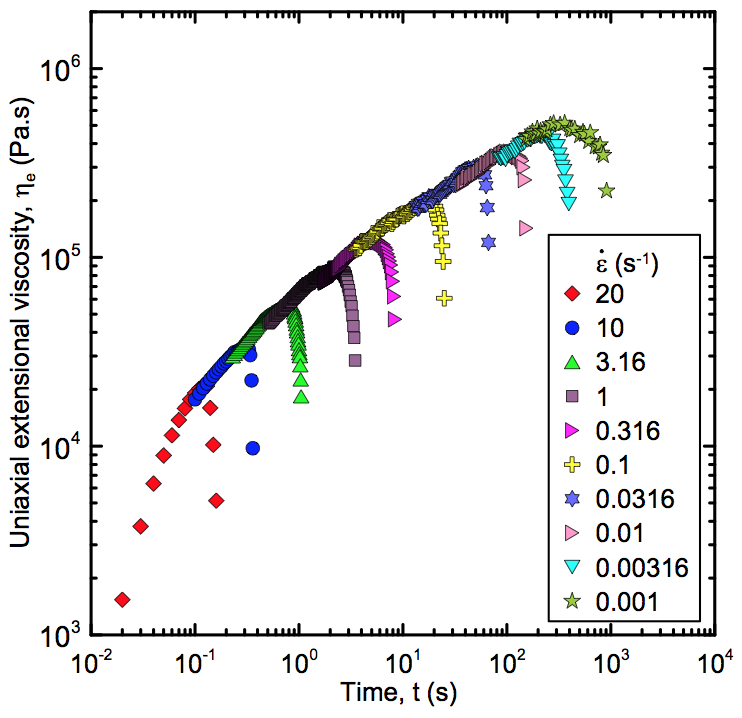

As can be seen in Figures 2 and 3, transient uniaxial

extensional viscosity curves (measured by Sentmanat

Extensional Rheometer SER-HV-A01 model attached to

Advanced Rheometric Expansion System ARES 2000) for

both HDPEs show no strain hardening peaks indicating

presence of linear chains only for both polymers.

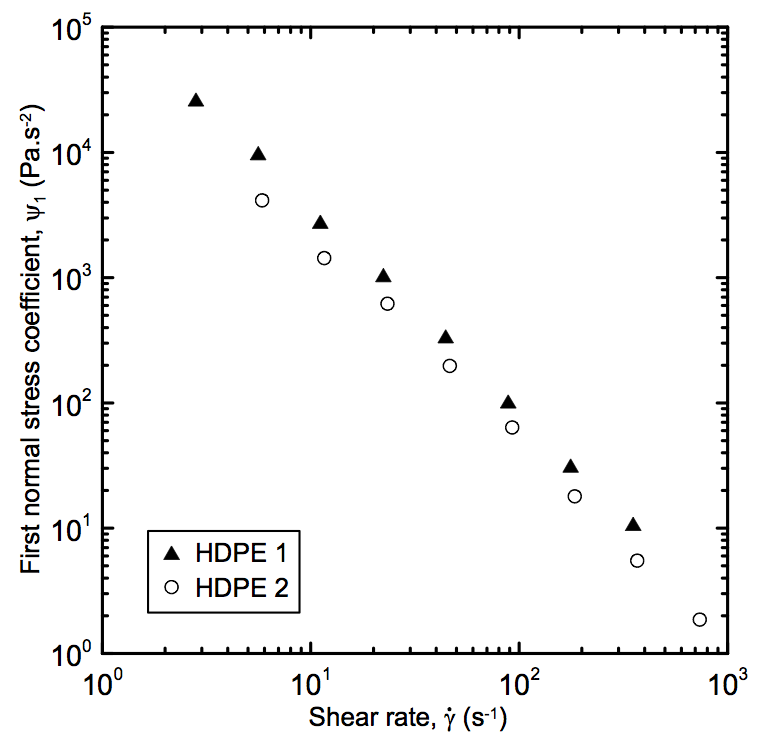

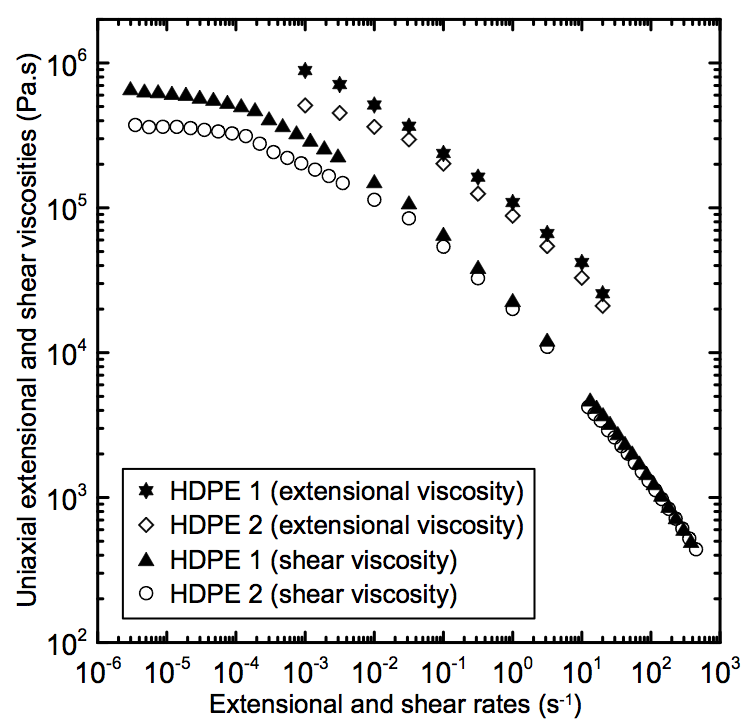

Moreover, as can be seen in Figures 4 and 5, HDPE 1 has

slightly higher steady shear viscosity (determined by

twin-bore capillary rheometer Rosand RH7-2 and

rotational rheometer ARES 2000 in parallel plates

configuration), uniaxial extensional viscosity and shear elasticity (determined according to Han’s methodology

[15]) than HDPE 2.

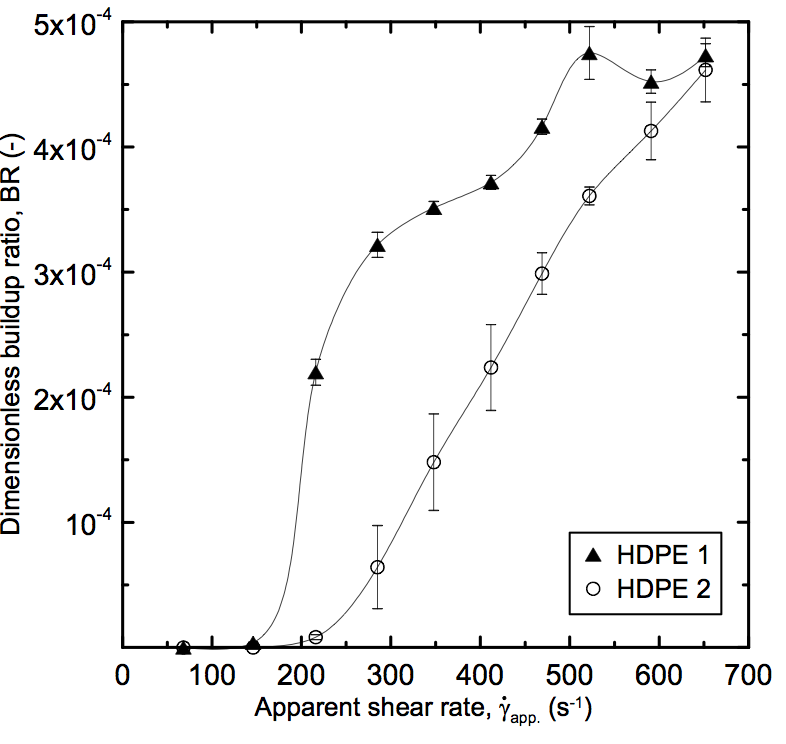

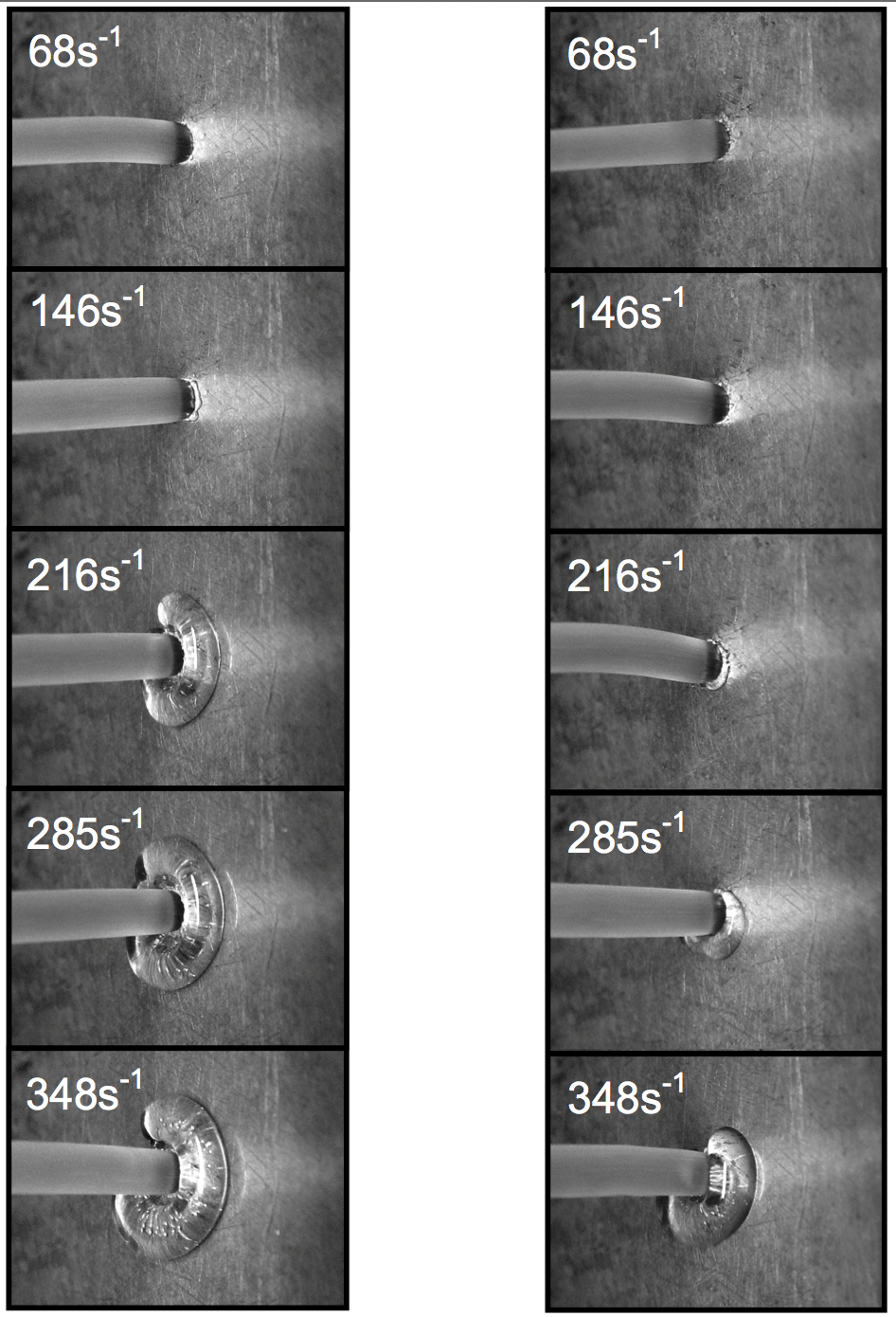

Apparent shear rate dependent die drool intensity in

the form of dimensionless buildup ratio, BR and real die

exit face visualization are provided in Figures 6 and 7,

respectively. It is clearly seen that the die drool

phenomenon is more pronounced for HDPE 1 sample in

comparison with HDPE 2 sample and its onset occurs at

lower apparent shear rates for HDPE 1 in comparison

with HDPE 2 sample. Due to the fact that these two linear

HDPE polymers having identical polydispersity index

(M

w/M

n) but HDPE 1 sample has higher M

z and M

z+1

molecular weight averages (indicating the presence of

very long chains) in comparison with HDPE 2 sample

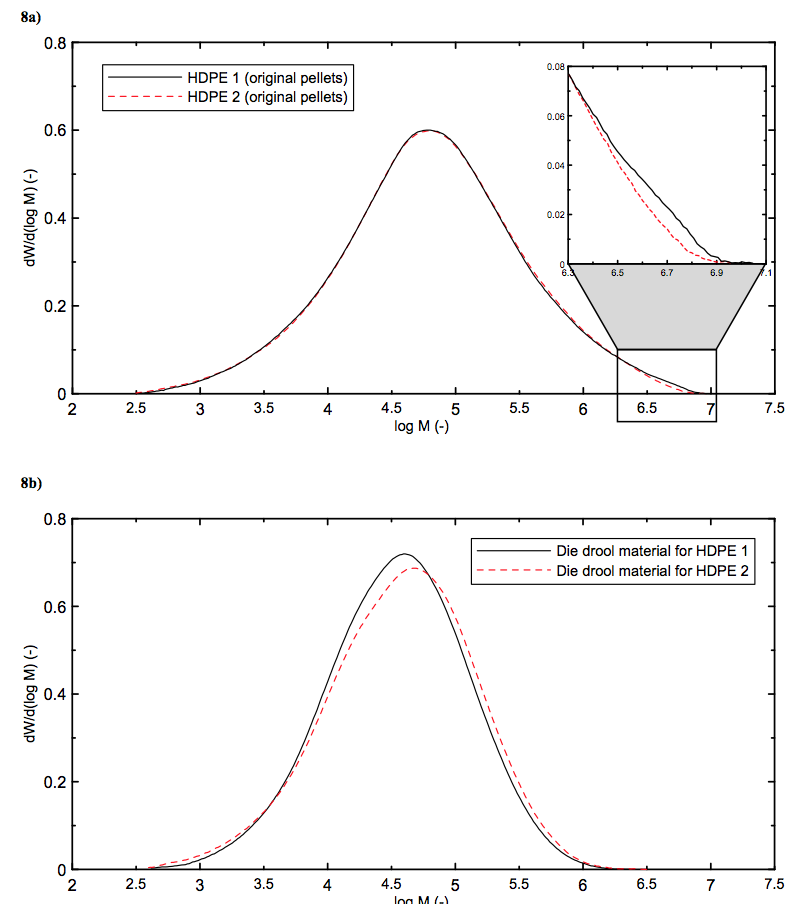

(see Table 1 and Figure 8a), it can be concluded that an

increase in linear HDPE chain length promotes the die

drool phenomenon. Interestingly, the die drool material

created during HDPE 1 sample extrusion has slightly

narrower MWD than die drool sample created during

HDPE 2 extrusion (see Table 2 for the Mw/Mn ratio).

Moreover, the content of long chains in the HDPE 1 die

drool sample is smaller (low M

z and M

z+1 averages) in

comparison with HDPE 2 die drool sample (high Mz and

M

z+1 averages) as can be seen in Figure 8b and Table 2.

This indicates that more elastic HDPE 1 sample is able to

more effectively push shorter chains toward the die wall

in comparison with less elastic HDPE 2 sample which is

in good agreement with our previous work [12, 16] and

the original Busse’s flow induced molecular weight

fractionation theory [17].

Conclusion

It has been found that small amount of very long linear

chains in the linear HDPE polymers promotes die drool

phenomenon. It has also been found that due to enhanced

melt elasticity by the presence of long linear chains of

linear HDPE polymer, the flow induced fractionation

(causing die drool phenomenon) is more effective which

results in narrow MWD of die drool sample containing

small amount of long chains (low M

z and M

z+1 averages).

Acknowledgement

The author wish to acknowledge Grant Agency of the

Czech Republic (Grant No. 103/09/2066) and Operational

Program Research and Development for Innovations

co-funded by the European Regional Development Fund

(ERDF) and national budget of Czech Republic, within

the framework of project Centre of Polymer Systems

(reg. number: CZ.1.05/2.1.00/03.0111) for the financial

support. The authors also wish to acknowledge

Ing. Martin Malicek from Unipetrol RPA company for

donation of both HDPE polymers, which have been used

in this work.

References

1. Klein, I. Plastics World 39(5), 112-113 (1981).

2. Gander, J. D., Giacomin, A. J. Polym. Eng. Sci. 37(7),

1113-1126 (1997).

3. Kurtz, S. J., Szaniszlo, S. R. US Patent 5,008,056

(1991).

4. Hogan, T. A., Walia, P., Dems, B. C. Polym. Eng. Sci.

49(2), 333-343 (2009).

5. Musil, J., Zatloukal, M. Chem. Eng. Sci. 65(23), 6128-

6133 (2010).

6. Holzen, D. A., Musiano, J. A. SPE RETEC (1996).

7. Priester, D. E. Annual Technical Conference-ANTEC,

Conference Proceedings 2, 2059-2061 (1994).

8. Ding, F., Zhao, L., Giacomin, A. J. and Gander, J. D.

Polym. Eng. Sci. 40(10), 2113-2123 (2000).

9. Chaloupkova, K., Zatloukal, M. Annual Technical

Conference-ANTEC, Conference Proceedings 4, 2379-

2383 (2007).

10. Zatloukal, M., Musil, J. Annual Technical ConferenceANTEC,

Conference Proceedings 2, 1181-1185

(2011).

11. Chaloupkova, K., Zatloukal, M. J. App. Polym. Sci.

111(4), 1728-1737 (2009).

12. Musil, J., Zatloukal, M. Chem. Eng. Sci. 66(20), 4814-

4823 (2011).

13. Musil, J., Zatloukal, M., Gough, T., Martyn, M.

AIP Conference Proceedings 1375, 26-42 (2011).

14. Chaloupkova, K., Zatloukal, M. Polym. Eng. Sci.

47(6), 871-881 (2007).

15. Han, C. D. Trans. Soc. Rheol. 18(1), 163-190 (1974).

16. Musil, J., Zatloukal, M. AIP Conference Proceedings

1152, 69-74 (2009).

17. Busse, W. F. Physics Today 19(9), 32-41 (1964).

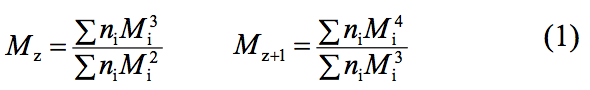

Table 1: Basic characterization of chosen HDPE polymers.

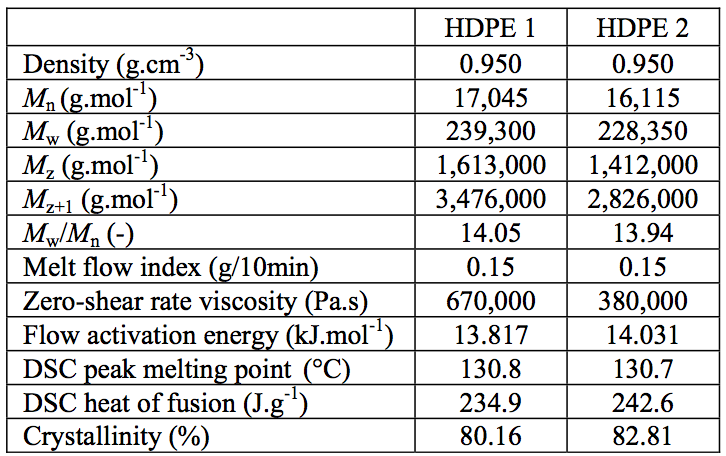

Table 2: Basic characteristics of die drool samples collected after 10 minutes of extrusion at apparent shear rate 348 s

-1.

Figure 1: Typical appearance of HDPE die drool phenomenon after 10 minutes of extrusion by using the proposed experimental set-up and chosen processing conditions (HDPE 1 at 160°C and apparent shear rate 652 s

-1.

Figure 2: Transient uniaxial extensional viscosity for HDPE 1 at 190°C.

Figure 3: Transient uniaxial extensional viscosity for HDPE 2 at 190°C.

Figure 4: Stable-state first normal stress coefficient for both investigated HDPE polymer melts measured at 190°C.

Figure 5: Stable-state shear and uniaxial extensional viscosities for both investigated HDPE polymer melts measured at 190°C.

Figure 6: Dimensionless buildup ratio (10 minutes of extrusion) as a function of apparent shear rate for both investigated HDPE polymer melts determined at 160°C.

Figure 7: Die exit face visualization after 10 minutes of extrusion of HDPE 1 (left) and HDPE 2 (right) at different apparent shear rates, T

die = 160°C.

Figure 8: Molecular Weight Distribution (MWD) of the analyzed polymer samples. 8a) MWD for HDPE 1 and HDPE 2 (original pellets). 8b) MWD for die drool materials collected under N

2 inert gas atmosphere at apparent shear rate 348 s

-1 and T

die = 160°C.

Return to

Paper of the Month.