Improved Approximations in Thermal Properties for Single Screw Extrusion

Eberhard Grünschloss* and María del Pilar Noriega

ICIPC – Plastics and Rubber Institute

Carrera 49 No. 5 Sur-190, Medellin, Colombia, South America

*Schweitzerstrasse 36, D-70619 Stuttgart, Germany Abstract

Actual screw design software is capable to simulate

the performance of a single screw extruder based on

elaborated program codes. The aim of this work is to

present improved approximations in relevant thermal

properties for simulation and design of single extrusion

screws in combination with analytical calculations

appropriate for the industrial practice. The developed

approximation functions for thermal properties, such as,

specific heat capacity, enthalpy, thermal conductivity and

density, were obtained looking for small number of

parameters. A comparison between the improved

approximation functions, existing known functions and

measured data for some common polymer families is

shown.

Background

The thermal properties of polymers affect the single

screw extrusion process from the feeding zone to the

metering and mixing zone. These properties have an effect

on solids conveying, melting rate and melt conveying of

an extruder screw. The melting rate of the polymer

material has an important effect on extrusion melting

efficiency and it is strongly affected by such properties as

specific heat, thermal conductivity and density obtained

from a p-v-T diagram.

Specific heat capacity describes the amount of

energy that it takes to raise the temperature of a polymer.

LDPE requires an average of 2.596 J/(g.K) in the molten

state, while PS requires 1.95 J/(g.K), [1]. Therefore, it

takes almost 33 % more energy to raise the temperature of

1 g of LDPE than 1 g of PS. Additionally, it means that

more power is necessary to process LDPE than PS at the

same extrusion processing conditions like output in kg/h

and melt temperature. It is well known that the specific

heat capacity is the derivative of enthalpy with respect to

temperature.

Thermal conductivity is the ability of the polymer to

conduct heat. In general, the polymers exhibit a low

thermal conductivity. LDPE has an average thermal

conductivity of 0.25 W/(m.K) in the molten state, while PS is 0.14 W/(m.K), [1]. Because LDPE has a higher

thermal conductivity than PS, the heat flux for LDPE

from barrel to polymer is higher.

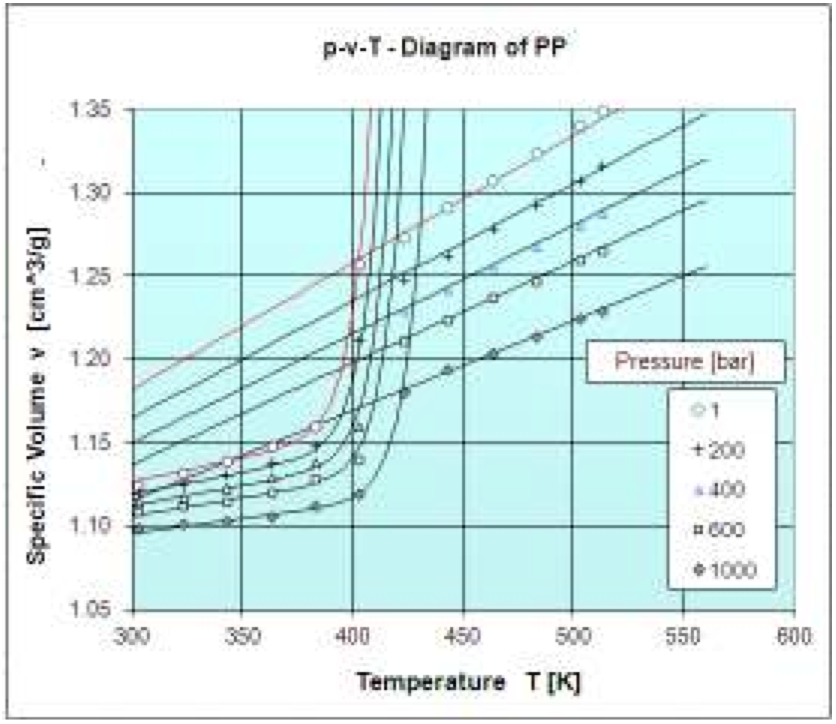

Solid and melt density can be obtained from p-v-T

diagram, for example, Tait´s equation of state. The density

is found from reciprocal of specific volume. Nevertheless,

other authors have shown in the literature that Tait´s

equation does not work well for semicrystalline polymers

[2]. The research work of Sanchez-Cho on equation of

state for polymers seems to be until now the most accurate

equation of state [2, 3].

Improved Approximations:

The developed approximation functions for thermal

properties were obtained looking for small number of

parameters, and they are: specific heat capacity for solid

state and molten state, enthalpy for solid state and molten

state, thermal conductivity from the solid state to the

molten state and density from the solid state to the molten

state.

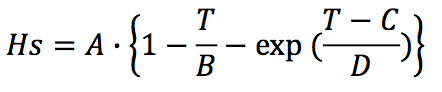

The solid state enthalpy (H

s) is proposed as a fourparameter

function as follows:

Where,

A: Parameter in J/g

B: Parameter in K

C Parameter in K

D: Parameter in K

T: Temperature in K

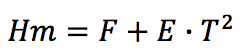

The enthalpy for molten state (H

m) is proposed as a

two-parameter function as follows:

Where,

F: Parameter in J/(g.K)

E: Parameter in J/(g.K

2)

T: Temperature in K

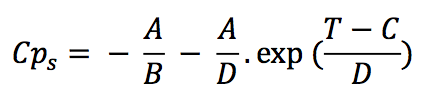

The specific heat capacity for solid state (Cp

s) is

suggested as a four-parameter function:

Where the parameters A, B, C and D are taken from the

enthalpy function,

A: Parameter in J/g

B: Parameter in K

C: Parameter in K

D: Parameter in K

T: Temperature in K

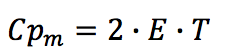

The specific heat capacity for molten state (Cp

m) is

suggested as a two-parameter function:

Where the parameter E is taken from the enthalpy

function,

E: Parameter in J/(g.K)

T: Temperature in K

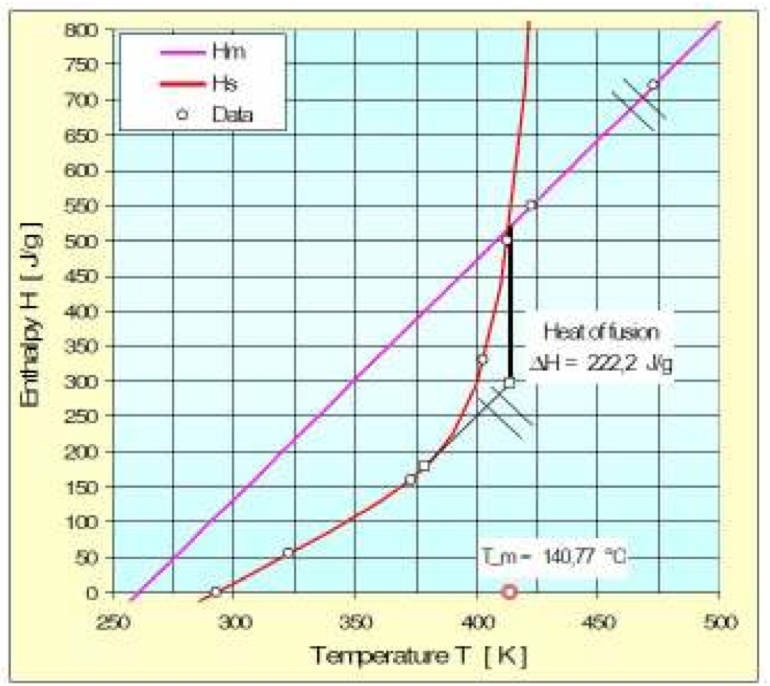

The heat of fusion for semicrystalline polymers can

be obtained graphically from the enthalpy function as

shown in Fig. 1 for a HDPE. The heat of fusion is the

amount of heat energy that is required to convert a

polymer from a solid to a liquid or melt.

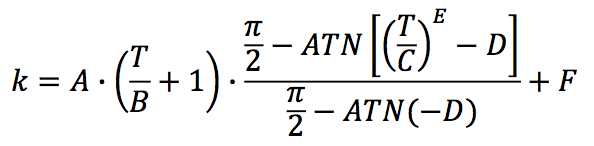

The thermal conductivity (k) from the solid state to

the molten state is proposed as one function with six

parameters:

Where,

A: Parameter in W/(m.K)

B: Parameter in K

C: Parameter in K

D: Dimensionless parameter

E: Dimensionless parameter

F: Parameter in W/(m.K)

T: Temperature in K

This function is suitable for the range from room

temperature up to typical melt temperatures in the single

screw extrusion process.

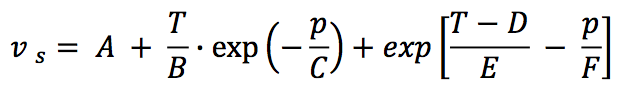

The solid state density (ρ

s) is obtained from

reciprocal of specific volume (υ

s) and it is proposed as a

six-parameter model, as follows:

Where,

A: Parameter in cm

3/g

B: Parameter in K

C: Parameter in bar

D: Parameter in K

E: Parameter in K

F: Parameter in bar

T: Temperature in K

p: Pressure in bar

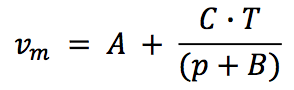

The density for molten state (ρ

m) is obtained from

reciprocal of specific volume (υ

m) and it is proposed as a

three-parameter model after Spencer and Gilmore, as

follows [4]:

Where,

A: Parameter in cm

3/g

B: Parameter in bar

C: Parameter in (bar.cm3) / (g.K)

T: Temperature in K

p: Pressure in bar

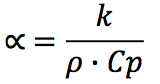

The thermal diffusivity (α) can be calculated from

previous functions, such as, specific heat, thermal

conductivity and density.

Other Authors have investigated extensions of some

of the above mentioned equations or functions, [5, 6, 7].

The functions described in this work have been found

more suitable for simulation and design of screws in

single screw extrusion, and they were obtained looking for

small number of parameters, what it is appropriate for the

industrial practice.

There is no fundamental theory behind the equations

presented in this paper. This is reasonable because in

practice the polymers are normally not pure but mixed

with additives and reinforcing agents, blended with other

polymers to combine their properties, etc. This will alter

the polymer physics and complicate an appropriate

fundamental theory.

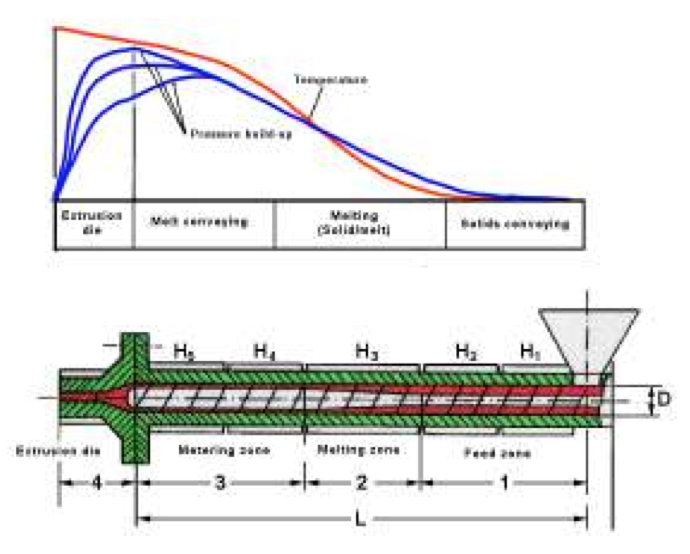

The previous approximation functions contribute to

an easier single screw calculation to simulate the performance of a single screw extruder with regard to

output, pressure build-up, melting rate, heat transfer and

melt temperature. These thermal functions can be used for

the calculations in the screw melting zone, screw metering

zone and extrusion die, Fig. 2, specially, for the prediction

of pressure build-up and melt temperature profile.

Experimental

Polypropylene: a polypropylene homopolymer

reference 505P produced by SABIC with a Melt Index

Flow, MFI, of 2.0 g/10 min at 230ºC/2.16 kg according to

ISO 1133. This is a multipurpose grade for extrusion and

injection molding applications.

Modulated DSC: A Q200 Differential Scanning

Calorimeter from TA Instruments was used for measuring

total heat flow, enthalpy and heat capacity. Test

conditions were carried out following the standard ASTM

E 1269.

A 10 mg of sample was heated from an initial temperature

up to a final temperature under high purity nitrogen, using

a heating rate of 20°C/min. An isotherm at final

temperature is required during 5 minutes.

Results

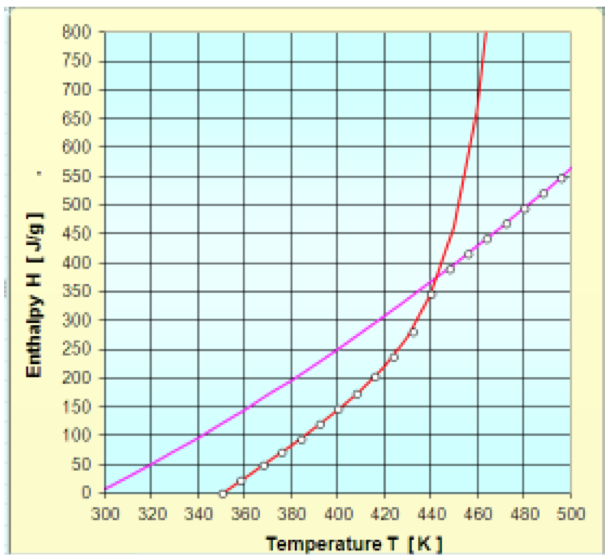

The solid state enthalpy (Hs) and for molten state

(Hm) for PP Ref. 505P proposed as two functions in

previous numeral have converged to the following

parameters:

A: -971.49 J/g

B: 350.44 K

C: 475.11 K

D: 15.18 K

E: 0.0034 J/(g.K

2)

F: -303.155 J/g

The Fig. 3 shows the measured data and the obtained

approximation functions. From the figure it is possible to

observe that the approximation functions match the data

very well.

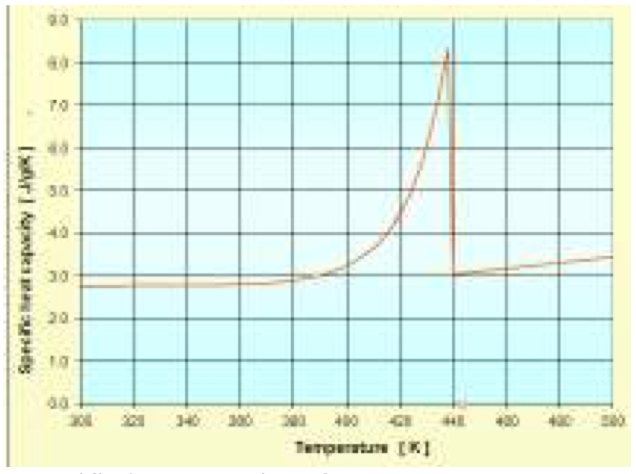

The specific heat capacity for solid state (Cp

s) and

for molten state (Cp

m) for PP Ref. 505P proposed as two

functions in previous numeral have the same parameter

values for A, B, C, D and E than the enthalpy functions,

since specific heat capacity is the derivative of enthalpy

with respect to temperature.

The Fig. 4 shows the obtained approximation functions

from measured enthalpy data. This figure illustrates that

the approximation functions match the data properly.

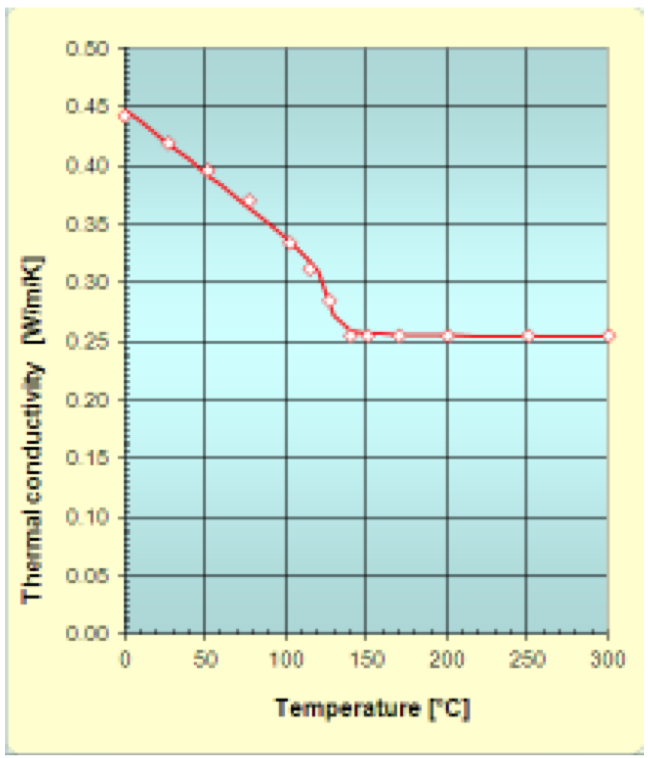

The thermal conductivity (k) from the solid state to

the molten state for a HDPE reported by VDMA [8] has

met the following parameters:

A: 0.19886 W/(m.K)

B: -0.00538 1/K

C: 0.00873 1/K

D: -4.76

E: 16.81785

F: 0.25451 W/(m.K)

The Fig. 5 shows the measured data and the obtained

approximation function. From the figure it is possible to

observe that the approximation function fits the data

satisfactorily.

The solid state density (ρ

s) for a PP measured by

Borealis is obtained from reciprocal of specific volume

and it has converged to the following parameters:

A: 1.042 cm

3/g

B: 3540 K

C: 2166 bar

D: 422.1 K

E: 8.364 K

F: 353.3 bar

The density for molten state (ρ

m) for a PP measured

by Borealis is obtained from reciprocal of specific volume

and it has met the following parameters:

A: 0.9537 cm

3/g

B: 2435 bar

C: 1.8542 (bar.cm3)/(g.K)

The Fig. 6 shows the measured data and the obtained

approximation functions for the solid and the molten state.

From the figure it is clear that the approximation functions

fit the data very well.

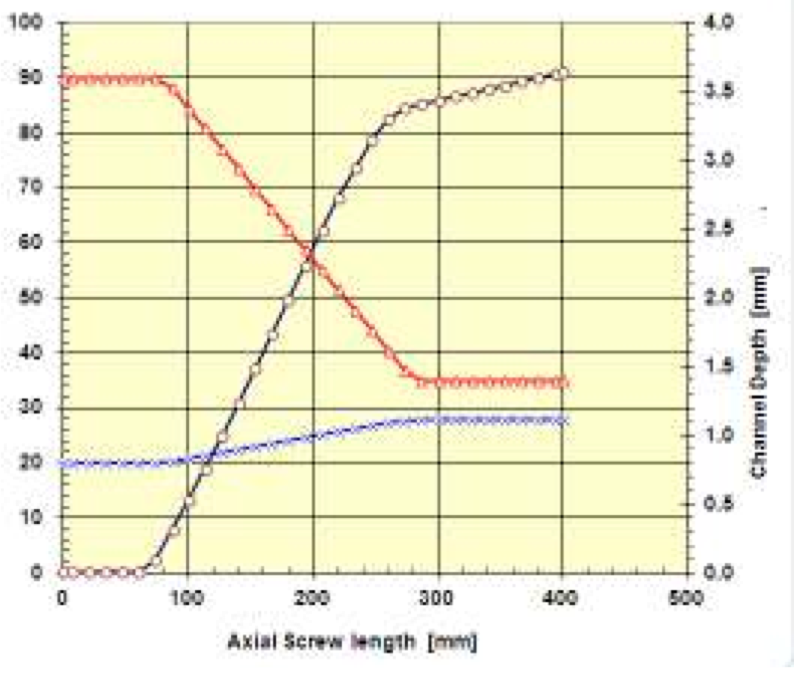

The Fig. 7 is demonstrating the use of the above

described thermal functions in combination with

analytical calculations, [9], for the prediction of pressure

build-up in a single screw of D = 20 mm and L/D = 20 for

PE processing. The left ordinate axis shows the screw

pitch, the right ordinate axis shows the screw channel

depth and the abscissa or X-axis is the axial screw length.

Solids bed profiles (SBP) could be obtained for

several polymers and single screws using the experimental

values of X/W versus L/D from a patented device

compared to analytical melting models using the

mentioned thermal functions, [10].

Conclusions

This work presented improved approximations with

reduced number of parameters in thermal properties that

are relevant for simulation and design of single extrusion

screws. These approximations in combination with

analytical calculations are appropriate for the industrial

practice, since they deliver accurate enough predictions of

output and pressure build-up of extruder screws, among

others.

There is no fundamental theory behind the equations

shown in this paper. This is reasonable because in practice

the polymers are normally not pure but mixed with

additives and reinforcing agents, blended with other

polymers to combine their properties, etc. This will alter

the polymer physics and complicate an appropriate

fundamental theory.

The developed approximation functions for thermal

properties, such as, specific heat capacity, enthalpy,

thermal conductivity and density, fitted the measured data

very well. The authors gave an adequate mathematical

representation of the measured data, suitable for inclusion

in future analytical models and papers.

References

/1/ Kühnle, H. and Grünschloss, E., “Berechnung der

Austragszone von Einschneckenextrudern”,

Rheologie in der Kunststofftechnik, Technische

Akademie Esslingen, Ostfildern, Germany, 1999

/2/ Zoller Paul, “PVT Reltionship and Equations of State

of Polymers,

/3/ Cho, J. and Sanchez, I., “PVT Relationship and

Equations of State of Polymers”

/4/ Spencer, R.S. and Gilmore, G.D., “Equation of state

for high polymers”, Journal of Applied Physics, 21,

pp. 523-526, (1950).

/5/ Sanchez, I. and Cho, J., “A universal equation state

for polymer liquids”, Polymer, Vol. 36, No. 15, pp.

2929 – 2939, 2005

/6/ Naranjo, Alberto, “Measurement of the Thermal

Diffusivity of Thermoplastics under Processing

Conditions”, IKV-Berichte aus der

Kunststoffverarbeitung, Mainz, G., Germany, 2004

/7/ Sedlacek, T., et.al. “On relationship between PVT

and rheological measurements of polymer melts”,

Annual transactions of the Nordic Rheology Society,

Vol. 13, 2005.

/8/ VDMA, “Thermodynamik”, Carl Hanser Verlag,

Munich, Germany, 1979

/9/ Grünschloss, E., “Polymer Single Screw Extrusion:

Modeling“, Encyclopedia of Materials: Science and

Technology, Elsevier Science Ltd., 2001

/10/ Noriega, María del Pilar, et. al., “Method and device

to visualize in-line and quantify the polymer melting

in plasticating screw machines without significantly

affecting its thermal regime”, U.S Patent No.

7314363, January 1, 2008.

Acknowledgments

Thanks are also due to the Instituto de Capacitación e

Investigación del Plástico y del Caucho (ICIPC) in

Medellín, Colombia, Institute for Plastics Technology

(IKT) in Stuttgart, Germany, German Academic

Exchange Service (DAAD) and ICETEX in Colombia for

their valuable support to develop this research project.

Nomenclature

D Extruder diameter

L/D Dimensionless Extruder length

X/W Dimensionless screw channel width

H

s: Solid state enthalpy

Hm: Enthalpy of the melt

Cp

s: Specific heat capacity of the solids

Cp

m: Specific heat capacity of the melt

k: Thermal conductivity

ρ

s: Solid state density

ρ

m: Density of the melt

υ

s: Specific volume of the solids

υ

m: Specific volume of the melt

α: Thermal diffusivity

R: Gas constant, 8.3144 J/(mol.K)

p: Pressure

T: Temperature

LDPE: Low density polyethylene

HDPE: High density polyethylene

PP: Polypropylene

PS: Polystyrene

Key Words: Single screw extruder, thermal properties,

specific heat capacity, enthalpy, density, thermal

diffusivity, LDPE, HDPE, PP, PS

Figure 1: Graphically obtained heat of fusion for HDPE

Figure 2: Zones in a single screw extruder

Figure 3: Enthalpy of PP- SABIC 505P: Measured data and approximations

Figure 4: Specific heat capacity of PP- SABIC 505P: Approximations

Figure 5: Thermal conductivity of HDPE: Measured data and approximation

Figure 6: p-v-T diagram of PP (Borealis): Measured data and approximations

Figure 7: Pressure build-up (ο) of a Ø20 mm screw for PE, channel depth (∆) and screw pitch (x) versus axial screw length

Return to

Paper of the Month.