Lateral Stress and Bulk Density of Pet Resin with Re-Cycle¶

Stephen J. Derezinski, Extruder Tech, Inc., Penfield, NY 14526Abstract

Solids conveying depends on the bulk density and

the lateral stress of the feed resin. Laboratory

measurements show that the addition of re-cycle PET

flakes to virgin PET pellet resin feed significantly changes

its lateral stress and bulk density. Data for different ratios

of re-cycle flake to PET pellets are presented. Also, data

for 100% PET pellet feed and 100% PET re-cycle flakes

are given for comparison.

Introduction

Extrusion of PET is widely used for packaging

and films. PET is also readily re-cycled, and the re-cycle

usually is in the form of chips or flakes. When the virgin

PET pellets are then mixed to some proportion with the recycled

PET, solids conveying performance is affected.

Solids conveying has been shown to depend on lateral

stress [1-5] and bulk density [3]. Therefore, the desire to

extrude PET pellets mixed with re-cycle motivated this

laboratory study of the lateral stress and bulk density of

mixtures.

Materials

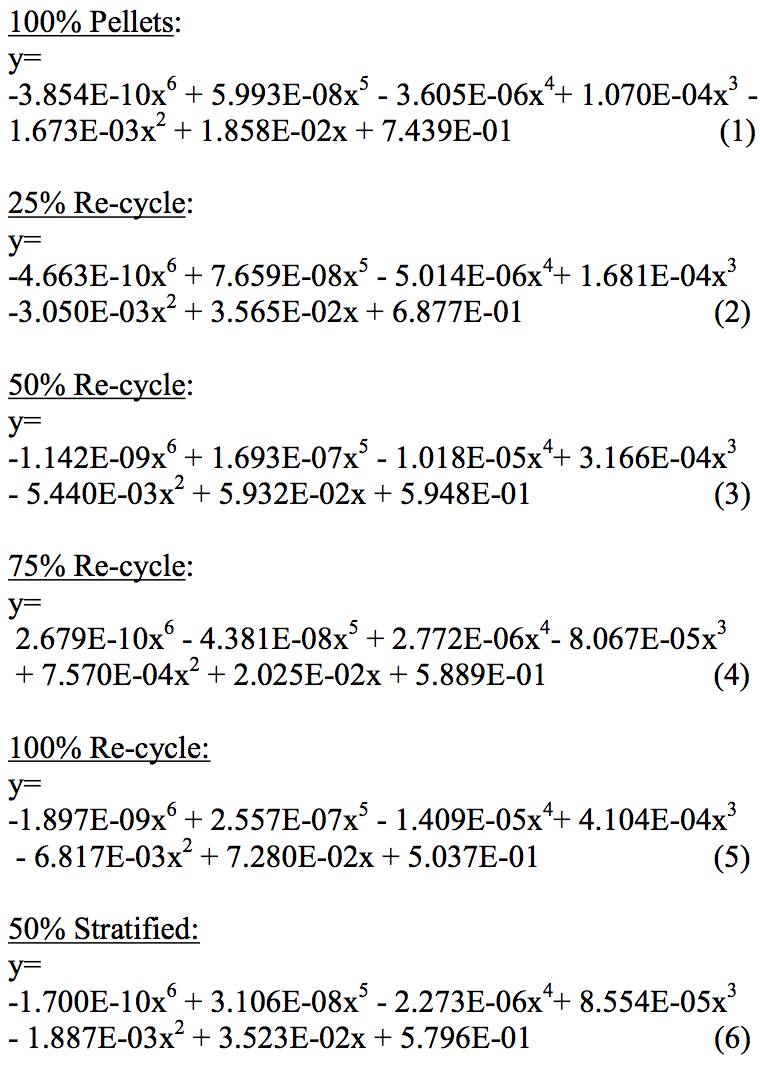

Virgin PET pellets and re-cycle PET flakes are

shown in Figure 1. The pellets have an average mass of

0.053 gram, and approximate dimensions of 3.2 x 3.2 x 4.2

mm. The pellets and re-cycle were mixed in proportions

of 25%, 50%, and 75% of re-cycle on a total mass basis.

The total mass of each mixture sample was 3 to 4 grams,

and samples were individually weighed for each test. The

mass of each component was measured to 0.01 gram. The

lateral stress and the bulk density of the mixtures were

then measured as a function of primary compressive stress.

Experimental Equipment

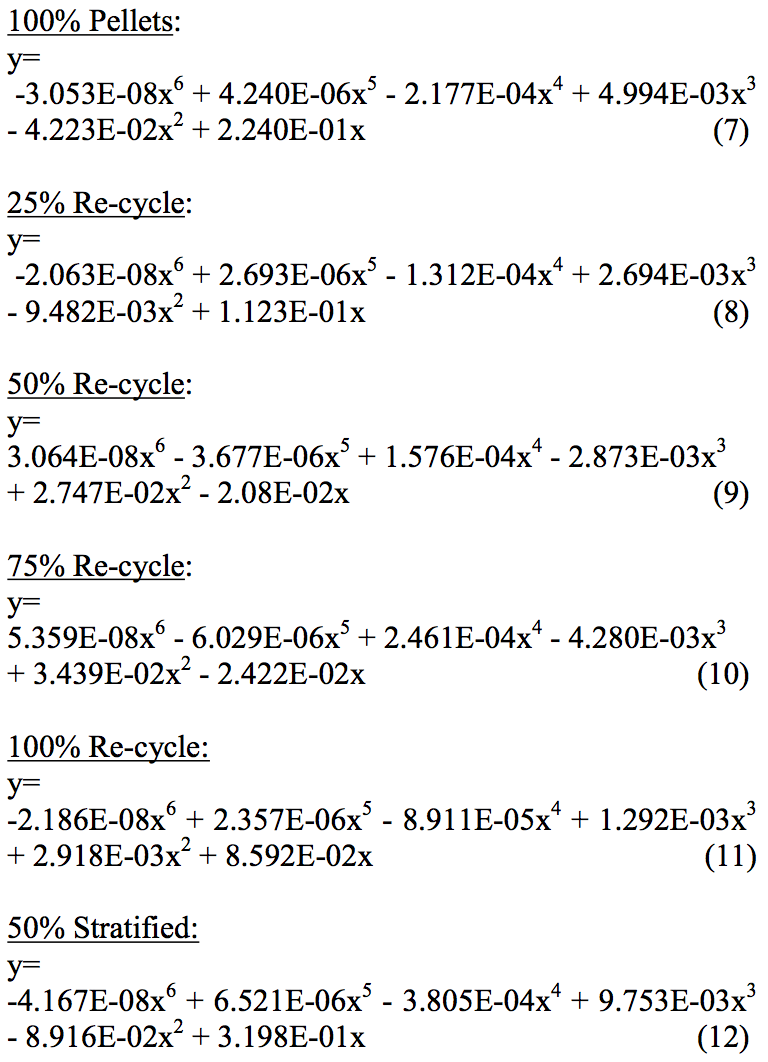

Figures 2 shows the test cell from previous work

[2] used to measure the stresses and bulk density of the

different mixtures. Load cells record the axial and lateral

forces and a linear displacement transducer records the

axial strain. The lateral strain is assumed to be zero as in

previous work [4], but some minimal lateral strain does

occur as a result of the deflection of the load cell.

However, it is insignificant in relation to the axial strain.

The data taken with the test cell include the axial

length of the specimen, the axial or primary load force, and

the resulting lateral load force. The dimensions of the test

chamber and the piston displacement measurement provide data to calculate the bulk density of the sample as it is

compressed and reduced in volume. The two load cells

and the dimensions of the test chamber give the needed

data to calculate the axial and lateral stresses developed

during compression.

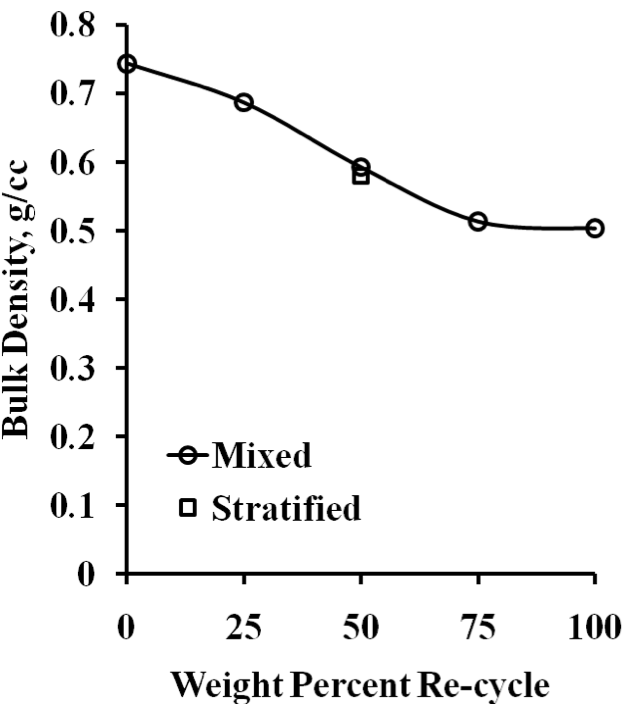

“Loose” Bulk Density Data

The “loose” bulk densities of the mixtures of

pellets and re-cycle were measured to be a function of the

fraction of PET re-cycle. “Loose bulk density” is defined

as that at minimal or zero stress, and Figure 3 shows the

typical values for the 5 different samples. Pure pellets and

pure re-cycle and proportions of 25%, 50%, and 75% of

recycle mass/total mass are given. The data were obtained

from the test cell before any strain or stress was applied.

Figure 3 shows that the loose bulk density of the pellets is

significantly greater than that of the re-cycle. Figure 3 also

shows that the loose bulk density is reduced in

approximate proportion to the mass of recycle that is

mixed.

Stratification of re-cycle and pellets is likely to

occur in the delivery system of an extruder. Therefore, a

sample datum for 50% ratio of re-cycle mass/total mass is

shown in Figure 3. The loose bulk density is shown to be

nearly the same as for the 50% mixed resin. A slightly

lower bulk density might be expected as the void space in

the pellet portion is only filled with air for the stratified

condition. However, this is shown to not be significant for

the 50% stratified mixture of pellets and re-cycle when

compared to the 50% sample that is mixed.

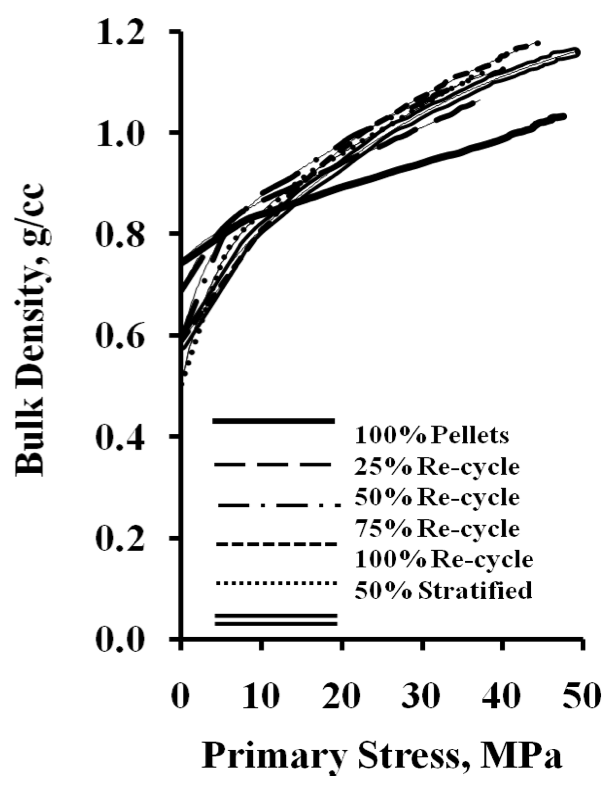

Bulk Density vs. Primary Stress Data

Data for the bulk density as a function of primary

stress are given in Figure 4. Variation in their value

depends on the primary stress as well as the mixture

proportion. The matter is complicated by the fact that bulk

density of PET pellets will be greater than mixtures at low

primary stresses and less than mixtures at high primary

stresses. The cross-over point of stress is at a primary

stress less than about 15 MPa.

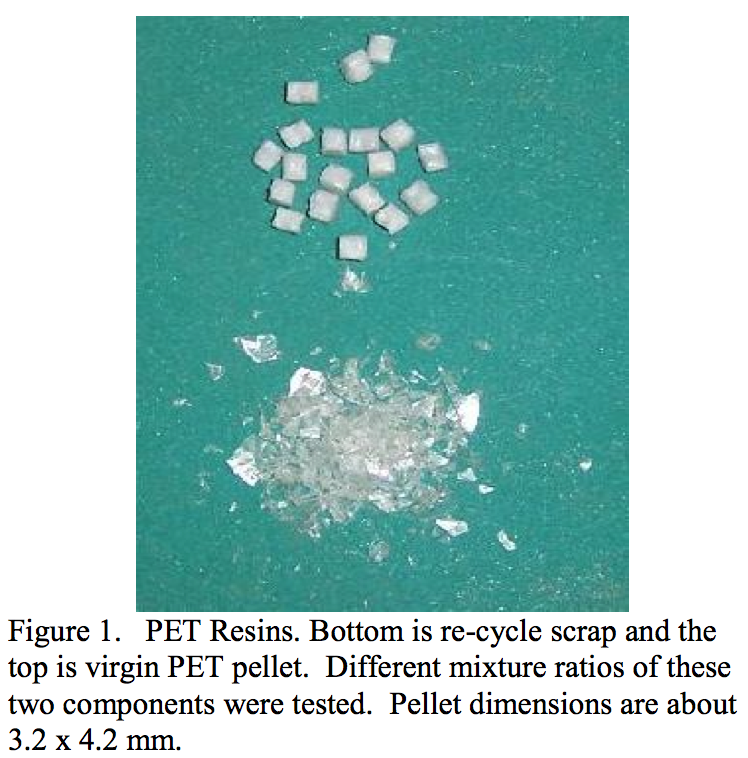

Bulk Density Regression Functions

The curves for bulk density of Figure 4 are

modeled with 6th order polynomials, and they are given

below. The correlation coefficient was greater than 0.999

for all the functions. The range of validity of primary

stress is 0 to 40 MPa. Above 40 MPa error is likely, but a

linear extrapolation for stresses moderately above 40 MPa could extend the useful range if need be. The results are

given in equation form for easy programming to provide

an accurate representation of the density data.

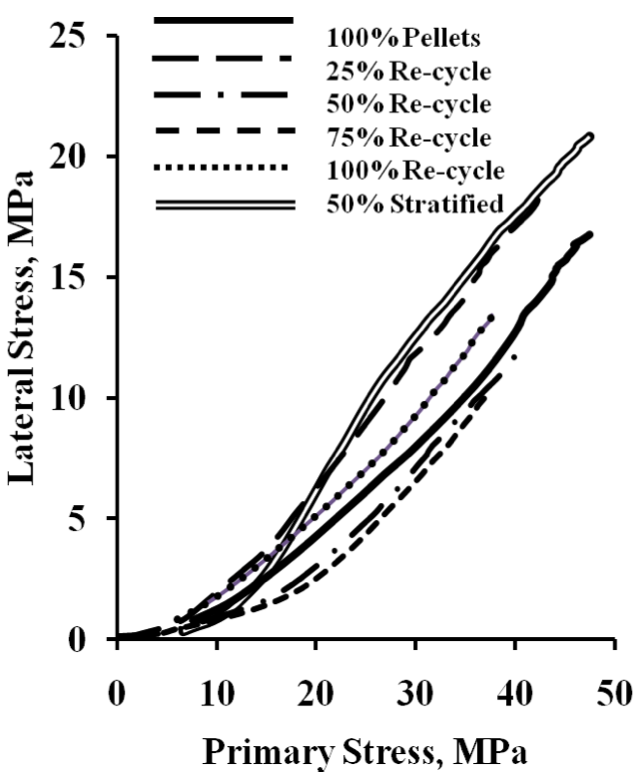

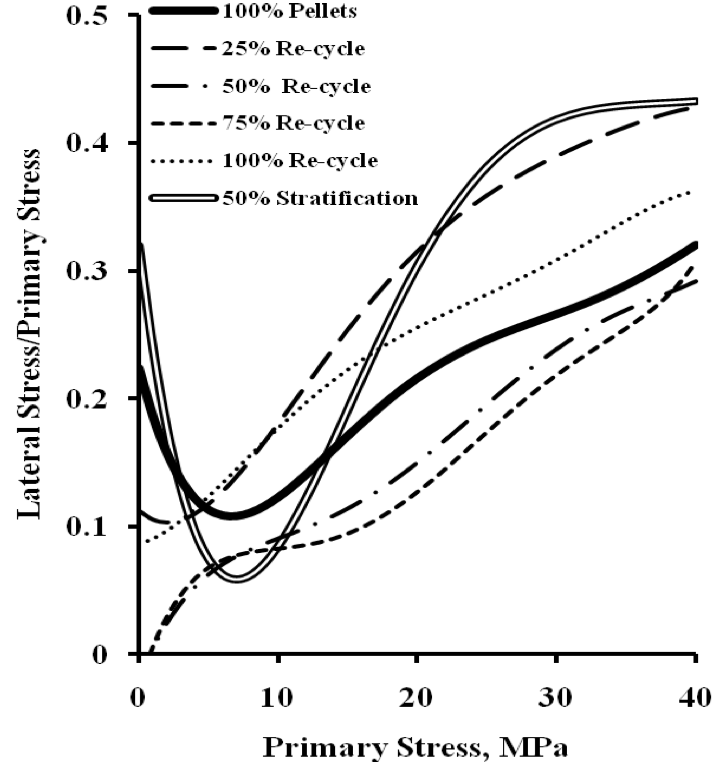

Lateral Stress vs. Primary Stress Data

Figure 5 shows the lateral stress for PET pellets

and re-cycle resin. Data for PET pellets alone (100%

pellets) is one basis for comparison with the mixtures of

pellets and re-cycle. Another basis is the data for 100%

PET re-cycle, and this is shown in Figure 5, also. These

two base line functions appear fairly similar. However, the

lateral stress for the 100% re-cycle is greater than that of

the pellets over the entire range of primary stresses.

The 25% and 50% mixture of re-cycle/total show

that lateral stress ratio is less than that for 100% pellets

over the entire range of primary stress, whereas 100% recycle

has a higher lateral stress than 100% pellets.

Therefore, the solids conveying rate with the addition of

re-cycle will be affected.

Bulk densities of the mixtures are also lower at

low stress, but are greater at higher stress. Therefore, the

combined effect of bulk density and lateral stress on solids

conveying is subject to the range of stress of the operation.

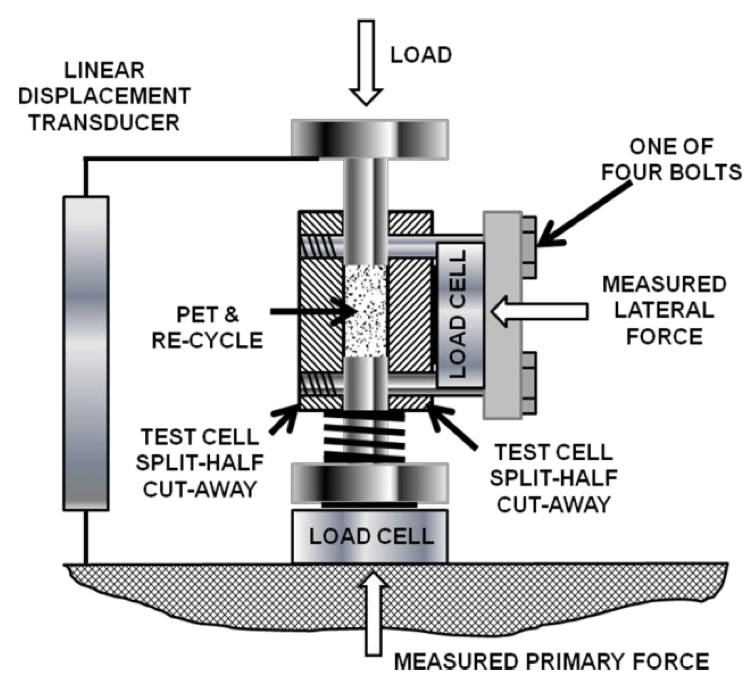

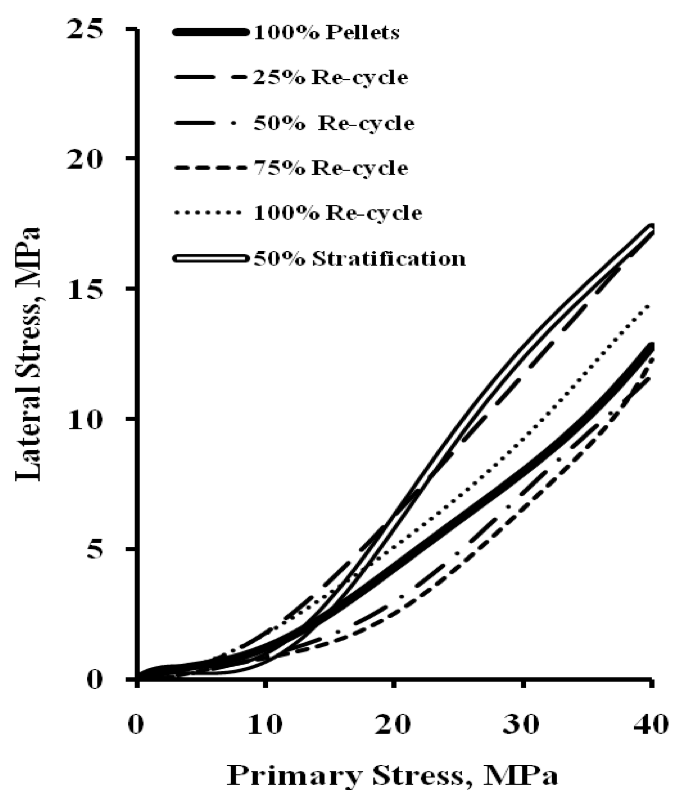

Lateral Stress Regression Functions

The following are the regression curves for the

data of lateral stress versus primary stress shown in Figure

5, and they are shown in Figure 6. A (0,0) intercept is

assumed (zero primary stress = zero lateral stress). The

trend line consistently used is a 6

th order polynomial. The

regression functions between 0 and 40 MPa do accurately

portray the data as can be seen comparing the data of

Figures 5 with the regression representations of Figure 6.

Therefore, the following equations are provided for

convenient accurate use of lateral stress data.

As with the bulk density regression functions,

above primary stress values of 40 MPa, error is likely.

Again, a linear extrapolation for primary stresses

moderately above 40 MPa could be used to extend the

useful range if need be.

Lateral Stress Ratio Functions

Lateral stress ratio [3,4] (the ratio of lateral stress

to primary stress) as a function of primary stress [2] is

easily obtained from the lateral stress polynomial

functions, Equations 7-12. The assumption that the data

have an intercept of 0,0 (zero lateral stress at zero primary stress) eliminates a constant term in Equations 7-12.

Therefore, Equations 7-12 can be divided by the primary

stress (x) and yield a finite result at x=0. This provides a

mathematical limit for the lateral stress ratio as primary

stress approaches zero. Previous work [2] for other

polymers has shown that those with lateral stress ratios of

0.3 or greater at low primary stress correlate with good

extrusion performance, and polymers with low lateral

stress ratios at low primary stress perform poorly.

Therefore, the limit of lateral stress ratio at zero stress is a

useful indicator of solids conveying performance.

Figure 7 shows the lateral stress ratio functions so

determined from Equations 7-12 with the mathematical

limit at zero primary stress (y intercept). The limits of

lateral stress ratio values at zero primary stress are unique

for the different ratios of pellets and re-cycle. It is highest

for the 100% Pellets (~0.22) and stratified 50% re-cycle

(~0.32). The mixtures of 25% re-cycle and 100% re-cycle

have a limit of lateral stress ratio of about 0.1. Pellets with

50% and 75% re-cycle show a limit near to zero.

The results of Figure 7 clearly indicate that

mixing virgin pellets and re-cycle produces non-linear

results. Also, the result is dependent on the level of

compressive stress. For example, resin with 25 % re-cycle

has lateral stress ratio less than that for 100% pellets at

primary stresses up to about 5 MPa. At 5 to 10 MPa stress

the lateral stress ratio for the mixture is about the same as

that for the 100% pellet resin. Above primary stress of 10

MPa, the lateral stress ratio of the 25% mixture is greater

than the pure pellets. The non-linearity and the reversing

of the effect can make processing difficult to manage and

that day to day operation would not be consistent since

mixture ratios likely could vary depending on the supply of

re-cycle or lack of mixing.

Figure 7 shows that the lateral stress ratio for 50%

and 75% re-cycle to always be lower than all other

samples, including pure pellets. Also, at zero primary

stress each of these two samples had zero lateral stress

ratio, whereas all of the other samples had finite values of

lateral stress at low primary stress.

Figure 7 also shows that the lateral stress ratio for

50% stratified pellets and re-cycle to have the greatest

variability of all the samples. Stratification of the recycle/pellet

mixture is inevitable, random, and difficult to

detect in the extruder. Stratification will, thereby, make

the lateral stress ratio inconsistent, and solids conveying

less predictable. Therefore, stratification should be

considered when flow instability occurs in the extrusion

process of mixtures of PET pellets and re-cycle.

Summary

Extrusion of PET pellet mixed with re-cycle

flakes in a single screw extruder is typically more difficult

than extruding PET pellets. Lateral stress and density for

mixtures of PET pellets and re-cycle flakes have been

shown here to depend on mixture fraction of re-cycle and

primary stress, and they are major factors in solids

conveying in single screw extruders. The dependence has

been shown to be non-linear and can depend on the level

of primary stress. Stratification is also likely to occur in

mixtures of re-cycle flakes and pellets, and this has been

shown to be a factor in lateral stress. The data here

provide quantitative evidence as to the sources of the

difficulty of extruding mixtures of PET pellets and PET recycle.

Hopefully, this will improve understanding of this

complex phenomenon and assist in the design of better

single screws for processing PET pellets with PET recycle.

Conclusions

1. For mixtures of PET pellets and PET re-cycle

flakes, the effect on lateral stress, as indicated by

the lateral stress ratio, is non-linear and dependent

on the level of primary stress. This greatly

complicates the solids conveying in single screw

extruders and makes consistent processing difficult.

2. The lateral stress of mixtures of PET pellets and

PET re-cycle flakes was measured to be a function

of the mixture ratio and primary stress.

3. Lateral stress for pure re-cycle flakes was measured

to be greater than for pure pellets. However, lateral

stress for mixtures with 50% and 75% re-cycle was

less than that for 100% pellets.

4. Lateral stress for a 50% stratified combination of

pellets and re-cycle flakes resulted in the greatest

values of lateral stress and the greatest variability of

lateral stress ratio.

5. Loose bulk density was measured to be greatest for

the pellets at about 0.75 g/cc. The addition of recycle

diminished the loose bulk density in

proportion to the amount of re-cycle. Pure re-cycle

has a loose bulk density of about 0.5 g/cc.

6. The bulk density of mixtures of PET pellets and

PET re-cycle flakes was measured in compression

as a function of mixture ratio and primary

compressive stress. The bulk density varied

between about 0.5 g/cc and 1.2 g/cc.

Acknowledgements

Very special thanks to son, Stephen J. Derezinski,

III of Platform Technology Ventures, Inc., for designing,

obtaining, building, and programming the computerized AD

data acquisition system for this work.

References

1. S. J. Derezinski 2009. “Laboratory Measurements

of Resin Bulk Specific gravity of PET and

LDPE,” ANTEC 2009 - Proceedings of the 67th

Annual Conference & Exhibition, Chicago, IL,

June 22-24, 2009, Society of Plastic Engineers,

pp. 136-141.

2. S. J. Derezinski 2010. “Measurements of Biaxial

Stresses During the Compression of Bulk Resin

Feed,” ANTEC 2010 - Proceedings of the 68th

Annual Conference & Exhibition, Orlando, Fl,

May 16-20, 2010, Society of Plastic Engineers,

pp. 617-622.

3. Chung, Chan I., Extrusion of Polymers Theory

and Practice, Hanser Publications, Munich, 2000,

pp. 161-162, 199-200.

4. M. A. Spalding, K. S. Hyun, and K. R. Hughes,

1996. “Stress Distribution in Solid Polymer

Compacts,” ANTEC 1996 - Proceedings of the

54th Annual Conference & Exhibition,

Indianapolis, IN, May 5-10, 1996, Society of

Plastic Engineers, pp. 191-198.

5. K. S. Hyun. and M. A. Spalding, 1997, “A New

Model for Solids Conveying in Plasticating

Extruders”, ANTEC 1997 - Proceedings of the

55th Annual Conference & Exhibition, 43, 1997.

Key Words

Stress, bulk density, solids conveying, single screw,

extrusion, pellets, PET re-cycle, PET, PET scrap, re-cycle

Figure 1. PET Resins. Bottom is re-cycle scrap and the top is virgin PET pellet. Different mixture ratios of these two components were tested. Pellet dimensions are about 3.2 x 4.2 mm.

Figure 2. The Test Cell for Measuring the Primary and Lateral Forces During Compression of Bulk Resin Feed as a function of bulk density [1,2]. Diameter of the cylinder is 12.7 mm. The linear displacement transducer records the height of the sample to establish the evolving bulk density value and lateral area of force.

Figure 3. Bulk Density of PET Feed versus percent of Re-cycle Flakes. Values are those measured with the test cell before load is applied.

Figure 4. Data for Bulk Density of the Pellet/Re-cycle Mixtures vs. Primary Stress

Figure 5. Raw Data for Lateral Stress for PET Pellets with Re-cycle vs. Primary Stress

Figure 6. Regression Functions for Lateral Stress versus Primary Stress A 6th order polynomial is used for each set of data of Figure 5. Regression coefficients are greater than 0.999.

Figure 7. Lateral Stress Ratio Functions for PET/Re-cycle Mixtures

Return to

Paper of the Month.