The Influence of Design and Processing Parameters on the Mixing Performance of a Fluted Mixer¶

Pavel Kubik, Tomas Bata University in Zlín, Department of Polymer Engineering, Zlín, Czech

Republic

Martin Zatloukal, Tomas Bata University in Zlín, Centre of Polymer Systems, Polymer Centre, Zlín,

Czech Republic

Yutaro Asai, I.T.S. Japan Corporation, Misaki, Funabashi-shi, Chiba, Japan

Ryuichi Haruna and Yoshihiko Iwasaki, Pla Giken Co. LTD,Toyotsu-cho, Suita-city, Osaka, Japan

Jiri Vlcek, Compuplast International Inc., Zlín, Czech Republic

Ilja Paseka, Compuplast Software spol. s r. o., Zlín, Czech RepublicAbstract

In this paper, the mixing efficiency of two slightly

different fluted mixing elements is studied. RGB spectral

analysis is used for the quantification of the mixing. The

overall mixing appears to be equal after sufficient mixing

time. The mixer without the wiping flight, however,

creates a stagnation layer of material which rotates

between the mixer and the barrel. This layer is

characterized by a long residence time. The residence time

of the layer is twice as long as for a mixer with the wiping

flight. The long residence time is again measured by RGB

spectral analysis and also visualized in the video. The

results of a 3D FEM simulation shows that the mass flow

rate of the stagnation layer represents almost 50% of the

total mass flow rate.

Introduction

Mixing is a very important process in single-screw

extrusion. Achieving good mixing performance, under

specified processing conditions, is a key requirement to

obtain a uniform and homogenous mixture. So, it is not

surprising that considerable effort is spent on analyzing

different types of “mixing elements”, “mixing heads” or

“mixing sections” in single-screw [1-6] and also twinscrew

[7-13] extrusion. In principle, there are two basic

mixing mechanisms. Dispersive mixing is based mainly

on reducing the size of mixture components by shear or

elongational stress. The second one is distributive mixing

that redistributes particles throughout the volume [14].

A fluted mixing element, also known as the Maddock

mixer [15], is one of the most often examined dispersive

mixing sections in extrusion. Almost forty years ago,

Tadmor and Klein [16], studied certain designs of fluted

mixing sections and proposed a model for calculation of

pressure development through the fluted mixing section.

Tadmor et al. [17] later improved the model by using the

Flow Analysis Network method. Esseghir et al. [18]

carried out a detailed comparative study of three different

single-screw mixing elements including the Maddock

mixer section.

Han and Lee [19] experimentally and also

numerically investigated the flow in the Maddock mixer.

Their work focused mainly on pressure drop and pressure

rise through the mixer. Their results clearly concluded that

pressure was generated, under specific processing

conditions, and therefore drag flow was predominated

over pressure-driven flow. In their work, only 2D analysis

was used to compute simulation results and the mixing

performance of the Maddock mixer section was not

evaluated.

In this work, the evaluation of the mixing

performance using the Red-Green-Blue (RGB) spectral

analysis is presented. The study is focused on color

dispersion of the material extruded by two general

purpose screws having slightly different fluted mixing

sections. The “Closed” design has alternating “shearing”

and “wiping” dams (or flights) while the “Open” design is

completely undercut so that there are no “wiping” dams. It

can be seen that the “Open” design is easier to

manufacture and many people assume that this geometry

change has little, or negligible, impact on its overall

mixing performance. To investigate this assumption,

experiments, comparing these two fluted mixer designs,

have been performed. A three dimensional Finite Element

Method (3D FEM) simulation is also used to help analyze

and better understand the fluted mixing element flow

field.

Methods

Two general purpose screw designs were prepared for

this experiment. The basic screw dimensions are

summarized in Table 1.

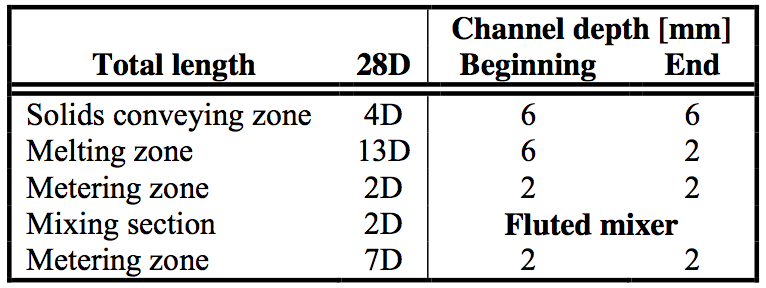

Table 1. Basic screw dimensions

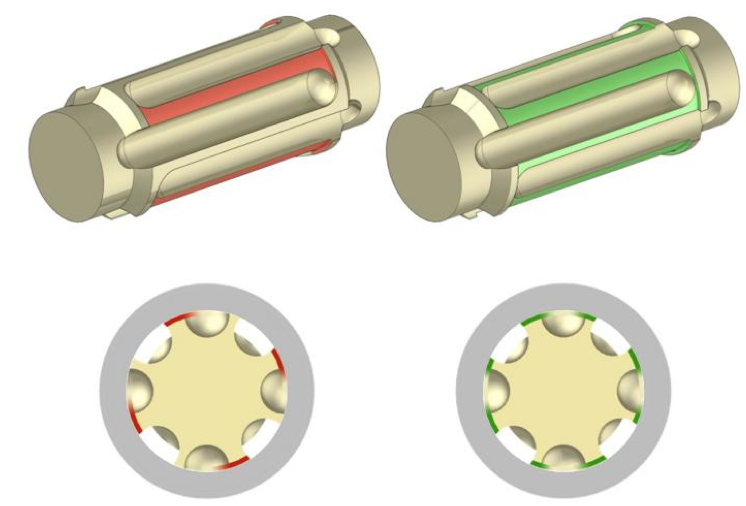

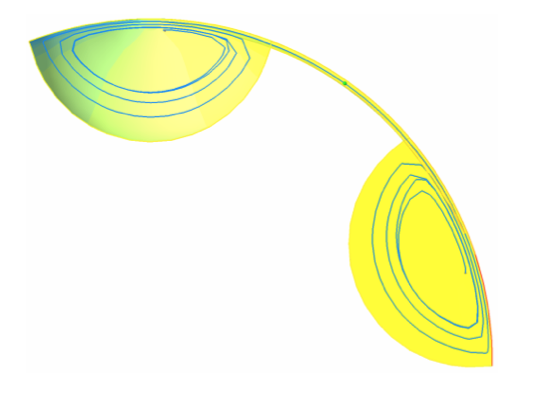

The only variation between these two screw designs

is the mixing section where two slightly different fluted

mixing elements were used, as shown in Figure 2. Both

mixers had three pairs of channels. The shearing gap

width was 9.5 mm, its depth was 0.4 mm and a radius of

each channel was 7.2 mm. The length of the shearing gap

was 80 mm.

The “Closed” mixer has separated pairs of inlet and

outlet channels with a shearing gap in between. The

wiping flight prevents material flow and cleans the barrel

surface.

The “Open” mixer has undercuts from both sides of

each channel. Thus, the material is not wiped from the

barrel surface. The melt can also enter the channel from

the side and not only from the inlet. Therefore, part of the

melt can continuously flow in the gap between the mixer

and the barrel.

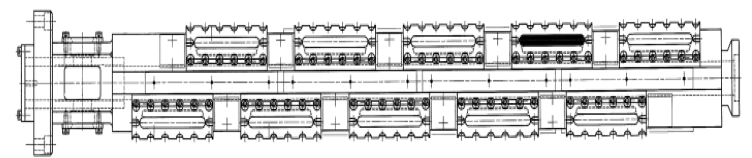

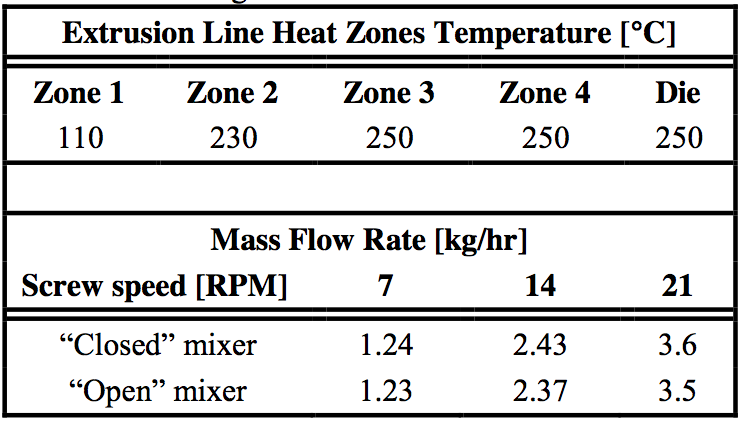

Experiments were done on a special extrusion line

with a barrel having several glass windows which are

alternately placed on both sides of the barrel as shown in

Figure 1. This allowed observation of the polymer melt

along the extrusion line from the solids conveying zone to

the metering zone. Dimensions of each window were

90x10 mm and the internal diameter of the barrel was 40

mm.

Figure 1. Barrel sketch

The mixer was positioned to be visible through the

glass window (black window in Figure 1). The open and

closed mixer configurations are shown in Figure 2.

Figure 2. “Closed” (right side) and “Open” (left side) mixer configurations

The output of the extrusion line was connected with a

small flat die followed by a system of chill rolls to obtain

a uniform film. All experiments were continuously

recorded by a video camera which was set on a tripod.

Experimental processing conditions are given in Table 2.

Table 2. Processing conditions

Material

The main material used for the study was Hi-Zex

6300M HDPE. Rheological properties were measured on

a laboratory grade twin-bore capillary rheometer (Imatek

R6000 [20]) with Φ 1x16mm long die and Φ 1×0.25mm

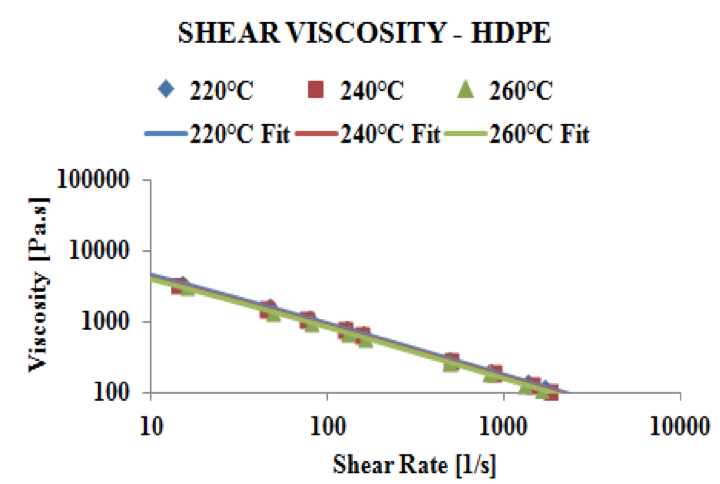

short die. Viscosity curves are shown in Figure 3.

Figure 3. Viscosity curves of HDPE

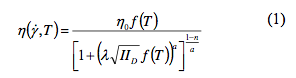

The rheological data were fitted by the well known

Carreau-Yasuda model, in which the viscosity dependence

is decribed by the following equation:

Where η

0 is the zero shear viscosity, a, n, λ are

constants, T is temperature and II

D stands for the second

invariant of the deformation rate tensor. The material

temperature dependence f(T) is exponential and is given

by an equation:

The parameter b represents the temperature sensitivity

and T

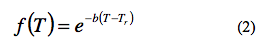

r is the reference temperature. The Model variables

are presented in Table 3.

Table 3. Carreau-Yasuda Model parameters

A LLDPE based, green masterbatch was used for

visualization and mixing performance analysis.

Experimental

The experiment was focused primarily on the mixing

performance of the fluted mixing elements. To avoid

blending errors, clear HDPE was pushed through the extrusion line until the hopper was almost empty. Next, a

certain amount of the colorant (about 60g) was added to

the hopper to a 2 cm layer. This layer of colorant was

followed by a new layer of clear HDPE of the same

volume. By this method, five distinct layers in order

colorant – HDPE – colorant – HDPE – colorant were

prepared. Each new layer was always added after the

previous layer had completely left the hopper. A screw

speed at 21 RPM was used to run this experimental

procedure.

The moment when the first colored particles appeared

at the end of the extrusion line was the starting point of

the measurement. Then, samples of the flat film were cut

to see interactions between the clear and colored regions

of the polymer. Thus, this experimental part provides

some indication about the speed of the mixing process.

All experimental parameters were identical for both

mixing sections. These samples were later analyzed in a

professional Canon scanner. The scanner light was strong

enough to reveal the mixing patterns of the samples. Hiresolution

tiff format pictures were prepared for further

analysis. All samples were 3x8 cm. Color pictures of

scanned samples were studied in special program routine

where the statistics of simple pixels were evaluated. Some

examples of the scanned flat film samples for the “Open”

and “Closed” mixer are presented in Figure 4 and 5,

respectively.

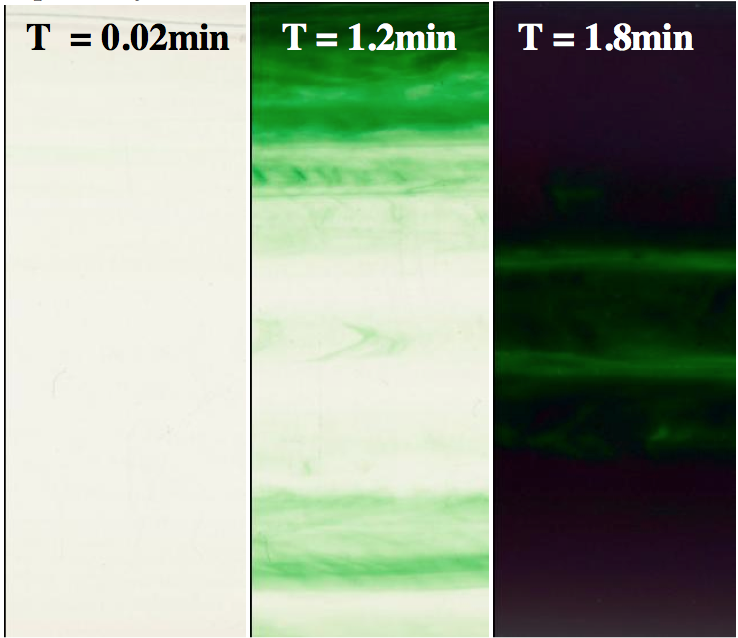

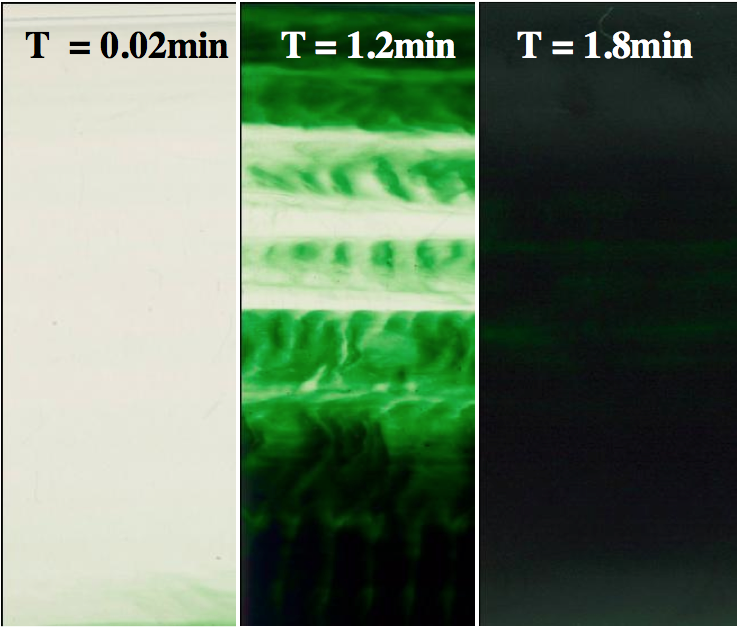

Figure 4. Film samples in different extrusion times by using the “Open” mixer

Figure 5. Film samples in different extrusion times by using the “Closed” mixer

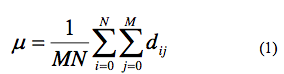

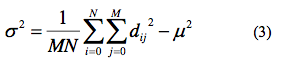

Then, an average value of RGB spectra and its

deviation was obtained for each pixel. The average value

of RGB spectra μ is described by the following equation:

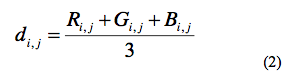

Where M, N represents the number of pixels of the

sample and d

ij stands for the RGB value of the relevant

pixel. d

ij was taken in each pixel as an average of three

RGB values:

RGB color components of a pixel range values from 0

({0,0,0} black) to 255 ({255,255,255} white). Thus, the

material without any additives, pure polymer melt, has a

high mean value of RGB. On the other hand, the dark

material with added colorant had to have a low mean

value of RGB. The degree of brightness, in between the

low and high mean value, represents the degree of mixing.

The value of the unmixed regions is the deviation of

average RGB color. The deviation of the average RGB

spectra was calculated by the equation:

Where M, N represents the number of pixels of the

sample and d

ij stands for the RGB value of the relevant

pixel and μ is the mean value of RGB color. The average RGB value reduces as the colorant is added into the

process until the mean value of RGB reaches a steady

state. The transition from the pure polymer to its colored

form is detected by an increase of the deviation of RGB.

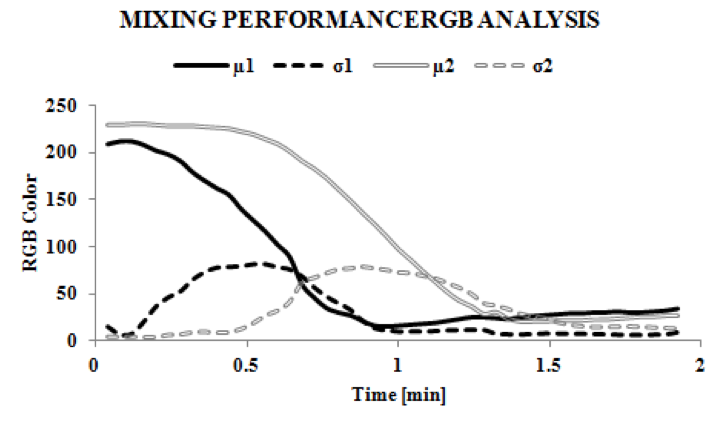

The results of RGB spectral analysis equations of the

mixing performance can be seen in Figure 6.

Figure 6. RGB analysis of the mixing performance 1 = Closed mixer, 2 = Open mixer

As shown in the figure, both curves of the average

RBG spectra started above 200, which meant that they

both were close to the white color with a minimum

amount of the green colorant. The decreasing trend of

both curves had a similar slope, but the “Closed” mixer

(μ1) reduced sooner than the “Open” mixer (μ2). The

difference between the “Open” and “Closed” mixer was

about 0.4 minutes. Furthermore, the final, steady state

RGB value for each mixer is very close. This means that

both mixers can provide similar mixing levels, given

sufficient time.

The absence of the wiping flight allowed the formation

of a layer of the slowly moving material which was

rotating close to the barrel surface. The second

experimental method was then focused on the behavior of

this layer. Probably the most significant variable to

characterize the behavior of this layer was the residence

time. Thus, one layer of colorant followed by the pure

polymer was again added into the almost empty hopper.

A low screw speed of 7RPM was intentionally used to

clearly see the layer behavior. Samples of the flat film

were again cut, in ten minute intervals, to calculate the

mean value of RGB of the polymer. The transition from

pure polymer to maximum color and back to the pure

polymer also gave a residence time of the flow field.

Samples were again evaluated with the RGB spectral

analysis.

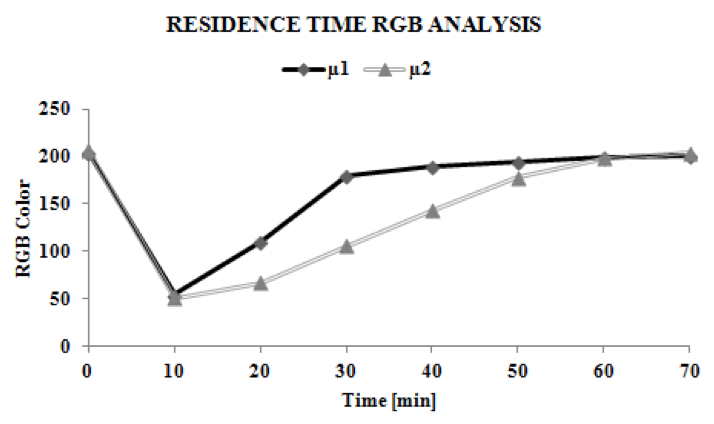

The RGB curves of the residence time of the “Closed”

(μ1) and “Open” mixer (μ2) are displayed in Figure 7.

Figure 7. Residence time RGB analysis

1 = Closed mixer, 2 = Open mixer

As can be seen, in Figure 7, the RGB curve started

from pure HDPE at time zero and after ten minutes, the

minimum RGB value green color was obtained. The first

ten minutes was sufficient time for both mixers to achieve

the same level of mixing. Then, the amount of green

colorant gradually reduced with each new sample taken

from the system. These results show that the “Closed”

mixer resulted in faster purging than the “Open” mixer

and returned close to its initial RGB value after forty

minutes versus seventy minutes with the “Open” mixer.

The longer purging time, of the “Open” mixer, was due to

the presence of the slowly rotating layer rotating in the

gap region. This layer was difficult to purge out because

of the absence of the wiping flight. The layer was still

clearly visible after ninety minutes but its effect on the

product color was negligible by this time. The experiment

was recorded to help visualize the rotation of the material

in this layer. The long residence time of the layer could

certainly influence the final quality of the due to polymer

melt degradation. Furthermore, this layer would also

affect the heat transfer from the melt to the barrel surface.

Screen captures from the video, comparing the color

change in between the “Open” and “Closed” mixers are

shown in Appendix 1.

Simulation Results

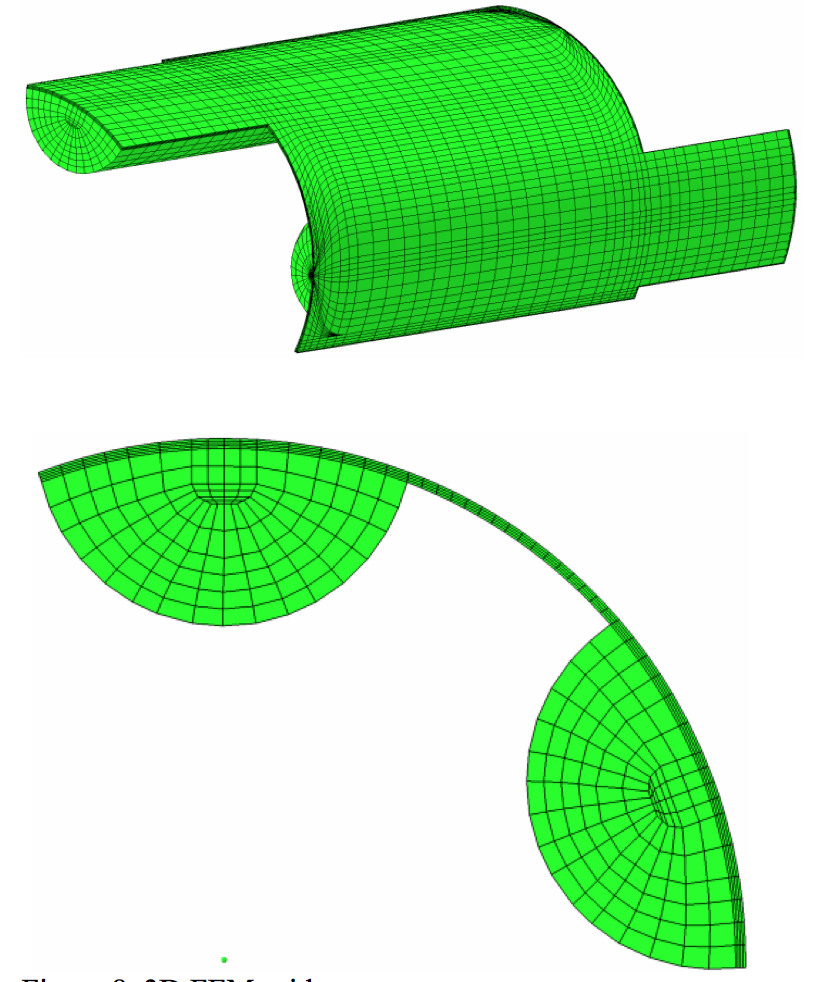

The slow, moving layer in the “Open” fluted mixer

configuration was further investigated by 3D FEM

simulation. A 3D FEM grid, of the mixer geometry, was

generated with the fluted mixer template in the Virtual

Extrusion Laboratory (VEL

TM) software [21]. To help

ensure high accuracy, quadratic, 27 node, brick elements

were used. The grid was constructed from 16,512

elements for the “Closed” mixer flow domain and 17,792

elements for the “Open” mixer. The periodic nature of the

geometry allowed for the analysis of only 1 pair of

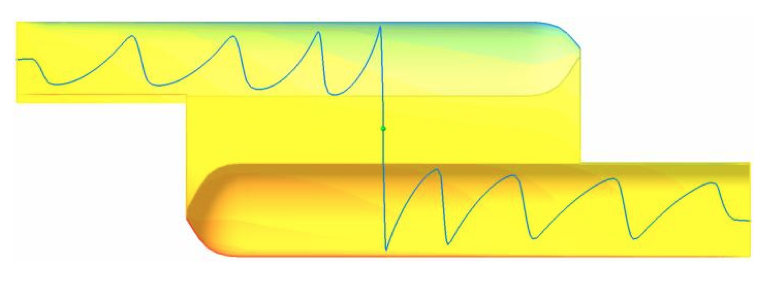

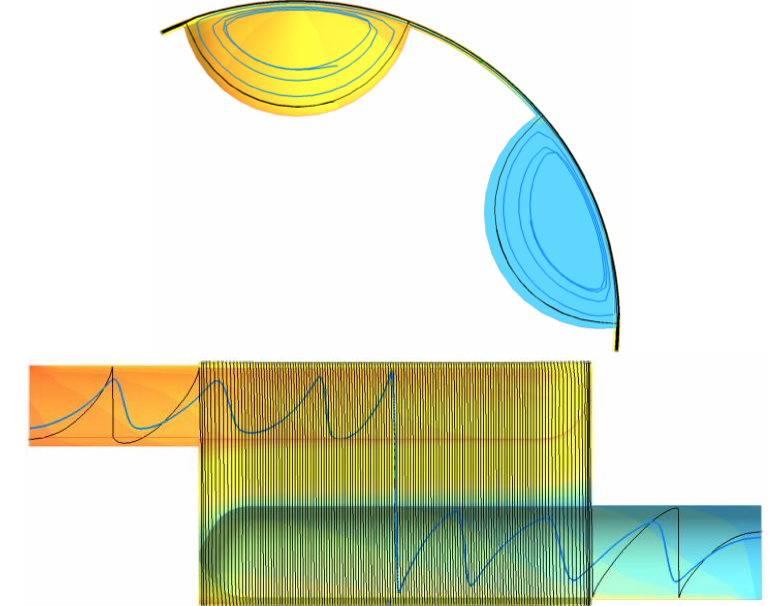

channels. The 3D FEM grid is displayed in Figure 8.

Figure 8. 3D FEM grid

The flow behavior was analyzed with over 60

particle pathlines. Some typical pathlines, which are

representative of the flow behavior in the “Open” and

“Closed” mixer, are depicted in Figures 9 and 10.

The “seed” location of the pathline was placed in

center of the shearing gap, in the middle of the mixer. The

same “seed” point was used for both the “Open” and

“Closed” mixer. However, the “Open” mixer had a second

pathline from a “seed” at the center of the second

undercut, as well.

Figure 9. Typical Pathline in the “Closed” mixer

Figure 10. Typical pathlines in the “Open” mixer

It can be seen, from figure 9, that the “Closed” mixer

resulted in the pathline making only one pass through the

shearing gap while Figure 10 show a pathline making

many rotations in the gap region. This represents a high

residence time layer near the barrel surface. This layer is

created because of the absence of the wiping flight.

Surprisingly, the layer fully filled the whole second

undercut channel. Then, the layer was squeezed above the

deep channel of the mixer and remained near the barrel

through the shearing gap and the other deep channel

before it reached the opposite undercut.

The squeezing of the layer is due to the rotation of

the material flowing from the inlet channel. Interestingly,

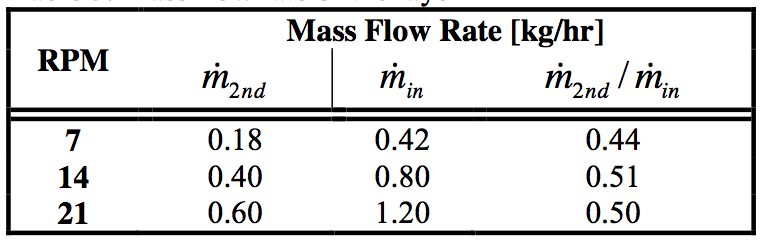

the mass flow rate of this layer was found to be constant

throughout the gap region essentially forming two almost

separate, independent flows inside of the “Open” mixer.

The mass flow rate over the second undercut was found to

be about 50% of the overall mass flow rate coming from

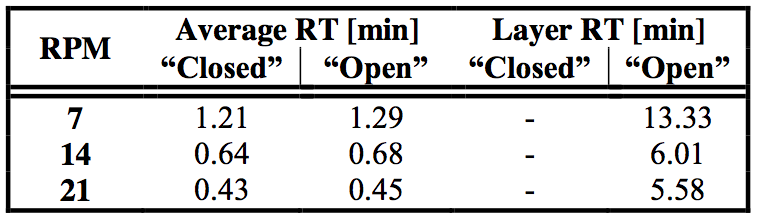

the inlet channel. The results are given in Table 5.

Table 5. Mass flow rate of the layer

The residence time of this layer, estimated by the 3D

FEM simulation, was also much longer than the overall

residence time of all other pathlines. The average

residence time calculated from more than sixty pathlines

in the “Closed” and “Open” mixers was similar. The

residence time of some typical pathline in the layer was

found to be at least ten times longer than the average

residence time of the mixers. Average and layer residence

times, at three screw speeds are shown in Table 6.

Table 6. Calculated residence times

Tables 5 and 6 indicate that about 50% of the material

flowing in the “Open” mixer has a much larger residence

time. This effectively results in the “Open” mixer having

a longer average residence time but also a much broader

residence time distribution; both of which, may result in

degradation problems for some polymers.

Conclusions

RGB spectral analysis was used to quantify the speed

of the mixing process for the “Open” and “Closed” fluted

mixers. The “Closed” mixer showed a transition from the

pure polymer melt to fully mixed that was 0.4 minute

faster than the “Open” mixer. However, the overall, final

mixing performance of both fluted mixer designs appears

to be seemingly equal.

The “Open” mixer configuration of the fluted mixing

element also creates a layer of the material which rotates

above the shearing gap and second undercut. This layer is

formed because of the absence of the wiping flight. An

almost independent, slow moving flow field appears to

form in this region. The mass flow rate of this layer is

equal to the mass flow rate over the second undercut

which is about 50% of the mass flow rate entering the

mixer. The layer is characterized by the long residence

time and increases the residence time distribution of the

mixer. RGB spectral analysis was used to calculate the

time needed for the purging of the colorant out of the

extruder. Purging time of the extruder equipped with the

“Open” mixer is twice as long as that for the “Closed”

fluted mixer. Recorded video of the experiment, on a glass

window extruder showed the development of the slow

moving layer in the “Open” mixer. The longer residence

time of the layer with the “Open” mixer is also calculated

by 3D FEM simulation. The long residence time of this

layer can explain some extrusion problems such as

polymer melt degradation. Thus, even if the “Open” fluted mixer is easier to manufacture, it is not recommended for

processing thermally sensitive polymers.

Acknowledgement

The authors would like to thank the Plagiken co., Ltd

for financing the experiments and Compuplast

International, Inc. for supplying of the VELTM software.

The authors also wish to acknowledge Operational

Program Research and Development for Innovations cofunded

by the European Regional Development Fund

(ERDF) and national budget of Czech Republic, within

the framework of project Centre of Polymer Systems (reg.

number: CZ.1.05/2.1.00/03.0111) for the financial

support.

References

1. A. L. Kelly, E. C. Brown and P. D. Coates, Polymer

Engineering and Science 46, 1706-1714 (2006).

2. D. Strutt, C. Tzoganakis and T. A. Duever, Polymer

Engineering and Science 40, 992-1003 (2000).

3. B. Elbirli, J. T. Lindt, S. R. Gottgetreu, and S. M. Baba,

SPE-ANTEC Tech. Papers 29, 104 (1983).

4. A. Kiani, R. Rakos, and D. H. Sebastian, SPE-ANTEC

Tech. Papers 35, 62 (1989).

5. G. M. Gale, SPE-ANTEC Tech. Papers 29, 109 (1983).

6. D. Herridge and D. Krueger, SPE-ANTEC Tech. Papers

48, 633 (1991).

7. G. Shearer and C. Tzoganakis, Advances in Polymer

Technology 20, 169–190 (2001).

8. D. Strutt, C. Tzoganakis and T. A. Duever, Advances in

Polymer Technology 19, 22–33 (2000).

9. M. A. Huneault, M. F. Champagne and A. Luciani,

Polymer Engineering and Science 36, 1694-1706 (1996).

10. V. L. Bravo and A. N. Hrymak, Polymer Engineering

and Science, 40, 525-541 (2000).

11. V. L. Bravo, A. N. Hrymak and J. D. Wright, Polymer

Engineering and Science 44, 779-793 (2004).

12. R. Valette, T. Coupez, C. David and B. Vergnes,

International Polymer Processing 24, 141-147 (2009).

13. T. Ishikawa, et al., International Polymer Processing

21, 354-360 (2006).

14. C. Rauwendall, Polymer Extrusion, Munich: Carl

Hanser Verlag, 1990.

15. B. H. Maddock, SPE Journal, 23, 23 (1967)

16. Z. Tadmor and I. Klein, Polymer Engineering and

Science 13, 382-389 (1973).

17. Z . Tadmor, E. Broyer, and C. Guttfinger, Polymer

Engineering and Science 14, 660-665 (1974).

18. M. E. Ghir, C. G. Gogos, D. W. YU, D. B. Todd and

B. David, Advances in Polymer Technology 17, 1-17

(1998).

19. C. D. Han, K. Y. Lee, and N.Wheeler, Polymer

Engineering and Science 31, 818-830 (1991).

20. http://www.imatek.co.uk/product-r6000.php

21. http://www.compuplastvel.com

APPENDIX 1

RESIDENCE TIME VIDEO SAMPLES |

RESIDENCE TIME VIDEO SAMPLES

“Open” mixer(left) | “Closed” mixer(right)

Return to

Paper of the Month.