Die Design Effect on Internal Die Drool Phenomenon

Martin Zatloukal1,2, Jan Musil1

1 Centre of Polymer Systems, University Institute, Tomas Bata University in Zlin, Nad Ovcirnou 3685, 760 01 Zlin, Czech Republic

2 Polymer Centre, Faculty of Technology, Tomas Bata University in Zlin, TGM 275, 762 72 Zlin, Czech RepublicAbstract

In this work, the effect of die exit design on the

internal die drool phenomenon occuring during extrusion

of HDPE has been experimentaly investigated. It has been

revealed, that firstly, the effect of flared length and die

exit angle on the internal die drool intensity during

extrusion of HDPE has non-monotonic character and

secondly, flared dies are more stabilizing in comparison

with chamfered dies.

Introduction

During extrusion process, there is a tendency for some

of the extruded polymer materials to adhere to exit edges

or open faces of extrusion die from which the extruded

material emerges. The material so deposited on the die

exit, can build up into a large compact usually degraded

mass or can form drips, flakes or powder which

frequently break away from the die, adhere perseveringly

onto extruded product surface and thus damage it. This

effect is in extrusion art defined as undesirable

spontaneous accumulation of polymer melt at the die exit

face and it is termed like “die drool”, “drooling”, “die

lip build-up”, “die bleed”, “die plate-out”, “die

deposit”, “die drip” or “die moustache” and the

accumulated material is generally named “drool”[1, 2]. It

is generally accepted that there are two types of the die

drool phenomenon; “external die drool phenomenon”,

which is generated just at the end of the die due to the

extrudate free surface creation and negative pressure

generation (causing the suction effect) [2, 3] and “internal

die drool phenomenon”, which is initiated inside the

processing equipment as the results of degradation [4] or

flow induced molecular weight fractionation [5]. In fact,

there is number of material, processing and die design

based parameters promoting and suppressing the die drool

phenomenon and some of them have been recently

documented such as pressure fluctuations in screw [6],

volatiles, low molecular fractions of the polymer, fillers,

poor dispersion of pigments [8], die swell [4, 6],

processing near degradation temperature [7, 9], dissimilar

viscosities in blends [10], broadening molecular weight

distribution [11-12], increasing melt elasticity [5, 7], shark skin [2, 3], slip-stick phenomenon [5, 12-13], or

abrupt corners at the die lips [3, 14, 15] have been found

to promote die drool. On the other hand, chain branching

increase [5], polymer processing aids addition [10], using

ceramics dies [16] or dies with PTFE

chemically/physically locked in die wall [8], silicon

rubber coated surface of extrusion die [13], hard chrome

dies [17], flared [3, 14, 15] or chamfered [3] die exits,

have been found to reduce this phenomenon. With respect

to the stabilizing role of the die design, it was initially

believed that flared dies are so effective due to occurrence

of stress undershoot inside flared section [1]. However,

Ding et al. [18] mathematically modeled stress field inside

the flared section and they concluded that stress

undershoot is not the main reason for suppressing

accumulation of drool mass at the die lips. They have

suggested that the history of the stresses upstream of the

exit, not just their instantaneous values at die lips, governs

the die drool reduction in flared dies. Recently,

Chaloupková and Zatloukal [3] were able to correlate

stabilizing efficiency of die exit chamfering, die opening

and die exit flaring with negative pressure, pressure

gradient and normal component of the pressure gradient

during extrusion of the metallocene based LLDPE at

which the external die drool has occurred.

In this work, experimental analysis has been

performed for extrusion dies at which chamfer angle and

flared length were systematically varied in order to

understand the role of die design for the internal type of

die drool phenomenon as well as to explore the

knowledge about parameters which could allow more

efficient die design optimization.

Experimental

In this work, well stabilized unfilled virtually linear

HDPE polymer melt (HDPE Liten FB 29 E2009 3220

4479, extrusion grade, Unipetrol RPA, Czech Republic,

material characterization is summarized in our previous

work [12]) has been used. The internal die drool

measurements were performed on specially designed

extrusion line equipped by replaceable capillary, which

has already been used in our previous studies [5, 7, 12].

The line was consisted of conventional Plasti – Corder

2000 model (Brabender, Germany) single-screw extruder

with diameter D = 30 mm and L = 25D (standard singlethread

screw with compression ratio 4:1, and lengths of

zones: feed L

1 = 10D, compression L

2 = 3D, metering L

3

= 12D), transition annular part, specially designed annular

extrusion die, photo camera Canon 600D model (Canon,

Inc., Japan) with resolution of 18 Mpx equipped with

Canon macro lens EF 100mm placed near the die exit for

die drool visualization and finally draw-off mechanism.

The die drool experiments were performed as follows.

Extruder zones (from the hopper to the die) were heated

to T

1 = 150°C, T

2 = 155°C, T

3 = 160°C and T

4 = 160°C,

respectively by keeping the annular tube (connecting die

and extruder) and die exit temperature constant, T

5 = T

6 =

160°C. The low exiting temperature 160°C for the HDPE

melt was chosen to achieve highly pronounced

fractionation effect due to high efficiency of melt to store

elastic energy as well as to suppress any thermal/oxidative

degradation. Further, mass flow rate (MFR) was chosen

750g.hr

-1 (apparent shear rate 673 s

-1) to ensure that the

flow condition lies above the slip-stick phenomenon, i.e

in the “superflow” regime at which the die drool intensity

is the highest as shown in [12]. In order to measure

fractionated (drooled) polymer mass accumulated at the

die exit, the following methodology was used. The

extruder was stopped after 10 minutes of extrusion and

the accumulated material was carefully manually removed

from the die lip by a tweezer, weighted on a sensitive

analytical balance and the procedure was repeated three

times for each capillary to calculate standard deviation.

Before each set of three independent 10 minutes tests (for

given capillary), barrel, screw and all parts of the die have

been disassembled and perfectly manually cleaned.

Finally, die drool intensity has been expressed in

dimensionless form through buildup ratio BR (introduced

by Gander and Giacomin in [1]):

where m is total mass flow rate of extruded polymer melt

and B

. means buildup rate:

where B is the mass of accumulated die drool material on

the die exit face and t

e is total extrusion time of each test

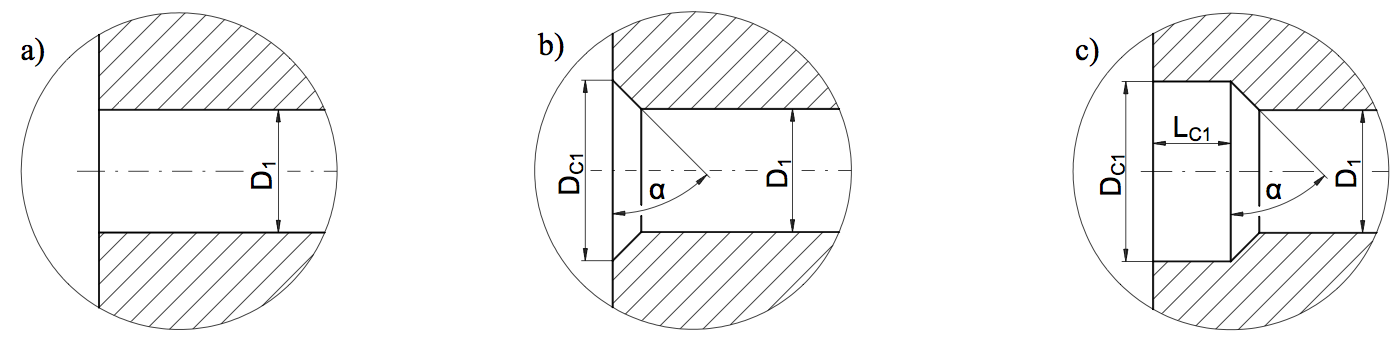

(10 minutes in our case). To evaluate die exit design

effect on accumulated drool mass following stainless steel

capillaries were used. The straight capillary with abrupt

die exit edge angle of 0° having diameter D1 = 1.6mm and

L/D ratio of 9.375 (see Figure 1a) and its two

modifications: chamfered die (see Figure 1b) with three

different die exit angles (α = 15°, 30° and 45°) and flared

die (see Figure 1c) with four different flared lengths

(LC

1 = 1mm, 2mm, 5mm, 8mm) and one fixed die exit angle (α = 45°). For both modified dies, the outer

diameter DC

1 was kept to be 2mm.

Results and Discussion ¶

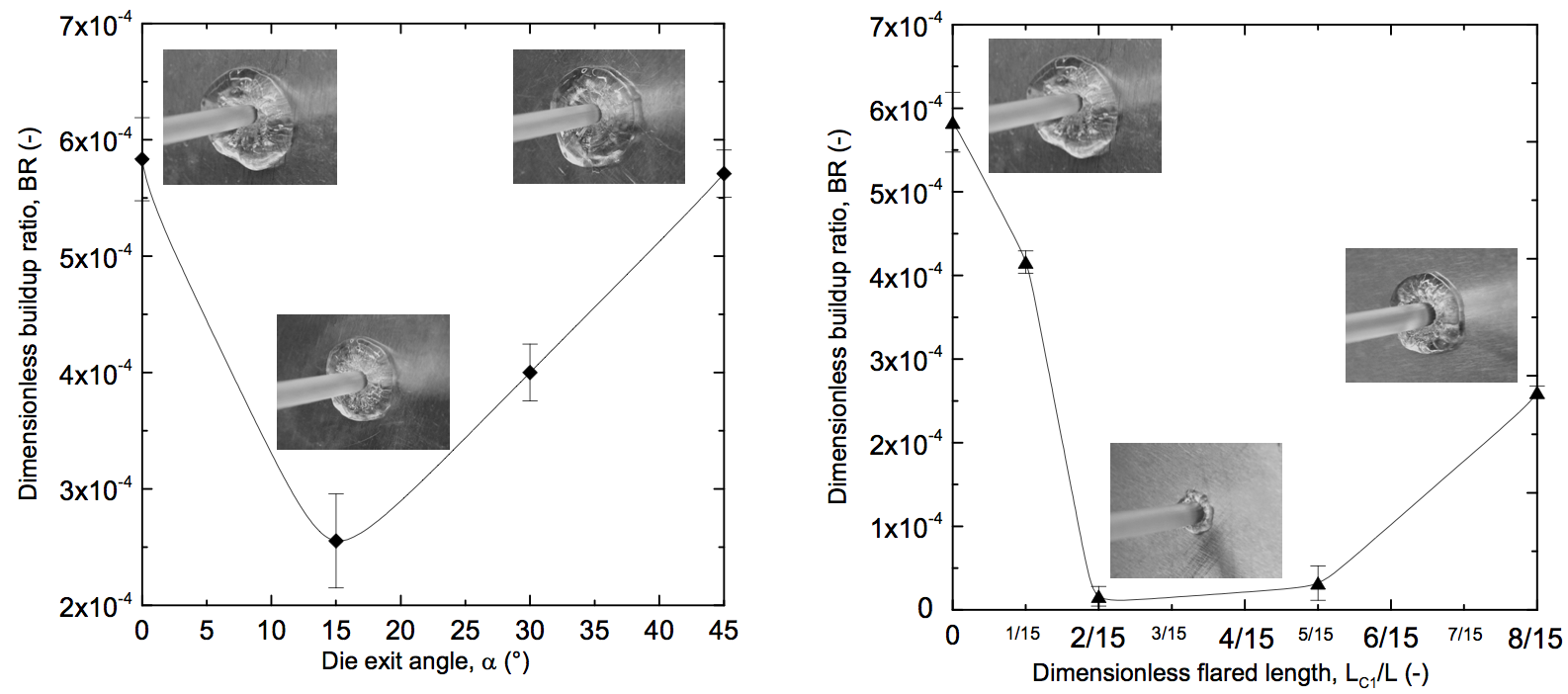

The effect of die exit angle and flared length

(expressed here in the dimensionless form as the flared

length, LC

1, divided by the capillary length, L = 15 mm,

i.e. by LC

1/L ratio) on the dimensionless buildup ratio is

provided in Figure 2a and Figure 2b, respectively. As can

be seen, this dependence has interestingly strongly nonmonotonic

character and secondly, flared dies are more

stabilizing in comparison with chamfered dies. In more

detail, there is one minimum for 15° die exit angle

(representing reduction of accumulated drool mass

intensity by 56%) and one minimum at 2/15

dimensionless flared length (for which drool mass

reduction is the highest, equal to 97%). The possible

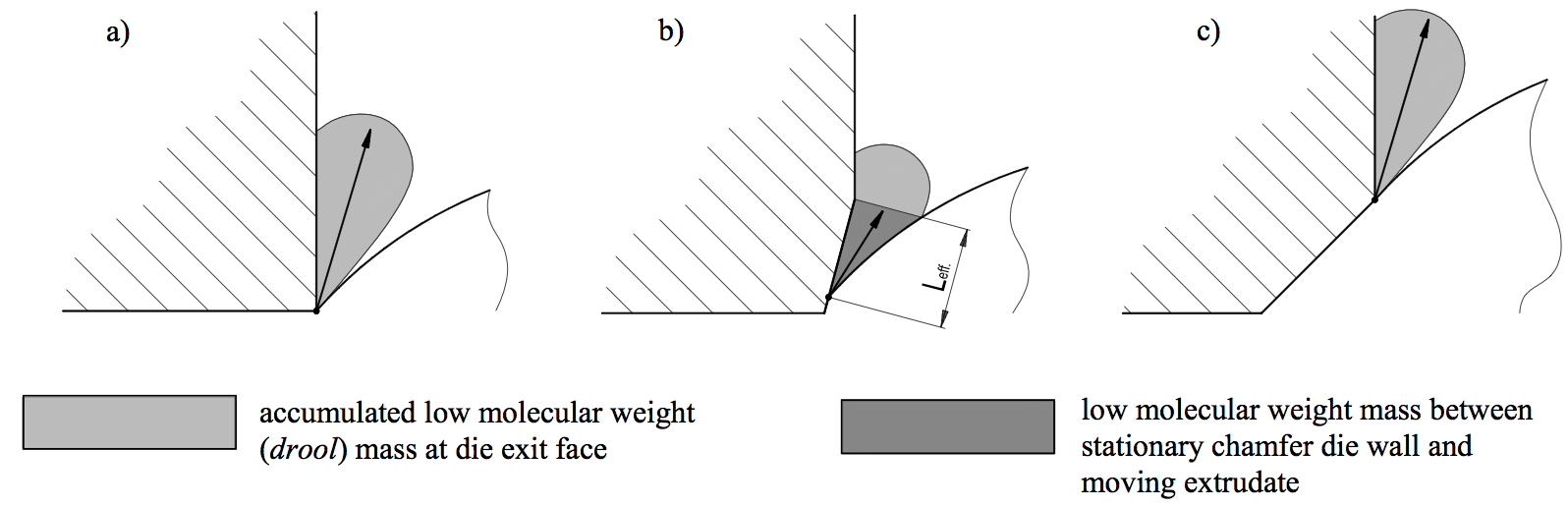

explanation of non-monotonic buildup ratio vs. die exit

angle dependence could be understood through

“detachment point” and “effective length”, Leff., location

as depicted in Figure 3. Here the detachment point

represents location at which extrudate detaches metal die

(due to the melt pressure/normal stresses at the die exit,

adhesion at metal wall/flowing melt interface and

extensional stress induced by the extrudate draw off)

whereas the effective length, Leff., is the distance in which

fractionated low molecular weight species are in touch

with the extrudate free surface as well as with the die

wall. Clearly, if the Leff. is high, there is high probability

that the low molecular weight fractioned polymer is

effectively removed from the die exit region by the

moving extrudate (because it happend under high

pressure) and only small portion of it remains at the die

exit face. This could happen for the most stabilizing case

(i.e. die exit angle equal to 15° as visualized in Figure

3b). On the other hand, a decrease in the die exit angle

down to 0° or increase it up to 30° or 45° could

continuously decrease the Leff. down to zero resulting to

the extreme situation at which the low molecular weight

fractionated polymer is not removed from the die exit

region and only its intensive accumulation takes place at

the die exit face resulting in intensive die drool

phenomenon.

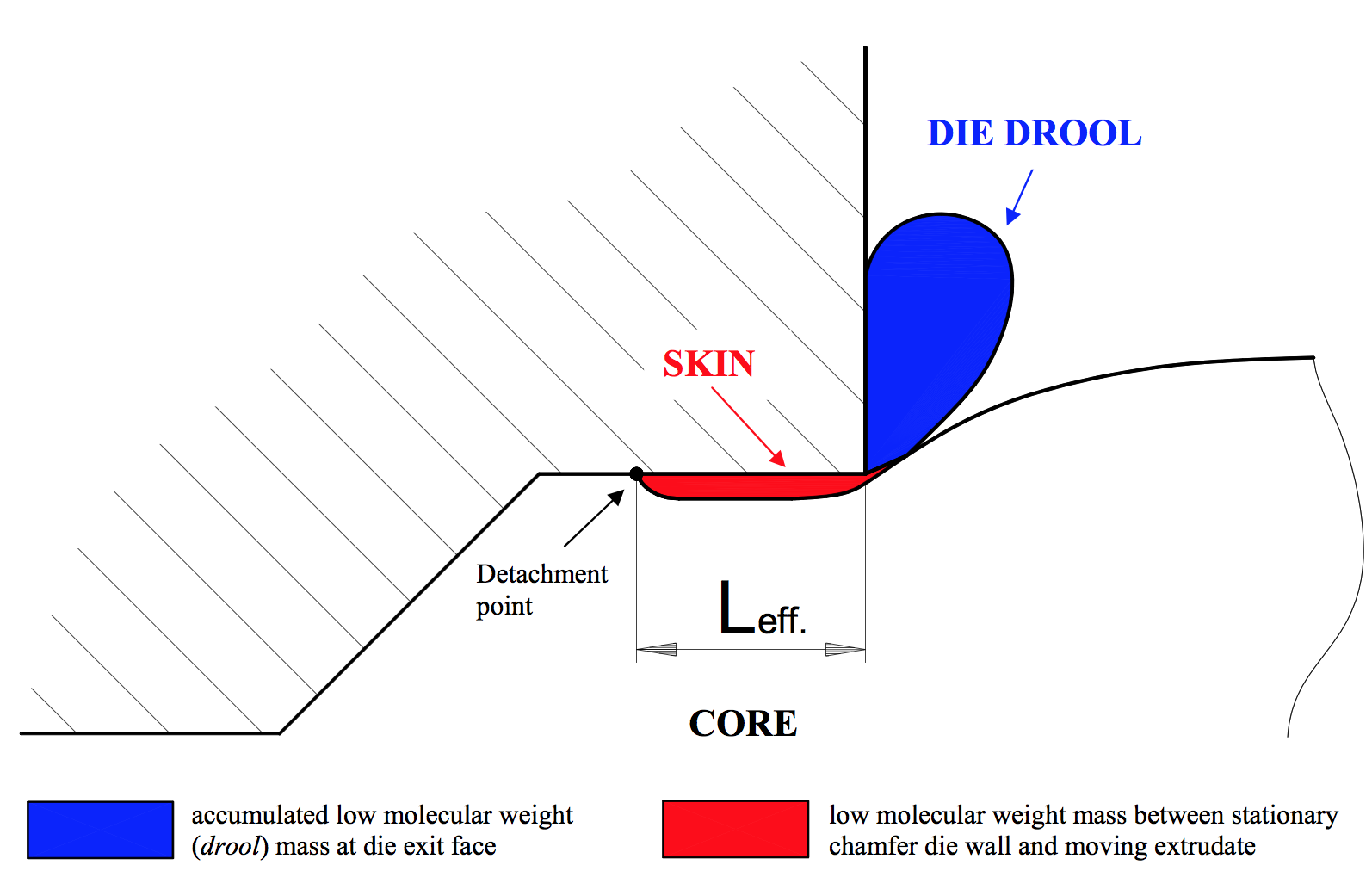

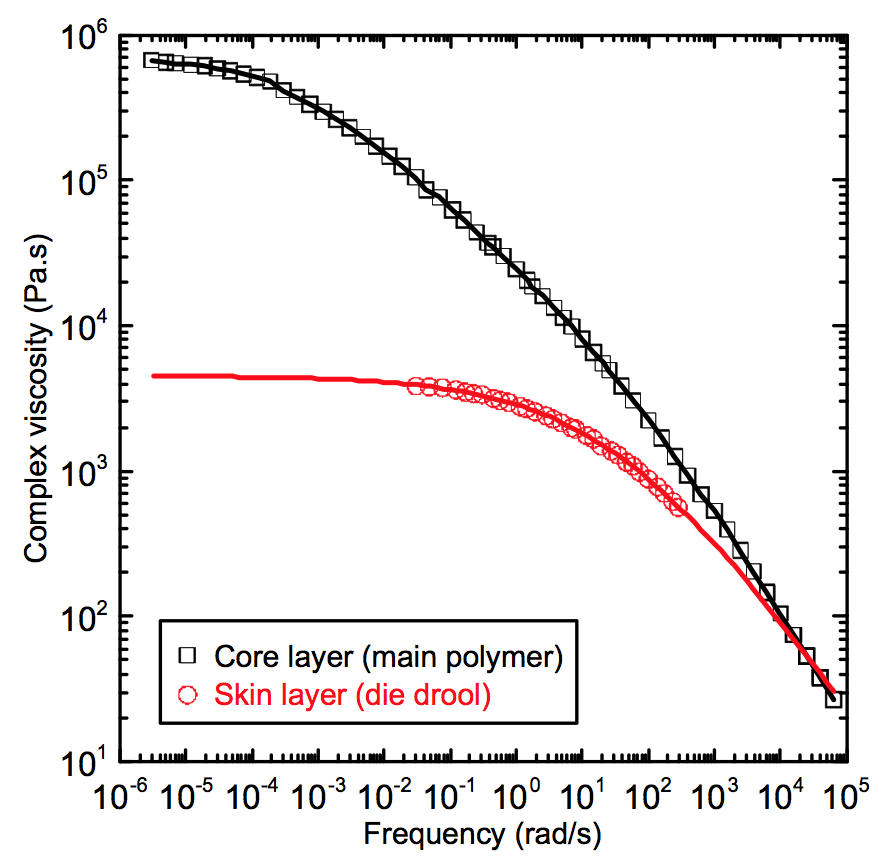

The flow situation inside flared section can also be

viewed as the special case of two-layer coextrusion (see

Figure 4) at which the low molecular weight species

(formed due to flow induced fractionation) represents the

low viscosity skin and the main polymer the high

viscosity core (flow viscosity curves measured on

Advanced Rheometrics Expansion System ARES 2000

for both layers are provided in Figure 5). Due to abrupt

channel opening at the die exit, low enough pressure,

normal stresses, adhesion and high extensional stress

from draw off “interface expansion” could take place

during which the low molecular weight layer decelerates,

expands in thickness and core layer starts to be separated

from the skin layer (detachment point) far away from the

die exit (effective length is high) at which low molecular

skin layer becomes intensively dragged with the core

extrudate layer out of the die, thus suppressing its

building up at the die exit face. Thus, increase in the

effective length, Leff., for given flared die leads to more

intensive drool suppression. It seems that for the given

HDPE polymer melt and chosen processing conditions

Leff. has maximum at 2/15 dimensionless flared length due

to low pressure and low normal stresses, which increase

the effect of the extensional stress from the draw-off on

the flow field in the upstream direction, i.e. the

detachment point is moved in the upstream direction too,

which is stabilizing. On the other hand, for the longer

dimensionless flared sections (5/15, 8/15), detachment

point presumably starts to move closer to the die exit (i.e.

Leff. decreases) due to increasing pressure and the normal

stresses in flared section resulting in smaller efficiency of

the extensional stress from the draw-off to influence the

flow field in the upstream direction i.e. the position of the

detachment point is moved more closer to the die exit,

which is destabilizing.

Conclusion

It has been revealed experimentally, that the effect of

die exit angle and flared length on the internal die drool

intensity during extrusion of HDPE has non-monotonic

character. It has been found that the optimum value for

the die exit angle and dimensionless flared length is 15°

and 2/15, respectively. It has been proved that flared dies

are more stabilizing in comparison with chamfered dies.

In more detail, 56% and 97% reduction in accumulated

drool mass has been achieved with respect to straight die

having abrupt die exit edge angle of 0° for the optimum

value of die exit angle and dimensionless flared length,

respectively, for the HDPE material and given processing

conditions. It has been suggested that suppresion

mechanism of the internal die drool phenomenon through

die exit modification can be understood throught the

balance between the melt pressure/normal stresses at the

die exit, adhesion at metal wall/flowing melt interface and

extensional stress induced by the extrudate draw off,

which can lead to flow situation at which low molecular

weight species are effectively removed from the die exit

region by the moving extrudate and only small portion of

them remains at the die exit face. This work suggests that

for the simulation based die design optimization with

respect to internal die drool phenomenon, fully

viscoelastic constitutive equation together with proper

boundary conditions (including adhesion forces between

die wall and polymer melt and considering the extensional

stresses due to extrudate draw off) should be utilized in

order to precisely determine the location inside the die at

which free surface of the extrudate starts to occur.

Acknowledgement

The authors wish to acknowledge Grant Agency of the

Czech Republic (Grant No. 103/09/2066) and Operational

Program Research and Development for Innovations co-funded

by the European Regional Development Fund

(ERDF) and national budget of Czech Republic, within

the framework of project Centre of Polymer Systems (reg.

number: CZ.1.05/2.1.00/03.0111) for the financial

support.

References

1. Gander, J. D., Giacomin, A. J., Polym. Eng. and Sci.

37(7), 1113-1126 (1997).

2. Chaloupkova, K., Zatloukal, M., Polym. Eng. Sci.

47(6), 871-881 (2007).

3. Chaloupkova, K., Zatloukal, M., J. App. Polym. Sci.

111(4), 1728-1737 (2009).

4. Hogan, T. A., Walia, P., Dems, B. C., Polym. Eng.

and Sci. 49(2), 333-343 (2009).

5. Musil, J., Zatloukal, M., Chem. Eng. Sci. 66(20),

4814-4823 (2011).

6. Klein, I., Plastics World 39(5), 112-113 (1981).

7. Musil, J., Zatloukal, M., Chem. Eng. Sci. 65(23),

6128-6133 (2010).

8. Kurtz, S. J., Szaniszlo, S. R., US Patent 5,008,056

(1991).

9. Holtzen, D. A., Musiano, J. A., Technical Papers,

Regional Technical Conference – Society of Plastics

Engineers (1996).

10. Priester, D. E., Annual Technical Conference –

ANTEC, Conference Proceedings 2, 2059-2061

(1994).

11. Musil, J., Zatloukal, M., Gough, T., Martyn, M.,

AIP Conference Proceedings 1375, 26-42 (2011).

12. Musil, J., Zatloukal, M., Chem. Eng. Sci., 81,

146-156 (2012).

13. Kulikov, O., Hornung, K., J. Non Newtonian Fluid

Mech. 124(1-3), 103-114 (2004).

14. Rakestraw, J. A., Waggoner, M. G., US Patent

5,458,836 (1995).

15. Ohhata, T. et al., US Patent 5,417,907 (1995).

16. Moore, S., Modern Plastics, 8, 37 (1994).

17. Musil, J., Zatloukal, M., Annual Technical

Conference – ANTEC, Conference Proceedings 2,

1181-1185 (2011).

18. Ding, F., Zhao, L., Giacomin, A. J., Gander, J. D.,

Polym. Eng. Sci. 40(10), 2113-2123 (2000).

Figure 1: Detailed section views of capillary exit regions: (a) straight capillary, (b) chamfered die, (c) flared die.

Figure 2: Effect of die exit design on dimensionless buildup ratio: (a) die exit angle effect, (b) dimensionless flared length effect.

Figure 3: Effect of die exit angle on extrudate detachment and accumulation process of low molecular weight mass for (a) 0°, (b) 15°, (c) 45° dies.

Figure 4: Visualization of the low viscosity skin (die drool layer) and high viscosity core (main polymer) inside and outside the die for the optimum 2/15 dimensionless flared length.

Figure 5: Frequency dependent complex viscosity for the die drool (skin) and main polymer (core) samples.

Return to

Paper of the Month.