An Experimental Investigation of the Plasticating and Friction Behavior of Pet Chips¶

Eldridge M Mount III

EMMOUNT Technologies, LLC

Canandaigua, NYAbstract

An experimental study of the plasticating and

frictional behavior of dried and preheated PET chips

on a moving, steel surface has been conducted using

an experimental apparatus called the Screw

Simulator. The Screw Simulator has been

specifically designed to reproduce the primary

plasticating [melting] and solid conveying

mechanisms of single screw extruders. The screw

simulator permits the direct observation and

measurement of a materials melting and frictional

properties. The PET resin plasticating and frictional

properties were studied as a function of metal surface

temperature, surface velocity, sample width and

applied load. In addition the materials bulk density as

a function of pressure at several preheating

temperatures was measured. These experimental

findings have important implications in the design

and scale up of single screw designs.

Introduction

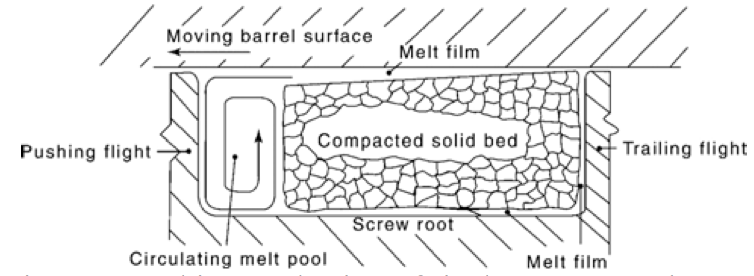

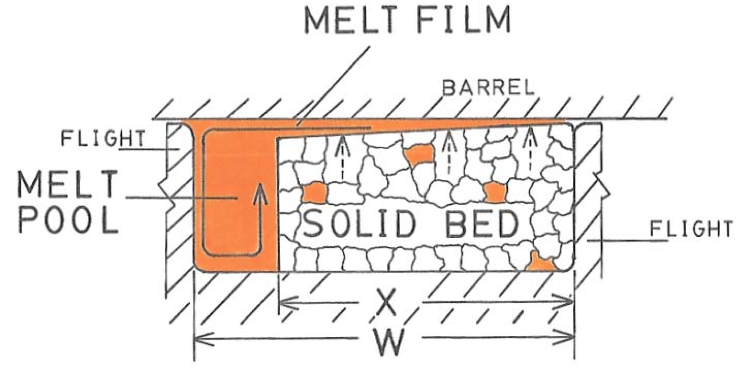

Melting within an extruder was for many years an

unknown mechanism. It was not until the pioneering

screw freezing experiments of Bruce Maddock

1 that

the standard mechanism of single screw melting was

described [Figure 1]. Once the melting mechanism

was understood there was an explosion of modeling

work to solve the melting problem for use in screw

design calculations

2, 3, 4, 5. The difficulty with the

initial melting models was that there was no

independent way to check the accuracy of the

assumptions and the subsequent melting rate

calculations. All of the models were checked by

estimating the overall performance of the extruder,

which combined the assumptions of an extrusion

model [solids conveying, melting and metering model

combination] over laid on the assumptions of the

melting model. Consequently, the melting model

verifications were all indirect verifications leaving the

correctness of the melting model assumptions and the

accuracy of the calculations in question

6, 7.

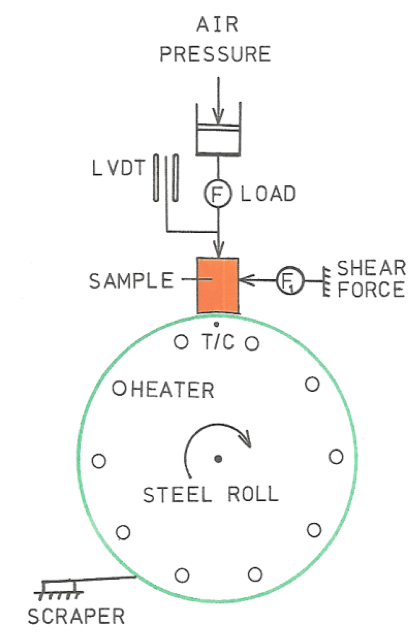

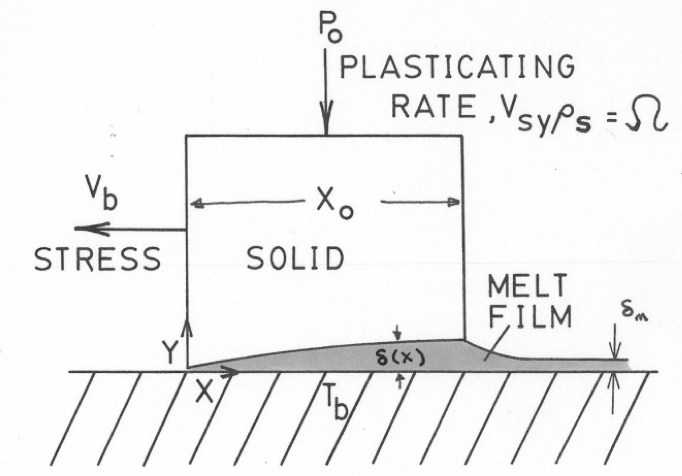

This was the situation until the development of

the “Screw Simulator” by Chung

8

[Figure 2]. The

screw simulator is a device specifically designed to

measure the frictional forces

9

and the melting rate of

polymers

10 using the solid conveying model of

Darnell and Moll

11 and the idealized melting model

of single screw extruders [Figure 3]. Prior to the

onset of melting the polymer rubs against the barrel

surface and controls the solid conveying of the

polymer into the screw. In the idealized mechanism,

melting occurs only at the interface between the solid

plug of polymer and the barrel surface. This is the

location where the power of the motor is dissipated

by viscous drag to generate the thermal energy used

to melt the polymer in a single screw

12. The solid

plug assumption can also be replaced by a compacted

bed of pellets

13.

The screw simulator, while similar in concept to

the device of Sundstrom and Young

14 allowed direct

experimental measurements of friction and melting at

conditions typical of operating extruders. Figure 4

shows the melting polymer system as implemented

with the screw simulator. The applied load P

0 forces

the compacted solid plug of width X

0 against the

heated [Tb] moving [Vb] roll surface (the relative

velocity of the solid against the metal surface). The

solid velocity in the y-direction [Vsy] is measured

directly by the LVDT and the mass of solid melting

per unit area [Ω] is equal to the amount of melt

dragged from under the solid plug on the barrel

surface. The molten polymer layer is removed by the

scraper to mimic the action of the pushing screw

flight in the melting mechanism of Figures 1 and 3.

The screw simulator for the first time permitted the

development and verification of the assumptions and

accuracy of the various melting models for

plasticating extruders

7.

The friction and melting measurements are

important as they are used to determine the

performance and design parameters of operating extruders. The measurements confirmed for the first

time that in the limit, single screw extruders are

melting limited apparatus

15, 16. Also, they can be used

to estimate the expected output of a single screw

extruder based on the screw dimensions, details of the

screw design, polymer type and operating conditions.

In particular the measurements have been used in a

scientific screw design method described by Chung

17,

18. Melting data for screw design calculations can be

obtained either experimentally or estimated using the

melting model of Mount, Watson & Chung

8 for fully

compacted solid beds or Kuo & Chung

13 for granular solid beds.

Experimental

The Screw simulator was used to measure the

bulk density, frictional properties and the melting

properties.

The resin sample was a polyethylene

terephthalate (PET) chip of 0.60 IV. Prior to testing,

the resin sample was dried and crystallized in a

vacuum oven heated to 165

oC to 177

oC [330

oF to 350

oF].

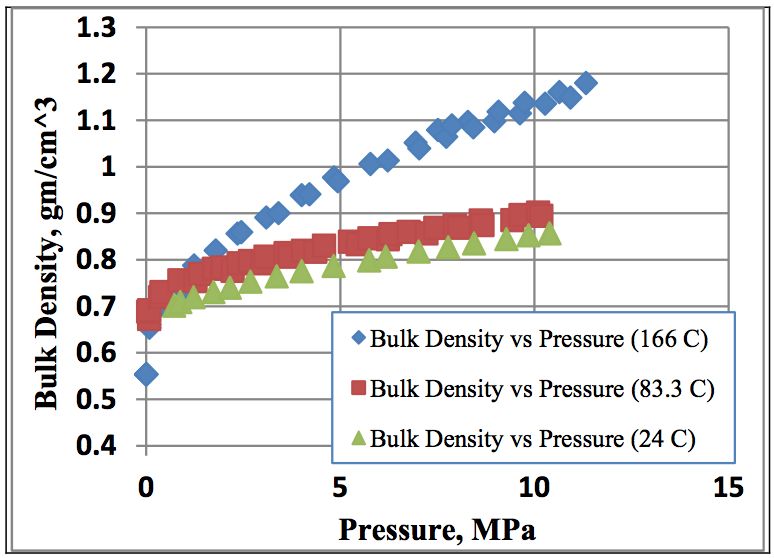

Bulk density measurements are obtained by

introducing a weighed sample to the screw simulator

sample cell (2.54 cm by 7.62 cm), the sample plunger

is inserted and the initial sample height measured at

6.89x10

-2-1.38x10

-1 MPa [10-20 psi] with the screw

simulators LVDT to give the initial sample volume.

Pressure is increased in a stepwise fashion and the

sample volume calculated as a function of pressure to

give the sample bulk density.

Friction coefficients were obtained by:

1. Presetting the roll speed and roll

temperature

2. Preheat the chip to 83.3

oC

3. add a known weight of polymer pellets to

the sample cell

4. apply the desired load to the sample

5. allow sample/roll interface to equilibrate

6. Activate recording equipment and rotate

the roll for several seconds to obtain

applied load and frictional force.

The roll is only rotated to give an initial frictional

force as extended operation generated significant

frictional heating of the interface which affects the

measurements.

Melting experiments are performed in the

following manner:

1. The roll velocity, temperature and load

are preset before the measurement is

started

2. The recording equipment is set to

measure LVDT position and the sample

restraining force [shear stress]

3. Preheat the chip to 83.3

oC

4. A pellet sample is introduced to just fill

the sample chamber, the plunger inserted

and the load applied and allowed to

equilibrate for 10-15 seconds to compress

the sample

5. The roll rotation is started and the

melting rate measured. During the

melting measurement, the roll surface is

scraped to remove the melt layer from the

roll surface

6. The height of the solid sample is

recorded with the Screw Simulator

LVDT and plotted as a function of time

during the experiment to obtain the solid

velocity in the direction of the roll

surface (Y direction)

7. At the end of the experiment the load is

released, the roll stopped and the

recording equipment stopped.

8. The melting velocity cm/min is measured

as the slope of the LVDT position vs.

time on the strip chart recording, the

melting shear stress is determined from

the measured sample chamber restraining

force.

Melting rate, Ω [kg/min/cm

2] is calculated as the

product of the solid velocity [cm/min] measured as

the slope of the LVDT chart recording and the pellet

bulk density (gm/cm

3) at the load applied to the

sample.

Melt viscosity was measured as a function of

temperature and shear rate using an Instron 3211

capillary rheometer. Temperatures were 260

oC, 270

o

C, 280

oC, 290

oC and 300

oC. Data was obtained

using a 0.1275 cm [0.0502 in] diameter by 7.623 cm

[3.0037in] 59 L/D long capillary with a 90 degree

entry angle. Prior to the viscosity measurements, the

pellet samples were dried for 9 hours in vacuum at

165

oC. Because the PET melt viscosity is Newtonian, the apparent viscosity is presented and

the data was not Rabinowitsch corrected.

Experimental conditions of surface temperature,

sliding velocity and applied load were varied one

variable at a time while maintaining the other two at a

constant value. For the friction measurements, the

applied load, P

0, was help at 6.89MPa (1000 psi) as

representative of most expectations for solid

conveying pressures. For the melting experiments an

applied load of 2.76MPa (400 psi) was selected as

representative of the pressure where the equilibrium

melting rate was observed. The sliding velocity of

55.9 cm/sec was chosen as representative of a 114.4

mm diameter screw, rotating at a screw speed of 93.4

rpm. For the friction experiments, a surface

temperature of 121

oC, as representative of a feed

zone temperature, and for the melting experiments, a

surface temperature of 276

oC and 293

oC, as

representative of melting and metering barrel zone

temperatures were used.

Calculations

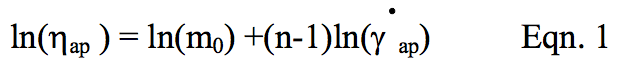

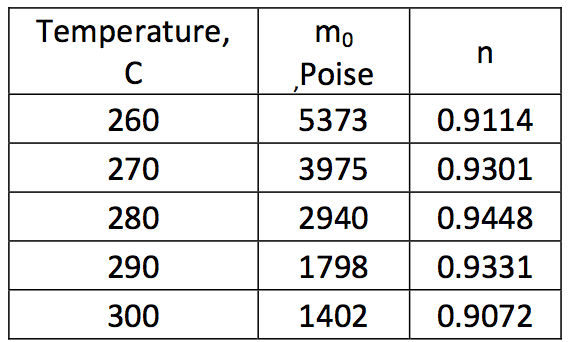

The viscosity data is plotted in Figure 1 and was

curve fit to Equation 1. The regression results are

found in Table 1.

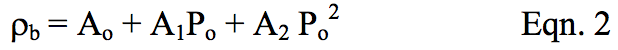

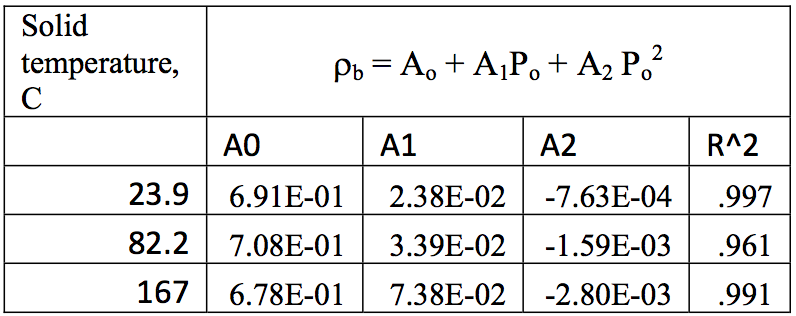

The bulk density was calculated for the

compressed solid volume and the initial weight of the

sample. The data is plotted in Figure 2 and was curve

fit to Equation 2. The regression coefficients are

listed in Table 2.

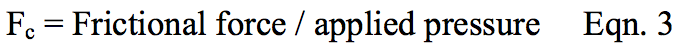

The melting and frictional data were obtained as

described and the experimental data used to calculate

the frictional coefficient [Equation 3] and the solid

melting velocity, V

sy in the Y-direction [Equation 4].

The melting rate Ω (kg/sec/cm) and the Melting

efficiency Ω/V

b (kg/cm

2-cm), are calculated with

Equations 4&5. The melting efficiency has units of

density but are better understood if they are expressed

as mass melted per unit area per unit distance slid or

gm/cm

2-cm.

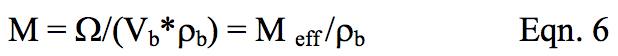

For calculations based on the Mount et al Model,

the dimensionless melting efficiency is described as

[Equation 6]

Results and Discussion

Figure 5 presents the bulk density data as a

function of pressure and chip preheating temperature.

It is clear that the preheat temperature used to dry the

chips has an impact on the solids bed compaction.

Preheat temperature will also have an impact on

melting rate as it decreases the energy required to

raise the solid to the melting point. Consequently, it

is important to maintain the chip temperature as high

as practical when transporting it from the chip drier to

the extruder feed pocket. In the case at hand the chip

was expected to drop in temperature from 166°C at

the exit of the drier to 83°C at the extruder feed

hopper. Consequently, the friction and melting

measurements were preformed with a solid

temperature of 83°C.

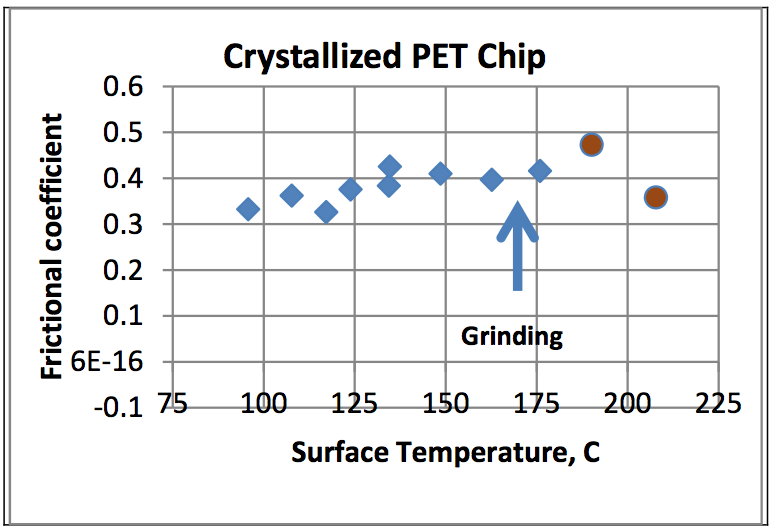

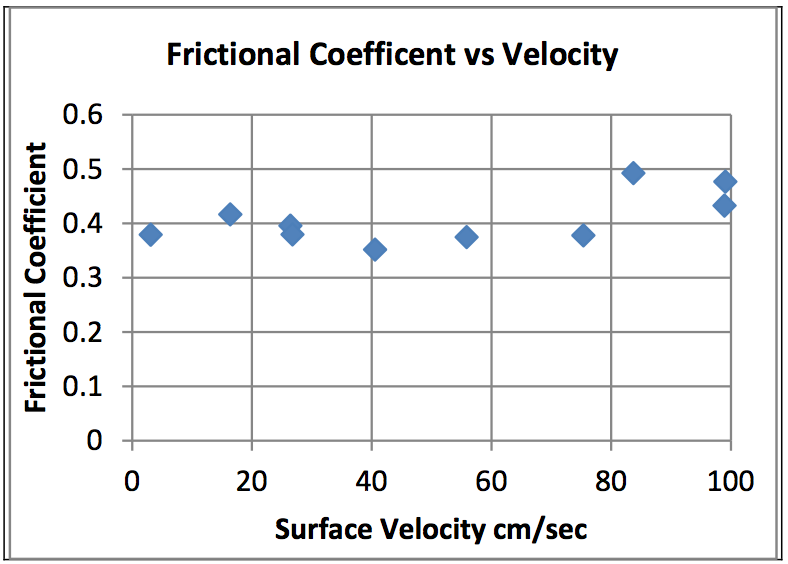

Figures 6, 7 and 8 presents the Solid frictional

coefficient (COF) data obtained as a function of metal

surface temperature [T

b], Roll surface velocity [V

b]

and applied load [P

0].

In Figure 6 the COF is seen to be a weak function

of surface temperature for a sliding velocity of 55.9

cm/sec and an applied load of 0.145 Pa. At

approximately 175°C the solid is observed to grind

[fine, white, powdery pieces of polymer adhered to

the roll surface] indicating the beginning of

mechanical melting [plastication]. At a surface

temperature of 190°C and 207°C the sample is

observed to be melting (filled circles) with a distinct

melt film on the roll surface, indicating an interfacial

temperature of greater than the melting point of

approximately 260°C.

In Figure 7, the COF remains fairly constant for

sliding speeds below 80 cm/sec and then jumps

slightly. This is likely due to the increased heat

generation at higher sliding speeds and indicates the

potential for a change in solids conveying rate at increased screw speeds. Operating at screw speeds

near the 80-85 cm/sec transition could potentially

cause surging in systems where the screw speed is

controlled by a device such as a melt pump. For

constant screw speed operation a jump in feeding

would be expected for screw speeds above 85 cm/sec

peripheral speeds. This could result in an increase in

specific output or surging depending on the screw

design and operating conditions. At any rate the

observed jump in COF is important to note.

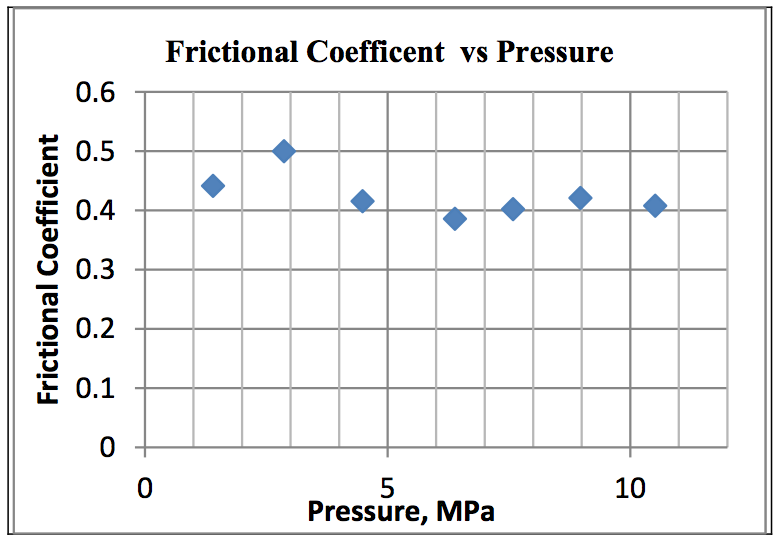

Figure 8 plots the COF as a function of applied

load. The COF is seen to remain fairly constant with

increasing pressure. At a pressure of 0.06 Pa there is

a slight jump in COF. This might be due to packing

variations of the pellets but no real explanation of the

observation can be given.

In all instances after the frictional measurements,

observations of the preheated chip samples at the

polymer/metal interface showed a void free interface

indicating that the sold bed deformed sufficiently to

completely contact the metal surface. At the

polymer/metal interface, the solid bed is behaving

like a solid plug.

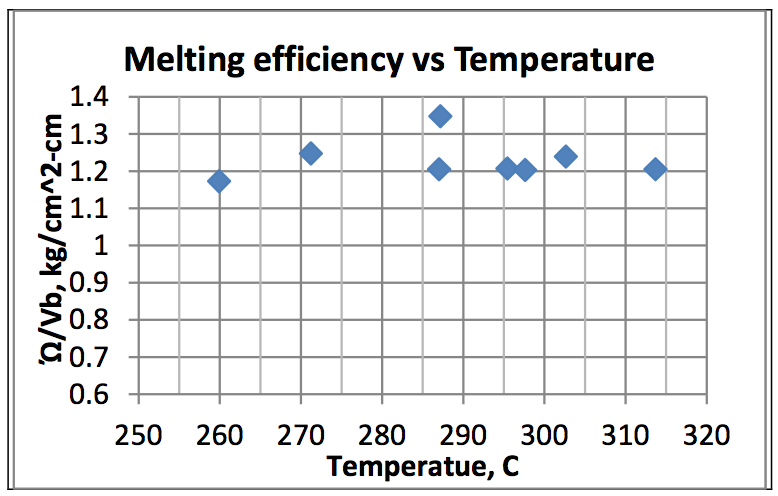

Figures 9, 10 and 11 present the plasticating

efficiency as function of metal surface temperature

[T

b], Roll surface velocity [V

b] and applied load [P

0]respectively.

Figure 9 Plots the melting efficiency vs. surface

temperature [T

b] for a solid temperature of 83.3°C, an

applied load of 0.145 Pa (1000 psi) and a surface

velocity of 55.9 cm/sec. The plot shows a slight

maximum around 275-280°C and would drop sharply

for surface temperatures below 250°C to the onset of

melting seen in Figure 6 at about 200°C. The melting

rate drops above 275-280°C due to the decrease in

melt film viscosity and melting stress [Figure 12] and

a subsequent drop in viscous dissipation in the melt

film. Consequently, there is no advantage to

increasing the barrel temperatures much above 270-

275°C unless the extruder is torque limited.

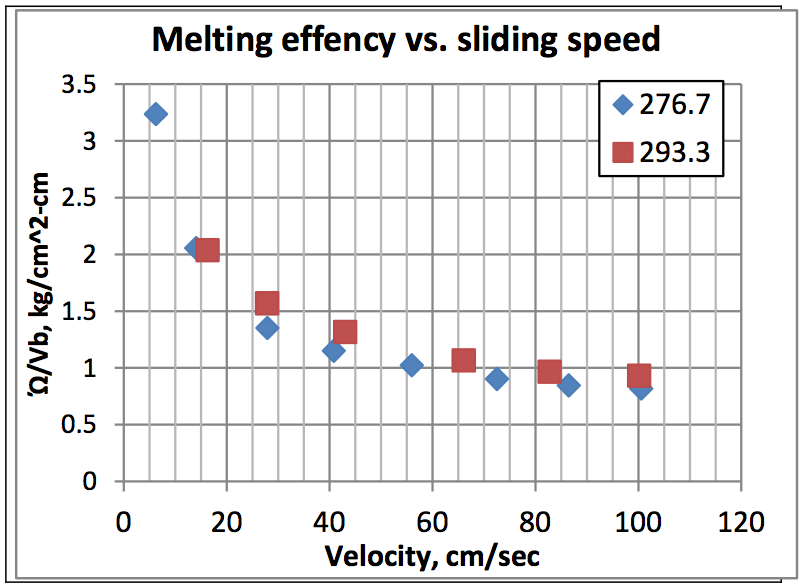

Figure 10 plots the melting efficiency vs. surface

velocity [V

b] for a solid temperature of 83.3°C, an

applied load of 2.76MPa (400 psi) and surface

Temperatures of 276°C and 293°C. The plot show a

marked decrease in kg/cm

2-cm slid and is indicative

of a decrease in melting efficiency, not melting rate,

with increasing screw speed. What this means is that as the sliding speed is increased, while more polymer

is melted per cm

2, less is melted per cm slid. This is

because while more energy might be dissipated in the

melt film under the melting solid, less of the energy

has time to diffuse to the melting interface and is

swept into the accumulating melt pool. This is why

melt temperature and torque increases with screw

speed.

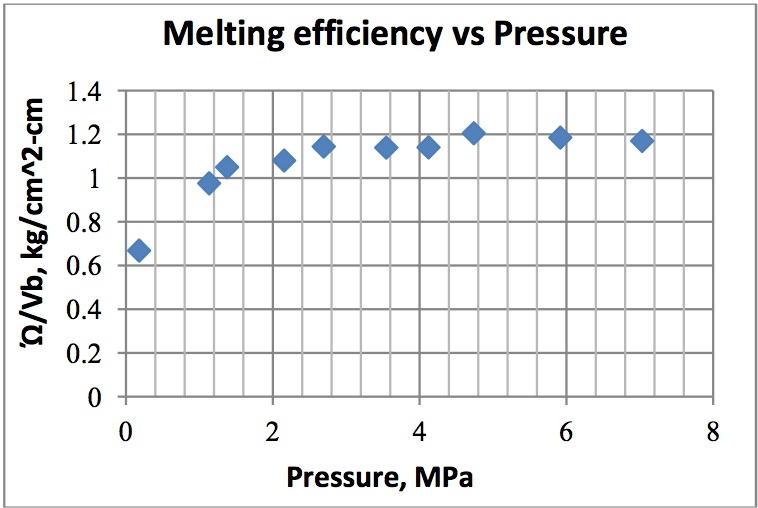

Figure 11 plots the Melting efficiency vs. applied

load for a solid temperature of 83.3°C, a surface

velocity of 55.9 cm/sec and a surface Temperatures

of 296°C. The melting efficiency is seen to increase

up to approximately 2.76MPa (400 psi) and reach a

constant value. This is likely due to thinning of the

melt film with increasing load to the point where the

solid bed is sufficiently compacted to form a “solid”

interface at the melting surface, limiting melt

penetration into the solid bed. It indicates that for

solids conveying pressures above 0.058 Pa the

melting process will be in equilibrium with the solids

conveying forces. Solids conveying forces higher

than 0.058 Pa will not benefit melting and may only

result in increased screw wear.

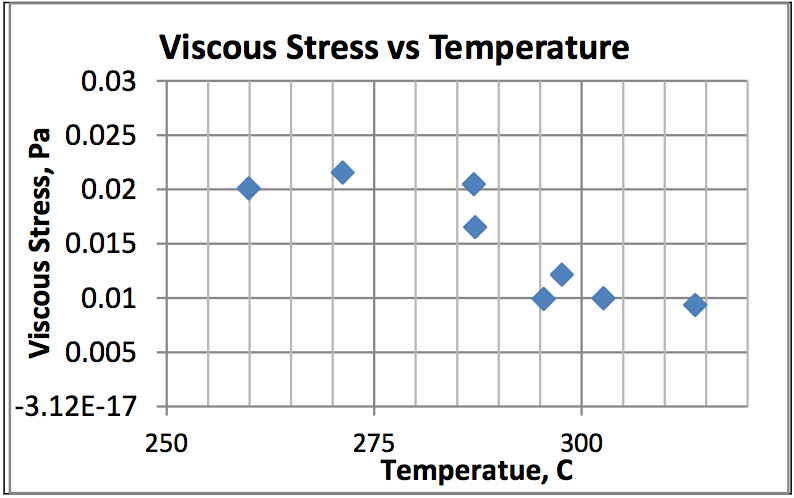

Figure 12 Plots the viscous stress vs. Surface

temperature for a solid temperature of 83.3°C, an applied

load of 6.89 MPa (1000 psi) and a surface velocity of 55.9

cm/sec. the viscous stress is seen to peak at approximately

275-280°C and then drop at approximately 285°C to a

constant value above 290°C. This matches well the

observed melting efficiency changes seen in Figure 9

and demonstrates the decrease in viscous dissipation

above 285°C leading to the decrease in melting

efficiency above 285°C.

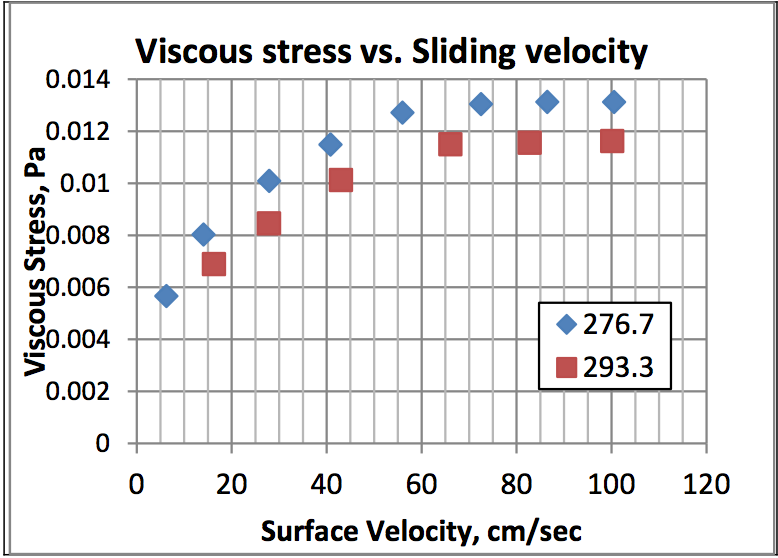

Figure 13 plots the viscous stress vs. surface

velocity [V

b] for a solid temperature of 83.3°C, an

applied load of 2.76MPa (400 psi) and surface

Temperatures of 276°C and 293°C. The viscous

stress is seen to reach a maximum or slowly

increasing stress above approximately 60 cm/sec,

perhaps indicating the formation of an equilibrium or

limiting melt film thickness. The limiting stress

value corresponds to the decrease in melting

efficiency observed in Figure 10.

Conclusions:

The experimental observations of the melting

performance of 0.6 IV PET pellets highlight the basic

frictional and melting behavior of the polymer. The data can be used to help optimize the performance of

PET screw designs for estimating output levels and

highlighting limiting behaviors as a function of

process settings. For instance, the impact of surface

temperature and sliding velocity, on COF and melting

efficiency, as well as highlighting transition points

such as the sudden increase in COF with temperature,

the maximum in melting rate with surface

temperature. This information can be used to set

optimum barrel temperature settings and screw

speeds for solids conveying and melting and avoid

settings which might result in extrusion instabilities.

References

1. Maddock, B. H.,”A Visual Analysis of Flow and

Mixing in Extruder Screws”, SPE Journal, May,

(1959), pp. 383-389

2. Tadmor, Z., “Fundamental Of Plasticating

Extrusion”, Poly. Eng. Sci., 6(3), 185 (1966)

3. Tadmor, Z, Duvdevani, I., Klein, I., “Melting in

Plasticating Extruders Theory and Experiments”,

Poly Eng & Sci,7, (1967), 198

4. Donovan, R. C., Polym. Eng. Science, 12(1), 59

(1972)

5. Chung, C. I., “A New Theory for Single-Screw

Extrusion,” Part 1 - Modern Plastics, 45(13), 178

(1968); Part 2 - Modern Plastics, 45(16), 110

(1968).

6. Chung, C.I., “Plasticating Single-Screw Extrusion

Theory,” Poly. Eng. Sci., 11(2), 93 (1971)

7. Mount III, E. M., “Plasticating Behavior of Solid

Polymers at Processing Conditions: Experimental

and Theoretical Study”, Ph.D. Thesis, Rensselaer

Polytechnic Inst., Troy NY (1978)

8. Chung, C.I., “A New Look at the Melting

Mechanism,” Plastics Eng., 32(6), 1149 (1976)

9. Chung, C.I., Hennessey, W. and Tusim,M.

“Frictional Behavior of Solid Polymers on Metal

Surfaces at Processing Conditions”, Poly. Eng.

Sci. , 17(1), 9 (1977).

10. Mount III, E.M., Chung, C.I. , “Melting Behavior

of Solid Polymers on Metal Surface at Processing

Conditions,” with Poly. Eng. Sci., 18(9), 711

(1978).

11. Darnell, W.H. and Mol, E.A.J., SPE Journal, 12,

20 (1956)

12. Chung, C. I., Mount III, E.M. and McClelland,

D.E., “Energy Efficiency in Plasticating Screw

Extrusion,” with, ACS-Organic Coatings and

Plastics Chemistry Preprint, 39, 74 (1978)

13. Chung, C.I., Kuo, S.H. “Analytical Melting

Model for Polymer Pellets,”, Poly. Eng. Sci.,

29(7), 448(1989)

14. Sundstrom, D.H., and Young, Chi-Chang, Polym.

Eng. Sci., 12, 59-63, (1972)

15. “On the Scale Up of Plasticating Extruder

Screws,” Poly. Eng. Sci., 24(9), 626 (1984).

16. Chung, C.I, EXTRUSION OF POLYMERS -

Theory and Practice 2nd edition, Carl Hanser

Publisher, Munich, 2010, p. 239

17. Chung, C.I., “Science and the Art of Screw

Design,” Proceedings of the Summer Meeting,

Polymer Processing Society, 11D (1989)

18. Chung, C.I., “A Scientific Approach to Screw

Design,” SPE-ANTEC Technical Papers, 43, pp

121–126 (1997).

Tables

Table 1: Viscosity data regression coefficients for Equation 1 with viscosity in poise. To convert poise to Pa-sec, divide result by 10

Table 2: Regression coefficients for bulk density [gm/cm

3] as a function of pressure [MPa]

Figures

Figure 1: Melting mechanism of single screw extruders as determined by Maddock.

Figure 2: Schematic diagram of the screw simulator

Figure 3: Idealized melting mechanism of single screw extruders assuming melting only at the barrel surface.

Figure 4: Mass balance around melting solid plug at the barrel surface

Figure 5: Bulk density vs. pressure for PET chip at various solid preheat temperatures

Figure 6: Plot of Frictional coefficient vs. surface temperature [T

b] for a solid temperature of 83.3

oC, an applied load of 6.89MPa (1000 psi) and a surface velocity of 55.9 cm/sec. The sample was observed to grind at 175

oC and the onset of plastication (circles) was observed above 190

oC (melting point is approximately 265

oC)

Figure 7: Frictional coefficient vs. surface velocity [V

b] at a preheat temperature of 83.3

oC, a surface temperature of 121

oC and an applied load of 6.89 MPa (1000 psi).

Figure 8: Frictional coefficient vs. applied load [P

0] at a preheat temperature of 83.3

oC, a surface temperature of 121

oC and an surface velocity of 55.9 cm/sec

Figure 9: Plot of melting efficiency vs. surface temperature [T

b] for a solid temperature of 83.3

oC, an applied load of 6.89MPa (1000 psi) and a surface velocity of 55.9 cm/sec.

Figure 10: Plot of melting efficiency vs. surface velocity [V

b] for a solid temperature of 83.3

oC, an applied load of 2.76MPa (400 psi) and surface Temperatures of 276

oC and 293

oC.

Figure 11: Plot of Melting efficiency vs. applied load for a solid temperature of 83.3

oC, a surface velocity of 55.9 cm/sec and a surface Temperatures of 296

oC.

Figure 12: Plot of viscous stress Vs. Surface temperature for a solid temperature of 83.3

oC, an applied load of 6.89 MPa (1000 psi) and a surface velocity of 55.9 cm/sec.

Figure 13: Plot of viscous stress vs. surface velocity [V

b] for a solid temperature of 83.3

oC, an applied load of 2.76MPa (400 psi) and surface Temperatures of 276

oC and 293

oC.

Return to

Paper of the Month.