Observations of Liquid-Liquid Encapsulation in Coextrusion of Inelastic Newtonian Fluids

Jonathan Lee, Jeffrey S. Allen, and Mahesh Gupta

Michigan Technological University, Houghton, MI 49931, USAAbstract

The conditions under which liquid-liquid

encapsulation can occur in coextrusion of polymers have

been experimentally studied. The objective of this study

was to determine if liquid-liquid encapsulation is a viscous

phenomenon, viscoelastic phenomenon, or a combination

of the two. The experimental observations discussed herein

focus on the role of viscous stresses on encapsulation in the

absence of viscoelastic behavior. Experiments with two

inelastic Newtonian fluids flowing side-by-side in a

transparent channel were conducted. Different

combinations of glycerol, silicone oil, and motor oil were

employed for the bi-layer flow experiments. Irrespective of

the difference in the viscosity, no core-annular

encapsulation was observed for bi-layer flows of glycerol

and silicone oil. In two of the experiments with bi-layer

flow of motor oil and silicone oil, motor oil encapsulated

the silicone oil, even when the viscosity of motor oil was

higher than the viscosity of the silicone oil. Since the flow

behavior remained unaffected even with large variation in

the viscosity of the fluids employed, it is concluded that

other fluid properties besides viscosity, such as wettability

of the fluid, may play an important role in reaching the

core-annular encapsulation often observed in bi-layer

flows. When gravity was acting perpendicular to the flow

direction the difference in the density of the fluids also

affected the layer arrangement.

Introduction

Liquid-liquid encapsulation is used to describe the

tendency of a liquid to displace another liquid in a

direction perpendicular to the flow direction, often along

the channel walls. This can result in one liquid forming an

annulus by completely wrapping around a core of another

fluid. Encapsulation has been observed in several fluidic

transport applications including the coextrusion of

viscoelastic polymers [1] as well as the lubricated

pipelining of crude oil and water, which are purely viscous

in nature [2]. There is disagreement in the literature on

whether viscosity difference alone result in encapsulation

or if other fluid properties need to be considered as well.

Some experimental observations report encapsulation is

driven by viscosity differences, but no model has been

shown to properly explain the behavior [3]. Multiple

unsuccessful attempts have been made at numerical

prediction of the encapsulation phenomenon using

generalized Newtonian formulations [4-6]. This indicates that a fluid property other than viscosity difference may

affect the initiation and development of encapsulation. The

results of an experimental parametric study of bi-layer flow

of several different fluid combinations are reported in this

paper.

Experimental Setup

Transparent channels were constructed to observe the

interaction of two fluids in a bi-layer flow. A 115 mm long

1 mm by 1 mm groove was micro-milled out of a smooth

12.5 cm thick polycarbonate plate such that two fluids

enter the channel at separate ports and converge at an angle

of 60° in a Y configuration. The machined surface of the

plate was clamped to another polycarbonate plate to form

the fourth wall of a square channel.

Transparent fluids were necessary in order to see

through the entire depth of the channel. Liquid-liquid

diffusion was avoided by running the experiments with

immiscible fluid pairs. One fluid pair was glycerol (Sigma

Aldrich) with polydimethylsiloxane (PDMS) silicone oil

(Gelest, Inc.). Another fluid pair was motor oil (Valvoline)

with the same PDMS silicone oil. Four different viscosity

grades of PDMS silicone oil were used with the glycerol

and motor oil to experiment with different viscosity ratios

between the fluids. All of these fluids are Newtonian with

fluid properties listed in Table 1.

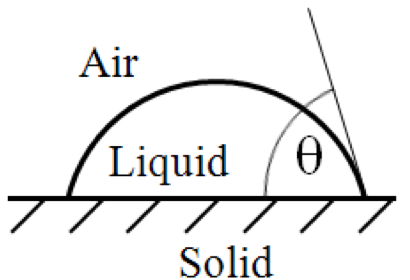

Viscosities of the fluids were determined using

Cannon-Fenske viscometers. Specific gravity values in

Table 1 are based on manufacturer specifications. The

contact angle of glycerol was measured by placing a drop

of the liquid onto a polycarbonate surface and observing

the angle, θ, that the fluid formed at the solid-liquid-air

interface. Figure 1 shows an illustration of this contact

angle measurement. The contact angles for the motor oil

and the silicone oils were too small to be accurately

measured by viewing a liquid drop on a polycarbonate

plate from the orientation indicated in Figure 1.

Approximations of the contact angles for these fluids are

shown in Table 1. Accurate measurements of the contact

angle for motor oil and silicone oil are currently being

performed.

Accurately visualizing the three-dimensional bi-layer

flow required an ability to focus on different planes at

various depths within the channel. To achieve a variabledepth

focus, fluorescent microparticles were added to the

fluids. A fluorescent light source was used for excitation of

the fluorescent microparticles and a stereomicroscope with

fluorescent filters allowed the particles to be focused upon

at different depths of the channel.

All experiments were performed at room temperature

with syringe pumps moving the fluids through the channel

at matched flow rates. The fluids were introduced into the

channel by first filling the channel with one fluid, and then

introducing the second fluid to generate a layered flow

condition. All experiments were repeated by alternating

which fluid was introduced to the channel first to observe

any difference in the final flow configuration. The

experiments were repeated with the channels oriented

horizontally and vertically to verify that gravity was not

inducing or hindering any encapsulation effects in any of

the experiments. The fluids were pumped over a range of

flow rates from 0.12 to 3.58 mm

3/sec. All of the reported

observations are based on repeated results from multiple

experiment trials.

Experimental Observations

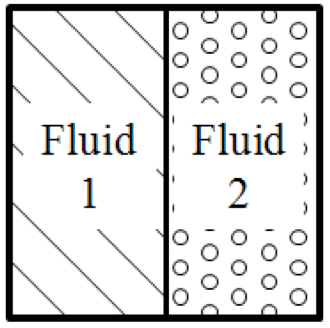

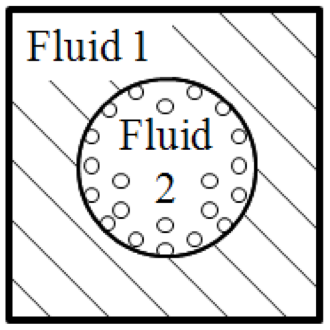

The configuration of the two fluids at the initial

contact with each other at the Y intersection is referred to

as a side-by-side configuration and is illustrated in Figure

2. As the side-by-side co-flow fluids travelled down the

channel the final flow configuration at the exit either (i)

remained unchanged, (ii) remained side-by-side with the

fluid interface oriented in a new direction with respect to

gravity, or (iii) evolved to fully encapsulated flow as

illustrated in Figure 3.

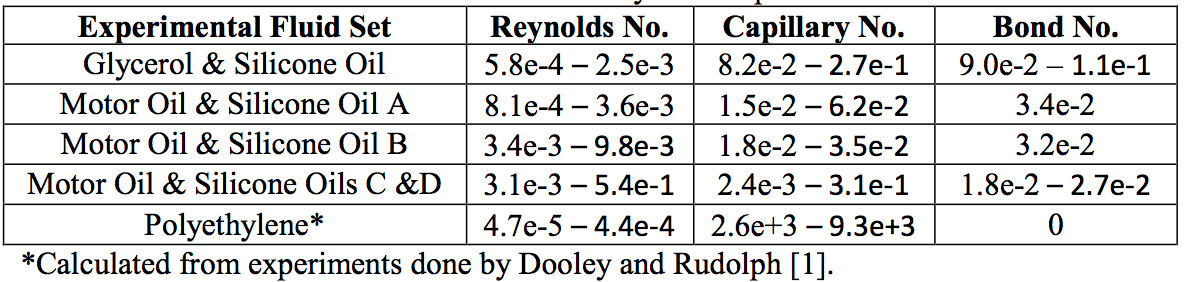

Values of Reynolds, capillary, and Bond numbers are

listed in Table 2 to quantify the relations of inertia to

viscosity, viscosity to surface tension, and gravity to

surface tension observed in each experimental set.

Approximate values of dimensionless numbers from

coextrusion of polyethylene performed by Dooley and

Rudolph [1] are included in Table 2 for comparison with

the conditions and fluids used in these experiments. The

Reynolds and Bond numbers indicate that inertia and

gravity have small influence on the liquid-liquid systems as

in a typical polymer coextrusion. However, the capillary

numbers indicate that surface tension effects here are more

prevalent relative to viscous effects here than in polymer

coextrusion. Despite the capillary number differences,

encapsulation as observed in polymer coextrusion has also

been observed in some of the experiments in this work.

Glycerol and PDMS Silicone Oil¶

The glycerol-silicone oil experiments never exhibited

encapsulation regardless of the viscosity difference

between the two liquids. The initial side-by-side flow

configuration was maintained throughout the length of the channel even though glycerol was much more viscous than

the silicone oils A, B, C, and D as listed in Table 1.

In the set of experiments where gravity acted

perpendicular to the flow direction, buoyancy-induced

layer rearrangement was observed. The lighter silicone oil

displayed a tendency to gravitationally stratify on top of

the heavier glycerol while the large contact angle of the

glycerol resisted deformation and limited the development

of the buoyancy driven layer rearrangement. Additionally,

the order in which the liquids were introduced affected the

extent of the development of gravitational stratification

relative to the initial side-by-side configuration. As the

thinner and more wetting fluid, silicone oil did not displace

the glycerol as easily as the glycerol displaced the silicone

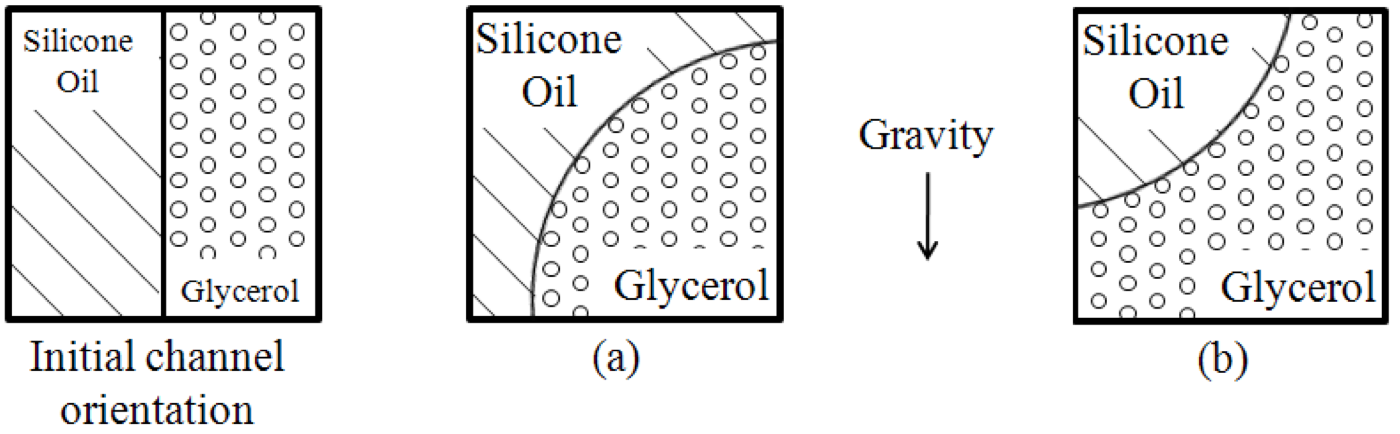

oil. Figures 4 and 5 illustrate a situation in which different

final flow configurations were observed by changing only

the order in which the fluids were introduced to the system.

Motor Oil and PDMS Silicone Oil¶

Encapsulation was observed for certain motor oilsilicone

oil combinations. When the high viscosity silicone

oil (A) was used, the less viscous motor oil fully

encapsulated the more viscous silicone oil regardless of the

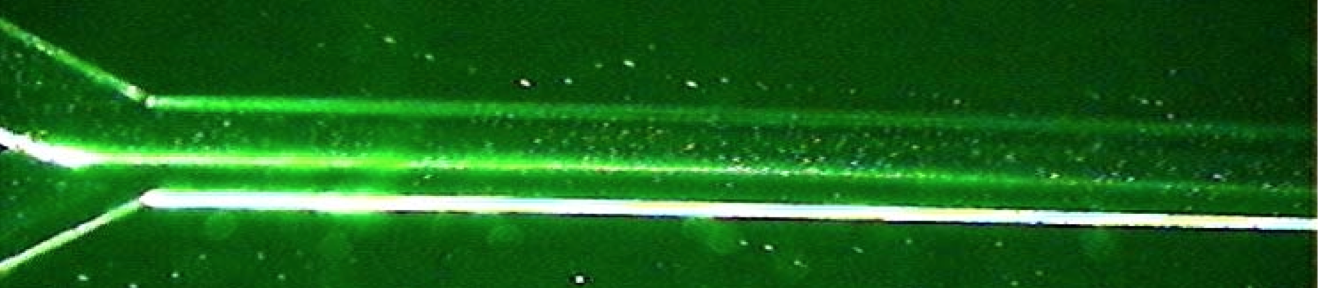

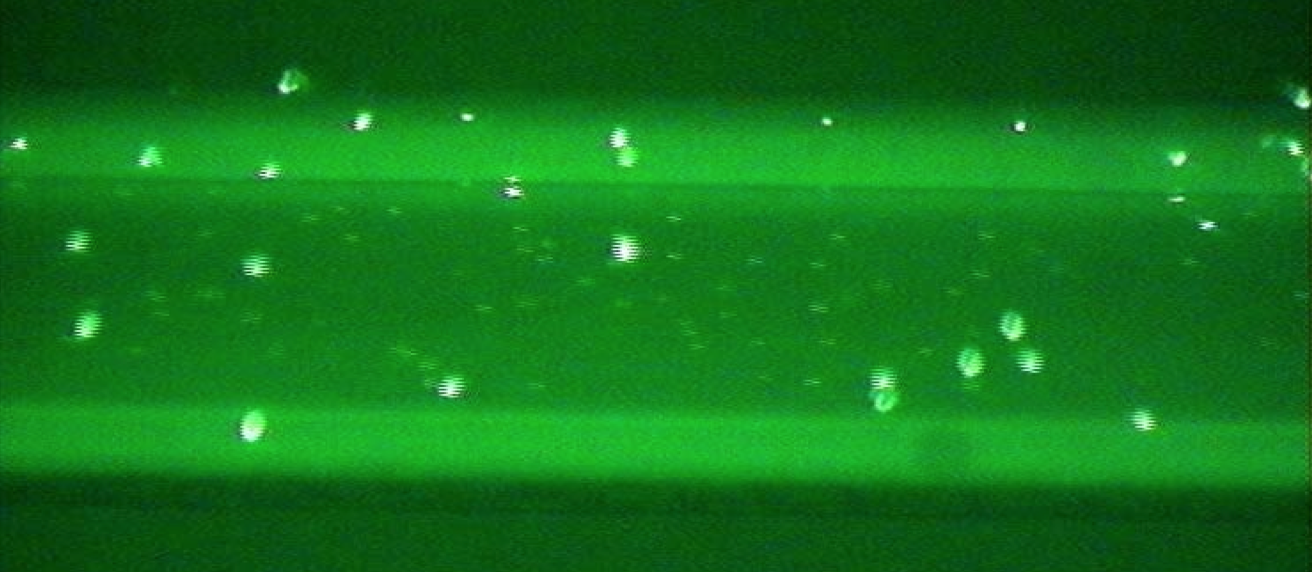

orientation of gravity. Images of encapsulated flow from

the motor oil-silicone oil (A) experiments are shown in

Figures 6 and 7.

When silicone oil (B), which has a smaller viscosity

than that of the motor oil, was used, the more viscous

motor oil fully encapsulated the less viscous silicone oil

regardless of the orientation of gravity. Figures 8 and 9

show the encapsulated flow from these experiments.

When either silicone oils (C) or (D) were used with

motor oil and the gravity was along the flow direction, in

spite of the large difference between the viscosities of the

motor oil and the two silicone oils the initial side-by-side

flow configuration was maintained for the length of the

channel. The side-by-side flow configuration in the

absence of buoyancy driven layer rearrangement is

depicted in Figures 10 and 11. When the gravity acted

perpendicular to the flow direction gravitational

reorientation occurred in both of these sets of experiments.

The buoyancy-induced layer rearrangement that occurred

in these experiments is illustrated with Figures 12 and 13.

Discussion

Glycerol and PDMS Silicone OilThe relatively large contact angle of glycerol was an

important factor in the final flow configuration in these

experiments. Figure 5 illustrates that the gravitational layer

rearrangement never reached a fully stratified state in the

glycerol-silicone oil experiments when gravity acted perpendicular to the flow direction. In contrast, Figures 12

and 13 illustrate that in the motor oil-silicone oil

experiments the gravitational layer rearrangement always

reached a fully stratified state. These differing observations

can be explained by the large contact angle of the glycerol.

The forces necessary to deform the glycerol contact line

perpendicular to the flow direction had an apparent

minimizing effect on the extent to which any gravitational

layer rearrangement occurred. Subsequently, the less

viscous silicone oil did not encapsulate the more viscous

glycerol as expected. The absence of encapsulation may

have been due to contact line pinning at the liquid-liquid-solid

interface.

Motor Oil and PDMS Silicone OilEncapsulation as reported by the literature claims that

the less viscous liquid will encapsulate the more viscous

liquid [1-6]. With silicone oil (A) this encapsulation was

observed. The experiments with silicone oil (B) and motor

oil resulted in the more viscous liquid encapsulating the

less viscous liquid. Because this “inverse encapsulation”

occurred in purely viscous fluids, an analysis suggests that

at least one property of Newtonian liquids other than

viscosity plays a role in the onset of liquid-liquid

encapsulation. The experiments with silicone oils (C) and

(D) with motor oil resulted in no encapsulation. Just like

with the glycerol experiments it is suggested that the larger

contact angle of the motor oil could have been resisting the

displacement by the thinner silicone oils along the channel

walls.

Conclusions

Transparent Newtonian fluids pumped through a

polycarbonate channel were visualized through a

stereomicroscope via fluorescent excitation of

microparticles. Either side-by-side or encapsulated flow

were observed as the final flow configuration in all of the

experimental combinations. Gravitational influence was

observed in all experiments in which gravity was acting

perpendicular to the direction of flow. However, the effect

of gravity did not change the final flow configuration from

the type which was observed when the gravity was acting

parallel to the direction of flow.

Encapsulation did not occur between glycerol and any

of the silicone oils. The relatively large contact angle of the

glycerol is expected to have been nullifying any force imbalance that would otherwise have initiated

encapsulation.

Encapsulation as described by the literature occurred

between motor oil and silicone oil (A). In this situation the

more viscous fluid was encapsulated by the less viscous

fluid. However, the opposite type of encapsulation

occurred between motor oil and silicone oil (B). Here the

less viscous fluid was encapsulated by the more viscous

fluid. There is currently no suggested explanation for this

phenomenon. In the experiments of motor oil and silicone

oils (C) and (D) a side-by-side configuration was the

resultant flow configuration. The apparent contact angle

difference between the fluids could once again lead to the

explanation for the lack of encapsulation in these trials.

Acknowledgements

This research was supported by the Department of

Mechanical Engineering - Engineering Mechanics at

Michigan Technological University. The authors would

like to thank Dr. Morrison and Jithendar Gujja for

assistance with fluid viscosity measurements.

References

1. J. Dooley and L. Rudolph, “Viscous and Elastic Effects

in Polymer Coextrusion”, Journal of Plastic Film &

Sheeting, 19, 111 (2003).

2. D. D. Joseph, “Lubricated pipelining”, Powder

Technology, 94, 211 (1997).

3. P. Yue, C. Zhou, J. Dooley, and J. Feng, “Elastic

encapsulation in bicomponent stratified flow of

viscoelastic fluids”, Journal of Rheology, 52, 1027

(2008).

4. A. Karagiannis, A. N. Hyrmak, and J. Vlachopooulo,

“Three-dimensional studies on bicomponent extrusion”,

Rheologica Acta, 29, 71 (1990).

5. K. B. Sunwoo, S. J. Park, S. J. Lee, K. H. Ahn, and S. J.

Lee, “Three-dimensional numerical simulation of

nonisothermal coextrusion process with generalized

Newtonian fluids.” Korea-Australia Rheology Journal,

12, 165 (2000).

6. M. Gupta, “Mesh Partitioning Technique for ThreeDimensional

Simulation of Coextrusion”, SPE ANTEC

Tech. Papers, 54, 217 (2008).

Keywords: Newtonian, encapsulation, contact angle,

fluorescent.

Table 1. Properties of fluids employed in experiments

Table 2. Dimensional analysis of experiments

Figure 1. Depiction of solid-liquid-air contact angle measurement θ.

Figure 2. Side-by-side flow configuration.

Figure 3. Fully encapsulated flow configuration. Fluid 1 forms an annulus and Fluid 2 forms a core.

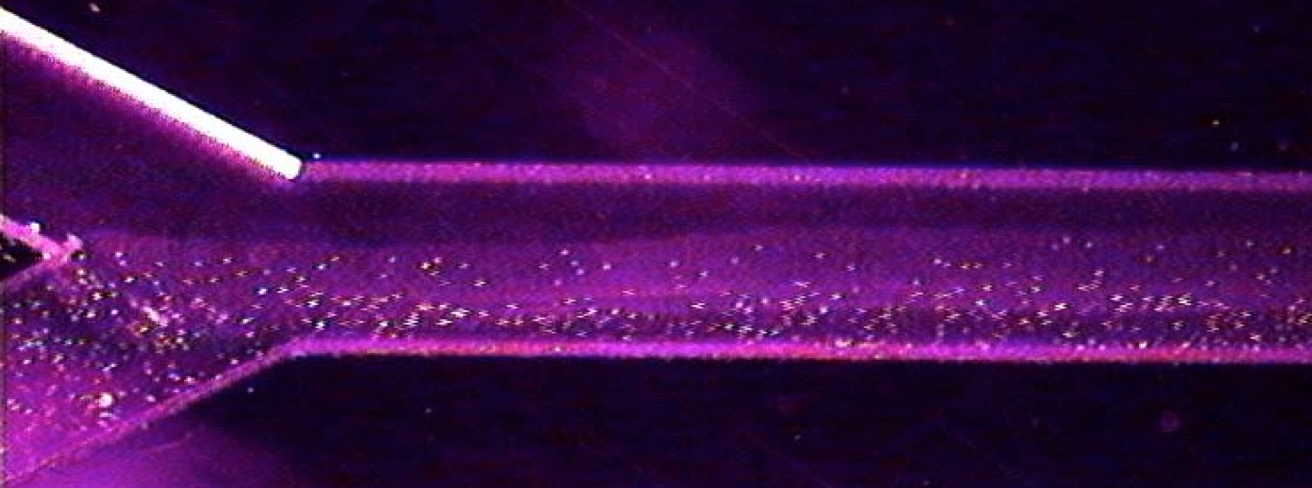

Figure 4. Silicone oil (A) (bottom) and glycerol (top) extruded left to right through the converging channel. Microparticles in the silicone oil are highlighted with the fluorescent light. Here gravity is oriented perpendicular to the page and buoyancy- induced stratification was observed. In this image buoyancy has altered the initial side-by-side configuration by moving one liquid-liquid-solid interface line up the page and the other down the page. The cross-sectional view shown in Figure 5(b) illustrates the final flow configuration of this image.

Figure 5. The final flow configuration of glycerol and silicone oil depicted in (a) resulted when the silicone oil was the first fluid in the channel and was displaced by glycerol. Provided that the exact same initial orientation was repeated, the flow configuration in (b) resulted when the glycerol was the first fluid in the channel and was displaced by silicone oil.

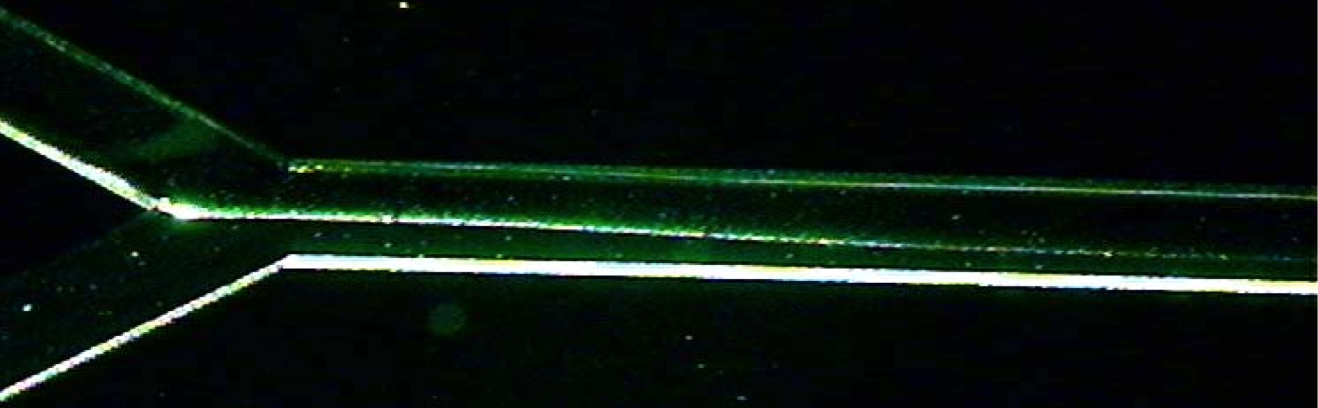

Figure 6. Silicone oil (A) (bottom) and motor oil (top) extruded left to right in the converging channel. Microparticles in the motor oil are highlighted with the fluorescent light filter. Here encapsulation was observed regardless of the orientation of gravity. The liquid-liquid-solid interface line seen in this image approached the side of the channel as the motor oil encapsulated the silicone oil.

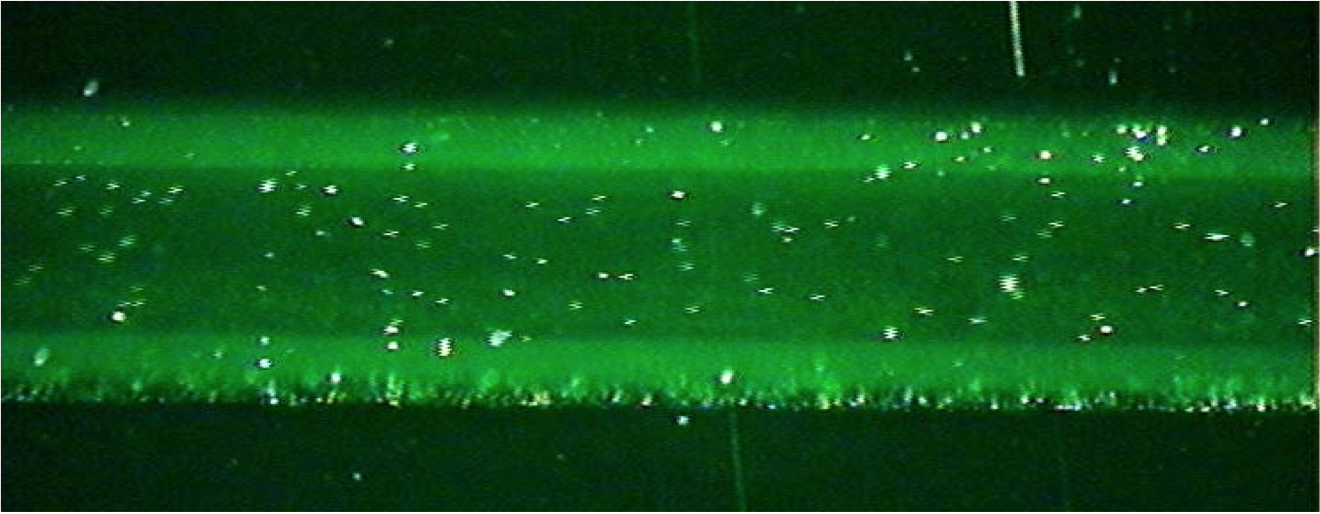

Figure 7. Silicone oil (A) (core- dark) and motor oil (annulus- light) extruded left to right. This magnification shows the fully encapsulated flow configuration with the silicone oil completely separated from all channel walls. Here the microparticles in the silicone oil are dimly visible while the microparticles in the motor oil are highlighted with the fluorescent lighting. In this image some of the microparticles in the motor oil are in focus and others are out of focus. This is an indication that the motor oil had fully encapsulated the silicone oil.

Figure 8. Silicone oil (B) (bottom) and motor oil (top) extruded left to right through the converging channel. Here encapsulation was observed regardless of the orientation of gravity. The liquid-liquid-solid interface line seen in this image approached the side of the channel as the motor oil encapsulated the silicone oil.

Figure 9. Silicone oil (B) (core- dark) and motor oil (annulus- light) extruded left to right. This magnification shows the fully encapsulated flow configuration with the silicone oil completely separated from all channel walls. Here the microparticles in the silicone oil are dimly visible while the microparticles in the motor oil are highlighted with the fluorescent lighting. In this image some of the microparticles in the motor oil are in focus and others are out of focus. This is an indication that the motor oil had fully encapsulated the silicone oil.

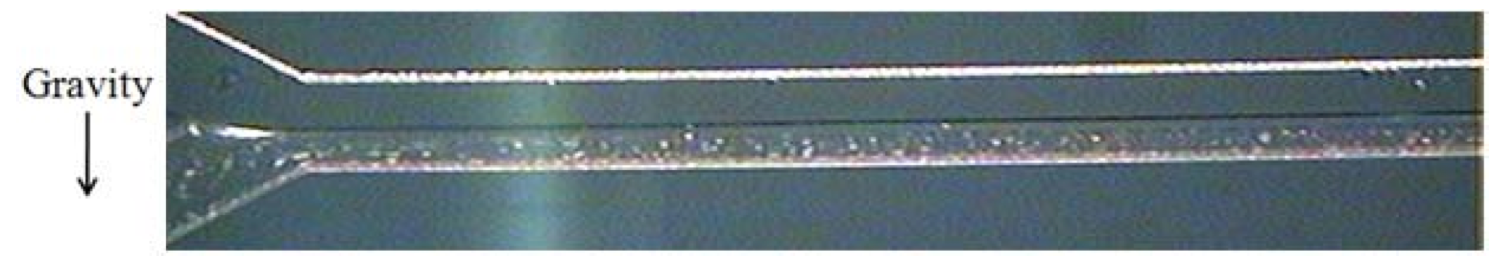

Figure 10. Silicone oil (D) (bottom) and motor oil (top) extruded left to right in the converging channel. Here buoyancy- induced layer rearrangement was not observed as the heavier silicone oil entered the channel already beneath the motor oil. The side-by-side flow configuration is shown here under normal lighting conditions.

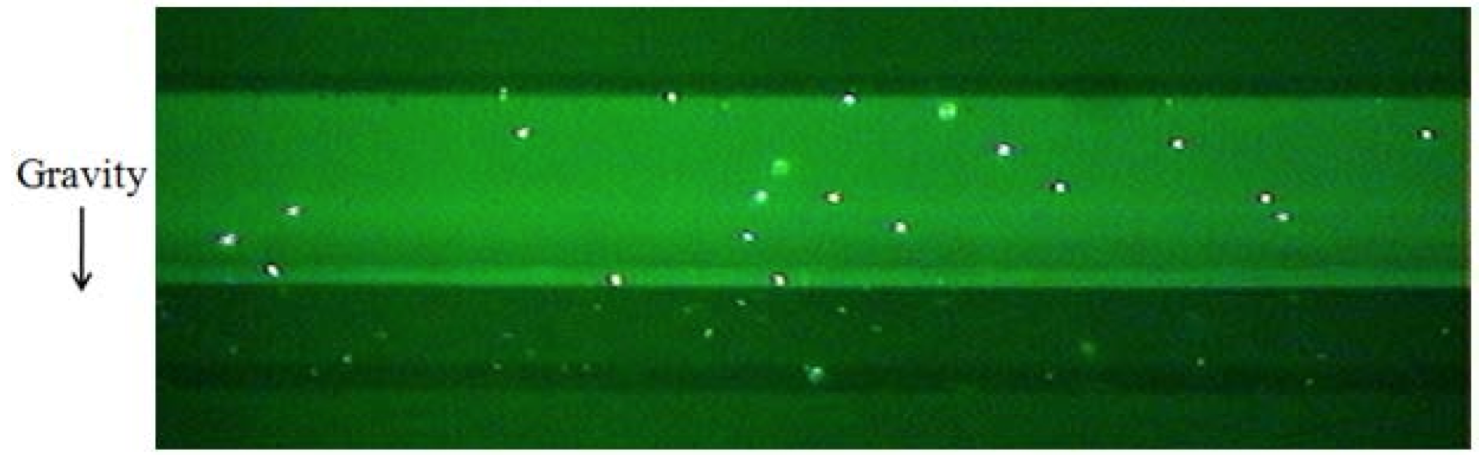

Figure 11. Silicone oil (C) (bottom) and motor oil (top) extruded left to right in the converging channel. Here buoyancy- induced layer rearrangement was not observed as the heavier silicone oil entered the channel already beneath the motor oil. A magnification of the side-by-side flow configuration is shown here with fluorescent lighting highlighting the microparticles in the motor oil.

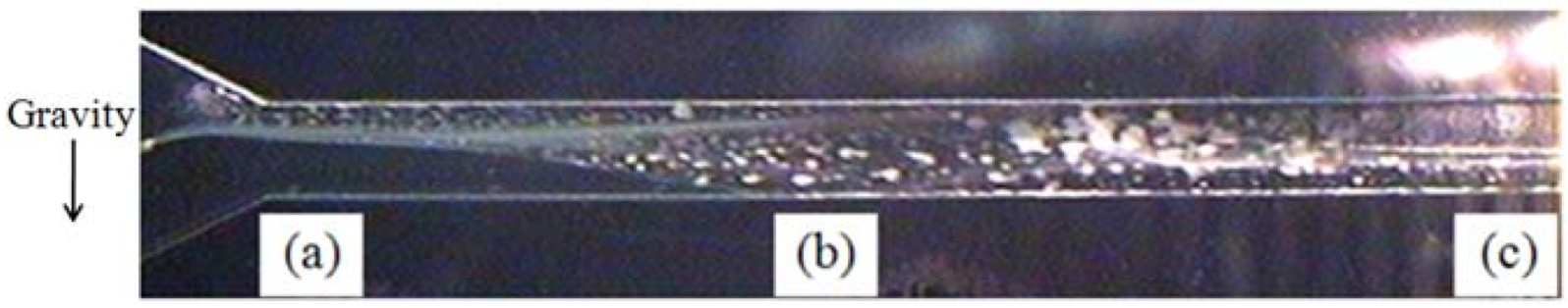

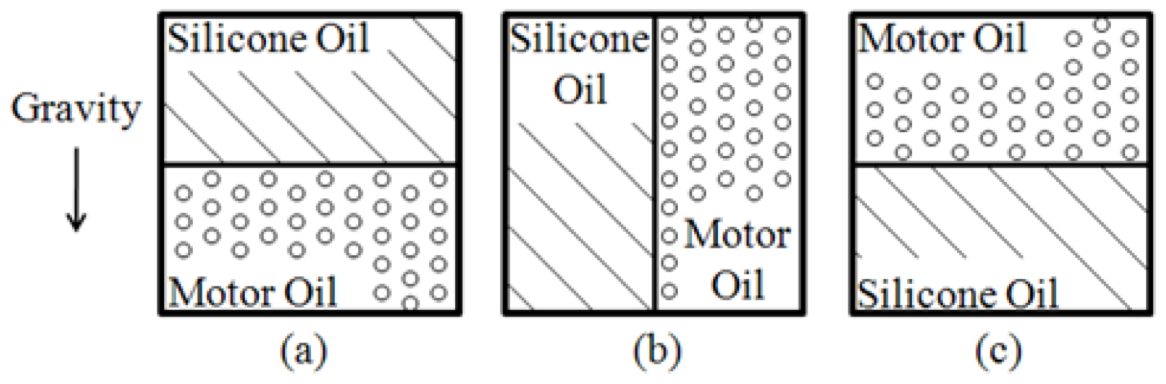

Figure 12. Silicone oil (C) (top at the intersection) and motor oil (bottom at the intersection) extruded left to right in the converging channel. Here buoyancy-induced layer rearrangement was observed as the heavier silicone oil did not enter the channel in a gravitationally stable arrangement with respect to the lighter motor oil. In the center of this figure the side-by- side configuration has rotated 90° relative to its original orientation. At the right edge of this figure the side-by-side flow configuration has rotated 180° relative to its original orientation. Cross-sectional images in Figure 13 illustrate the flow configuration at points (a), (b), and (c) in this image.

Figure 13. This sequence of cross-sectional images illustrates the gravitational layer rearrangement depicted in Figure 12.

Return to

Paper of the Month.