Variables Strength Stress Bead Analysis in a Twin Screw Extruder

William Pappas, Harry Brown II, Graeme Fukuda, Roba Adnew and David Bigio,

University of Maryland, College Park, MDAbstract

An experiment has been created that relates stress

distribution history with residence time distribution. To

quantify the results, stress beads that break up at a specific

stress were used to measure the percent of material that

sees those critical stress values throughout the extruder.

Two different strength stress beads were used along with

two different screw geometries at the mixing section to

complete the experiment. This paper describes results for a

range of different throughputs and speeds in the extruder.

Introduction

Extrusion is a viable technique for creating an

array of different products across a broad spectrum of

disciplines. Examples include pipes and tubes, chemical

pressure-sensitive adhesives, and active ingredient patches

for pharmaceutical industries [1]. One of the more

intriguing applications for extrusion is the production of

composite materials using fillers, such as carbon

nanofibers. This process produces an extruded material

with altered properties than that of the base polymer, such

as heightened thermo-conductive and mechanical strength

properties. There are several factors that determine the

change in properties of an extruded material. One such

factor is the amount of mixing a material within an

extruder experiences. To be able to determine the degree

of mixing, it is important that one accurately models the

stress that is induced for a given screw geometry and

operating condition.

Mixing with a twin-screw extruder is categorized

as either distributive or dispersive. Distributive mixing

uniformly distributes particles throughout the melt and

dispersive mixing breaks large particles and distributes

them throughout the melt. Narrow kneading blocks are

used for distributive mixing as the melt flows in and

around the paddles, producing low shear. Dispersive,

however, is a high shear process as it utilizes wide

kneading blocks. Wide kneading blocks force the material

around the blocks that is squeezed between the paddles and

the barrel wall [2].

There have been numerous attempts in the past to

find a correlation between stress in an extruder and a

residence-time distribution. Efforts have been made to use

the residence distribution to imply intensity of mixing by

various methods, e.g.; Peclet number or a number of passes

[3]. Typical residence distributions, however, only provide

an axial history of the flow and give no information

regarding the stress history. In a recent study, it was shown that for any given operating condition there was a higher

percentage of stress beads that saw the critical stress for

wide kneading blocks compared to narrow kneading

blocks. It was also revealed that the amount of stress

increases as specific throughput and screw speed increased

[8].

The aim for this paper is to explore in greater

depth what accounts for these breakup differentials in wide

and narrow kneading block residence stress distributions

(RSD). Two different batches of stress beads were utilized

to aid in the insight to this question. The two different

critical stresses at which these beads break up in give a

larger range of data, allowing to further pin-point where

the true damage is occurring in the extruder. Operating

conditions were the same for all experiments so the

comparison is strictly due to geometry.

Materials

The extrusion material used for this experiment

was high-density polyethylene (HDPE) Alathon H6018 in

pellet form from Equistar Chemicals. The HDPE had a

density of 0.960 g/cc and a melt index of 18.0 g/10 min.

Stress sensitive sensor beads were utilized as the

method to measure the stress in the extruder. The beads

are used to measure shear stress during mixing by breaking

at specific critical stress levels which are dependent on the

bead diameter. When the beads are subjected to stress

levels beyond the critical shear stress, the beads break and

release their encapsulated dye which stains the polymer

melt. Two levels of stress beads were selected to

determine if the individual bead could distinguish between

the stresses induced by the different mixing elements. The

critical stresses of the two beads used in this experiment

were 92 kPa and 119 kPa.

Using the same dye that is encapsulated by the

stress beads, Red B Disazo for the 119 kPa stress level

beads and Automate Blue 8A for the 92 kPa, “reference”

dye shots were produced. These shots were prepared by

dissolving polystyrene pellets in xylene, and adding

concentrated amounts of dye. The solution was allowed to

solidify over a 24 hour period. The batch was then cut into

small pieces and weighed to the amount of the measured

stress bead shots. The dye shots were used to produce

reference RTD curves that represented 100% breakup of

the stress beads.

Equipment

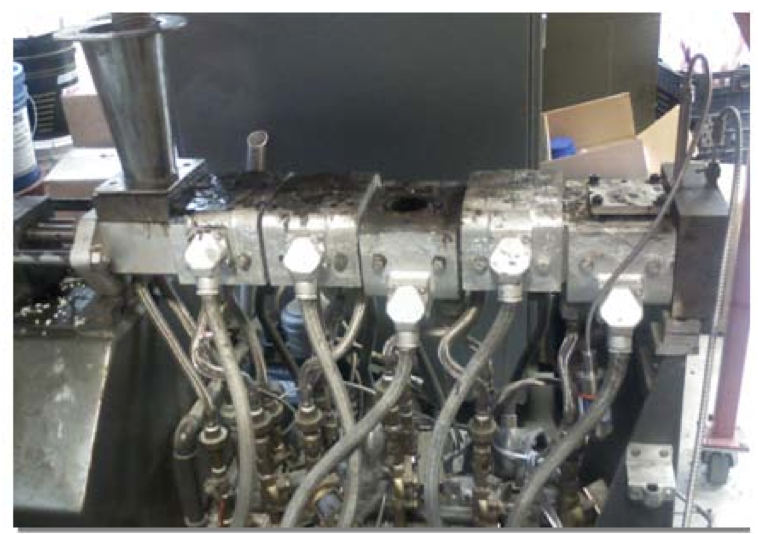

The experiments were performed using a 28-mm

Coperion CoTSE extruder with an L/D = 32 using two

screw configurations of interest. The melting section of

both screw designs remained unchanged for the duration of

the experiment and consisted of one right-handed kneading

block (28-mm) and one left-handed kneading block (14-

mm). The mixing section of the first screw design

contained two right-handed kneading blocks (15 and 42-

mm) and one left-handed conveying element (28-mm).

The second screw configuration consisted of four righthanded

kneading blocks (15-mm) and one left-handed

conveying element (28-mm). The extruder set up consists

of a feed port and one vent port just before the mixing

section, as seen in Figure 1. The extruded polymer was

cooled via a chill roller where it was then collected as

strips.

Figure 1. 28-mm Coperion Co-Rotating TSE

A reflective optical probe was placed just before

the die of the extruder. The probe consists of a split fiberoptic

bundle, where light was emitted from one of the fiber

bundles. The light reflected off the polymer and screw

elements, and was collected by the other fiber bundle,

where it was converted into a voltage signal.

Experiment

The extruder and pellet feeder were set to the

desired operating condition. The five barrels were set to a

temperature of 200

oC and the die was set to 195

oC. The

data acquisition program began sampling for 15 seconds to

establish a baseline. Due to the transparent nature of HDPE

during extrusion, TiO

2 pellets were fed at a constant rate

during the experiment to provide a white background to the

polymer melt so the optical probe could make

measurements. Both the stress beads and the solid pieces of

dye were injected into the vent port through a modified

syringe. The tip was removed and covered tightly with a

layer of thin lens paper. Then either the pieces of dye or stress beads were loaded into the syringe so that they lay

on top of the lens paper. Adding a plastic point to the

rubber tip allowed the plunger to pierce the lens paper

releasing the shot. When the TiO

2 white baseline became

constant the syringe would be held over the vent port and

the shot would be injected in a single impulse. This method

proved more precise in minimizing the channels the shot

would disperse in. Since small amounts of the dye shots

were fed into the extruder, the concentration of the dye and

polystyrene had a negligible effect on the viscosity of the

HDPE melt. Once the stained polymer had been

completely extruded, the data acquisition program was

reset and the program was again run for 15 seconds to

establish a baseline. In total, nine operating conditions

were tested, with two dye and two stress bead shots fed per

condition.

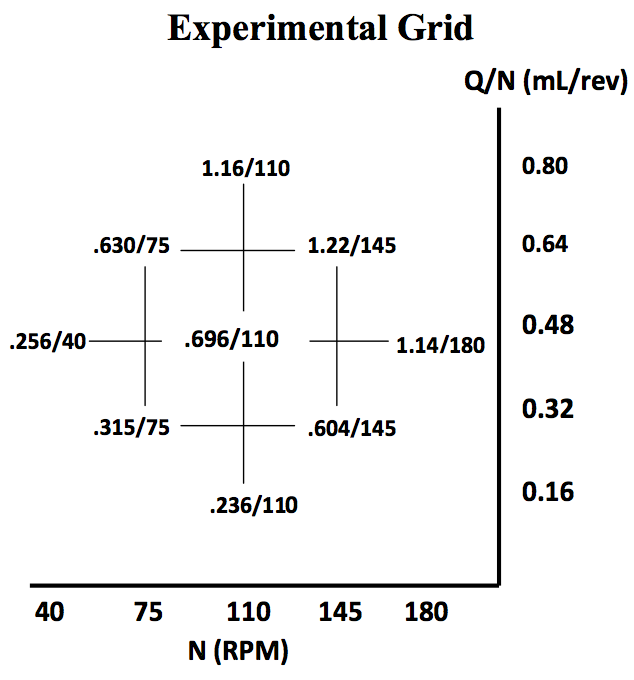

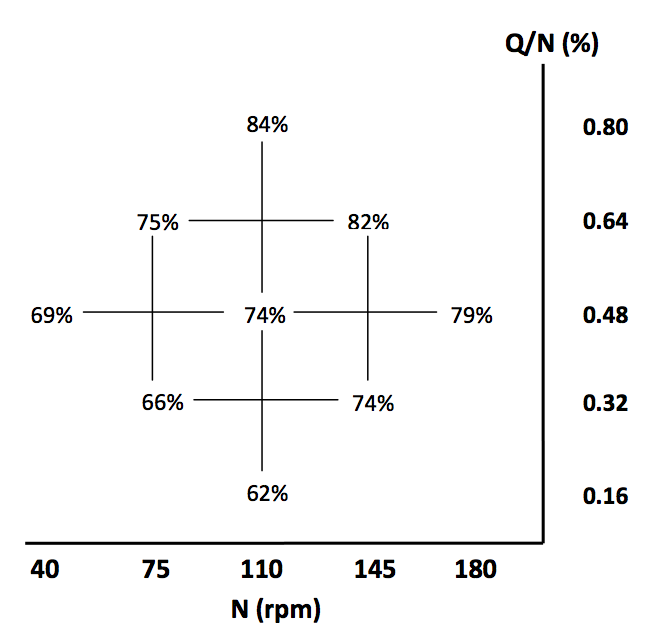

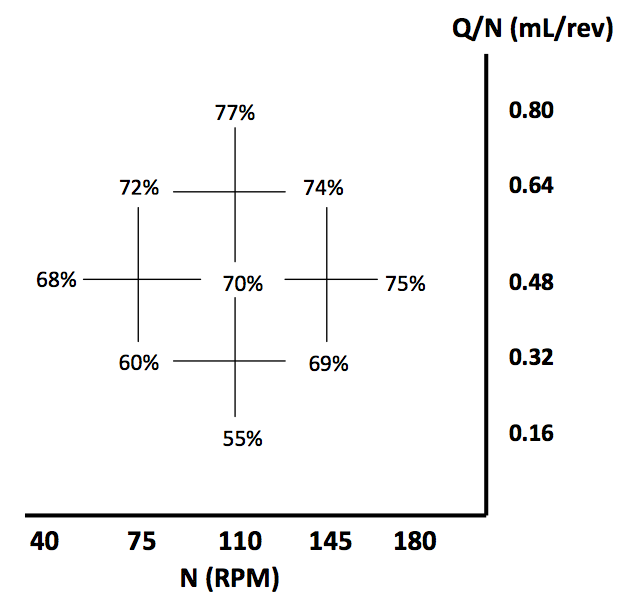

Figure 2. CCD grid of experimental conditions

A central composite design (CCD) of experiment

grid was used to layout the data to show relationships

between percent breakup and different operating

conditions, as seen in Figure 2. This approach was chosen

because of the expected non-linear relationship between

breakup and the chosen parameters. The specific locations

on the grid represent the operating conditions for this

study.

The ranges of the conditions were determined by

the capabilities of the extruder. The first number of a

condition represents the throughput, Q, measured in mL/s.

The second number represents the screw speed, N, in rpm.

N vs. Q/N was chosen because RTDs scale with Q and N.

Theory

To better understand what mechanisms are

responsible for breaking the beads, both shear and

elongation (extensional) stress calculations were

preformed. The shear stress was calculated using the

following equation:

Where τ is shear stress (Pa), μ is viscosity of the polymer

(Pa-s), y is shear rate (1/s), and n is the power law index.

The shear rate is defined as:

where N is screw speed (rpm), D is the screw diameter

(mm), and h is the channel height (mm).

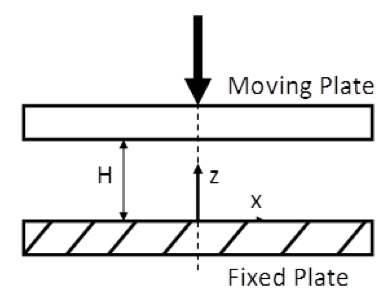

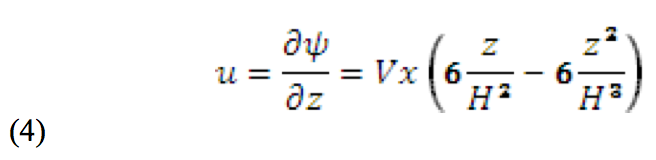

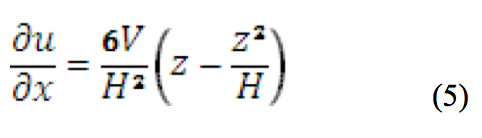

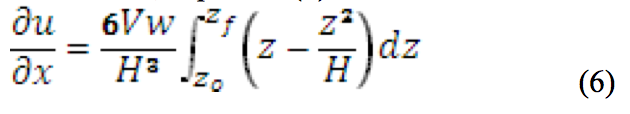

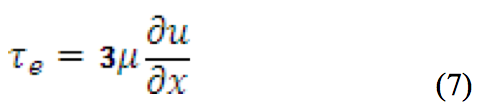

The extensional equation is derived by

considering a flow between two plates. One of the plates is

stationary, and the other is moving towards the plate, as

seen in the following figure below (Figure 3).

Figure 3. Squeezing plate figure

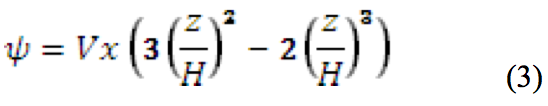

Starting with the vorticity equation and

substituting in the stream function equation to solve for the

stream function (which is done so in almost every fluid

mechanics text book), the resulting equation is given by:

From Equation (3), the horizontal velocity component (u)

can be obtained by:

The term of interest is the extensional shear rate in the

horizontal direction. To obtain this, Equation (4) is

differentiated with respect to x.

Integrating the z term over the height between the two

plates, and adding scale terms to keep the dimensions of

the equations the same, Equation (6) is derived.

Where V is the velocity of the moving plate (mm/s), H is

the final height between the plates (mm), w is the width of

the kneading block paddle (mm).

The extensional stress (τ

e) can be calculated using

Equation (7).

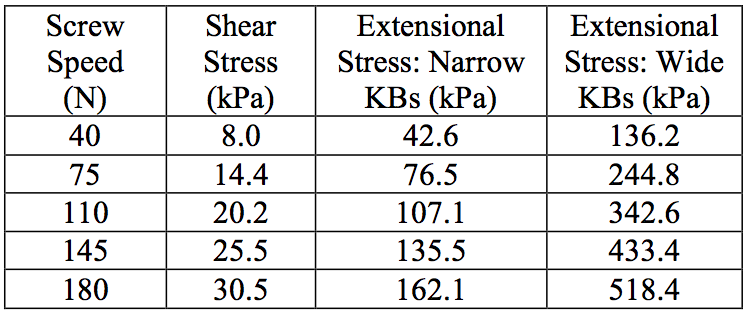

The results from both calculations are displayed in Table 1.

Table 1. Calculated shear and extensional stresses

The extensional stress equation is a good

approximation of the stress since it increases as the width

of the kneading block paddle increases. Breakup in the

kneading blocks could either occur in the flow in the

channel or through the gaps between paddles. This would

induce shear stress. Another possibility could be due to the

squeezing of the fluid when opposing paddles approach

one another. This causes elongational stress. Comparing

the calculations, it is clear that the elongational stress has a

higher magnitude than the shear stress approximations.

This could provide some insight into the mechanisms that

is causing the bead breakup.

Experimental Results

Percent BreakupThe average percent breakup for all nine

experimental conditions was calculated and the results

inserted into the Central Composite Design grid for

analysis as a way to compare the breakup history in the

wide and narrow kneading block configurations. To

determine the percent breakup of stress beads, the areas

under the RTD and RSD curves were calculated and used

in the followed equation:

Where Ac is the area under the RSD curve and Ar is the

area under the dye RTD curve.

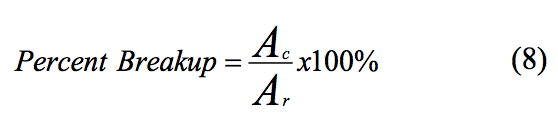

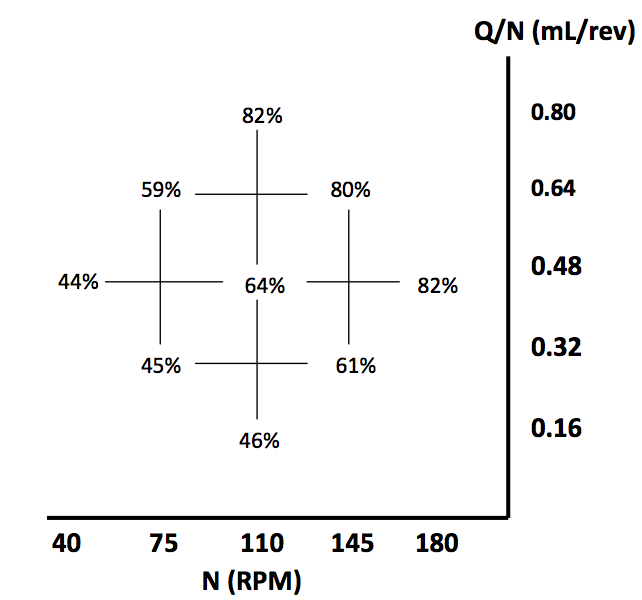

The first set of beads used in the experiment was the higher

critical stress beads (119 kPa). Figures 4 and 5 below

displays the percent breakup of stress beads in the CCD

grid using Screw 1 and Screw 2, respectively.

Figure 4. Percent breakup of 119 kPa beads using wide kneading blocks

Figure 5. Percent breakup of 119 kPa beads using narrow kneading blocks

The CCD grids displayed in Figures 4 and 5 indicate that

there are trends in the data that are consistent between the

two screw geometries. As screw speed is increased for a

given specific throughput, the percent breakup of the stress

beads also increases. Additionally, as specific throughput

increased, the percentage of broken beads also increased

for a given screw speed.

Given the experimental error, which was

calculated to be 2%, the average range of breakup for both

grids is approximately 35% between the lowest and highest

magnitude of breakup. However, differences between the

grids exist. The magnitude of the percent breakups is

different between the two geometries. The wide kneading

blocks reach a maximum value of 82%, while the narrow

kneading blocks only reach a maximum percent breakup

value of 70%. Similarly, for a given operating condition,

the percent breakup due to the wide kneading blocks is

larger than the narrow kneading blocks, in every case.

Through the trends in the data, screw geometry

and screw speed are not enough to predict the amount of

bead breakup that will occur. A consideration for the

specific throughput also needs to be accounted for when

predicting breakup.

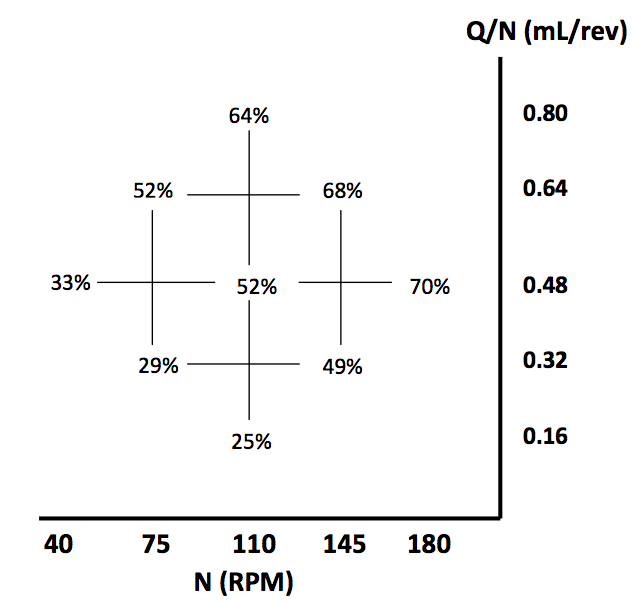

The second set of stress beads (92 kPa) were then

used, and the results of the experiments using wide

kneading blocks were plotted in Figure 6 and the results

using narrow kneading blocks were plotted in Figure 7.

Figure 6. Percent breakup of 92 kPa beads using wide kneading blocks

Figure 7. Percent breakup of 92 kPa beads using narrow kneading blocks

Similar to the plots shown in Figure 3 and 4, there

are also consistent trends in the results of the experiments

using the 92 kPa stress beads. It is seen again that by

increasing Q/N and N, a higher percentage of stress beads

that break is produced.

The average range of breakup for this set of

geometries is approximately 15% between the lowest and

highest breakup. The maximum breakup for the wide

kneading blocks was found to be 84% and a maximum

value of 77% for the narrow kneading blocks. Similar to

the other results using the 119 kPa beads, the wide

kneading blocks caused more beads to break for each

operating condition in the experimental grid.

Looking at the two CCD grids for the 119 kPa

beads and the two grids for the 92 kPa stress beads, there

are similar trends between the two. For both sets of beads,

as screw speed and flow rate are increased, the percentage

of broken stress beads increased in every condition.

Additionally, wide kneading blocks caused more breakup

than narrow kneading blocks for each condition for both

levels of stress beads. This again confirms the fact that

wide kneading blocks are ideal for dispersive mixing

because of the larger induced extensional flow.

Comparing the differences between the two sets

of stress beads (Figures 3 and 4 versus Figures 5 and 6), it

is apparent that there was less breakup using the stress

beads that had a critical stress of 119 kPa than the beads

with a critical stress of 92 kPa. This is most noticeable for

the three operating conditions with the lowest flow rates

(.256mL/s - 40 rpm, .315mL/s - 75rpm, and .236mL/s -

110rpm) where the average difference between breakups of

the wide kneading blocks was approximately 20% between

119 kPa and 92 kPa stress beads, and even more apparent

using the narrow kneading blocks where the average

difference between the two stress beads is over 30%.

However, the differences in percent breakup for the three

operating conditions with the highest flow rates (1.16mL/s

– 110rpm, 1.22mL/s – 145rpm, and 1.14mL/s – 180rpm)

are not as large. The average difference for the narrow

kneading blocks is a little more than 5% and there appears

to be no difference for the wide kneading block geometry.

This is due to the limitations of the analytical method,

which can be seen in the residence stress distribution

curves.

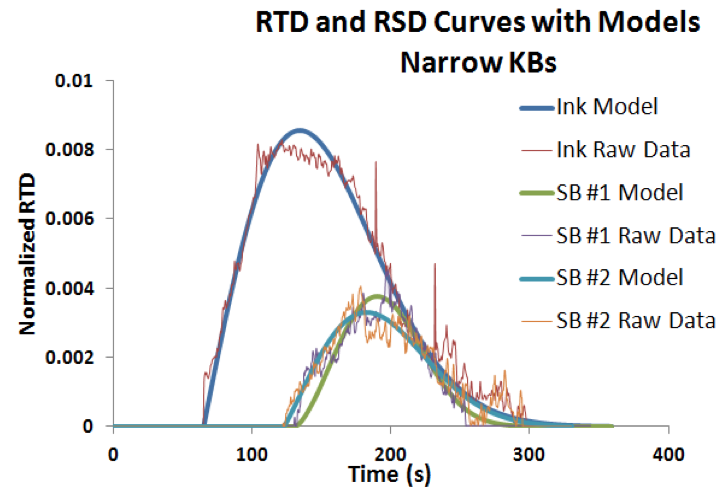

Residence Stress DistributionsUsing the RTD and RSD curves generated by the

experiments, a visual representation of the percent breakup

could be generated, as seen in Figure 8.

Figure 8. Normalized narrow kneading blocks RTD and RSD curves for .315mL/75rpm condition

The figure above shows the normalized RTD and

RSD curves produced by the ink and 119 kPa stress beads (SB) shots, as well as models generated using a Weibull

model. The percent breakup for this particular operating

condition was 29%. The two sensor bead shots are nearly

identical, indicating that the experiment is repeatable.

Additionally, the amplitude of the ink curve is much larger

than the sensor bead curves, indicating that 100% breakup

was not achieved. It is clear that there is a delay between

the start of the ink curve and the start of the sensor bead

curves. As a percentage of the beads flow through the

center of the channels in between the paddles of the

kneading blocks, the beads experience very little shear

stress. This delay time provides evidence that 100%

breakup of sensor beads will never be achieved, and could

indicate why more than 80% breakup could not be

achieved for the 92 kPa stress breads using wide kneading

blocks.

Conclusions

A previous paper has introduced the use of stress

sensitive beads as an effective tool to measure the stress

history in the complex geometries found in twin-screw

extruders. For this experiment a comparison of wide and

narrow kneading block screw configurations was

performed over a range of specific throughputs (Q/N) and

screw speeds (N) as well as over two different strength

stress beads. For a given operating condition the

percentage of beads broken was higher for wide kneading

blocks when compared to narrows, of equal length, and for

the 92 kPa beads when compared to the 119 kPa beads, of

equal amounts.

These results can be interpreted in two ways.

They first help to reaffirm that for the wide kneading

blocks a higher percentage of stress beads experienced the

critical stress at the same operating conditions, in all cases.

This outcome has been replicated twice for each operating

condition because this pattern holds true for both sets of

beads. Secondly the results help to validate the use of the

stress beads by showing that the beads do not break

arbitrarily, but at certain predetermined critical stress

values.

Through the calculation of shear and extensional

stresses through the kneading blocks, it can be concluded

that extensional stresses play a dominate role as the

mechanism that causes the stress beads to break. This

indicates that the stresses occur in the region between the

two screws when the material on one paddle is forced to

flow to either side of the paddle and is squeezed by the

paddle from the other screw.

These results illustrate the validity of this method

of modeling stress in a twin-screw extruder. Further analysis and experiments can yield even more insights into

the stress history of an extruder. Such that it may be

possible to dictate how much material sees certain levels of

stress by selecting a screw geometry, specific throughput

and screw speed.

References

1. K. Kohlgruber, “Co-Rotating Twin - Screw

Extruders”, Hanser Gardner Publications, Inc., Ohio,

pp 22-275 (2008).

2. H.F. Giles, Jr., J.R.Wagner, Jr., and E.M. Mount, III,

“Extrusion: The Definitive Processing Guide and

Handbook”, William Andrew, Inc., New York, pp.

119-121 (2005).

3. Z. Tadmor and C.G. Gogos, “Principles of Polymer

Processing”, John Wiley & Sons, Inc., New Jersey, pp.

648-650 (2006).

4. J. Curry and A. Kiani, “Measurement of Stress Level

in Continuous Melt Compounders”, SPE-ANTEC

Tech. Papers, 36, 1599-1602 (1990).

5. J. Curry and A. Kiani, “Experimental Identification of

the Distribution of Fluid Stresses in Continuous Melt

Compounders – Part 2”, SPE-ANTEC Tech. Papers,

37, 114-118 (1991).

6. M. Gallant, “Continuously Graded Extruded Polymer

Composites for Energetic Applications”, PhD Thesis,

2003.

7. J. Cheng, Y. Xie, D. Bigio, “Characterization of

Kneading Block Performance in Co-Rotating Twin

Screw Extruders”, SPE-ANTEC Tech. Papers, 198-

202, (1998).

8. D. Bigio, W. Pappas, H. Brown II “Residence Stress

Distributions in a Twin Screw Extruder”, SPE-ANTEC

Tech. Papers, 1382-1386 (2011).

Return to

Paper of the Month.