Comparison of the Flow Performance Between Internal and External Deckling in Flat Film Extrusion Die Systems¶

Olivier Catherine, Cloeren Incorporated, Orange, TXAbstract

Deckles are devices useful to adjust the slot width of

extrusion dies, and hence the extruded product width.

There are basically two types of deckles: (i) internal

deckles are made of components placed inside the die

flow channel to block the flow channel to a specified

width upstream the die lips, and (ii) external deckles

typically comprise blockage devices positioned directly

on and external to the die lips, at the exit orifice. To

understand the fundamental differences in flow

performance between the two technologies, 3D

Computational Fluid Dynamics (CFD) models were built.

A comparison of the original die width to the internally

and externally deckled dies is carried out by evaluating

the flow characteristics such as velocity uniformity at the

die exit and Residence Time Distribution (RTD) in the die

flow channel. The flow models show that the performance

of an internally deckled die is close to that of a nondeckled

die, while the external deckle system results in

non-uniform flow distribution and broad RTD due to the

occurrence of a large stagnation area upstream of the

external deckle.

Introduction

High performance flat film dies are typically tailored

to specific process conditions, a specific polymer

rheology, and a specific slot gap. However, flexibility is

often needed in the production process. The extrusion

equipment may be required to process different outputs,

temperature conditions or even different materials from

the original design target. Along those lines, it is not

unusual for processors to have requirements for different

product widths. In order to minimize the edge trim, while

the ideal technical solution would be to use a different die

width for each product width, a more practical solution

may be to use flow width restriction devices, also known

as deckles, to change the width of the extrudate flowing

form/exiting the die.

Deckle systems can be fairly complex assemblies but,

in principle, they are relatively simple in concept as they

consist for the most part of devices that block off the flow

channel portion to reduce flow channel to a desired width.

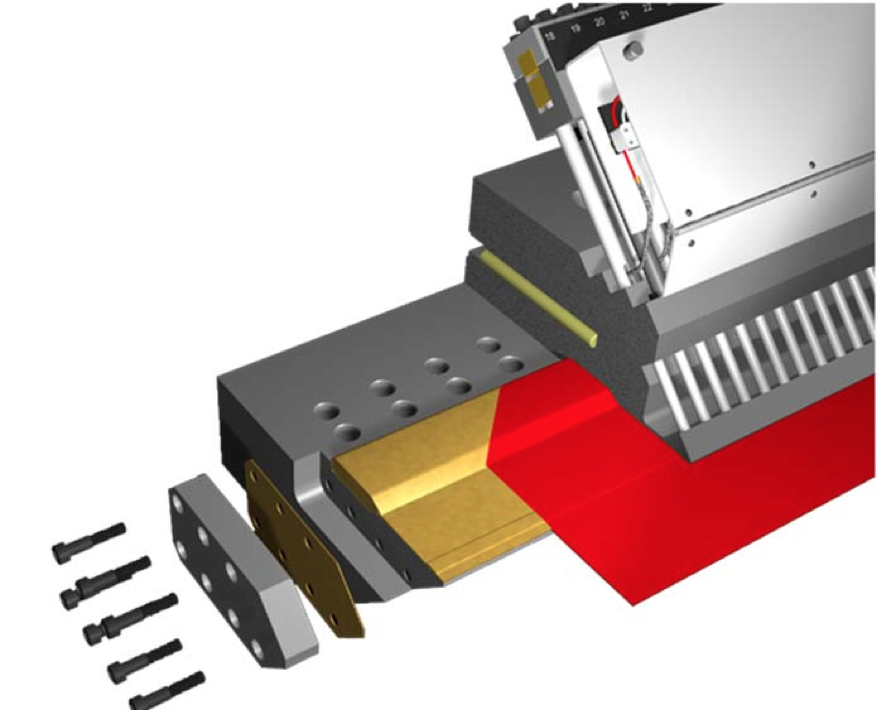

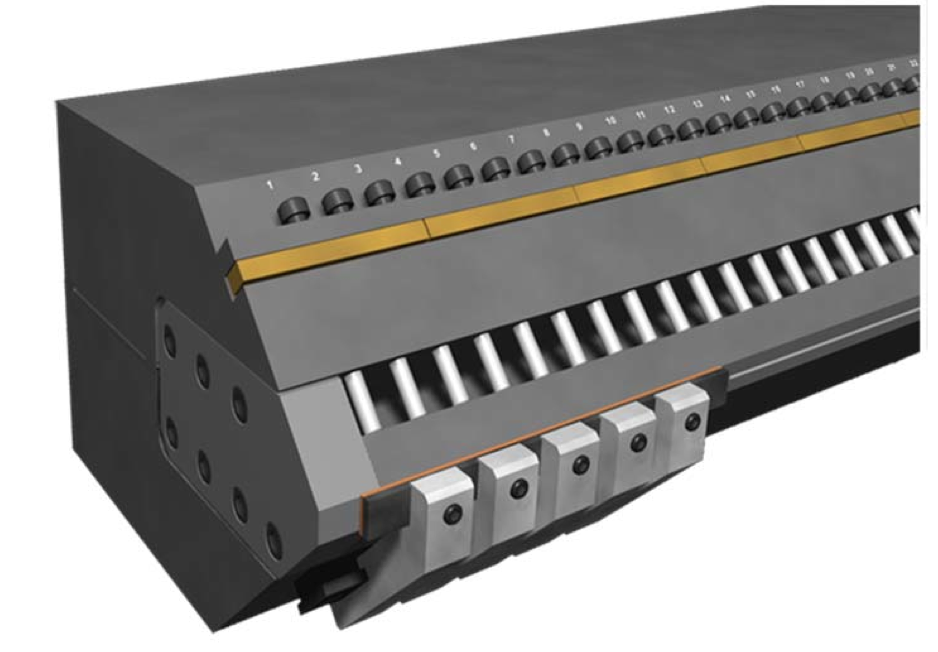

The first type of deckle is the internal system (Figure 1). It

is located in the flow channel and is known to be the most

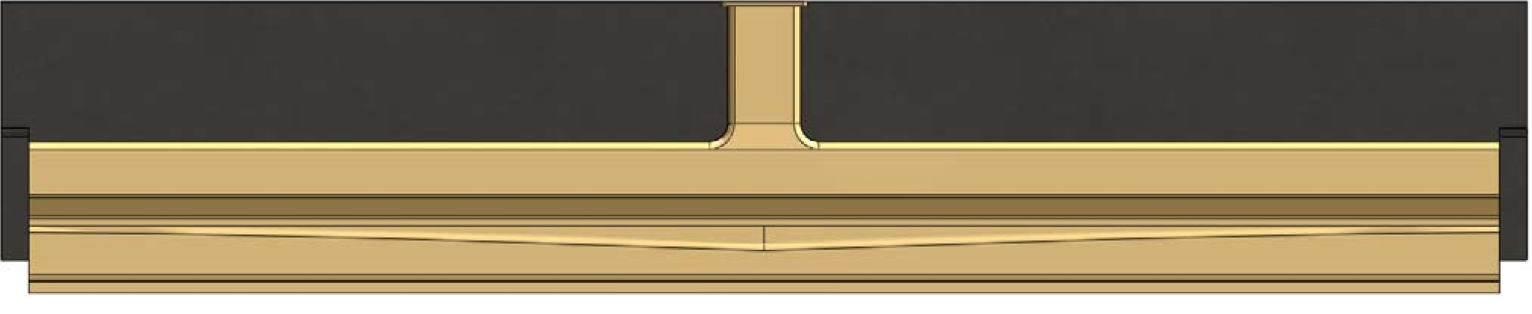

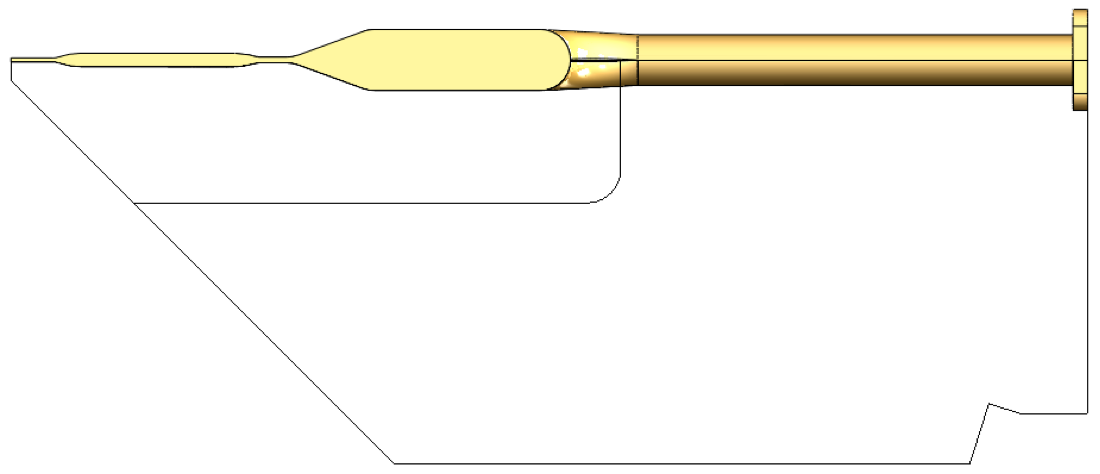

streamlined of deckle systems. A more simple and cost

competitive system is the external deckle, shown in Figure

2, which basically consists of an seal placed on the die lips to create a local flow blocking device to regulate the

die slot width.

Performance differences are expected between the

two deckle solutions and 3D CFD studies are run to

understand and teach the fundamental differences between

the two solutions. The study uses the finite element CFD

program, Solid Works Flow Simulation 2011 SP1.0,

which was previously validated for non-Newtonian, nonisothermal

flow and used for a previously published

study[1].

This flow simulation study is divided in three main

sections: (i) a model of the original (full-width) die; (ii)

two models corresponding to 250 mm and 500 mm

external deckles; and finally (iii) two models

corresponding to 250 mm and 500 mm internal deckles.

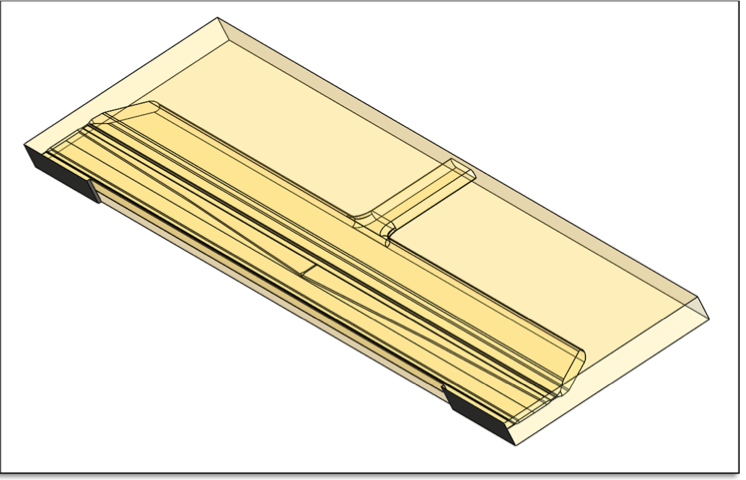

Die geometry

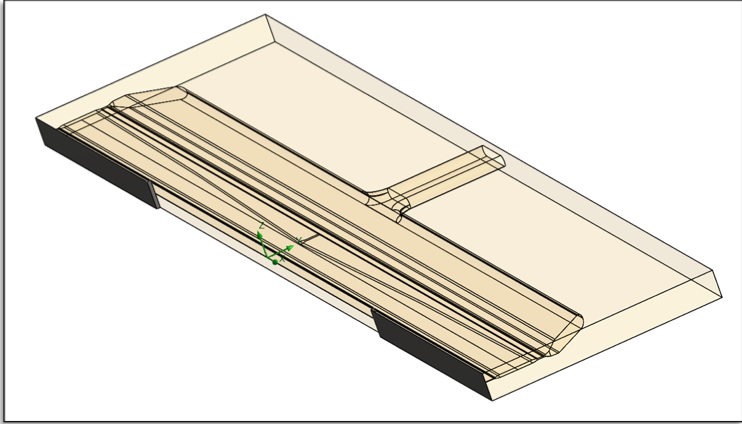

This work deals with a flat film extrusion scenario.

For comparison sake, the specific output was kept

constant for all three slot widths. The initial die slot width

is 2050 mm and the deckled scenarios correspond to a slot

width of 1550 mm and 1050 mm for the 250 mm deckles

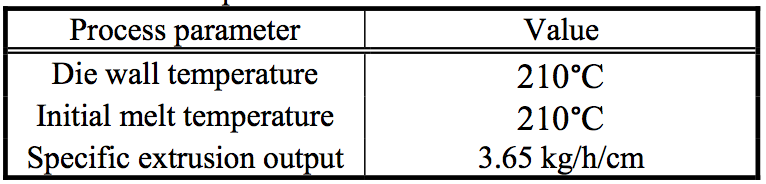

and 500 mm deckles respectively. Table 1 details the

basic process parameters, Figure 3 and Figure 4 show the

die flow channel geometry used for this study. The die

designed by Cloeren Incorporated features rectangular

entrance and manifold channels, as well as a two stage

preland.

Table 1: Process parameters

Polymer and rheology¶

The polymer used for this study is a compounded

blend of two grades of ethylene-vinyl acetate copolymer

(EVA):

Where EVA-1 is an EVA manufactured by DuPont which

has a vinyl acetate comonomer content of 18 wt%, a

density of 0.94 g/cm

3

and a melt flow index (MFI) of 0.7 g/10 min (190°C/2.16 kg). EVA-2 is also produced by

DuPont and also has a vinyl acetate comonomer content

of 18 wt%, a density of 0.94 g/cm

3

and a MFI of 2.5 g/10

min (190°C/2.16 kg).

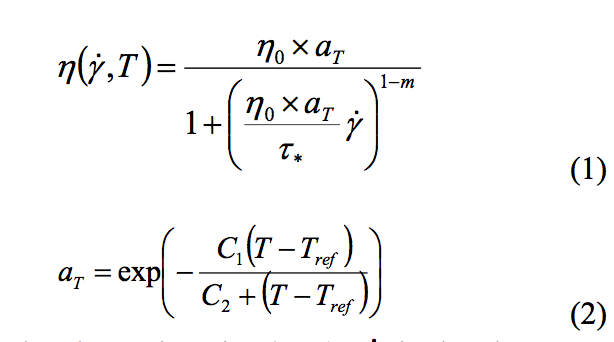

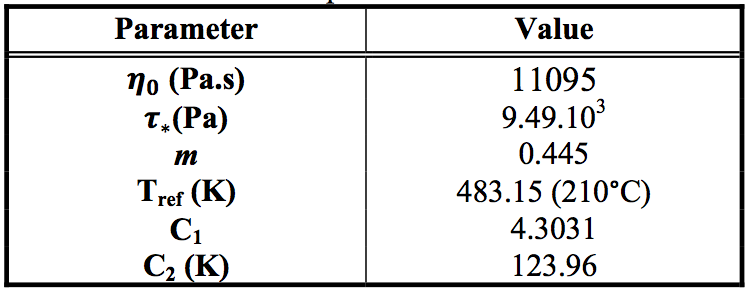

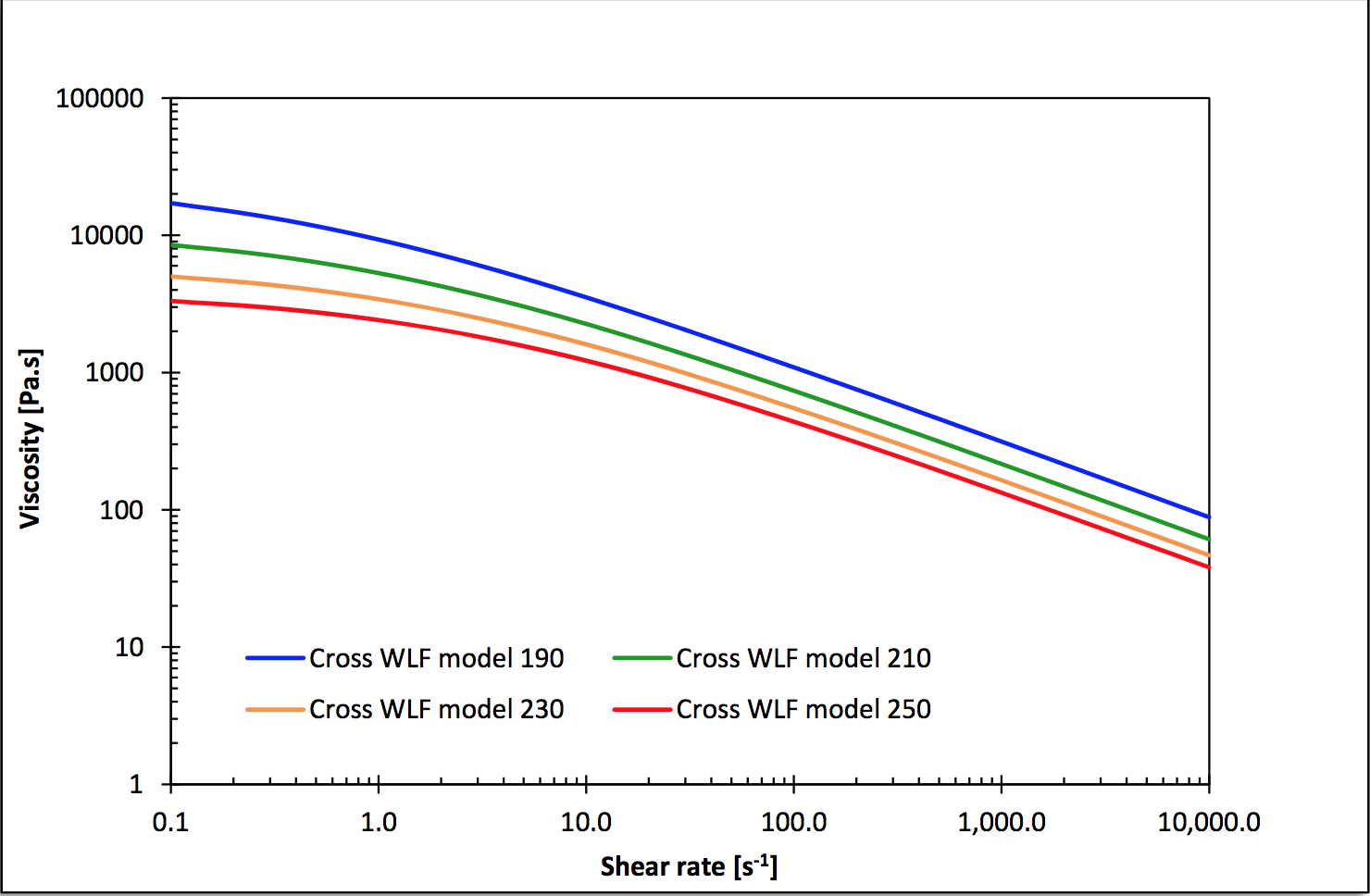

The shear viscosity behavior of this EVA compound

is modeled by the combination of the Cross model[2] for

the shear dependency and the WLF model[3] for the

temperature dependency, according to equations (1) and

(2).

Where ή is the shear viscosity (Pa.s), y is the shear rate

(1/s), T is the temperature (K), ή0 is the zero shear

viscosity (Pa.s), τ* is the characteristic shear stress (Pa)

and m is the pseudo-plastic index. ή0, τ* and m are the

Cross model parameters. The time-temperature

superposition principle (TTS)[4] is included in the Cross

model through the shift factor a

T, which follows a WLF

model, which uses the C

1 and C

2 (K) parameters. The

parameter values used for this work are summarized in

Table 2 and illustrated in Figure 5.

Table 2: Cross and WLF parameters

Finally, the following thermal properties were used: melt

density ρ= 0.795 g.cm

-3, thermal conductivity k=0.25

W.m

-1.K

-1 and specific heat C

p= 3.14 J.g

-1.K

-1.

Flow simulations

The Non-Newtonian, non-isothermal flow

simulation method and governing equations are similar to

those previously published [1].

SolidWorks Flow Simulation 2011 SP1.0[5] was used

to solve the coupled thermal-flow problem and a mesh

with brick elements was built. The boundary conditions

for this model are: (i) a symmetry condition at the

centerline for flow and temperature; (ii) a fully developed

flow at the entrance ; (iii) an initial fluid temperature and a flow rate are imposed at the entrance; (iv) at the outlet

surface (lip opening/exit orifice), the exit pressure is set to

1 atm and; (v) finally, on the flow channel walls, we

assume a non-slip condition (v=0 mm/s) and a uniform

temperature (210°C) is applied.

1 - Full-width die

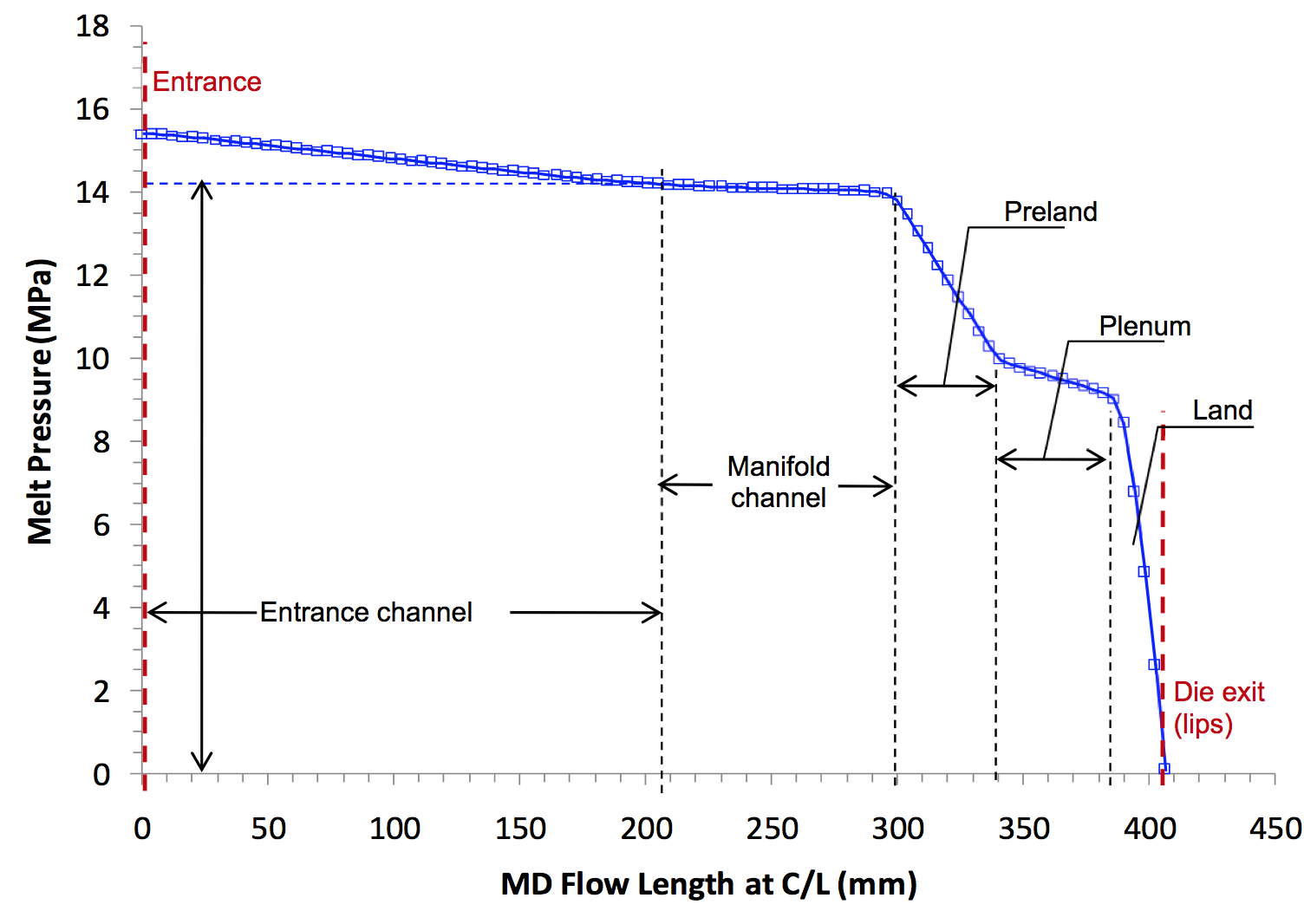

The die flow channel design was optimized for the

full width configuration, which corresponds to a slot

width of 2050 mm for a total extrusion output of 748.3

kg/h. A flow simulation was run for these conditions with

the geometry illustrated in Figure 3. The calculated

pressure drop is about 15.5 MPa, and Figure 6 shows the

evolution of the melt pressure as a function of the position

along the main flow direction (MD) at the centerline of

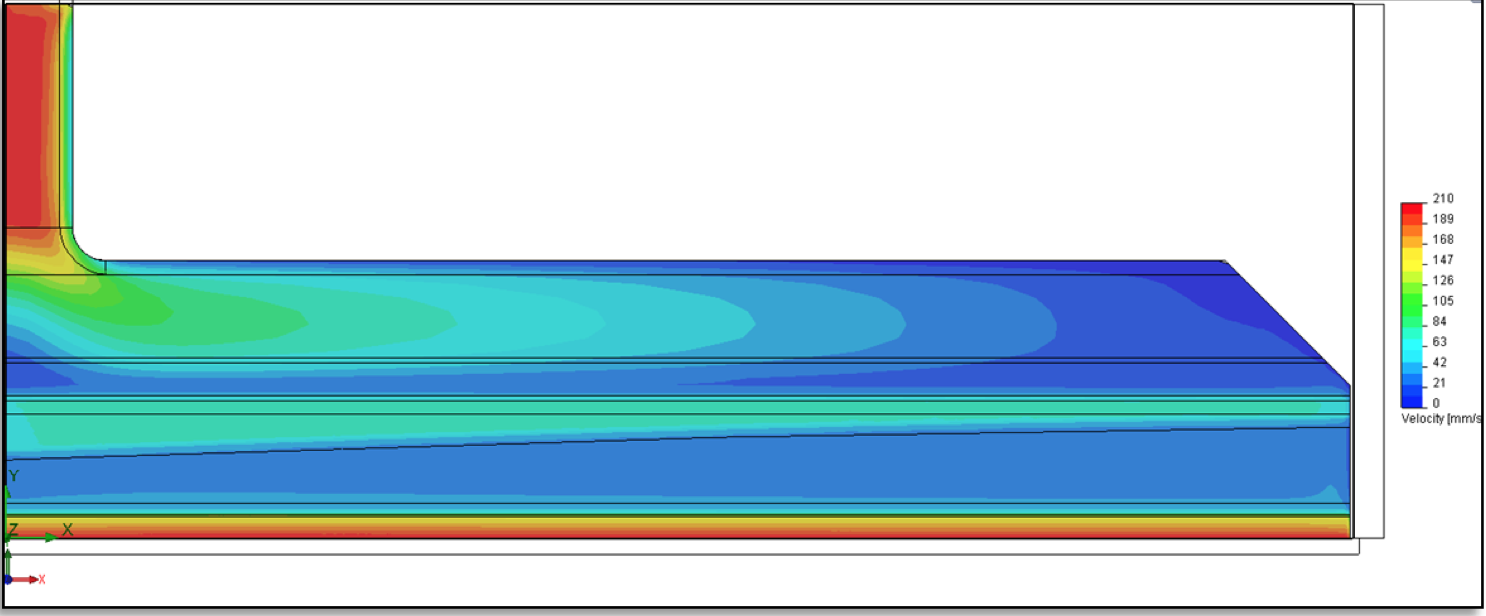

the die. Figure 7 shows the velocity contour plot on the

plane defined at mid-plane of the height of the lip land

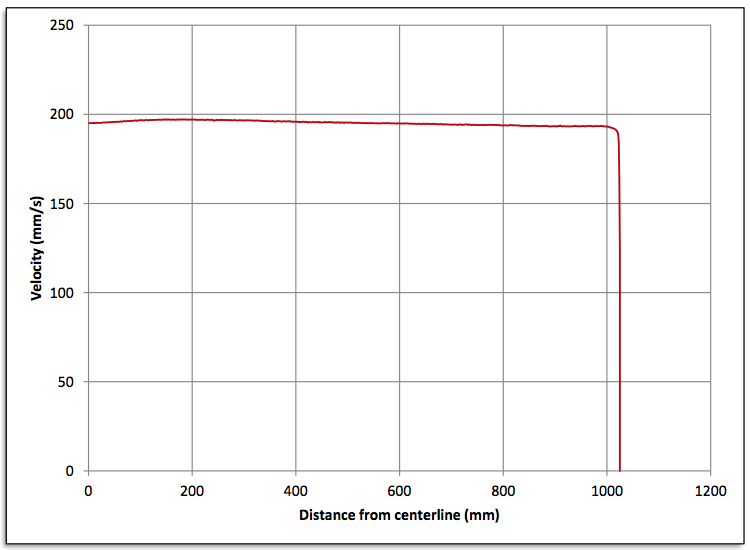

gap. As can be seen in Figure 8, the exit velocity across

the die width is very uniform.

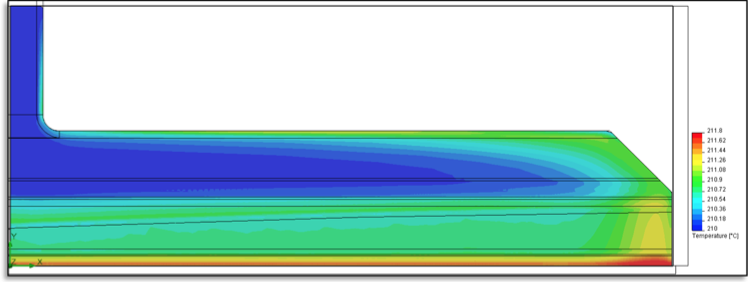

Because of the relatively high melt viscosity, viscous

dissipation in the die can be a legitimate concern.

However, as shown in Figure 9 the predicted temperature

elevation at die exit due to viscous dissipation is

controlled. The plot shows a maximum temperature of

211.8°C at the mid-plane of the flow stream. By way of

general information, the peak temperature proximate to

the die wall, in the lip land area, was calculated at

214.6°C. As usual for non-isothermal flow assuming a

uniform die wall temperature, the warmer portion of the

melt is observed near the die ends of the die width.

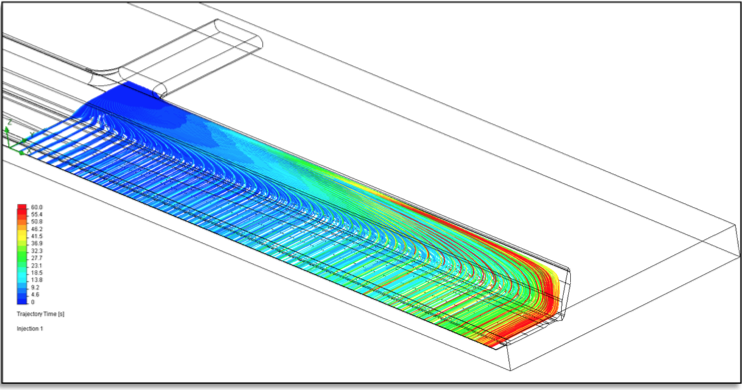

Finally, another critical parameter in this study is the

residence time distribution in the die. For this study, the

numerical estimation of the residence time is very

challenging due to the existence of low flow rate regions.

The best method in this case is to perform a virtual

injection of particles in the flow. Residence time is

evaluated by tracking the particles from the entrance to

the exit. This numerical method is relatively common and

many publications can be found for RTD and mixing

performance estimation in twin screw extrusion[6 -

8]. This method provides a relative comparison of residence time

distribution for different die configurations. There are

many parameters that define a particle injection study, like

for example the type of particle material, the particle size,

the initial temperature etc… These parameters will not be

detailed here, however, in order to compare the die deckle

variations, these parameters are kept constant throughout

the study. One thousand particles were injected in a plane

near the entrance of the manifold channel. On each

resulting particle trajectory, the trajectory time is plotted.

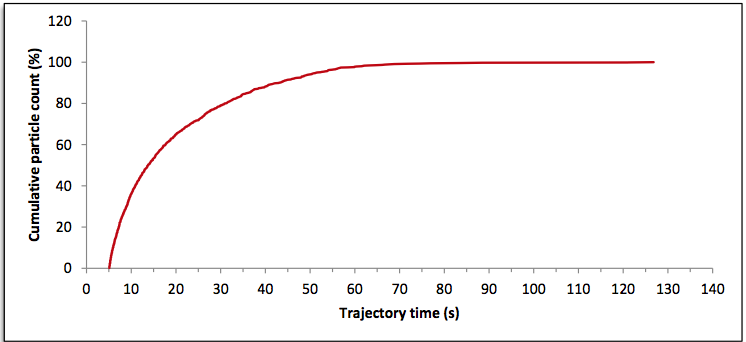

The resulting plot is shown in Figure 10. This particle

injection study yields to statistics of major interest, like

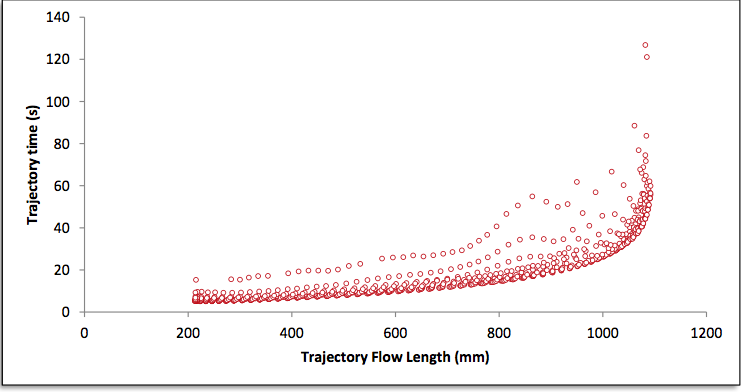

for example, the cumulative residence time distribution curve shown in Figure 11, and the residence time

envelope, shown in Figure 12.

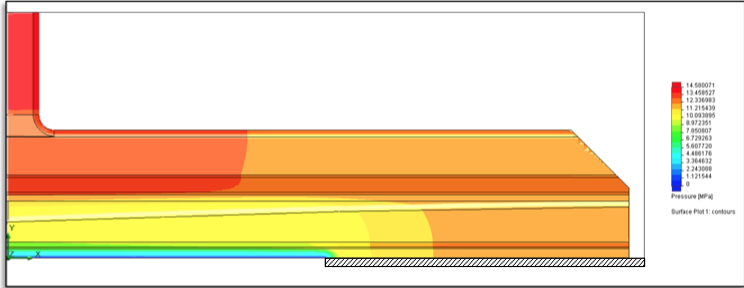

2 - Externally deckled die

Two flow simulations were carried out for the

situation where external deckles are used, corresponding

to deckles of 250 mm per side (total slot width of 1550

mm) - see Figure 13 - and deckles of 500 mm per side

(total slot width of 1050 mm) – see Figure 14.

The total extrusion output was adjusted with the slot

width to keep the specific extrusion output constant, at

3.65 kg/hr/cm. Consequently, the calculated melt pressure

drop in the die for both deckle configurations is close to

that of the full die width. Specifically, the 250 mm deckle

configuration resulted in a melt pressure drop through the

die of 14.7 MPa and the 500 mm deckle configuration in a

melt pressure drop through the die of 14.6 MPa. For

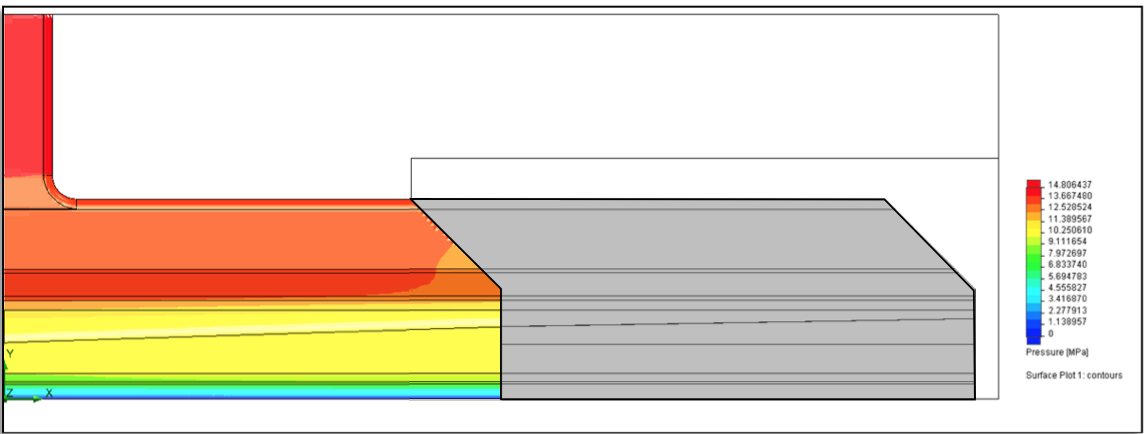

illustrative purposes, the melt pressure contour plot

through the die flow channel using the 500 mm deckles is

shown in Figure 15.

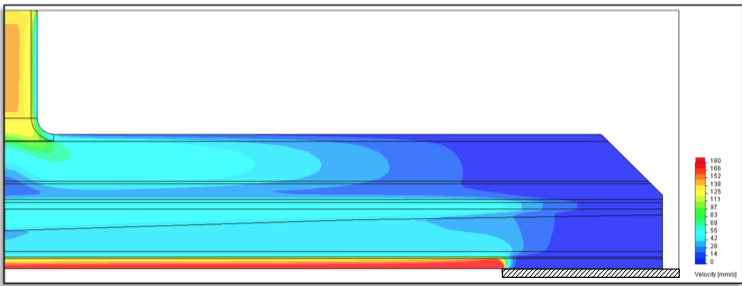

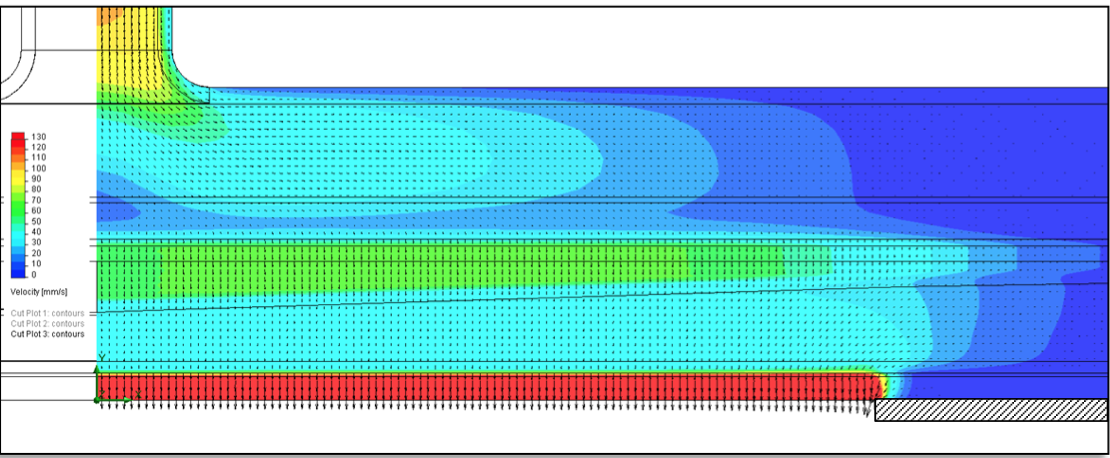

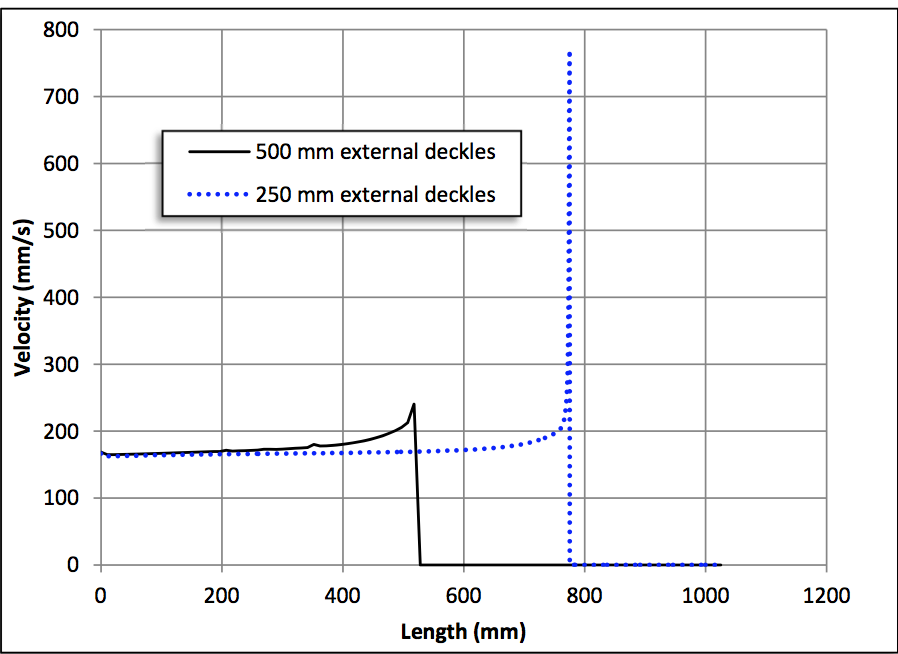

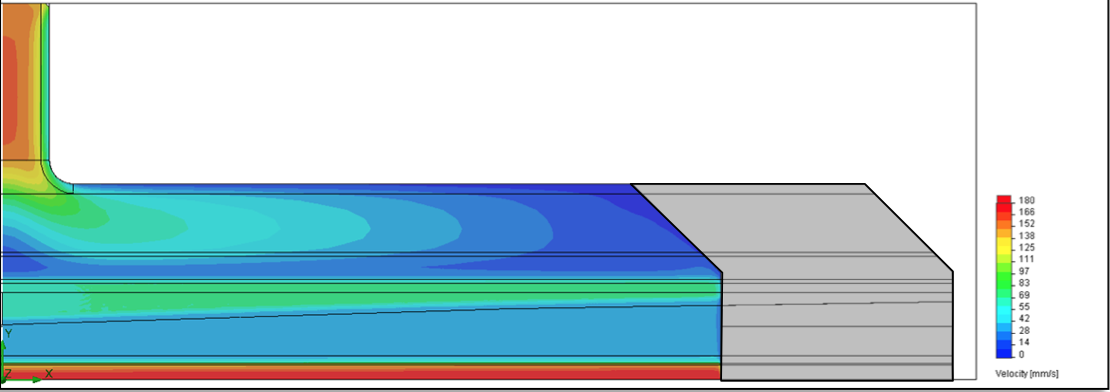

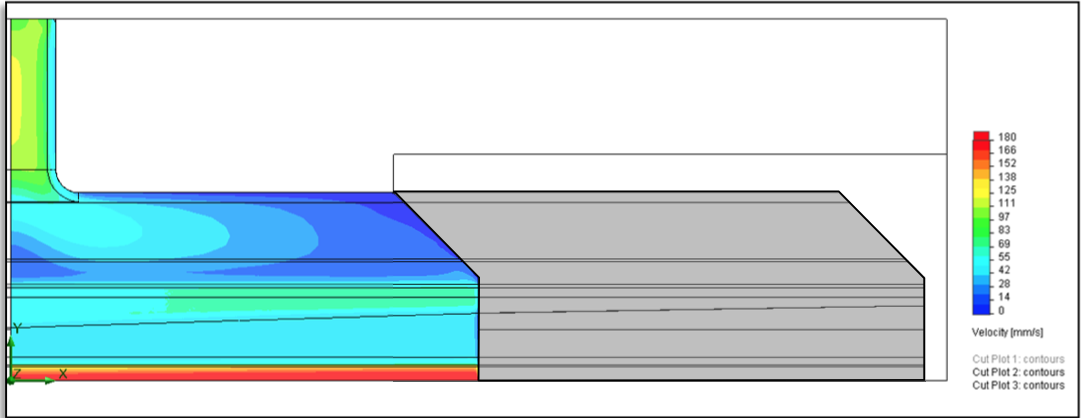

Velocity contour plots for the externally deckled die

are shown in Figure 16 and Figure 17 for the 250 mm

deckles and the 500 mm deckles respectively. These plots

show the occurrence of a large area upstream the deckles

where the flow velocities are low. These zones can be

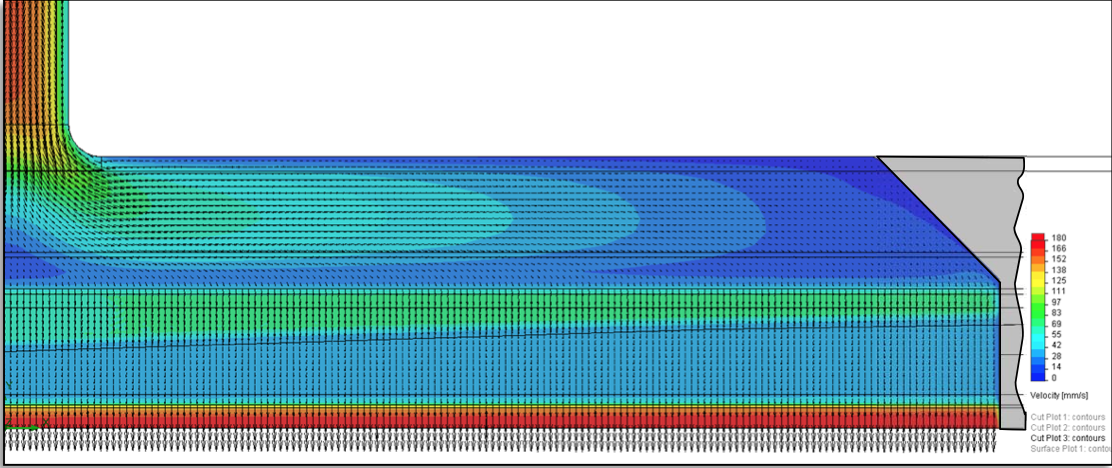

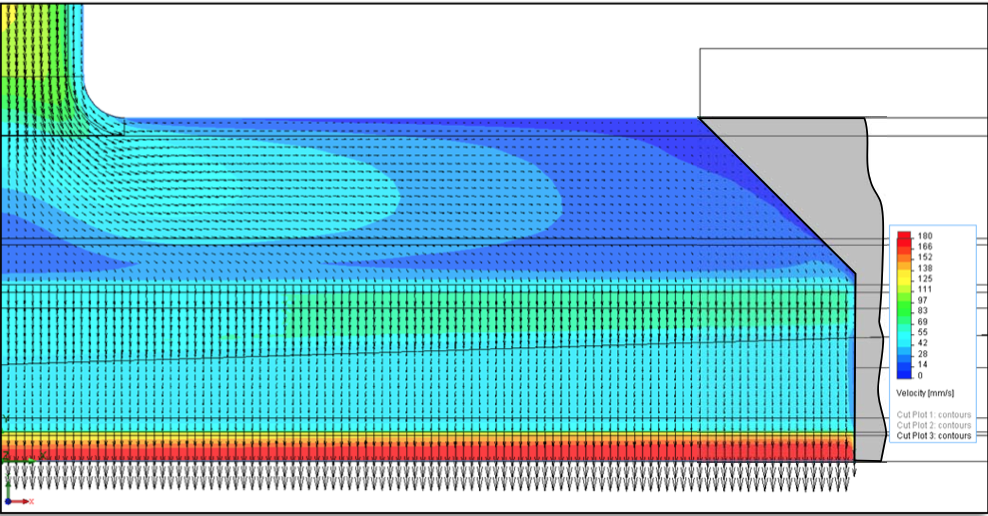

considered stagnation areas. In order to understand the

flow patterns better, velocity vectors are plotted on top of

the contour plots in the deckle area, near the exit. In

particular, Figure 18 shows the existence of a strong

velocity gradient in the area of the slot proximate to the

deckle extremity. This gradient is caused by the excess

polymer flowing from a portion of the area upstream and

behind the deckle. This phenomenon is further

characterized by the exit velocity profiles shown in Figure

19.

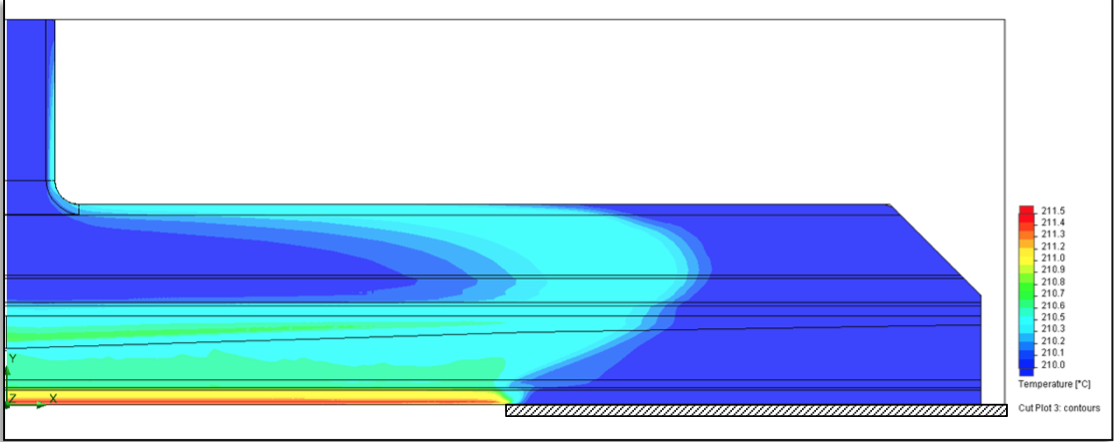

The thermal characteristics of the flow in the

externally deckled dies are illustrated by the temperature

contour plot shown in Figure 20. This shows a classic

shear heating effect on the side walls of the entrance

channel, along the back wall of the manifold channel.

However, the melt is dissipating heat in the area upstream

and behind the deckled region to match the die wall

temperature owing to the very low flow velocities. As a

result, this cold area provides a good correlation to the

stagnant melt flow regimes.

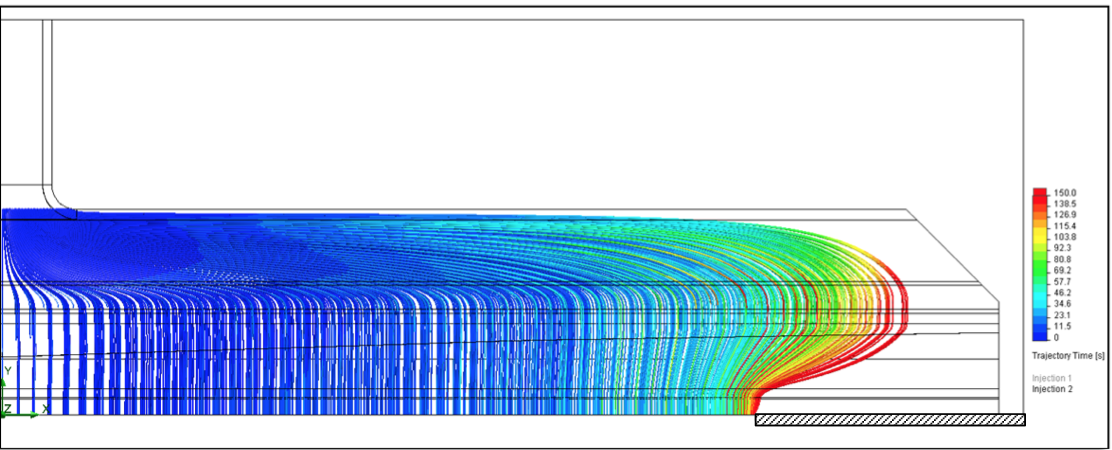

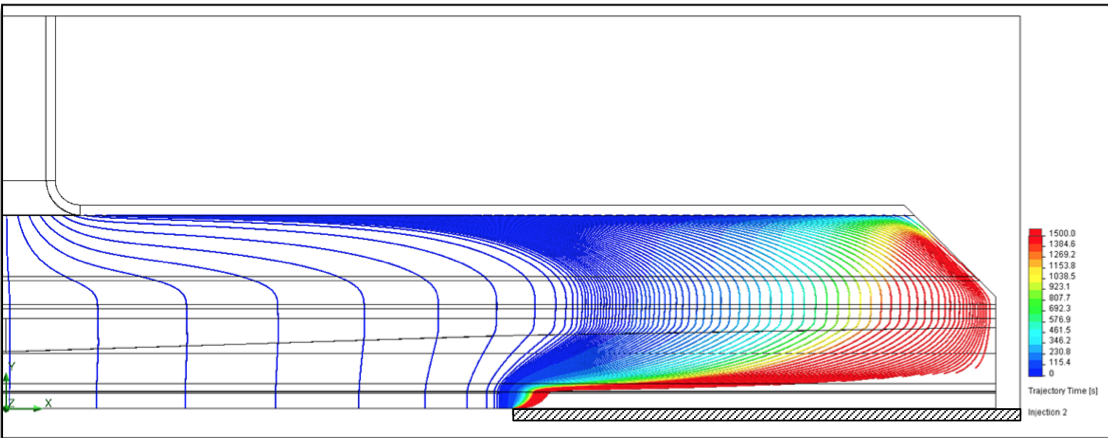

Capturing the residence time distribution in the

deckled configuration proved challenging; and two steps

are necessary to really evaluate the whole die flow

pattern. When using the particle injection near the

manifold channel entrance similarly to what is done for

the full width die, it is possible to compare the residence

time figures to that of the full width reference. However, this particle injection method does not fully capture the

high residence time area at the very ends of the flow

channel and immediately upstream the deckles, as shown

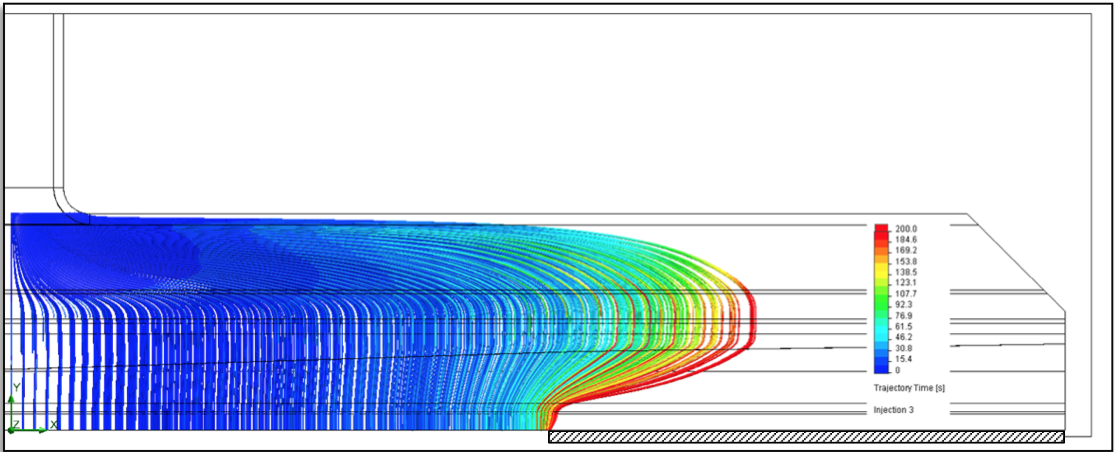

by the particle trajectories in Figure 21 and Figure 22.

These trajectories however may be seen as the measurable

majority of the flow reaching the die exit and therefore, it

is interesting to study their statistics compared to the full

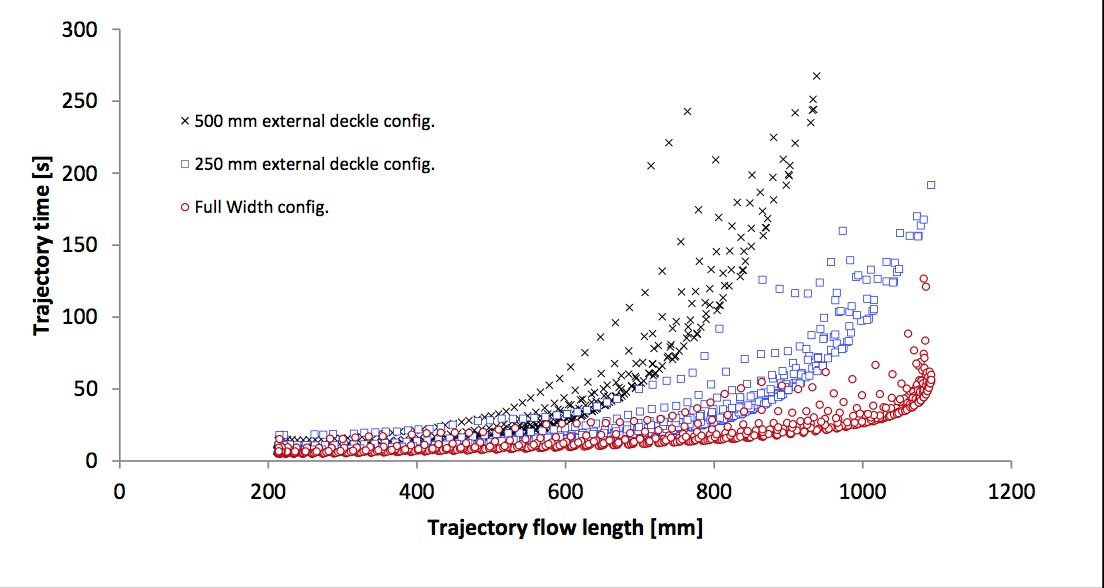

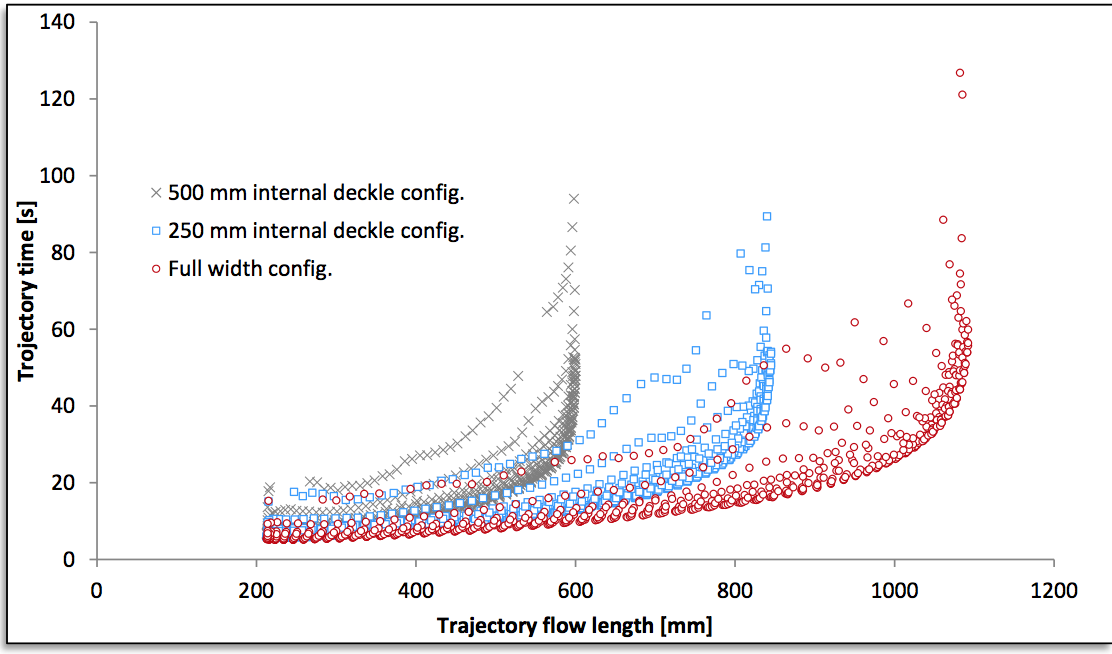

width configuration. For example the cloud plots of

trajectory time versus trajectory flow length for all three

configurations (Figure 23) show interesting results. The

larger the deckles, the longer the residence time, despite

the shorter flow lengths associated with the active width

of the die. Interestingly, the maximum flow length for the

250 mm deckle configuration is very close to that of the

full width configuration because of the flow trajectories

inside the low velocity region ultimately exit the die near

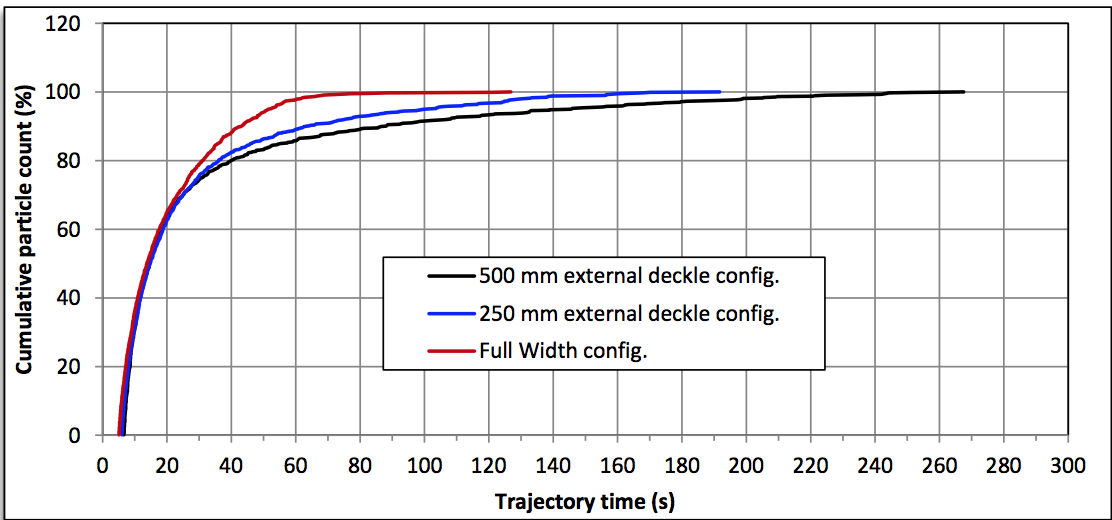

the deckle inner end defining the exit slot. The RTD

curves (Figure 24) characterize residence time associated

with external deckles.

Nevertheless, these figures are not complete because

as mentioned before, the trajectories do not capture the

regions near the end of the manifold channel. It is possible

to obtain a representation of the residence time in these

regions when injecting particles along the back of

manifold channel, as close as the entrance as possible.

Figure 25 shows that the residence time in these regions

can be well in excess of 300 s for the 250 mm external

deckle configuration, while Figure 26 illustrates a

residence time greater than 1,500 s for the 500 mm deckle

configuration. While these numbers should not be

interpreted as absolute values, they provide a good

indication of the flow pattern and RTD in the externally

deckled dies. As can be appreciated from this modeling,

residence time increases exponentially with external

deckle width.

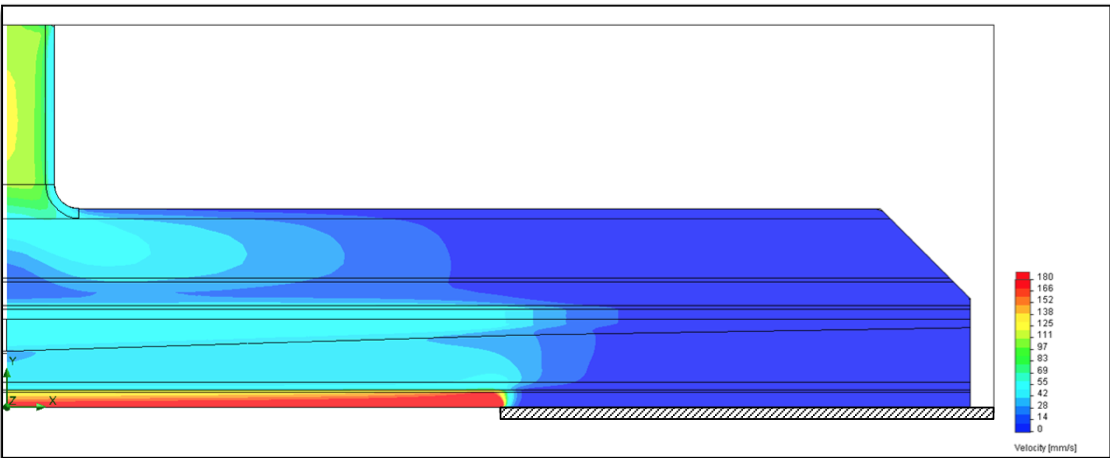

3 - Internally deckled die

Similar to the flow simulations for the external deckle

system, two flow simulations were run for the internal

deckle scenarios with 250 mm and 500 mm deckles

respectively. The principles applied for the boundary

conditions for the internal deckle models were the same as

for the external deckle flow simulations.

Calculated pressure drop is about 14.8 MPa for both

conditions, which is comparable to the full width model.

This is expected because the specific output is kept

constant relative to the effective slot width for all the

simulations. For illustration purposes, the pressure

contour plot for the 500 mm internal deckle scenario is

shown in Figure 27.

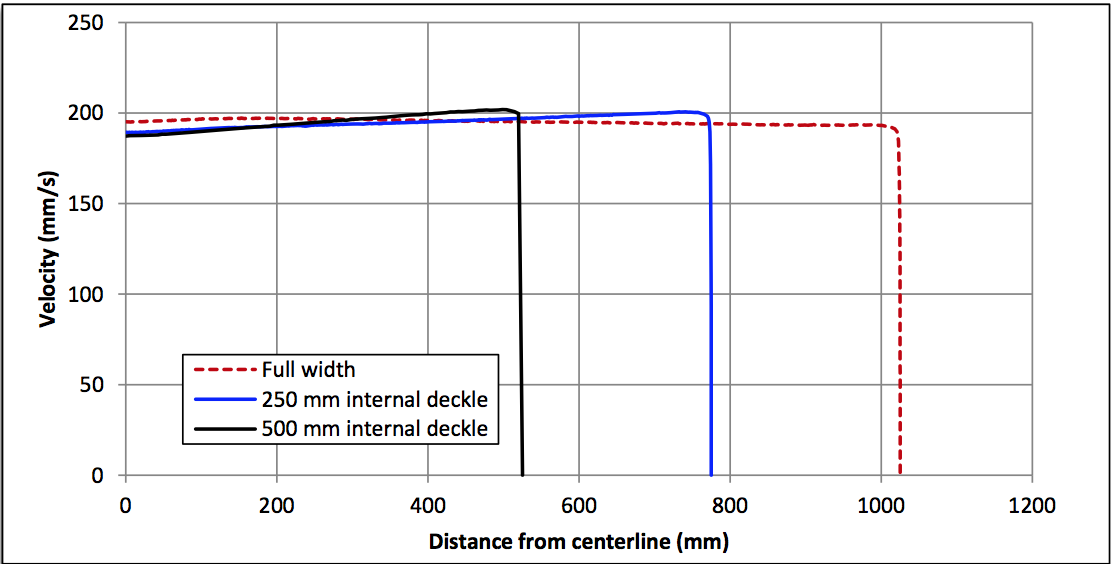

Velocity contour and vector plots are shown in Figure

28 and Figure 29 respectively, for the 250 mm internal

deckles; and in Figures 30, 31 respectively, for the 500 mm internal deckles. The internal deckle configuration

results in higher overall flow velocities compared to the

corresponding external deckle widths. The internal deckle

device beneficially replaces this low velocity regimes

present in the flow channel when using the external

deckles. Also, the flow velocities at the die exit are much

improved. Compared to the external deckle scenario,

internal deckles result in a much more uniform velocity

profile at the exit of the die, particularly at the end regions

of the deckled die width. The velocity surge that was

present with external deckles at the die exit near the

deckle is nonexistent with internal deckles. Figure 32

shows the flow profile at the die lips. It exhibits slightly

more end flow when wider deckles are used. The die

preland, which is designed to uniformly distribute the

flow across the full slot width, becomes less adapted for

narrower slot widths. However, this behavior is acceptable

because even when using 500 mm deckles, the flow

distribution is satisfactory and well within the range of

correction from typical lip adjustment systems.

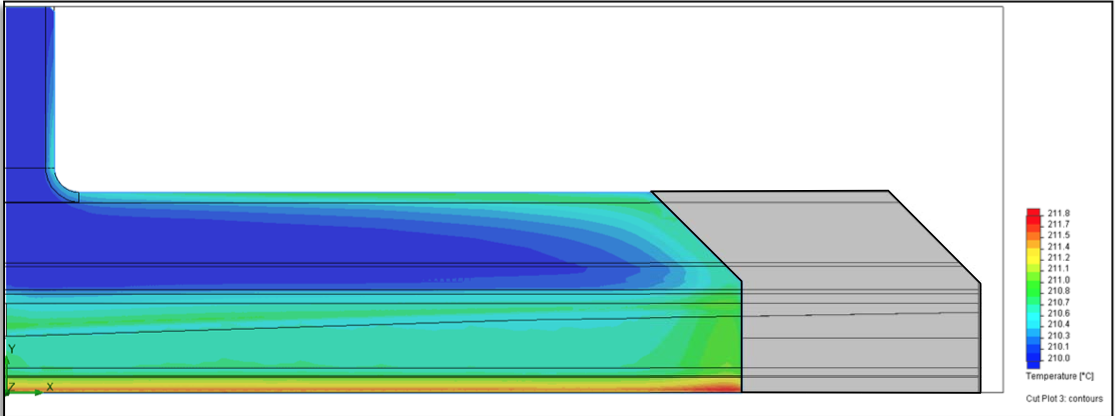

The melt temperature pattern is very similar to that of

the full width die, with temperature gradients from the

wall to the mid-plane of the channel. The temperature

contour for the 250 mm internal deckle configuration is

shown in Figure 33. The temperature profile at the die lips

exhibits slightly warmer melt near the ends, which is a

signature of shear heating in the flow channel. The

intensity of this phenomenon however is largely

insignificant as demonstrated by the modest temperature

increase (1.8°C).

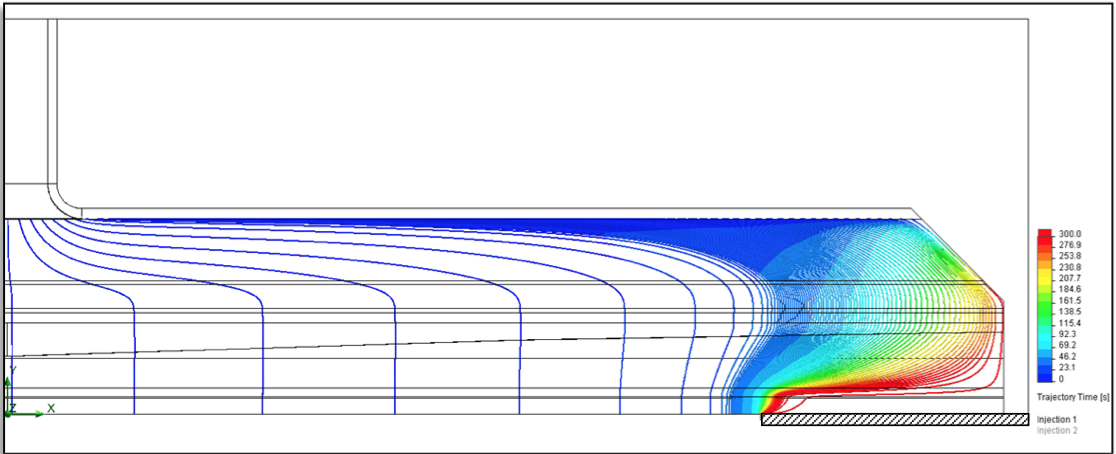

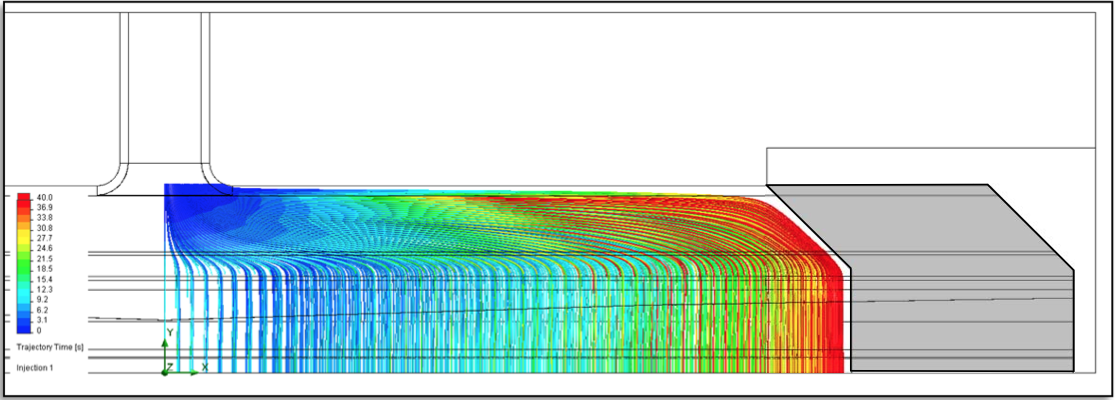

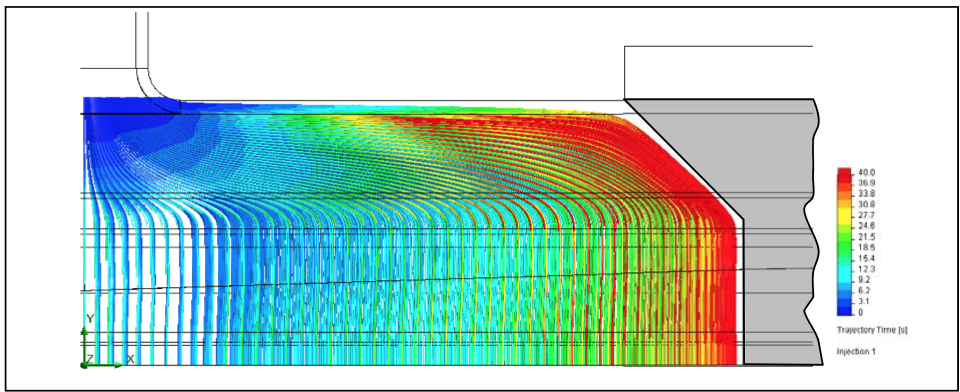

The virtual particle injection method was used to

evaluate the RTD for internal deckle configurations. The

resulting particle tracings are shown in Figure 34 and

Figure 35 when injecting particles near the entrance of the

manifold channel for the 250 mm internal deckle

configuration and the 500 mm internal deckle

configuration respectively. This analysis shows a

relatively streamlined flow pattern, equivalent to that of

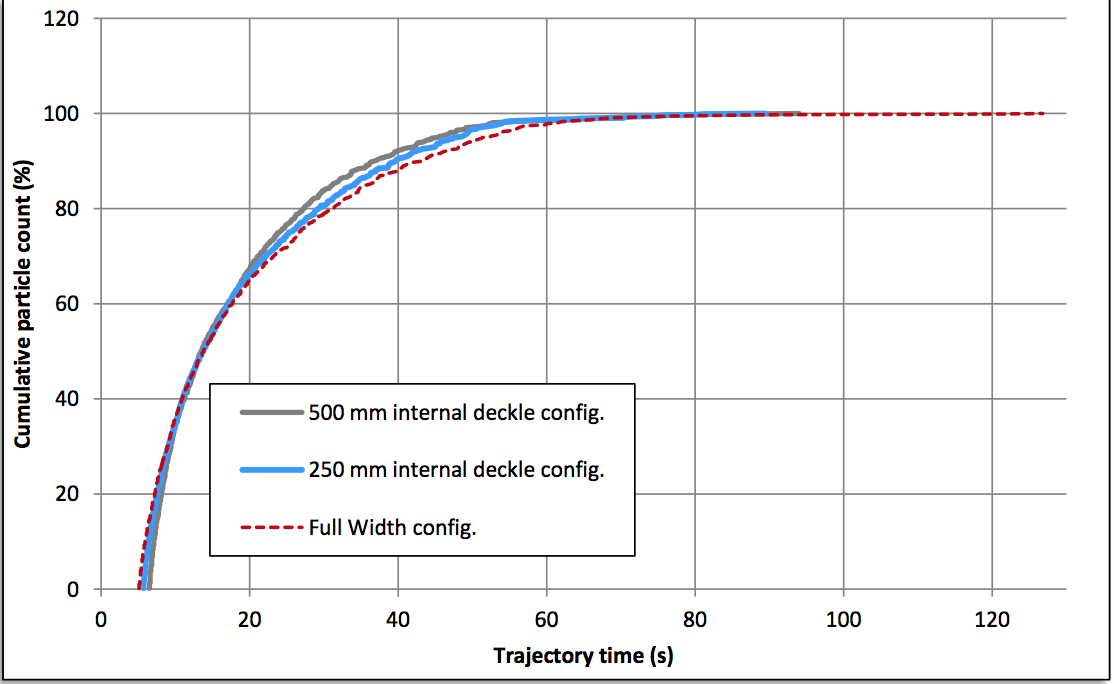

the full width die in both cases. The relationship between

residence time and flow length is shown in cloud graph in

Figure 36. The shapes of the RTD clouds show that

internal deckle configurations behave very similarly to a full width die. Correspondingly, the shapes of the RTD

curves (shown in Figure 37) exhibit a behavior of

similarity between internally deckled and the full width

configuration dies. The main different lays in the smaller

values of maximum residence time when using wider

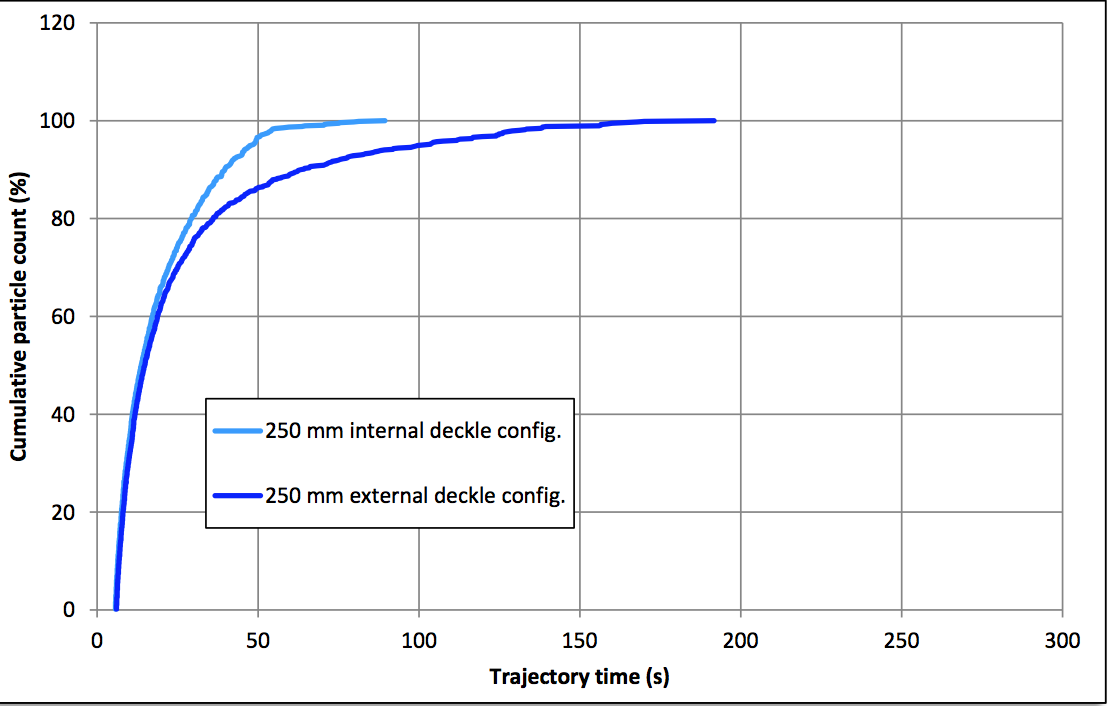

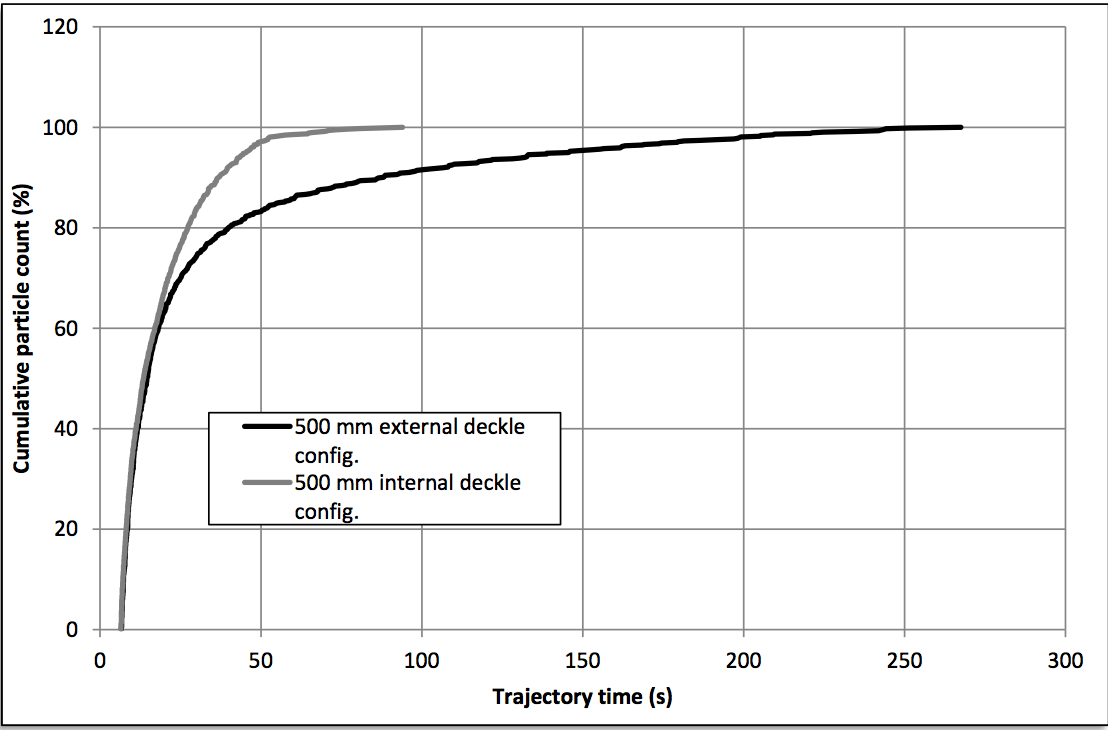

deckles (narrower slot width). Finally, a direct comparison

of RTD curves between the internal style and external

style deckles is shown in Figure 38 for the 250 mm deckle

configurations and Figure 39 for the 500 mm deckle

configurations.

Conclusion

CFD was successfully used to compare two

styles of deckle systems commonly used in flat film or

sheet extrusion. The use of advanced CFD tools like

virtual particle tracking allows for the performance

evaluation of the polymer flow between two different

deckle configurations. For instance, it is possible to

illustrate and quantify the flow stagnation upstream of

external deckles. Flow non-uniformity with this system is

also demonstrated. By comparison, it was found that

internal deckle systems compare very similarly to full

width dies as the flow at the exit of the die remains fairly

uniform and unaffected by the die width.

[1] O. Catherine, SPE-ANTEC Tech Papers (2011)

[2] M. M. Cross, Polymer Systems: Deformation and

Flow (1968)

[3] M. L. Williams, R. F. Landel and J. D. Ferry, J. Am.

Chem. Soc., 77, 3701 (1955)

[4] J. D. Ferry, Viscoelastic properties of polymers. 3rd

edit. (1980)

[5] Dassault Systèmes, S.A.

[6] V. L. Bravo, A. N. Hrymak, and J. D. Wright, Polym.

Eng. Sci., 44: 779–793 . (2004)

[7] X. –M Zhang, L.-F Feng, W.-X Chen and G.-H Hu,

Polym. Eng. Sci., 49: 1772–1783 (2009)

[8] F. Ilinca, J. F. Hetu, Intern. Polym. Proc., XXV 4:

275-285 (2010)

Figure 1. Schematic of a fixed width internal deckle system

Figure 2: External deckle system consisting of (1) a seal, (2) the deckle seal plate and (3) retaining fingers with (3) set screws

Figure 3: Die geometry used for the flow studies – plane view

Figure 4: Die geometry used the flow studies – side view

Figure 5: Viscosity curves of the selected Cross WLF model

Figure 6: Pressure drop profile at the centerline in the main flow direction (machine direction), from entrance (0 mm) to exit (400 mm), showing the contribution of the flow channel portions

Figure 7: Velocity contour plot on the plane defined a mid-height of the lip land

Figure 8: Computed exit velocity profile

Figure 9: Temperature contour plot on the plan defined at mid-height of the lip land gap

Figure 10: Estimation of residence time distribution by virtual particle injection

Figure 11: RTD (Residence Time Distribution) curve for full width die

Figure 12: Trajectory time across the die width as a function of trajectory length for full width configuration

Figure 13: Die geometry for 250 mm external deckles

Figure 14: Die geometry for 500 mm external deckles

Figure 15: Melt pressure distribution map in the die using the 500 mm external deckles

Figure 16: Velocity contour plot through the flow channel with 250 mm external deckle

Figure 17: Velocity contour plot through the flow channel with 500 mm external deckles

Figure 18: Velocity contour plot superimposed with velocity vectors representing the direction and the intensity of the velocity field

Figure 19: Exit velocity profiles for the externally deckled die

Figure 20: Temperature contour plot on midplane for the 500 mm external deckle configuration

Figure 21: Result of virtual particle injection for the die with the 250 mm external deckle configuration - Particles injected near the entrance to the manifold channel

Figure 22: Result of virtual particle injection for the die with the 500 mm external deckle configuration - Particles injected near the entrance to the manifold channel

Figure 23: Comparison of trajectory time to trajectory flow length clouds for external deckle configurations

Figure 24: Comparison of cumulative residence time distribution curves for external deckle configurations

Figure 25: Result of virtual particle injection for the die with the 250 mm external deckle configuration - Particles injected at the midplane near the back wall of the manifold channel

Figure 26: Result of virtual particle injection for the die with the 500 mm external deckle configuration - Particles injected at the midplane near the back wall of the manifold channel

Figure 27: Melt pressure contour plot for the 500 mm internal deckle configuration

Figure 28: Velocity contour plot for the 250 mm internal deckle configuration

Figure 29: Velocity contour plot superimposed with velocity vectors representing the direction and the intensity of the velocity field for the 250 mm internal deckle configuration

Figure 30: Velocity contour plot for the 500mm internal deckle configuration

Figure 31: Velocity contour plot superimposed with velocity vectors representing the direction and the intensity of the velocity field for the 250 mm internal deckle configuration

Figure 32: Velocity profile at the die lips (at mid plane)

Figure 33: Melt temperature contour plot on the mid plane of the die for the 250 mm internal deckle configuration

Figure 34: Result of virtual particle injection for the die with the 250 mm internal deckle configuration - Particles injected at the midplane near the entrance of the manifold channel

Figure 35: Result of virtual particle injection for the die with the500 mm internal deckle configuration - Particles injected at the midplane near the entrance of the manifold channel

Figure 36: Comparison of trajectory time to trajectory flow length clouds for internal deckle configurations

Figure 37: Comparison of cumulative residence time distribution curves for internal deckle configurations

Figure 38: Comparison of RTD curves for internal and external deckles (250 mm)

Figure 39: Comparison of RTD curves for internal and external deckles (500 mm)

Return to

Paper of the Month.