Modeling of Anisotropic Polymers during Extrusion

Arash Ahmadzadegan, Michael A. Zimmerman, Anil Saigal

Department of Mechanical Engineering

Tufts University

Medford, MA 02155 Abstract

It is known that a liquid crystal polymer (LCP) melt

aligns in the direction of the shear flow when it passes

through an extrusion die. This alignment causes thin films

of the anisotropic LCP material to display different

properties in different directions. To overcome this

problem, many complex die design technologies have

been developed that involve moving surfaces. However,

there is a clear need to develop a method of predicting

crystal orientation (alignment) to aid in die design. This

paper investigates different modeling methods, and

develops a numerical modeling technique using FLUENT,

to predict molecular alignment by correlating it to

streamlines of flow. This model also incorporates the

complex rheology of the LCP in predicting the resulting

alignment. It is shown that for a new cross-flow design of

the extrusion die that at around Re=500 the maximum

angle between the vectors is 80 degrees and at lower Re it

does not satisfy the desired angle between the two flows.

Introduction

Any rod like molecule or crystal tends to orient itself

in the direction of shear as it moves with in a flow. Since

polymers consist of long chains of molecules, they

experience the same phenomena when flowing in the melt

condition. For most polymers, the molecules change

direction and distribute uniformly in space during the

solidification. However due to the higher inertia of the

crystals in the liquid crystalline polymers, the oriented

crystals will keep their order during the solidification and

as a result the final product will show anisotropy in the

material properties.

This investigation focuses on film casting of LCPs

and develops ways to prevent the anisotropy of properties

in the final product. The challenge here is to alter the

rheology of the polymer melt inside the die in order to

have isotropic material properties in the plane of the film.

The use of biaxial shear flow during extrusion,

elongational strain after extrusion, electromagnetic field

effects, and thermal treatment to develop isotropic films

has been discussed by Lusignea et al. [1].

Farrell and Lawrence use co-rotating extrusion dies to

produce biaxially oriented films of LCPs [2]. Due to the

complexity of this type of dies and built-in instabilities

during this extrusion process, a simpler stationary

extrusion die is desirable.

Geometry

An important parameter to be considered when

designing the geometry of polymer dies is that the flow

pattern inside the die highly influences the polymer

extrusion process and any sharp edges inside the die which

result in the flow to become turbulent should be avoided

[3]. Turbulence inside the die increases the residual

stresses which will be released after the extrudate leaves

the die and causes instabilities in the extrusion process.

The conventional die for extrusion of polymer films or the

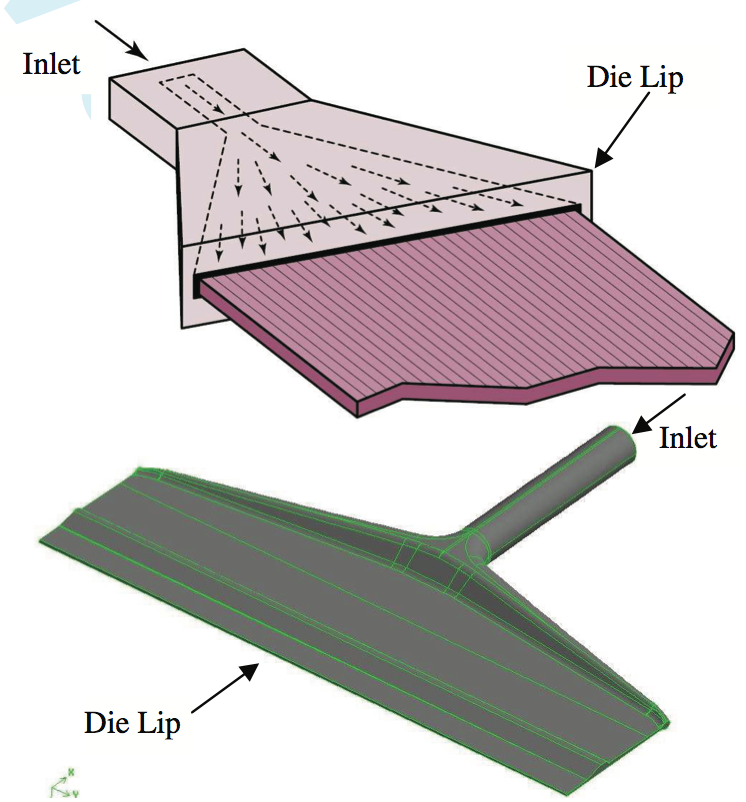

coat-hanger design is shown in Figure 1. These dies are

designed such that the velocity of the extrudate coming

out of the die is constant across the lip of the die.

Figure 1. Schematic of a coat-hanger die (up) inside the actual die (down) [4]

In this study, simulation of the polymer flow inside

this die geometry was performed with different material

properties to investigate the difference between the

rheology and the dependence of pressure drop on the

material properties. Another type of dies which is

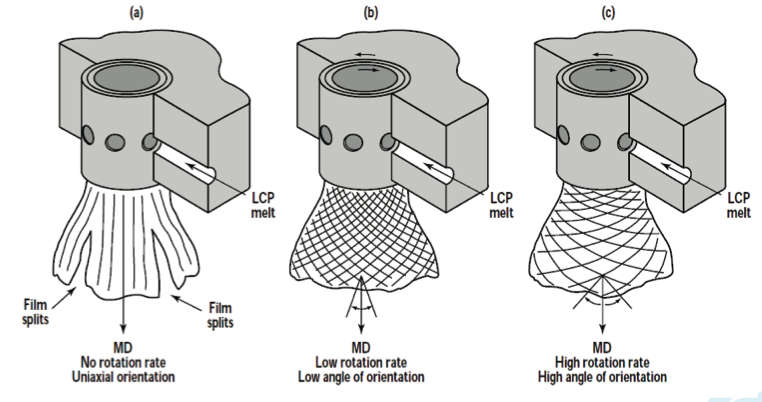

designed to produce plane isotropic properties is corotating

extrusion die. The co-rotating extrusion dies try to

use the viscosity of the polymer to produce a laminar flow

with a lateral shear flow that has a three dimensional

profile at the lip of the die. This geometry, as shown in

Figure 2, has two co-rotating cylinder which operate at

high temperature and the polymer melt flows between

them. The change in the direction of the crystallines is

introduced through the shear effect of the cylinders.

Figure 2. Geometry of the co-rotating biaxial die [4]

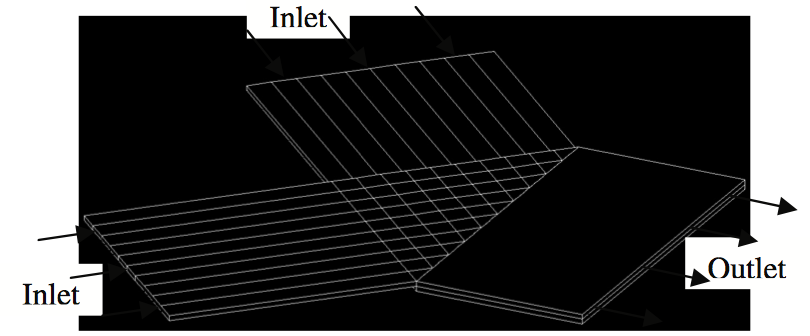

A new design for the die geometry introduced here

uses cross flows to produce the required lateral shear

across the thickness of the film. As a result, no moving

part is used in the die. A simple geometry of cross-flow

die consists of two cross flows which interact with each

other along the mid-plane. The interaction of these two

symmetrically positioned flows causes the mid-plane to

exit the lip normal to the exit plane while from the midplane

to the upper and lower planes velocity vectors

change direction gradually. To construct this geometry,

preprocessing software GAMBIT was used since it can

export the geometry, mesh and boundary conditions to

FLUENT. The idea of interacting cross flows was built

with 20 channels in which the flow in half of them is

perpendicular to the other half. These channels are open

along the interface between them and provide the

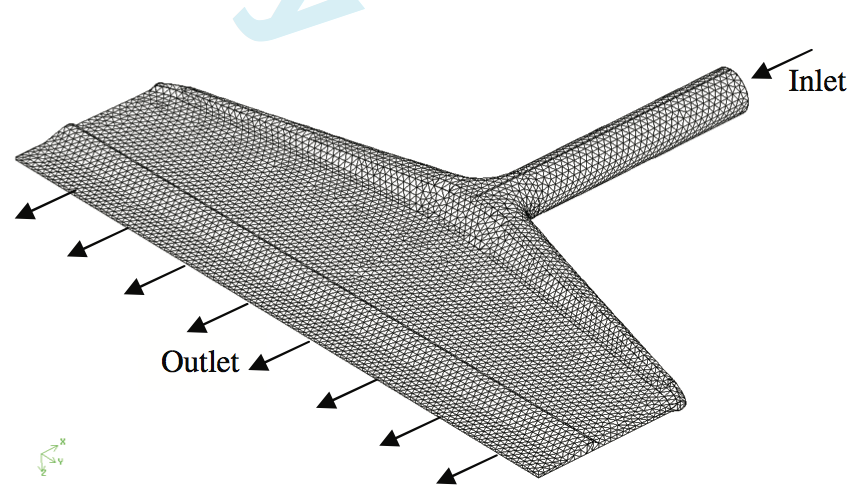

interaction of flows inside the die (Figure 3).

Figure 3. Geometry of the cross flow

This geometry can be constructed by machining the

channels inside the upper and lower part of the die since

the interface between them is open. It should also be noted

that since the velocity of the polymer is inherently 3D in

this flow, it is not possible to make a 2D geometry

representing cross flows.

Grid Generation

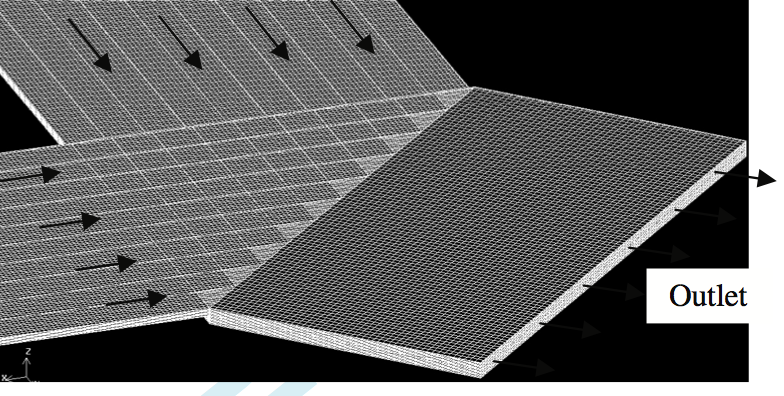

The required mesh to decompose the geometry to

finite volumes was generated in GAMBIT. Structured

cubic elements were generated for the geometry of the

crossed flow with the consideration of the flow pattern.

Using hexahedral elements, it is possible to achieve higher

accuracy of the results with much fewer grids. In addition

these types of grids are more desirable because modeling

the free surface is only possible with structured grids

normal to the approximate direction of flow. The

maximum skewness of the generated grids is calculated to

be 0.25 and the maximum aspect ratio of elements is 7.1,

which are in the range of acceptable values. There are a

total of 410,000 elements inside and outside the die.

Figure 4 shows the constructed grid in different locations

of the die.

Figure 4. Structured grid on cross flow geometry

Figure 5. Unstructured grid on the geometry of the coat-hanger die

Due to the complexity of the coat-hanger die,

unstructured hexahedral elements were chosen for

decomposing the geometry into finite volumes. Figure 5

shows the generated mesh for the coat-hanger geometry

(mesh density is reduced here for demonstration purpose).

The mesh consists of 3,000,000 elements with the worst

skewness of 0.777 and worst aspect ratio of 3.5 which are

both in the range of acceptable limits.

Material Properties and Boundary Conditions¶

Two different models for material properties were

used to simulate the flow inside the die. The first model

considers the fluid to be Newtonian and defines a constant

viscosity. In this model stress and strain inside the flow

are linearly proportional. For this case the viscosity of the

fluid was taken to be 0.1 Pa.s for low viscosity and 220

Pa.s for high viscosity.

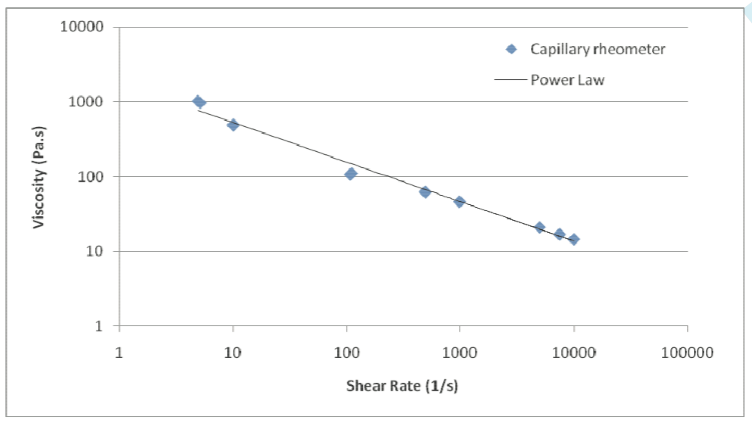

The second model was chosen based on the available

experimental results for one type of LCP. An experiment

based on capillary rheometer with capillary length of 20

mm and diameter of 1 mm has been done. This

experiment was done under isothermal condition where

the temperature was kept constant at 350°C. (Figure 6).

Figure 6. Viscosity of LCP as a function of shear rate used in the simulation

By looking at the curve of viscosity vs. strain rate on

a log-log scale, it appears that it can be modeled by the

power law model. Based on this information the nonNewtonian

power law model was used as a second model

to simulate the flow inside the die. In the power law

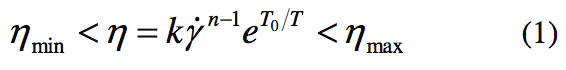

model, equation (1) is used in the constitutive equation to

model viscosity [5]:

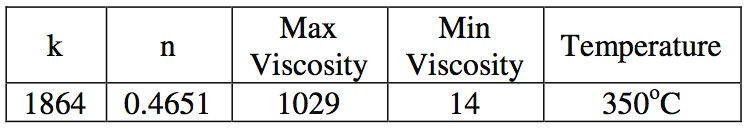

To find the parameters to substitute in this equation,

the automatic option of Polymat software was used.

Moreover, for defining this model completely, the minimum and maximum values of viscosity should be

given which was chosen to be the maximum and minimum

values in the capillary experiment. (See Table 1).

Three different boundary conditions were used to

define the boundaries of the geometry which include

velocity inlet, walls and outlet. The channels inside the die

were modeled as zero thickness walls with zero tangent

and normal velocities. Also, since there is no free wall

boundary condition, the flow outside the die is also

considered to be through a channel. It should be noted that

the interfaces between the upper and lower channels are

defined as an interface which mean two flows have

interaction.

Table 1. Constants Used for Non-Newtonian Power Law Model

Solution Considerations and Results¶

FLUENT uses finite volume method to solve the

constitutive equations on the meshes [5]. One important

consideration before beginning the simulation is the

importance of inertia terms in the equations. Since most

polymers have high viscosity, flow is mostly driven by

pressure and the non-linear inertia terms can be neglected.

The importance of inertia terms can be found by

calculating the Reynolds number of the flow. In all the

following simulations, the inertia terms were included.

Ignoring the inertia terms helps with the convergence of

the solution since these terms introduce non-linearity to

the equations but it also reduces the accuracy of the results

especially when Reynolds number is not small. Steady

state first order pressure based implicit solver was used in

all cases.

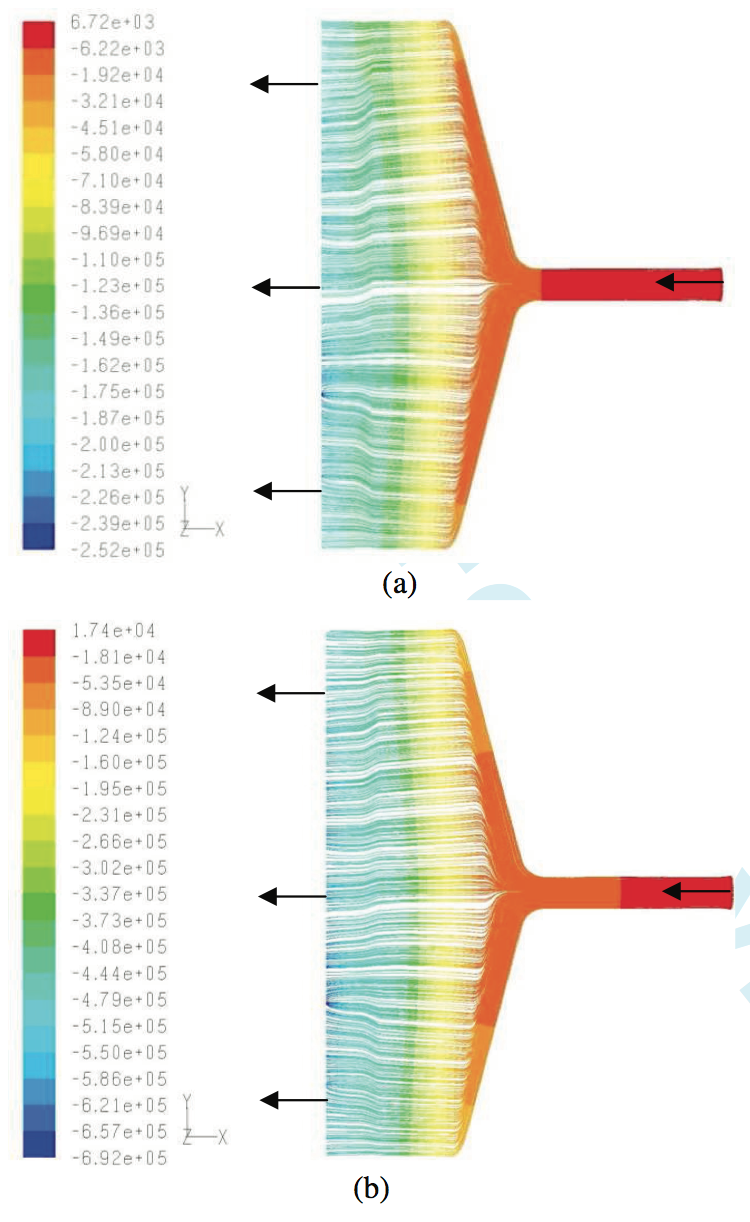

Figure 7 shows the pathlines colored by the pressure

for the two cases of Newtonian constant viscosity and

non-Newtonian power law viscosity models. For

Newtonian flow, the value for the viscosity is chosen as

the mean value of the viscosities obtained from the

capillary rheometry experiment which is 220.1 Pa.s.

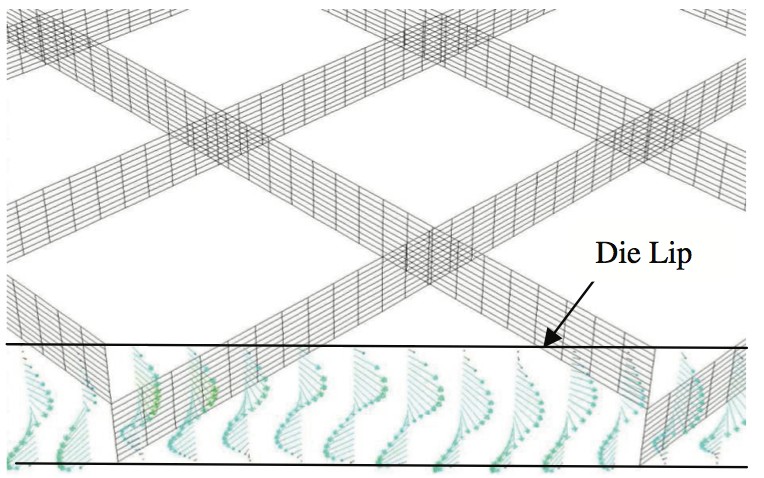

Figure 8 shows the velocity vectors at the lip of the

cross-flow die geometry. As can be seen, velocity vectors

change from -45 to 45 degrees across the thickness of the

film. Velocity vectors are always tangent to the

streamlines. In this study, the director of crystallines are

tangent to the streamlines which means that almost the

same biaxial pattern can be achieved using two cross

flows instead of complicated rotating dies.

Figure 7. Pathlines colored by static pressure inside the coat-hanger geometry for the case of (a) constant viscosity and (b) power law

Figure 8. Velocity vectors across the thickness at the lip of the die (Newtonian model)

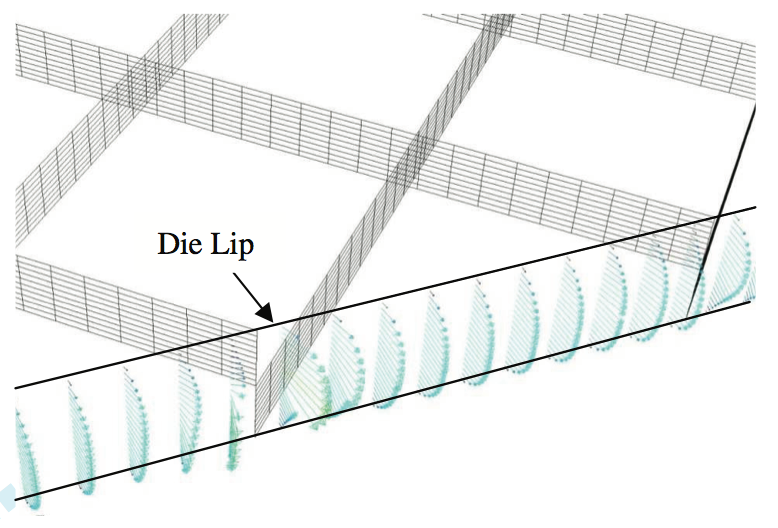

Figure 9 shows the result found by using the power

law model based on capillary rheometer. As can be seen

the change in direction of velocity vectors across the die is

very small and hard to recognize except for the vectors in

the vicinity of the fins.

The simulation of rheology inside the cross-flow die

has been done using two different Newtonian and one

non-Newtonian viscosity models. The first Newtonian

model simulation is done using a constant viscosity of 0.1

Pa.s (See Table II).

Figure 9. Velocity vectors across the thickness at the lip of the die (non-Newtonian model)

It can be seen from the velocity vectors that in this

case the relative importance of inertia terms forces the

fluid to keep its direction until it exits the die lip. The

second Newtonian model used the average value of the

viscosities obtained during the capillary rheometry

experiment which is 220.1 Pa.s. For this high value of

viscosity, inertia forces are negligible compared to the

viscous forces and flow reaches its fully developed

condition in a very short distance and the only change in

the velocity vectors are observed to be in vicinity of fins.

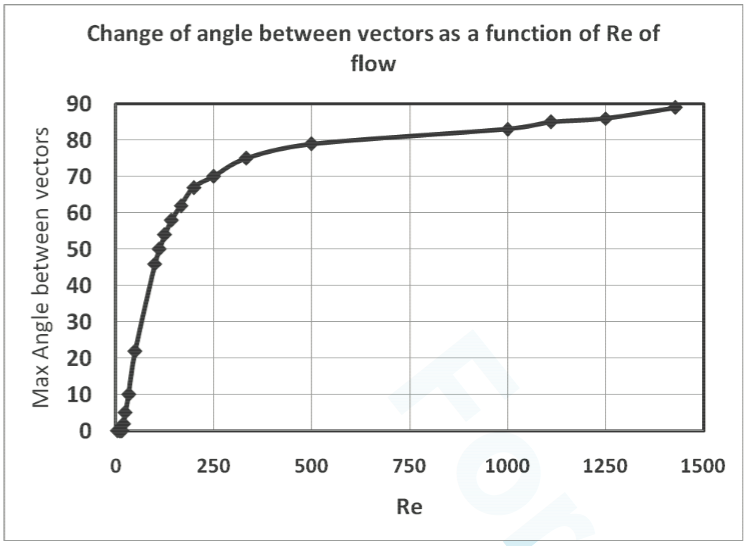

Since the maximum angle between two cross flows

depends both on inertia and viscous forces, this angle is

derived for several different Reynolds numbers based on

the thickness of the each crossed flow channel with

Newtonian model.

These results are shown in Figure 10. By increasing

the Re of the flow, the relative importance of the inertia

forces increases and we approach 90 degrees (from -45 to

+45 degrees). On the other hand, at very low Re, flow

approaches its fully developed condition and there will be

no difference in the angle.

Figure 10 shows that there is a turning point at around

Re=500 when the angle is 80 degrees and at lower Re the

maximum angle between the vector does not satisfy the

desired angle between the two flows.

Figure 10. Change of angle between vectors as a function of Re of flow

The last simulation on the cross flow geometry is

done using the actual experimental results of the capillary

rheometer. In this case due to the shear thinning effect of

the viscosity, the pressure drop is less than the pressure

drop obtained for constant viscosity and also the velocity

profile at the die lip is more flat.

Discussion and Summary¶

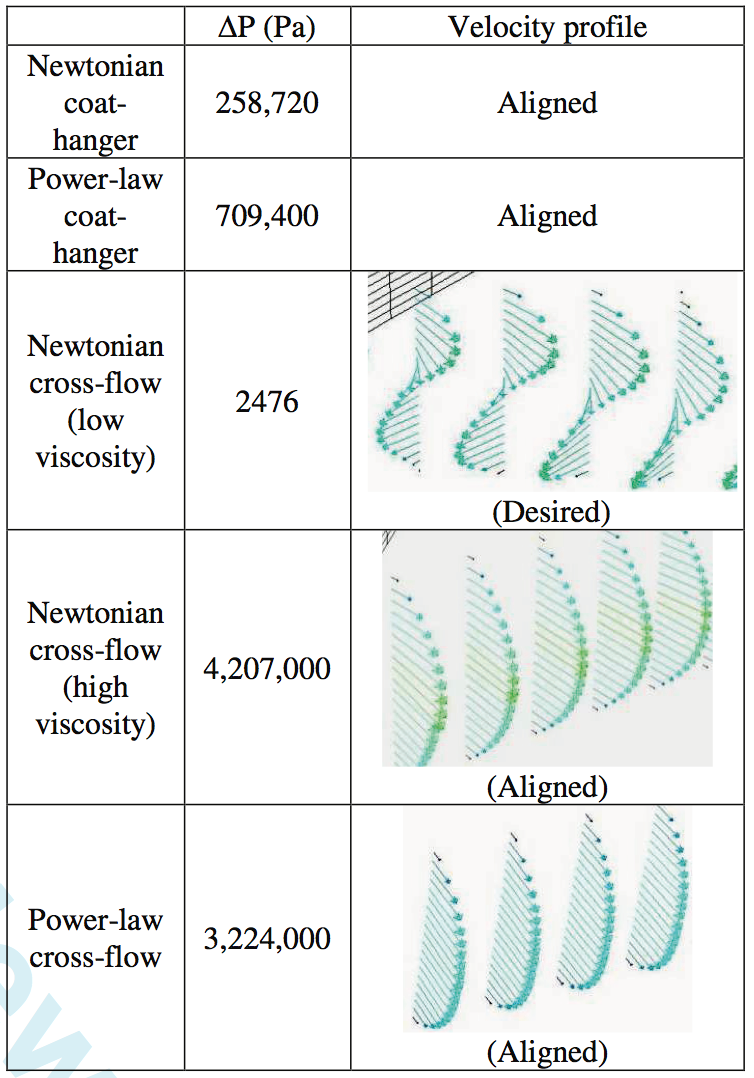

The results of the simulations of the Newtonian and

non-Newtonian material models for the coat-hanger and

cross-flow die geometries are compared in Table 2. From

these results it can be observed that it is possible to obtain

the correct molecular orientation using this new crossflow

die geometry but for the orientation of the

crystalline. One solution for increasing the change in the

direction of velocity vectors can be increasing the number

of fins inside the die or increasing the angle between the

two cross flows. It is also clear that the design of the die

geometry is directly related to the material and processing

characteristics such as viscosity and inlet velocities.

Table 2. Summary of the simulation results

References

1. R. Lusignea, K. Blizard and L. Rubin, High

Performance Processing For High Performance

Polymers, Mat. Res. Soc. Symp. Proc. Vol. 305,

1993.

2. B. Farrel and M. Lawrence, The processing of liquid

crystalline polymer printed circuits, Proceedings of

52nd Electronic Components and Technology

Conference, 2002.

3. R. Ahmad, R.F. Liang and M.R. Mackley, The

experimental observation and numerical prediction of

planar flow and die swell for molten polyethylenes, J.

Non-Newtonian Fluid Mech., 59 (1995) 129-153.

4. R. Lusignea, High-barrier packaging with liquid

crystalline polymers, TAPPI Journal, Vol. 80: No.6,

1997.

5. Fluent Documentations, Ver. 6.3, 2010.

Return to

Paper of the Month.