The Effect of Coathanger Die Manifold Symmetry on Layer Uniformity in Multilayer Coextrusion

Joseph Dooley, Hyunwoo Kim, Patrick C. Lee, and Robert Wrisley

The Dow Chemical Company, Midland, MIAbstract

Multilayer coextrusion is a process in which two or

more polymers are extruded and joined together in a

feedblock or die to form a single structure with multiple

layers. This paper will discuss the effect of die manifold

channel symmetry of the flow of coextruded structures

through coathanger style dies.

Introduction

Many polymers are extruded through various styles of

dies to produce monolayer and multilayer products.

Coextrusion is a common method used for producing

multilayer structures. Coextrusion is a process in which

two or more polymers are extruded and joined together in a

feedblock or die to form a single structure with multiple

layers. This technique allows the processor to combine the

desirable properties of multiple polymers into one structure

with enhanced performance characteristics. The

coextrusion process has been widely used to produce

multilayer sheet, blown film, cast film, tubing, wire

coating, and profiles [1-6].

This paper will discuss the effect of die manifold

channel symmetry on the flow of coextruded structures

through coathanger style dies. Experimental and numerical

data will be shown on the flow of coextruded polymer

melts through several different die manifold channels

containing different levels of symmetry. These data will

then be used to show how the flow and layer distribution of

coextruded structures is affected by the symmetry or

asymmetry of the die channel.

Background

Many different types of monolayer and coextruded

polymeric structures are currently produced using different

styles of dies. However, analyzing the flow of polymer

melts through dies can be difficult due to the complex three

dimensional flow patterns that exist [7-10]. This analysis

becomes even more complex when multiple layers of

different materials are introduced into the structure through

coextrusion methods [11-21].

Shaping operations for polymers cover a wide range of

technologies producing products such as flat sheet, cast

film, blown film, pipe, bottles, fibers, profiles, and many

others. Since each of these products requires a different

die to shape the polymer into its final form, the number of die types that have been developed is enormous. Because

of the large number and different styles of die designs,

many die distribution manifold styles have been developed.

These designs have varying levels of channel symmetry

depending on the final product shape and the difficulty in

the fabrication of the die. The purpose of this work was to

experimentally and numerically determine the flow and

layer distribution of coextruded structures flowing through

coathanger style dies containing distribution manifold

channels with different levels of geometric symmetry.

Experimental

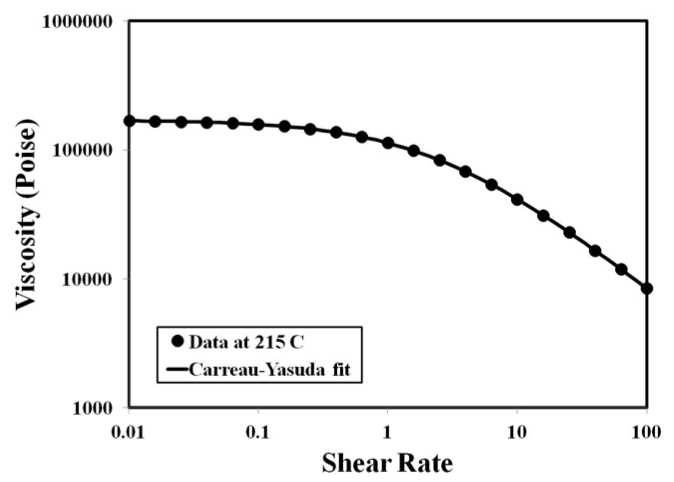

A commercially available resin, STYRON 484 High

Impact Polystyrene (HIPS) resin manufactured by

Americas Styrenics was used in the experiments. This

resin has a Melt Flow Index of 2.8 (dg/min, 5 kg weight,

200 ºC) and a specific gravity of 1.04. The rheology of this

resin at our processing temperature of 215 ºC is shown in

Figure 1.

Figure 1. Rheology of HIPS Resin at 215 oC.

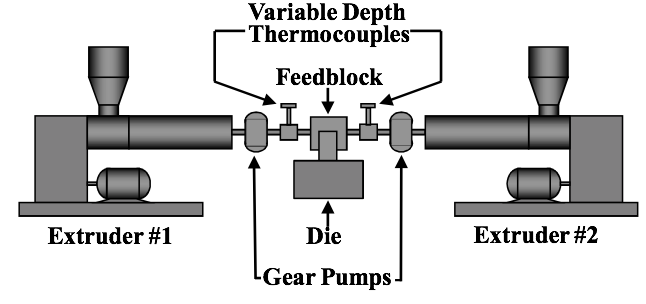

The coextrusion line used in this study consisted of

two 31.75 mm (1.25 inch) diameter, 24:1 L/D single screw

extruders and a 25.4 mm (1.0 inch) diameter, 24:1 L/D

single screw extruder. The extruders fed individual gear

pumps to ensure uniform flow of the polymer melts to the

feedblock and dies. The gear pumps were attached to a

feedblock by transfer lines that contained variable depth

thermocouples to ensure consistent and uniform

temperatures from the extruders. A feedblock was used to

produce layered coextruded structures with either 3 or 200

layers. These layer arrangements allowed us to look at both simple (3 layer) and more complex (200 layers)

systems as they flowed through the die. The layered

structures consisted of 10% skin layers and an 80% core by

volume. Coextruded structures were made using the same

material in each extruder with different colored pigments

added to each to allow determination of the interface

location in the structure.

A schematic diagram of the extrusion line set-up is

shown in Figure 2. This simplified diagram shows only

two of the three extruders that can be used in this system.

This system can be configured in different combinations to

produce the 3 layer and 200 layer coextruded structures

described earlier.

Figure 2. A schematic diagram of the extrusion line.

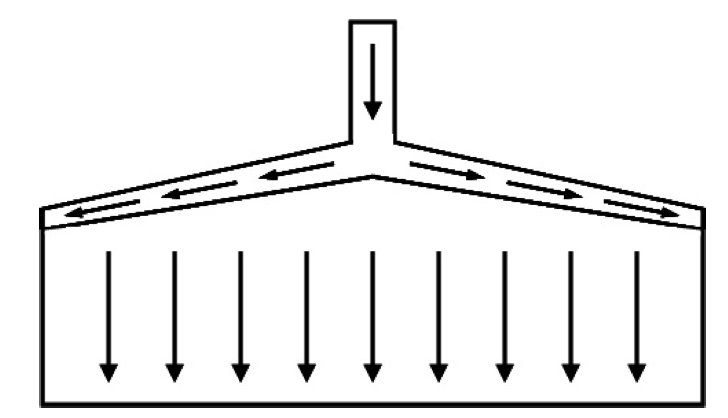

The flow through a coathanger style die is shown

schematically in Figure 3.

Figure 3. A schematic diagram showing the flow through a coathanger die geometry.

Figure 3 shows how the flow enters the distribution

manifold at the top and then is distributed across the die

width and then flows downward through the land region.

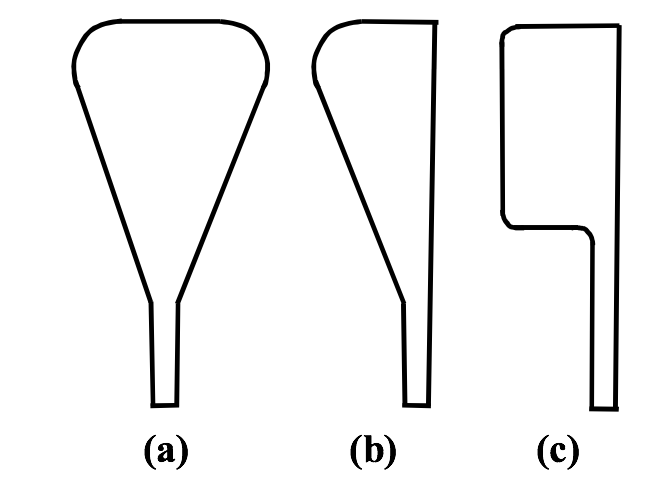

Attached to the exit of the feedblock were coathanger

style dies containing different cross-sectional geometries in

their distribution manifolds. These geometries are shown

schematically in Figure 4.

Figure 4. Coathanger die manifold cross-sectional geometries.

Figure 4a shows a teardrop shaped manifold geometry

commonly used in many coathanger style dies. This

geometry is symmetric about its vertical centerline. Figure

4b shows a half teardrop shaped manifold geometry. This

type of geometry is not symmetric about its vertical

centerline. This type of manifold is used when a

streamlined design is desired but when only one face of the

die is machined with a distribution manifold. This is more

common when machining a blow molding head or a blown

film die. Figure 4c shows a manifold geometry that is

rectangular in shape and has no taper at the bottom of the

channel. This manifold is highly asymmetric about its

vertical centerline and not well streamlined. These three

manifold geometries allowed us to study the symmetry

effects on the flow and distribution of coextruded

structures.

For a typical experiment, the coextrusion line was run

for 30 minutes to ensure that steady-state conditions had

been reached. The experiments were run at a temperature

of 215ºC and an extrusion rate of 9.0 kg/h. When steady

state was reached, the extruders were stopped

simultaneously and the coextruded material was cooled

while still in the die channel, solidifying the material. After

it had cooled to room temperature, the polymer “heel” was

removed from the die and cut into sections to expose the

cross-sectional faces along the die. This procedure allowed

the major deformations of the interfaces to be examined.

Results

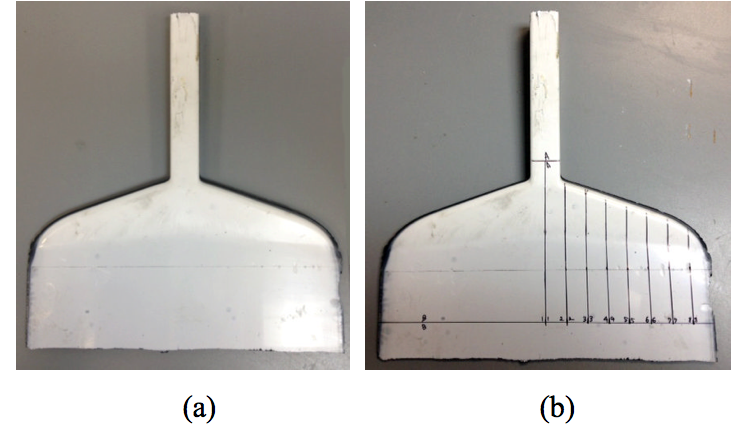

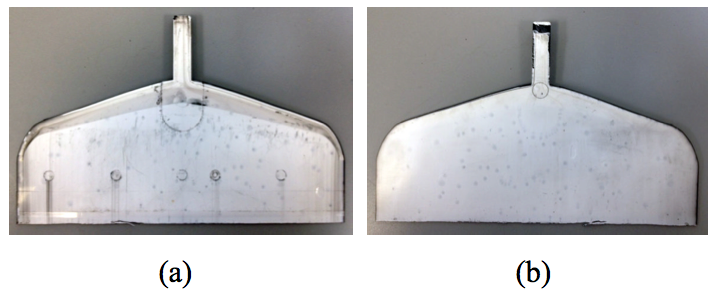

The experimental setup shown in Figure 2 was first run

with an 8 inch wide coathanger die containing the crosssectional

geometry shown in Figure 4a. The frozen heel

produced in this experiment is shown in Figure 5. Figure

5a shows the die heel top surface as it was removed from

the die while 5b shows the die bottom surface labeled

where it will be cut into sections to expose the crosssectional

faces along and across the die.

Figure 5. “Frozen” heel from the die with a symmetrical manifold geometry similar to the diagram in Figure 4a. The top (a) and bottom (b) surfaces are shown.

The initial experiments using the die with the

symmetric manifold were run with a three layer structure

with the skins pigmented white and the core pigmented

black so that the interface locations could be determined.

Figure 6 shows a cross-sectional cut of the three layer

structure before it enters the die distribution manifold.

This Figure shows that the entering structure is symmetric

and the layers are fairly uniform in thickness. The

uniformity of these layers has been slightly affected by the

highly viscoelastic properties of this polystyrene resin, as

has been discussed previously (11-21). However, for the

purposes of this study, these slight non-uniformities were

thought to have little impact on the results of these

experiments.

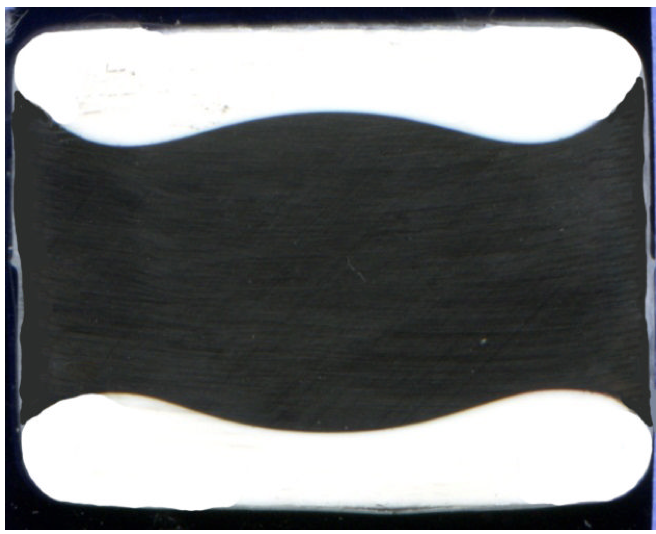

Figure 6. The three layer structure prior to entering the die distribution manifold.

Figure 7 shows the cross-sectional cuts for a 3 layer

structure in the symmetrical die manifold. The image on

the far left is near the centerline of the die and the image on

the far right is near the edge of the die. These images show

the progression of the layer interface locations as the structure flows down the distribution manifold from left to

right.

Figure 7. Cross-sectional cuts for a 3 layer structure in a symmetrical manifold. Flow progresses down the channel from left to right with the image on the left taken from near the center of the die and the image on the right taken from near the edge of the die.

Note in Figure 7 that the thicknesses of the skin layers

remain relatively constant as the structure flows down the

distribution manifold.

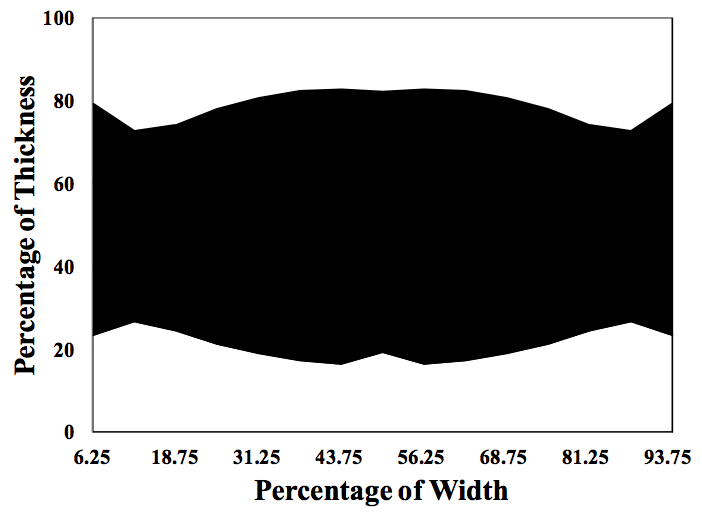

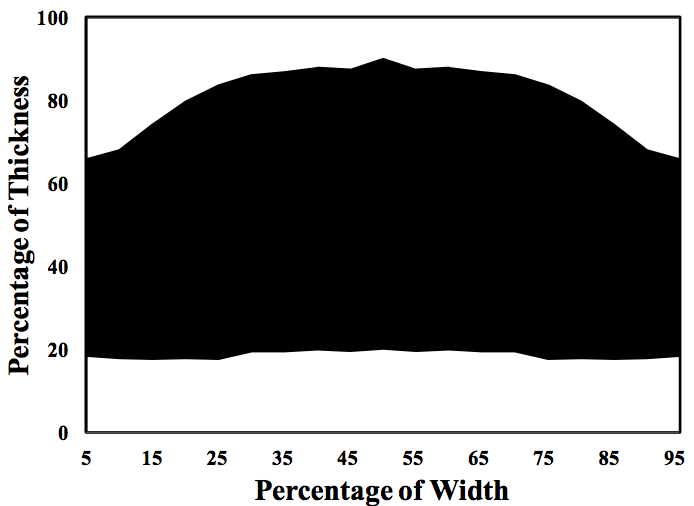

Figure 8 shows the relative thicknesses of the skin and

core layers from the left to the right edge of the die in the

land region. In this Figure, the core is shown in black and

the skins in white. This Figure shows that the skin layer

thicknesses are fairly uniform across the width of this

structure. When this same experiment was done with a 200

layer sample, the results were very similar.

Figure 8. Skin and core layer thicknesses across the width of the die land for a 3 layer structure in a symmetrical manifold.

The next experiment consisted of running the three

layer sample through the half teardrop asymmetric die

manifold shown in Figure 4b. The 10 inch wide frozen

heel produced in this experiment is shown in Figure 9.

Figure 9a shows the die heel top surface as it was removed

from the die while 9b shows the bottom surface. This

Figure shows that the distribution manifold is cut only in

the top surface as was shown in Figure 4b.

Figure 9. “Frozen” heel from the die with an asymmetrical half teardrop manifold geometry similar to the diagram in Figure 4b. The top (a) and bottom (b) surfaces are shown.

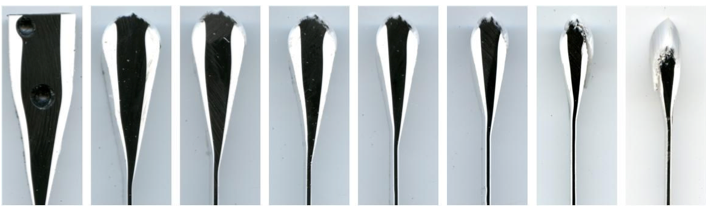

Figure 10 shows the cross-sectional cuts for a 3 layer

structure in the half teardrop asymmetrical die manifold.

These images show the progression of the layer interface

locations as the structure flows down the distribution

manifold from left to right.

Figure 10. Cross-sectional cuts for a 3 layer structure in a half teardrop asymmetrical manifold. Flow progresses down the channel from left to right with the image on the left taken from near the center of the die and the image on the right taken from near the edge of the die.

Figure 11 shows the relative thicknesses of the skin

and core layers from the left to the right edge of the die in

the land region. This Figure shows that the bottom skin

layer thickness is fairly uniform across the width of this

structure, although the center is slightly thicker than the

edges. However, the top skin layer, which is the side of the

die in which the distribution manifold was cut, shows

significantly more asymmetry with the layer being thinner

near the center and thicker at the edges of the die.

Figure 11. Skin and core layer thicknesses across the width of the die land for a 3 layer structure in a half teardrop asymmetrical manifold.

When this same experiment was done with a 200 layer

sample, the results were very similar. However, running a

200 layer sample does yield more information on the flow

of the layers compared to a 3 layer sample. Figure 12

shows an example of a 200 layer sample from near the

center of the half teardrop distribution manifold. The black

layers in the image are actually bands of 25 alternating

black and white layers but they are too small to see in this

picture. However, the thicker white layers between the 25

layer bands are visible and show the paths that the layers

take as they flow (from right to left in this image) from the

distribution manifold and down through the land region.

Figure 12. A cross-sectional view of the two hundred layer structure near the center of the die with the half teardrop distribution manifold.

Figures 10 through 12 all show that the slight amount

of asymmetry in the half teardrop distribution manifold

affected the distribution of the layer thicknesses in this

structure. Comparing Figure 8 for the symmetrical

manifold and Figure 11 for the half teardrop manifold also

shows this affect. It appears that the asymmetry causes

more of the top skin to flow down the distribution manifold

rather than flowing down towards the land. This causes the

top skin layer to be thinner near the center of the die and

thicker near the edge, as is shown in Figure 11.

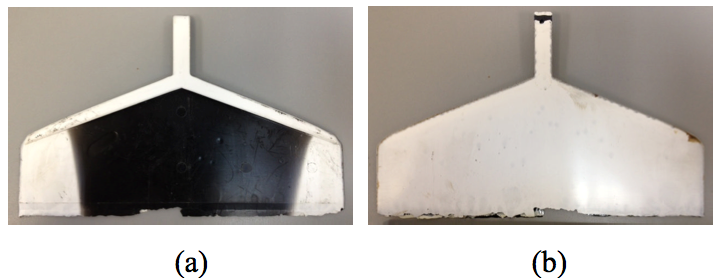

The next experiment consisted of running the three

layer sample through the rectangular asymmetrical die

manifold shown in Figure 4c. The 10 inch wide frozen

heel produced in this experiment is shown in Figure 13.

Figure 13a shows the die heel top surface as it was

removed from the die while 13b shows the bottom surface.

Note that the bottom surface is completely white while the

top surface is white in the distribution manifold and the

edges of the land but black in the middle of the land area.

This is significantly different than the white surfaces shown

in Figure 5 for both surfaces of the heel produced using the

symmetric die manifold

Figure 13. “Frozen” heel from the die with an asymmetrical rectangular manifold geometry similar to the diagram in Figure 4c. The top (a) and bottom (b) surfaces are shown.

Figure 14 shows the cross-sectional cuts for a 3 layer

structure in the rectangular asymmetrical die manifold.

These images show the progression of the layer interface

locations as the structure flows down the distribution

manifold from left to right.

Figure 14. Cross-sectional cuts for a 3 layer structure in a rectangular asymmetric manifold. Flow progresses down the channel from left to right with the image on the left taken from near the center of the die and the image on the right taken from near the edge of the die.

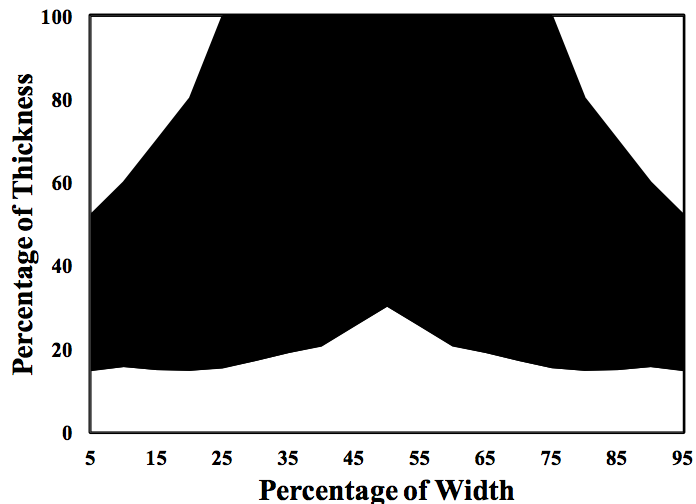

Figure 15 shows the relative thicknesses of the skin

and core layers from the left to the right edge of the die in

the land region. In this Figure, the core is shown in black

and the skins in white. This Figure shows that the skin

layer thicknesses are very non-uniform across the width of

this structure. Note that the skin layer on the bottom is

thicker in the center and thinner on the edges. The top skin

layer by comparison is even more asymmetrical than the

bottom skin layer. The top skin layer is non-existent in the

center of the sample but it becomes very thick at the edges

of the die. When this same experiment was done with a

200 layer sample, the results were very similar.

Figure 15. Skin and core layer thicknesses across the width of the die land for a 3 layer structure in a rectangular asymmetrical manifold.

Figures 13 through 15 all show that the large amount

of asymmetry in the rectangular distribution manifold

affected the distribution of the layer thicknesses in this

structure. Comparing Figure 8 for the symmetric manifold,

Figure 11 for the half teardrop manifold, and Figure 15 for

the rectangular manifold shows that as the level of

asymmetry of the distribution manifold increases, the nonuniformity

of the layer distribution also increases. It

appears that as the asymmetry of the distribution manifold

increases, more of the skin layers flow down the

distribution manifold rather than flowing towards the land.

This causes the skin layers to be thinner near the center of

the die and thicker near the edge.

Numerical

In order to better understand the flow patterns in the

various die geometries and how they affected the layer

distributions, numerical models were developed using

Computation Fluid Dynamics (CFD) techniques. ANSYS

Polyflow© [22], a three dimensional (3D) finite element

program, was used to model the flow through coathanger

die geometries with distribution manifolds similar to those

shown in Figure 4.

Simulation of the flow of fluid in a die involves the

numerical solution of the equations governing viscous fluid

flow on the specified computational domain, subject to the

stated boundary conditions. Steady, laminar flow of an

isothermal, incompressible, non-Newtonian fluid, such as

that in a coathanger die, can be described by the following

forms of the equations of continuity and motion:

where P, u , p, and τ are the density, velocity vector,

pressure, and deviatoric stress tensor, respectively.

Equation (2) shows the equation of motion in stressdivergence

form. This is the form typically used for flows

involving non-Newtonian fluids, as it properly accounts for

the spatial variation of viscosity.

In order to solve these equations for polymer flow, an

appropriate rheological constitutive equation must be

determined. In this study, a Carreau-Yasuda model was

used. The Carreau-Yasuda model is one of several

different generalized non-Newtonian viscosity models

which can be used to describe the shear rate dependence of

a polymer's viscosity. Because of its flexibility, the model

has proven useful in describing the rheological behavior of

a variety of polymers.

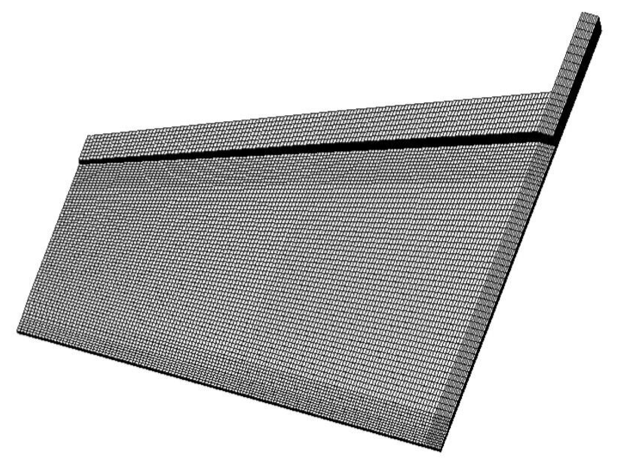

Figure 16 shows a discretized flow domain, or mesh,

for a coathanger die with a rectangular, asymmetrical

distribution manifold. This Figure shows that flow through

only half of the die was simulated due to the symmetry of

the model about the center plane. This mesh was used with

appropriate boundary conditions and constitutive equations

to determine the 3D flow fields within the die.

Figure 16. Finite element mesh for a rectangular asymmetrical manifold.

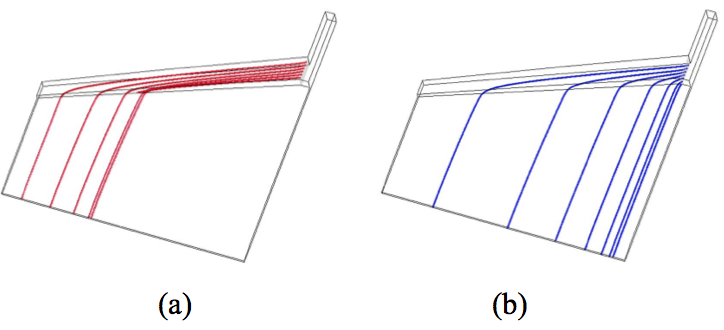

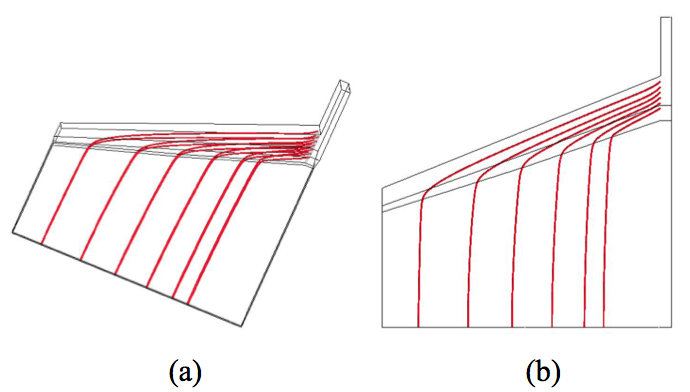

Figure 17 shows a particle path plot for the die with

the rectangular, asymmetrical distribution manifold shown

in Figure 16. In this plot, a series of equally spaced,

massless particles are placed at the upper (17a) and lower

(17b) interface locations between the skin and core layers

near the entry to the distribution manifold and allowed to

flow through the geometry and indicate the subsequent

locations of those interfaces. This Figure shows that the

upper skin layer (17a) does not flow down to the land

immediately but moves a significant distance down the

distribution manifold before it enters the land region. The

lower interface (17b) follows a more normal flow path

which distributes the interface across the width of the die.

The results of these plots agree with the experimental

results shown in Figures 13 through 15.

Figure 17. Particle path plots tracing the upper (a) and lower (b) interface locations in a 3 layer structure in a rectangular asymmetrical manifold.

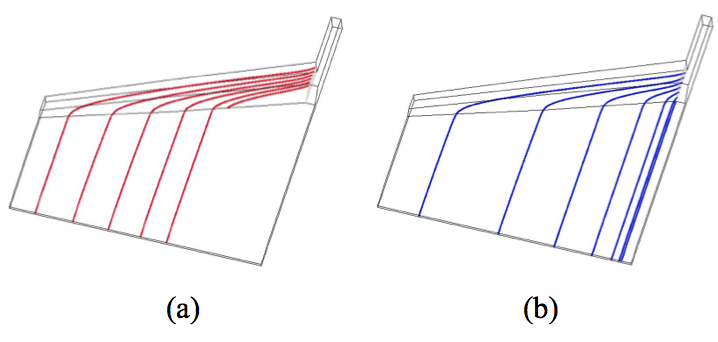

The next geometry simulated was similar to Figure 16

but a 45 degree taper was added to the exit of the

distribution manifold. This creates geometry similar to the

half teardrop geometry shown in Figure 4b. Figure 18

shows a particle path plot for the die with the half teardrop,

asymmetrical distribution manifold. In this plot, a series of

equally spaced, massless particles are placed at the upper

(18a) and lower (18b) interface locations between the skin

and core layers near the entry to the distribution manifold

and allowed to flow through the geometry and indicate the

subsequent locations of those interfaces. This Figure

shows that the upper skin layer (18a) does not flow down

to the land immediately but moves a significant distance

down the distribution manifold before it enters the land

region. The lower interface (18b) follows a more normal

flow path which distributes the interface across the width of

the die. The results of these plots agree with the

experimental results shown in Figures 9 through 11.

Figure 18. Particle path plots tracing the upper (a) and lower (b) interface locations in a 3 layer structure in a half teardrop asymmetrical manifold.

Comparing Figures 17 and 18 shows that the lower

skin layer interfaces are fairly similar but the upper skin

interfaces are different. The half teardrop manifold

geometry is slightly more symmetrical than the rectangular

manifold geometry and so the upper skin interface begins to flow down into the land region sooner giving a

somewhat more uniform layer distribution across the die.

The next geometry to be simulated was similar to

Figure 18 but mirrored about the axis of the surface

opposite the distribution manifold. This creates geometry

similar to the symmetrical teardrop geometry shown in

Figure 4a. Figure 19 shows particle path plots for the die

with this distribution manifold geometry. In this plot, a

series of equally spaced, massless particles are again placed

at the upper and lower interface locations between the skin

and core layers near the entry to the distribution manifold

and allowed to flow through the geometry and indicate the

subsequent locations of those interfaces. This Figure

shows that the upper and lower skin layers flow uniformly

across the die, which is expected because of the symmetry

of this geometry. In fact, Figure 19b shows that if the

results are viewed from the front of the manifold, the

particle paths for the upper and lower skin interfaces are

identical and appear as single lines. The results of these

plots agree with the experimental results shown in Figures

5 through 8.

Figure 19. Particle path plots showing the upper and lower interface locations in a 3 layer structure in a symmetrical teardrop manifold, where (a) and (b) show different viewing angles of the final results.

Conclusions

A unique series of experiments and numerical

simulations were conducted to determine the effect of die

manifold channel symmetry on the flow of coextruded

structures through coathanger style dies. Experimental and

numerical data were developed on the layer uniformity of

coextruded structures which were processed through

several different die manifold channels containing different

levels of symmetry. As the asymmetry of the die manifold

increases, more of the skin layers on the manifold side flow

down the distribution manifold rather than flowing towards

the land. This causes the skin layers to be thinner near the

center of the die and thicker near the edge. The data show

that as the asymmetry of the distribution manifold

increases, the layer uniformity of the coextruded structure

decreases.

References

1. L.M. Thomka and W.J. Schrenk, Modern Plastics, 49,

4, 62 (1972).

2. C.D. Han, J. Appl. Poly. Sci., 19, 7, 1875 (1975).

3. W.J. Schrenk, Plastics Engineering, 30, 3, 65 (1974).

4. J.A. Caton, British Plastics, 44, 3, 95 (1971).

5. L.M. Thomka, Plastics Engineering, 18, 2, 60 (1973).

6. C.R. Finch, Plastics Design Forum, 4, 6, 59 (1979).

7. C.I. Chung and D.T. Lohkamp, Modern Plastics, 53,

3, 52 (1976).

8. H.H. Winter and H.G. Fritz, Polymer Engineering and

Science, 26, 543 (1986).

9. Y. Matsubara, Polymer Engineering and Science, 19,

169 (1979).

10. J. Dooley, SPE-ANTEC Technical Papers, 36, 168

(1990).

11. J. Dooley and B.T. Hilton, Plastics Engineering, 50,

2, 25 (1994).

12. J. Dooley and L. Dietsche, Plastics Engineering, 52,

4, 37 (1996).

13. J. Dooley and K. Hughes, TAPPI Journal, 79, 4, 235,

(1996).

14. B. Debbaut, T. Avalosse, J. Dooley, and K. Hughes,

Journal of Non-Newtonian Fluid Mechanics, 69, 2-3,

255 (1997).

15. J. Dooley, K.S. Hyun, and K.R. Hughes, Polymer

Engineering and Science, 38, 7, 1060 (1998).

16. B. Debbaut and J. Dooley, Journal of Rheology, 43, 6,

1525 (1999).

17. P.D. Anderson, J. Dooley, and H.E.H. Meijer, Applied

Rheology, 16, 4, 198 (2006).

18. P. Yue, J. Dooley, and J. Feng, Journal of Rheology,

52, 1, 315 (2008).

19. P. Yue, C. Zhou, J. Dooley, and J. Feng, Journal of

Rheology, 52, 4, 1027, (2008).

20. J. Dooley, “Viscoelastic Effects in Melt Flow,”

Chapter 8, in Extrusion of Polymers - Theory and

Practice (2nd Edition), Hanser (2010).

21. P. Lee and J. Dooley, TAPPI, Polymers, Laminations,

Adhesives, Coatings, & Extrusions Conference,

Seattle, WA, Paper 10-2 (2012).

22. ANSYS, Inc., 275 Technology Drive, Canonsburg,

PA, 15317, USA, www.ansys.com.

Keywords: Coextrusion, die design, symmetry, distribution

manifold, layer uniformity, CFD.

Return to

Paper of the Month.