Residence Stress Distributions in a Twin Screw Extruder

David Bigio, William Pappas, Harry Brown II, , Beserat Debebe and William Dunham,

University of Maryland, College Park, MDAbstract

An experiment has been created to directly relate

the stress distribution history (RSD) with the Residence

distribution. Stress beads are used to determine the

percentage of material that experiences a certain amount of

stress at each location on the residence distribution. This

experiment directly relates stress data as a function of the

residence distribution and will be recorded for a range of

specific throughputs. A comparison of a mixing section

comprised of narrow versus wide kneading blocks is

performed to demonstrate the power of the approach.

Introduction

Extrusion is a viable technique for creating an

array of different products across a broad spectrum of

disciplines. Examples include pipes and tubes, chemical

pressure-sensitive adhesives, and active ingredient patches

for pharmaceutical industries [1]. One of the more

intriguing applications for extrusion is the production of

composite materials using fillers, such as carbon

nanofibers. This process produces an extruded material

with altered properties than that of the base polymer, such

heightened thermo-conductive and mechanical strength

properties. There are several factors that determine the

change in properties of an extruded material. One such

factor is the amount of mixing a material within an

extruder experiences. To be able to determine the degree

of mixing, it is important that one accurately model the

stress that is induced for a given screw geometry and

operating condition.

Mixing with a twin-screw extruder is categorized

as either distributive or dispersive. Distributive mixing

uniformly distributes particles throughout the melt and

dispersive mixing breaks large particles and distributes

them throughout the melt. Narrow kneading blocks are

used for distributive mixing as the melt flows in and

around the paddles, producing low shear. Dispersive,

however, is a high shear process as it utilizes wide

kneading blocks. Wide kneading blocks force the material

around the blocks that is squeezed between the paddles and

the barrel wall [2].

There have been numerous attempts in the past to

find a correlation between stress in an extruder and a

residence-time distribution. Efforts have been made to use

the residence distribution to imply intensity of mixing by

various methods, e.g.; Peclet number or a number of passes

[3]. Typical residence distributions, however, only provide

an axial history of the flow and give no information regarding the stress history. There have also been some

attempts to quantify the stress in an extruder. Curry et al

using the percent breakage of glass beads as a way to

quantify the stress under different conditions and screw

designs [4, 5]. The limitation of the approach is the effort

to obtain a few values along the residence distribution.

Gallant used stress beads to quantify the maximum stress

in an extruder for an energetic application [6]. Cheng et al

used stress beads to characterize different mixing section

designs [7].

The purpose of this research is to establish the

methodology to measure the Residence-stress Distribution

(RSD) and compare it to the RTD. Another goal is to

determine the stress history of different screw designs

using narrow and wide kneading blocks and whether it can

distinguish the difference between different screw

geometries, as a function of operating conditions.

Materials

The extrusion material used for this experiment

was high-density polyethylene (HDPE) Alathon H6018 in

pellet form from Equistar Chemicals. The HDPE had a

density of 0.960 g/cc and a melt index of 18.0 g/10 min.

Calibrated microencapsulated sensor (CAMES)

beads from Mach I, Inc. were utilized as the method to

measure the stress in the extruder. The beads are designed

to measure shear stress during mixing by breaking at

specific critical stress levels which are dependent on the

bead diameter. The selected range of diameters for the

experiment was 53 - 63μm. When the beads are subjected

to stress levels beyond the critical shear stress, the beads

break and release their contents (Red B Disazo dye) which

stain the extruded material.

Using the same dye (Red B Disazo) that is

encapsulated by the CAMES beads, “reference” dye shots

were produced. These shots were prepared by dissolving

polystyrene pellets in xylene, and adding concentrated

amounts of dye. The solution was allowed to solidify over

a 24 hour period. The batch was then cut and weighed to

the appropriate amount to match that of the measured

CAMES shots. The dye shots were used to produce

reference RTD curves that represented 100% breakup of

the CAMES beads.

Equipment

The experiments were performed using a 28-mm

Coperion CoTSE extruder with an L/D = 32 using two

screw configurations of interest. The melting section of

both screw designs remained unchanged for the duration of

the experiment and consisted of three right-handed

kneading blocks (15, 30, and 45-mm), two neutral blocks

(20-mm), and one left-handed kneading block (15-mm).

The mixing section of the first screw design contained two

right-handed kneading blocks (15- and 45-mm) and one

left-handed convey element (15-mm) with a 5-mm pitch.

The second screw configuration consisted of five righthanded

kneading blocks (15-mm), one neutral block (20-

mm), and one left-handed conveying element (15-mm)

with a 5-mm pitch. The extruder set up consists of a feed

port and one vent port just before the mixing section, as

seen in Figure 1. The extruded polymer was cooled via a

chill roller where it was then collected as strips.

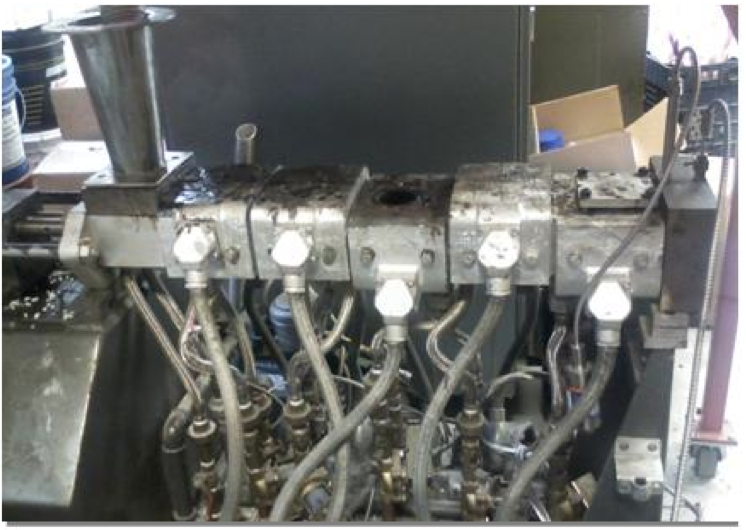

Figure 1. 28-mm Coperion Co-Rotating TSE

A reflective optical probe was placed just before

the die of the extruder. The probe consists of a split fiberoptic

bundle, where light was transmitted from one fiber

bundle. The light entered the melted polymer, reflected off

the polymer and screw elements, and was collected by the

other fiber bundle, where it was converted into a voltage

signal.

Experiment

The extruder and pellet feeder were then set to the

desired operating condition. The five barrels were set to a

temperature of 160oC and the die was set to 155

oC. The

data acquisition program began sampling for 15 seconds to

establish a baseline. Due to the transparent nature of

HDPE during extrusion, TiO

2 pellets were fed at a constant

rate during the experiment to provide a white background

on the polymer melt for the optical probe. The solid pieces

of dye were fed into a channel via the vent port as an

impulse. Since small amounts of the dye shots were fed into the extruder, the concentration of the dye and

polystyrene had a negligible effect on the viscosity of the

HDPE melt. Once the stained polymer had been

completely extruded, the data acquisition program was

reset and the program was again run for 15 seconds to

establish a baseline. CAMES beads were then fed into the

vent port. In total, nine operating conditions were tested,

with one dye and three CAMES shots fed per condition.

Experimental Grid

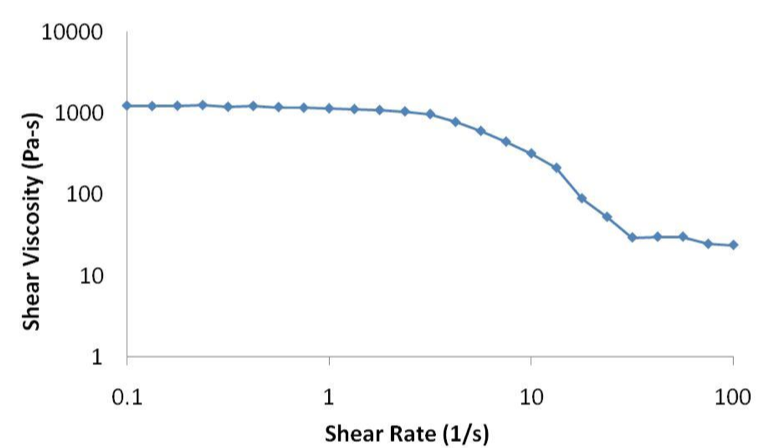

A central composite design (CCD) of experiment

grid was used to layout the data to show relationships

between percent breakup and different operating

conditions, as seen in Figure 2 . This approach was chosen

because of the expected non-linear relationship between

breakup and the chosen parameters. The specific locations

on the grid represent the operating conditions for this

study.

Figure 2. CCD grid of experimental conditions

The ranges of the conditions were determined by

the capabilities of the extruder. The first number of a

condition represents the throughput, Q, measured in mL/s.

The second number represents the screw speed, N, in rpm.

N vs. Q/N was chosen because RTDs scale with Q and N.

It was found that Q/N was a key variable in determining

the characteristics of RVDs and RRDs, which will be of

interest in a later study [8].

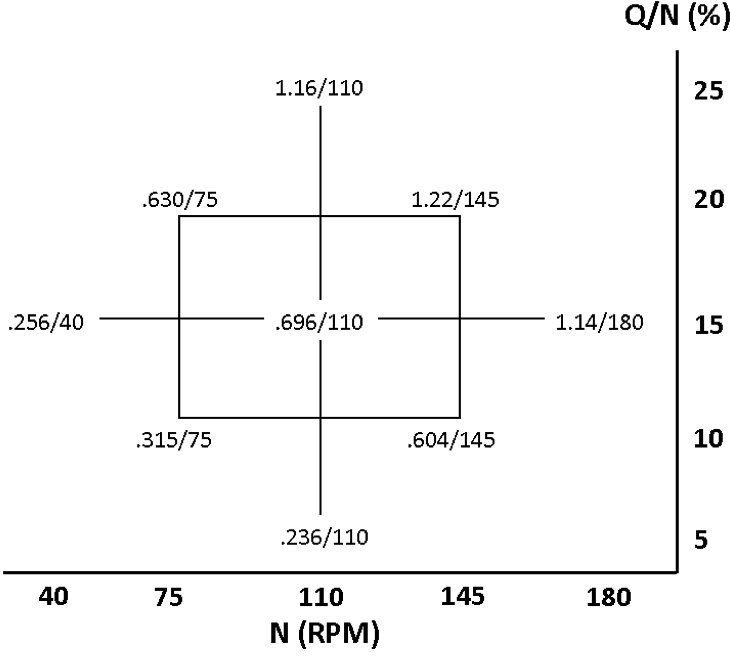

In order to ensure that the stress beads would

break in the designed operating region, viscosity data was

generated using a Rheometrics RDA-III rheometer and the

results plotted in Figure 3.

Figure 3. Shear viscosity for HDPE at 160

oC

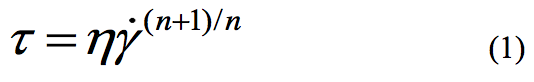

Furthermore, the slope of this graph was used to

calculate the shear stress by using the equation:

Where τ is shear stress (Pa), η is viscosity of the polymer

(Pa-s), ? is shear rate (1/s), and n is the slope. The shear

rate is defined as:

where N is screw speed (rpm), D is the screw diameter

(mm), and h is the channel height (mm).

Using the dimensions of the 28-mm conveying

element that has a channel height of 4-mm, the stresses

induced at each operating screw speed were evaluated and

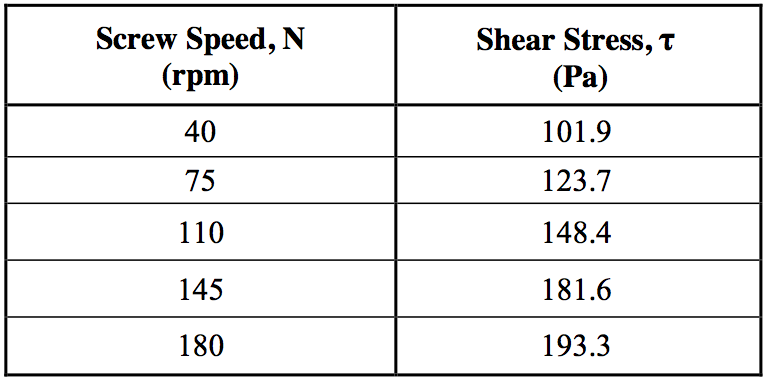

are displayed in Table 1.

Table 1. Calculated shear stress

The approximate critical stress value at which the

CAMES beads break at was determined to be 120 Pa,

using data obtained from MACH I. Table 1 shows that, for

the given range of screw speeds, the amount of bead

breakup would occur at a low level for the lower screw

speeds and increase at the highest speeds.

Experimental Results

Percent Breakup

The average percent breakup for all nine

experimental conditions was calculated and the results

inserted into the Central Composite Design grid for

analysis as a way to compare the breakup history in the

wide and narrow kneading block configurations. To

determine the percent breakup of CAMES beads, the areas

under the RTD and RSD curves were calculated and used

in the followed equation:

Where A

c is the area under the CAMES RSD curve and A

r is the area under the dye RTD curve.

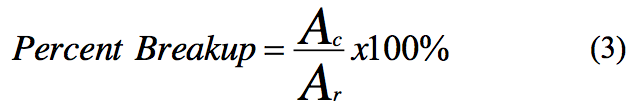

Percent breakup generated from screw configuration 1 (i.e. wide kneading blocks) is presented in

Figure 4.

Figure 4. Percent breakup using wide kneading blocks

Figure 4 presents the percent breakup for the wide

kneading block configuration and indicates that there are

trends within the data as a function of screw speed and

specific throughput. As screw speed increases for a given

Q/N, the percentage of broken beads also increases. This

is expected as shear rate increases as screw speed also

increases as given by equation (2).

Another noticeable trend within the data is

percent breakup of beads increases as specific throughput

increases. As the specific volume of material in the

channel increases, the pressure on the melt while inside the kneading blocks also increases, inducing higher levels of

stress on the beads.

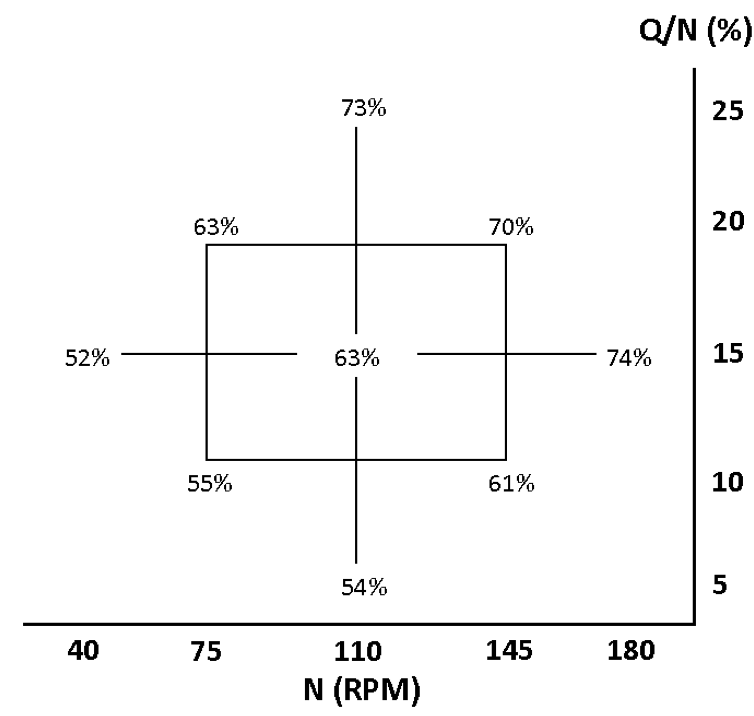

Average percent breakup was calculated using the

narrow kneading blocks screw design (screw configuration

2) and inserted in the CCD grid as shown in Figure 5.

Figure 5. Percent breakup using narrow kneading blocks

Figure 5 above shows similar trends within this

data to that of Figure 4. Again, it can be seen that

increasing N and Q/N yields a higher percent breakup.

Comparing the two average percent breakup grids

(Figure 4 and Figure 5), it is apparent that screw

configuration 1 (wide kneading blocks) broke up a larger

percentage of CAMES beads than in the narrow kneading

blocks configuration. This result is consistent with the

common understanding that the wide kneading blocks are

better for dispersive mixing due to the wider paddles and

the higher extensional flows. The narrow kneading blocks

are commonly described as better for distributive mixing,

as confirmed by the lower stress levels.

To confirm that the range of obtained breakup

was outside of experimental error, an error analysis was

performed on both sets of data. It was determined that

there is approximately a 2% error for both wide and narrow

kneading blocks. This provides validation that the range of

percent breakup is independent of experimental error and

that there is in fact a significant increase in percent breakup

as N and Q/N are increased.

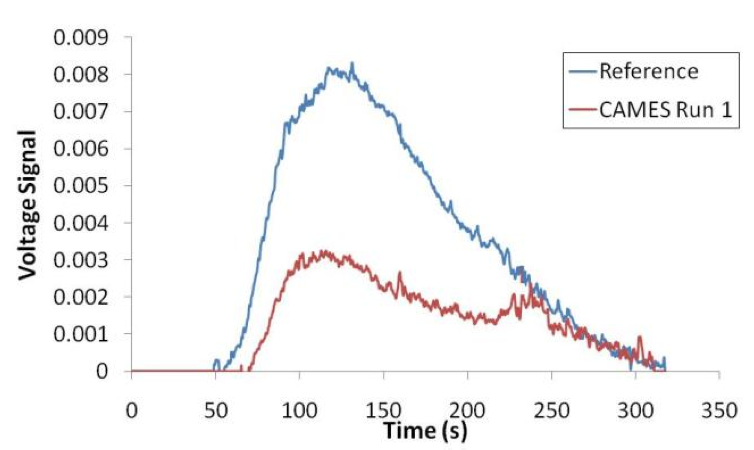

Residence Stress Distributions

Residence time and stress distribution curves were

generated from the data acquisition program and plotted

together for each condition. Figure 6 displays the RTD

and RSD curves for a given operating condition using the

wide kneading blocks configuration.

Figure 6. Normalized wide kneading blocks RTD and RSD curves for .236/110 condition

Figure 6 shows the normalized RTD and RSD

curves generated by the dye and CAMES shots,

respectively. This figure shows the quality of the data

collected by each individual run, which validates the claim

that the feed method did not affect the output curves. The

two RSD curves are essentially identical to each other

demonstrating the experimental repeatability. The curves

also show that the CAMES beads are passive tracers,

following identical paths in the extruder as described by

the RTD. Upon inspection, it is clear that the RTD curve

has higher amplitude than the RSD curves, indicating that

100% breakup of the CAMES beads was not achieved.

Since the residence distribution is the time history

through the screw’s geometry, it can be viewed as the

history of the flow path through the mixing zone. The dye

that comes through first transverses the least tortuous path,

staying in the center of the channels; whereas the tail of the

distribution passes back through the paddles. The

difference in the RTD and RSD curves confirms that

description. Initially the percentage of the flow that

experiences the critical shear stress is a small percentage of

the total flow; whereas, the figure does indicate that at the

tail end of the curves, the majority of CAMES beads did

break during this segment as the RTD and RSD curves

overlap.

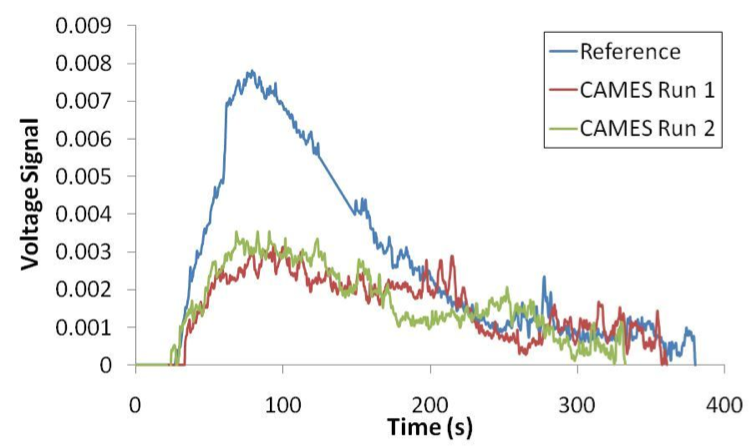

The RTD and RSD curves generated using the

narrow kneading blocks are plotted in Figure 7.

Figure 7. Normalized narrow kneading blocks RTD and RSD curves for .236/110 condition

The comparison of the RTD and RSD curves for

the narrow kneading blocks configuration follows the same

pattern as the wide kneading blocks where the initial part

of the flow experiences little of the critical stress whereas

all of the flow in the tail of the RSD experiences the

critical stress. The one difference is there is a lag time

between the start of the RTD and the RSD. This can be

interpreted as the initial part of the RSD experienced little

to no shear stress until about 20% of the RTD is complete.

Conclusions

A novel method for directly generating a

Residence Stress Distribution using a stress sensitive bead

(CAMES, MACH I, Inc.) has been demonstrated to be an

effective tool to measure the stress history in a complex

geometry as might be experienced in a twin screw

extruder. A comparison of wide and narrow kneading

block screw configurations was performed over a range of

specific throughputs (Q/N) and screw speeds (N). The

wide kneading block configuration showed a higher

percentage breakup of the stress beads when compared

with the narrow kneading blocks of equal length. The

interpretation of that result was that a higher percentage of

the CAMES beads experienced the critical stress at the

same operating conditions, in all cases.

For a given screw configuration, there was an

increase in percentage bead breakup as a function of screw

speed and as a function of specific throughput. The higher

values of each resulted in higher bead breakup.

Finally, plotting the Residence Time Distribution

and the Residence Stress Distribution simultaneously

reveals more in depth insights. A residence distribution is

generally understood to be the time history through the

extruder, but it can also be understood to represent the

actual path through the machine. The average percentage

bead breakup is not evenly experienced over the time

distribution. The initial percentage is low, whereas, the

percentage breakup near the tail of the distribution is

nearly 100%. That can be interpreted as the initial flow through the mixing section experiences little breakup,

perhaps it mostly remains in the middle of the channels;

and the tail of the flow has followed a path that repeatedly

goes through the paddles resulting in a 100% breakup of

the beads.

These insights can be used to help screw

configurations for breakup and distribution of many

important additives like carbon nanotubes or

pharmaceuticals, one needing a high degree of stress and

the other needing a low degree of stress but good

distribution.

References

1. K. Kohlgruber, “Co-Rotating Twin - Screw

Extruders”, Hanser Gardner Publications, Inc., Ohio,

pp 22-275 (2008).

2. H.F. Giles, Jr., J.R.Wagner, Jr., and E.M. Mount, III,

“Extrusion: The Definitive Processing Guide and

Handbook”, William Andrew, Inc., New York, pp.

119-121 (2005).

3. Z. Tadmor and C.G. Gogos, “Principles of Polymer

Processing”, John Wiley & Sons, Inc., New Jersey, pp.

648-650 (2006).

4. J. Curry and A. Kiani, “Measurement of Stress Level

in Continuous Melt Compounders”, SPE-ANTEC

Tech. Papers, 36, 1599-1602 (1990).

5. J. Curry and A. Kiani, “Experimental Identification of

the Distribution of Fluid Stresses in Continuous Melt

Compounders – Part 2”, SPE-ANTEC Tech. Papers,

37, 114-118 (1991).

6. M. Gallant, “Continuously Graded Extruded Polymer

Composites for Energetic Applications”, PhD Thesis,

2003.

7. J. Cheng, Y. Xie, D. Bigio, “Characterization of

Kneading Block Performance in Co-Rotating Twin

Screw Extruders”, SPE-ANTEC Tech. Papers, 198-

202, (1998).

8. J. Gao, G.C. Walsh, D. Bigio, R. M. Briber, M. D.

Wetzel, “A Residence Time Distribution Model for

Twin Screw Extruders”, AIChE Journal, 45, 2542

(1999).

Return to

Paper of the Month.