Co-Rotating Fully Intermeshing Twin-Screw Compounding: Advancements for Improved Performance and Productivity¶

Paul G. Andersen, Coperion Corporation, Ramsey, NJ

Frank Lechner, Coperion GmbH, Stuttgart, GermanyAbstract

The co-rotating fully intermeshing twin-screw

extruder is the primary production unit for compounding

of polymer based materials. It also has had a long term

presence in processing material in the chemical and food

industry and more recently in pharmaceuticals. While this

equipment celebrated its 50th anniversary several years

ago and might be considered a “mature” technology, it has

not experienced a decline in new developments as might

be expected, but rather a significant number of

advancements continue to evolve. This paper will

highlight several significant developments of the past 10

to 15 years. These are the implementation of high torque

(power) designs, the use of increased rpm in conjunction

with high torque for improved operating flexibility and

productivity, and finally a technology breakthrough for

feeding difficult to handle low bulk density materials.

Introduction

While several initial concepts for co-rotating twinscrew

devices were patented in the early 1900’s by

Wuensche [1] and Easton [2, 3], the co-rotating design

used as the basis for essentially all twin-screw

compounding systems marketed today is based on the selfwiping

element geometry know as the Erdmenger profile.

The initial design and development of this self-wiping

element profile is described in German Patent 862,668

granted to W. Meskat and R. Erdmenger in 1952 with a

priority date of 1944 [No US patent filed]. The objective

of the design at that time was for mixing high viscosity

liquids already in the fluid state, such as postpolymerization

reaction products.

The above noted patent along with the numerous

related patents which followed (all issued to Erdmenger or

one of his colleagues at Bayer) defined the base design

parameters for the eventual development and

commercialization in the late 1950’s by Werner and

Pfleiderer of the ZSK twin-screw extruder, as well as the

many copies introduced during the intervening 50 plus

years. The key feature of the design is the self-wiping

characteristic of one screw with respect to the other. This

eliminates stagnation and eventual degradation of material

as it is transported along the length of the compounding

extruder.

As mentioned, the overall importance of the invention

of this self-wiping screw geometry is that it is the basic

patent related to the co-rotating twin-screw compounding

system predominantly used today in the plastics, food and

chemical industry. (For additional information related to

the early development advances please see the ANTEC

2009 paper by Andersen et al. [4] and White’s 1991 book

on Twin Screw Extrusion [5].)

Since the development of the basic principles for corotating

twin-screw extruder there have been a significant

number of incremental improvements to the technology.

These include numerous new screw element geometries as

noted by Bierdel [6], the two-lobe element profile for

increased internal free volume (the initial profile described

in the first Erdmenger patent was based on a low free

volume 3 lobe geometry), new screw shaft geometries for

improved power transmission, and new process

applications for the system [7]. However one of the most

significant steps forward was achieved with the

identification of the fundamentals of high rpm / high

torque compounding technology [8]. This is the basis for

US Patent 6,042,260 granted to Heidemeyer et al. on

March 28, 2000.

==High torque, high rpm co-rotating twin-screw

compounding technology==

Since the introduction of the first high torque, high

available rpm ZSK MegaCompounder (Mc) in the mid

90’s, new advances in power transmission technology

(gearbox as well as screw shaft design and material of

construction) have permitted an additional 50% increase

in torque capacity from the Mc specific torque or power

volume factor (PVF: Md/a

3

[Md = torque/shaft (Nm), a =

centerline distance (cm)]) of 11.3 to the Mc

18 PVF of 18.

The impact of this advancement in power

transmission capacity is a resultant significant increase in

productivity (production rates), efficiency and system

flexibility for compounders.

The key to the success of this technology is the

increase in the power (torque) transmission capacity in

combination with increased screw rpm. A system that

simply runs at higher rpm will at some juncture impart

enough additional energy to the material being processed

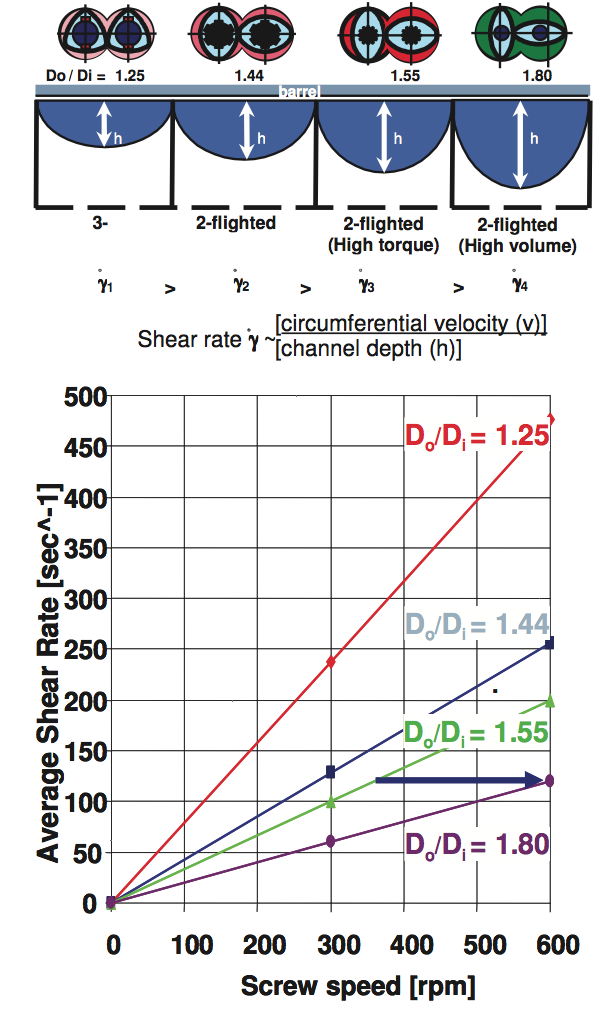

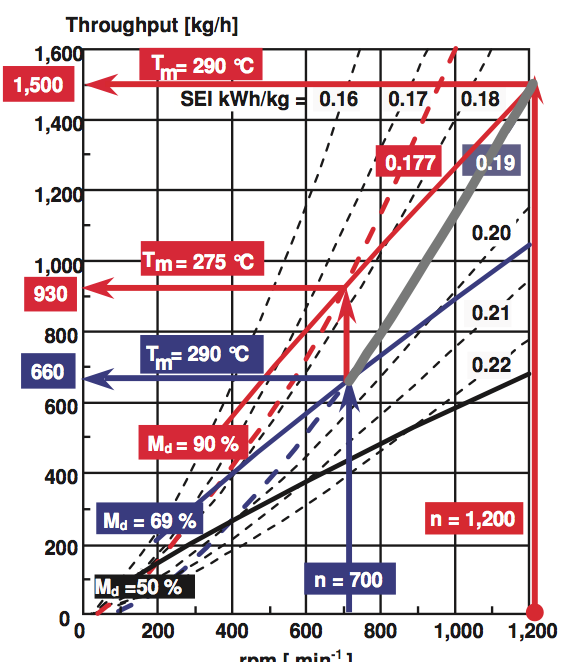

to cause degradation. Figure 1 illustrates this latter point.

It shows that the average shear rate (energy input)

increases linearly with screw rpm for any screw Do/Di

(outer diameter to inner diameter ratio). Therefore the

resultant material discharge temperature will increase

proportionately. However, since the twin-screw

compounder runs primarily in a starve feed mode, the

higher power transmission capability provides the

compounding unit the ability to process at a higher fill

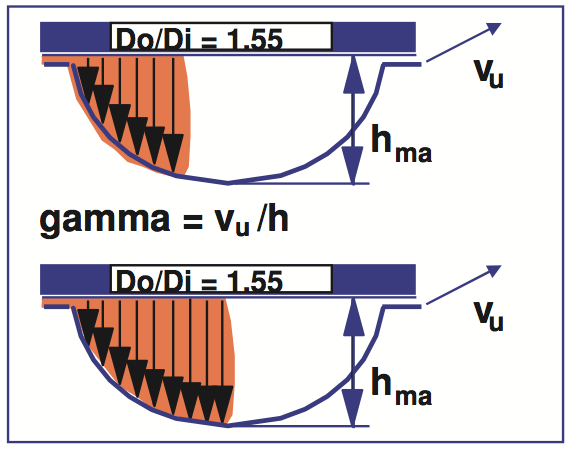

factor and therefore rate per rpm (i.e. Figure 2 comparison

of lower fill degree top graphic vs. the higher fill degree

bottom graphic). In turn, this fill factor increase has a

positive impact on lowering material temperature.

Figure 1: Impact of Do/Di & RPM on Shear Rate

As shown in the screw channel for the lower portion

of Figure 2, the additional material is added to the screw

profile in the deeper (lower shear rate) middle section of

the element geometry profile. This in turn reduces the average shear rate for all the material and consequently the

total energy input (i.e. resultant discharge temperature) per

kg of product produced. Therefore the processor has the

flexibility to run the extruder at higher rpm without

exceeding material temperature limits. As an example,

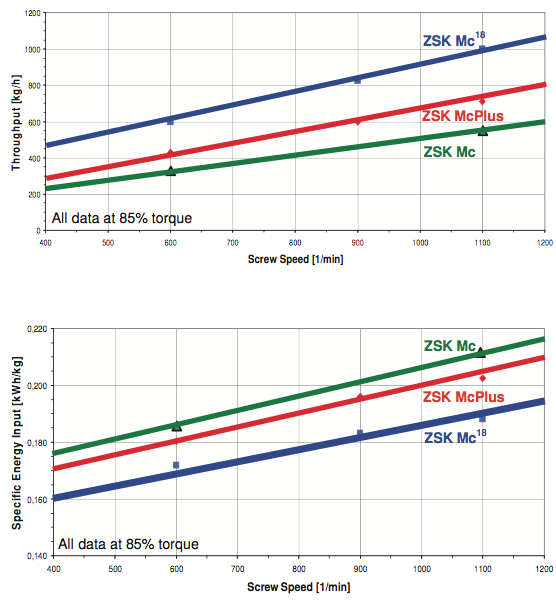

Figure 3 shows a comparison of 3 generations of twin screw

compounding units based on a ZSK 45 geometry

processing 30% glass filled nylon 6, the ZSK Mc (power

volume factor of 11.3), the ZSK Mc Plus (power volume

factor 13.6) and the ZSK Mc

18 (power volume factor 18).

Figure 2: Impact of degree of fill on average shear rate

In the top portion of Figure 3, the throughput vs. rpm

is shown for the 3 generations. As would be expected, the

unit with the greater power volume factor (ZSK Mc

18) has

the greatest throughput rate as a function of rpm.

However, as shown in the lower portion of the figure, it

also has the lowest specific energy input. By combining

these two results (higher rate at lower SEI), this data

shows that there is a double economic advantage for using

the highest power volume factor equipment available.

First, because of the lower SEI (Specific Energy Input –

also known as Sme: Specific mechanical energy), the

higher PVF unit can produce an increased throughput rate

which is disproportionately greater than the percent

increase in the power volume factor for one machine

generation to the other. (In this particular example, the

rate increase is between 70 and 80% while the PVF

increase is just over 50 %.) A general guide for rate

increase is: New Rate = Old Rate x (PVF High

Power/PVF Low Power) x (SEI Low Power/SEI High

Power). Second, there is an absolute energy saving per Kg

of product produced.

An additional point needs to be stressed about high

torque high rpm compounding extruders. These machines

do not have to be run, or even designed to run, at

maximum rpm. As Figure 3 has shown, there is rate increase and energy savings advantage at any rpm.

However, there is another power/rpm synergy that permits

a second disproportionate increase in rate and therefore

production economics.

Figure 3: Comparison of rate and SEI for 30% glass filled nylon 6 vs. rpm for three generations of extruders based on the ZSK 45 geometry

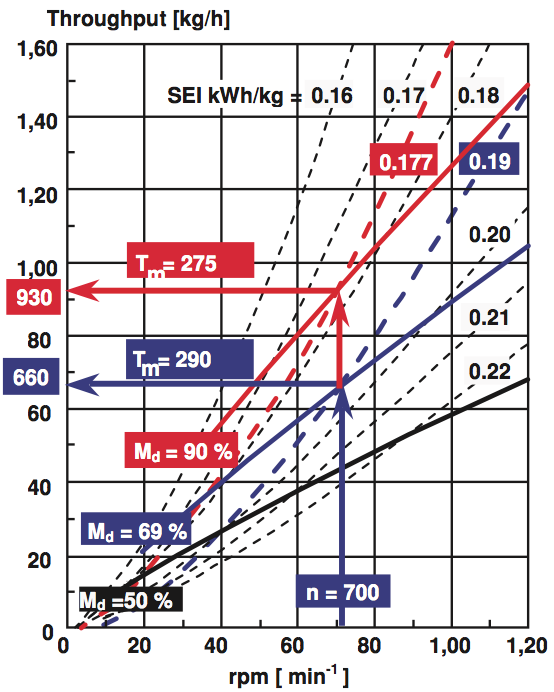

An example of this relationship [8] can be seen in

Figure 4 where throughput rate is plotted against screw

speed for three torque utilization values. SEI is also shown

as a field parameter. The data comes from an ABS

(Acrylonitrile-Butadiene-Styrene) graft co-polymer

compounding process on a ZSK 58 Mc (D

o/D

i

= 1.55, torque = 1250 N-m/shaft, PVF = 11.3). The lines for 69%

and 90% torque compare respectively 90% torque

conditions on a lower power ZSK 58mm

SuperCompounder (Sc) extruder (D

o/D

i

= 1.55, 960 Nm/shaft,

PVF 8.7) vs. 90% on the Mc (1250 N-m/shaft).

This is a torque difference of 30% between the two

machines. For this example, a constant screw speed of 700

rpm was selected. At 69% torque (90% on the 960 Nm/shaft

extruder) a throughput rate of 660 kg/h, with a SEI

of 0.19 kw-h/kg and a melt temperature of 290° C was

obtained. Increasing the rate to 90% torque led to a

reduction of SEI from 0.19 to 0.175 kw-h/kg. This

resulted in a 40% rate increase to 930 kg/hr, not just the

30% increase as one might have expected. At the same

time the melt temperature dropped 15°C down to 275°C.

This is especially advantageous for heat and shear

sensitive materials. They can be run at increased rates but

lower temperatures.

Figure 4: Utilization of increased torque

Figure 5: Utilization of increased torque and rpm

However, if the original temperature of 290° C is

satisfactory, then Figure 5 illustrates the really significant

impact of combining high torque with high rpm. The rpm

can be increased to 1200 with an associated rate of 1500 kg/hr and a material discharge temperature of 290° C, the

same as the lower torque operating system. This is a rate

increase of more than 150% from the original 660 kg/hr.

The productivity and economic impact of increasing

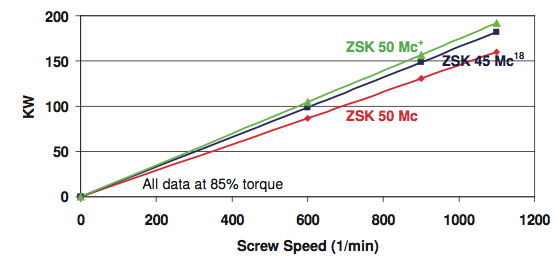

throughput by more than 150% is significant. However,

there is another potential option for the company looking

at installing a new line. If you do not need to produce

1500 kg/hr, but only the original lower rate of 660 kg/hr,

then you may be able to purchase a smaller diameter

extruder. As example, the new ZSK 45 Mc

18, has more

than 10% greater KW vs. rpm than the ZSK 50 Mc and

has only slightly lower KW than the ZSK 50Mc

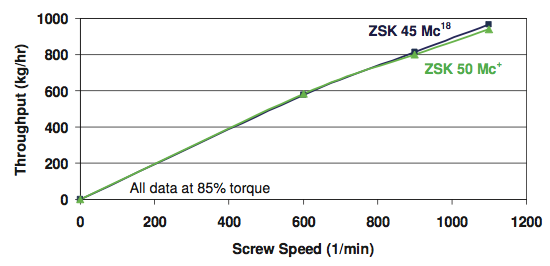

+, Figure 6. However, as shown in Figure 7, it can actually produce

an equivalent or even greater output than the larger

diameter unit.

Figure 6: Comparison of available power for ZSK 45 Mc18 vs. previous generations of the larger diameter ZSK 50 compounding extruder.

As shown in Figure 3, the ZSK 45 Mc18 can produce

approximately 600 kg/hr of 30% glass filled nylon 6 at

600 rpm, and 970 kg/hr at 1100 rpm. Making the

assumption that the SEI obtained when running the ZSK

45 at Mc Plus conditions (0.18 kw/kg at 600 rpm and

0.202 kw/kg at 1100 rpm) translates to the larger ZSK 50

Mc Plus, then the ZSK 50 Mc Plus would produce

approximately 580 kg/hr. at 600 rpm, roughly the

equivalent of the ZSK 45 Mc18. At 1100 rpm, the ZSK 50

Mc Plus would produce approximately 950 kg/hr., again,

the same or slightly less than the ZSK 45 Mc

18 (Figure 7).

Feed Enhancement Technology (FET)

High torque extrusion technology is only an

economically viable manufacturing process when the

process takes advantage of all the available power.

However, many compounds produced today contain high

levels of low bulk density material, such as sub-micron,

non compacted talc. These materials are difficult to feed

into the extruder because of the significant volume of air

which must be removed. Additionally as bulk density

decreases, the materials tend to fluidize more easily.

Fluidization lowers the “effective” bulk density even

further and exacerbates feeding issues. Typical unit operations within the compounding process where

material is more susceptible to fluidization are: transfer

from storage vessel to feeder, from feeder to twin-screw

extruder and within the feed zone conveying section of the

twin-screw extruder. While there are methods to minimize

the potential for fluidization such as dense phase

conveying from storage to feeder, minimization of the

feeder height above the extruder feed opening,

incorporating a vent into the feed hopper, extending the

length of the conveying zone in the extruder feed section,

the process eventually reaches a feed volume limitation,

which more often than not is well below an economically

viable production rate.

Figure 7: Rate as function of rpm for ZSK 45 Mc18 vs. the larger, more powerful ZSK 50 Mc+ (30% glass filled N6).

The FET technology has been presented in

detail. However, as background, a brief description of the

principle is presented below.

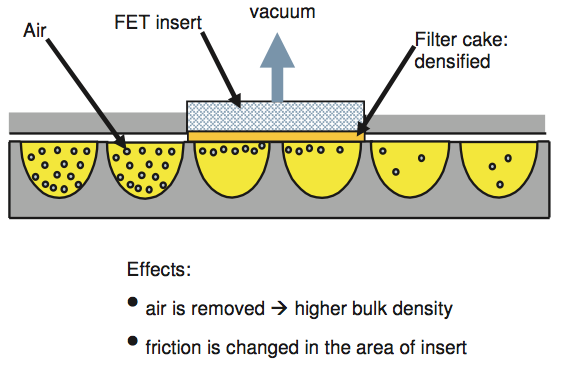

The objective of FET is to increase the feed intake /

feed zone throughput capacity for difficult to feed

materials. This is accomplished by improving the

conveying efficiency through an increase in the coefficient

of friction between the feed and barrel wall i.e.

minimize/eliminate wall slip.

The conveying efficiency / coefficient of friction

increase is achieved by “adhering” a layer of feedstock

material to a portion of the barrel wall through the

application of vacuum to a specially designed section of

the barrel wall in the feed zone which is porous and

permeable to the gas, but not to the feed product.

Therefore the pore size of the porous section of the barrel

wall relative to the particle size of the powder is very

crucial. Additionally the optimum vacuum level applied

to the device depends on particle size and shape of the

feedstock. If particles were to penetrate the pores, the

efficacy of the process would be reduced. However, if

powder were to penetrate the pores it could be back

flushed out by applying a pressure through the vacuum

line(s). While powder infiltrating the porous barrel wall

could be problematic, even more critical would be the

presence of polymer melt or other fluid. Both of these materials would smear over the porous surface or even

penetrate the pores and clog the porous structure.

The working principle of FET is illustrated in Figure

8. By applying the vacuum through the porous material,

air surrounding the polymer or filler is evacuated as it

passes the FET barrel section insert. As the air is sucked

toward the insert, it entrains and carries the particles

toward the insert surface. The air goes through but the

material remains behind to coat the surface. This coating,

or filter cake, of densified polymer powder has the effect

of increasing the coefficient of friction between the wall

surface and the bulk of the material. The layer of material

adhering to the barrel wall due to the vacuum is

continuously renewed by the rotating screws.

Additionally, the bulk density of the powder is increased

as it passes the insert. These two effects combine to

improve the conveying efficiency.

Figure 8: FET operating principle

It has been demonstrated that the overall production

rate could be increased by incorporating FET [9].

However, there are other impacts of the technology.

Similar to the advantages detailed previously in this paper

of using a higher torque capacity compounding unit,

increasing the rate of the highly filled polymer

compounding line while all else remains the same, results

in a lower overall energy consumption per unit of product

produced. Lower unit energy translates into lower product

temperature, which in turn would mean less potential for

material degradation or stabilizer package consumption.

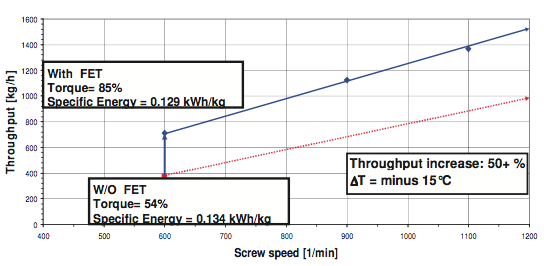

Figure 9, illustrates this point. This data is for 40%

talc (Luzenac 1445) filled PP run on the new generation

Coperion Mc

18 ZSK 45 mm twin-screw compounding

extruder. Without the FET technology, the compounder

can not take advantage of the higher torque capacity of the

extruder. However, by implementing the FET, the system

runs at full torque (~85%), the throughput has been

increased more than 50% and the discharge temperature

lowered significantly.

Figure 9: Impact of improved feed intake on rate and material temperature

Summary

Significantly higher throughput rates are achieved

when polymers can be processed at high rpm. However,

for most systems simply increasing the rpm of an existing

extruder will not accomplish the desired results. While

rates will be increased, product properties may fall below

acceptable levels. On the other hand, by combining high

rpm with increased torque capability, polymer processing

economics can be significantly improved without

deterioration of product properties.

Also, while compounders will continue to have issues

with handling low bulk density feed materials; with FET

they now have an additional tool to help them utilize the

full flexibility of the twin-screw compounding extruder.

References

1. A. Wunsche, German Patent 131,392 (1901)

2. R. W. Easton, British Patent 109,663 (1916)

3. R. W. Easton, U.S. Patent 1,468,379 (1923)

4. P.G. Andersen, Chi-Kai Shih, Mark A. Spalding,

Mark Wetzel, Tim Womer, SPE-ANTEC Tech.

Papers, 55, (2009)

5. J. L. White, Twin Screw Extrusion: Technology and

Principles (1991)

6. M. Bierdel, Co-Rotating Twin-screw Extruders:

Fundamentals, Technology, and Applications (2007)

K. Kohlgrueber & W. Wiedmann Editors

7 P.G. Andersen, Plastics Compounding, D.B. Todd

ed., 71-124 (1998)

8. P.G. Andersen, E. Haering, K. Kapfer, SPE-ANTEC

Tech. Papers, 43, (1997)

9. P.G. Andersen, M. Hoelzel, T. Stirner, SPE-ANTEC

Tech. Papers, 57, (2011)

10. P.G. Andersen, M. Hoelzel, T. Stirner, SPEEUROTEC

2011

Key Words: Twin-screw, compounder, High torque, High

rpm, feed enhancement, powder filler

Return to

Paper of the Month.