Producing Microlayer Blown Film Structures Using Layer Multiplication and Unique Die Technology¶

Joseph Dooley, Jeff Robacki, Steve Jenkins, Patrick C. Lee, and Robert Wrisley

The Dow Chemical Company, Midland, MIAbstract

Many polymers are extruded through blown film

dies to produce monolayer and multilayer films. The

most popular style of die in use today to produce

blown films is the spiral mandrel die. This type of die

can be used effectively for many polymers in

structures containing up to approximately 10 layers.

This paper will discuss technology in which layer

multiplication techniques are combined with unique

die geometries to produce microlayer blown film

structures with significantly greater numbers of layers.

Introduction

Coextrusion is a common method used for

producing multilayer blown films. Coextrusion is a

process in which two or more polymers are extruded

and joined together in a feedblock or die to form a

single structure with multiple layers. This technique

allows the processor to combine the desirable

properties of multiple polymers into one structure with

enhanced performance characteristics. The

coextrusion process has been widely used to produce

multilayer sheet, blown film, cast film, tubing, wire

coating, and profiles [1-6].

Many polymers are extruded through blown film

dies to produce monolayer and multilayer films. The

most popular style of die in use today to produce

blown films is the spiral mandrel die [7]. This type of

die can be used effectively with many polymers to

produce monolayer and multilayer blown films.

However, this type of die normally cannot be used to

produce microlayer blown films because the complex

flow path in these dies can disrupt the continuity of the

layers.

This paper will discuss a new, unique microlayer

coextruded blown film technology in which a

microlayer structure is formed using feedblock and

layer multiplication technology and then processed

through a unique blown film die to produce a

microlayer blown film structure.

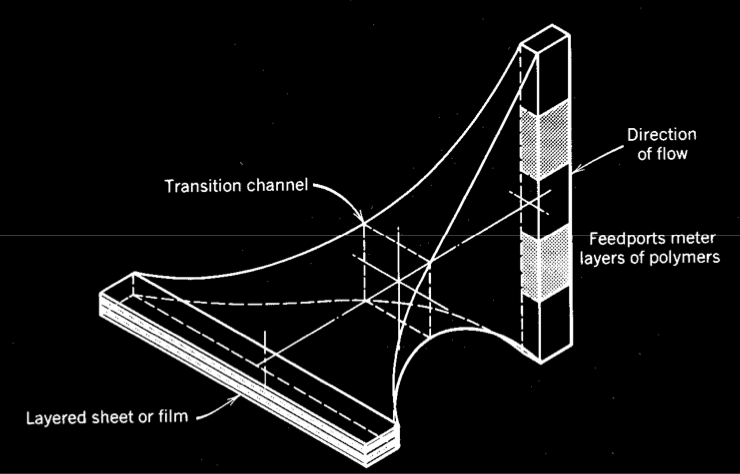

Coextrusion

A breakthrough technology was originally

developed by Schrenk and Chisholm to produce

multilayer coextruded planar structures [8, 9]. In this

technique, the layers are joined together in a device

called a feedblock prior to the die. This layered

structure is then processed through a single die

manifold. This feedblock technique is shown

conceptually in Figure 1.

Figure 1. Feedblock coextrusion to make multilayer planar products.

Another method used to produce planar

coextruded structures is with a multimanifold die. In

this technology, planar layers are formed individually

in separate die manifolds and then the layers are joined

together before the exit of the die.

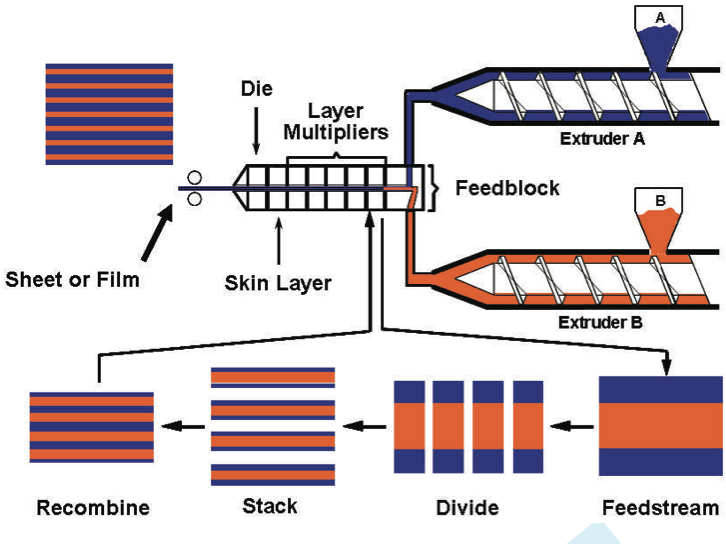

Microlayer Coextrusion

The feedblocks and dies discussed in the previous

section are suitable for producing multilayer structures

with typically ten layers or less, which is adequate for

many industrial applications. However, there have

been multilayer structures developed that require

hundreds or thousands of layers to produce unique

properties [10-13]. Among these properties are

enhancements in mechanical and optical properties.

In order to produce film or sheet structures with

hundreds or thousands of layers, new techniques were

developed to produce those structures. Standard feedblock techniques would not allow this many layers

because of mechanical difficulties in joining so many

layers. Methods to produce hundreds of layers were

developed by Schrenk and co-workers [14-16]. A

common technique is shown schematically in Figure 2.

Figure 2. The microlayer coextrusion process.

Figure 2 shows how layers are joined together in a

feedblock to form a three-layer structure. However, at

the end of the feedblock, a layer multiplier is added

that vertically divides the layers and then stacks and

recombines the structure in order to increase the total

number of layers. A series of layer multipliers can be

added to significantly increase the number of layers in

the final structure.

One important point to be made with this type of

microlayer coextrusion is that this process was

developed to produce flat sheet or cast film products.

A large portion of the film industry uses the blown

film process rather than the cast film process because

of the biaxial orientation that is imparted to the film

producing a product with more balanced properties.

This process will be described in more detail in the

following section.

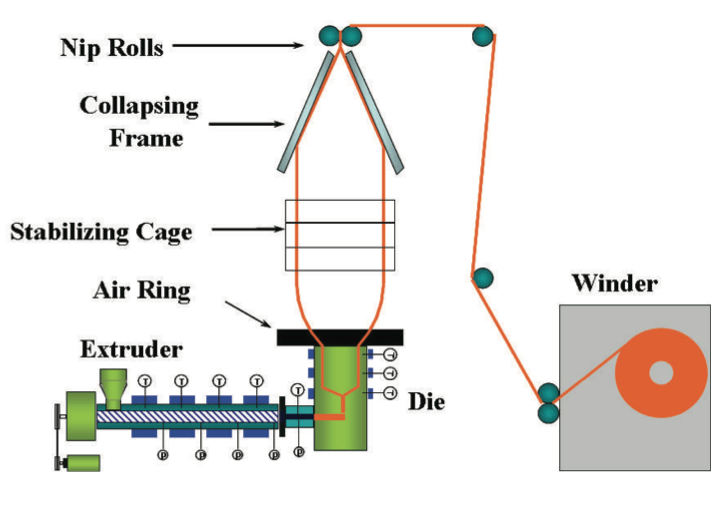

The Blown Film Process

A schematic diagram of the blown film process is

shown in Figure 3. In this process, an extruder is used

to melt and forward molten resin into an annular film

die. Air is injected into the center of the annular die to

inflate the polymer bubble. The bubble is cooled by

an air ring that blows air on the surface of the bubble

to lower its temperature until it becomes solidified.

Above the die, a stabilizing cage may be used to

minimize movement of the bubble as it is collapsed in

the collapsing frame to make a flat film. This film is then pulled over idler rolls and fed into a film winder

to make the finished film roll.

Figure 3. The blown film process.

A key part of this process is the blown film die.

The blown film die takes the polymer melt from the

extruder and shapes it into a tubular geometry to form

the film bubble. This bubble must be uniform in

thickness and temperature in order to form a uniform

bubble. The different types of annular blown film dies

that can be used in this process are described in the

following section.

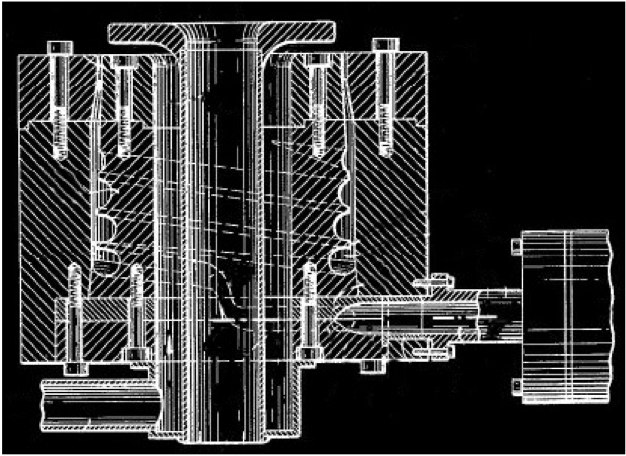

Blown Film Dies

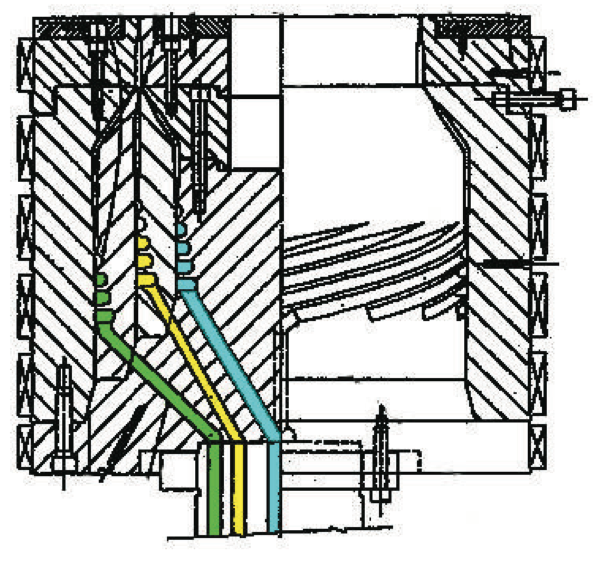

A schematic diagram of a spiral mandrel die is

shown in Figure 4 [17]. In a spiral mandrel die, the

cylindrical surface of the inner mandrel is spirally cut

with grooves that become shallower as you progress

down the channel. Since several spiral grooves are

typically cut into a single manifold, there is flow down

the channel grooves and also a leakage flow across the

lands separating the grooves. This combination of

flows produces a more uniform flow rate at the exit of

the annular die and so a more uniform thickness in the

resulting film. This type of design essentially

eliminates the weld line difficulties seen in previous

film dies. The application of this technology to the

blown film industry was a significant breakthrough and

spiral mandrel dies are now the dominant style of die

used today in the blown film industry.

Figure 4. A single layer spiral mandrel die.

In order to make a multilayer blown film structure

using spiral mandrel technology, a separate die

manifold must be made for each layer. This concept is

illustrated in Figure 5. Note in this figure how each

layer is formed by a separate spiral mandrel manifold

at a different radial distance from the center of the die.

The individual annular flow streams are formed and

then joined together near the exit of the die. If a

multilayer feed stream was fed to the entry of this style

of die, the layered structure could be destroyed as

portions of the layers flowed down the spirals but other

portions flowed across the land areas and over the next

spiral. This combination of flows would produce an

overall flow pattern that could disrupt the continuity of

the original layered melt fed to the die.

In this style of die, increasing the number of layers

in the structure is accomplished by increasing the

diameter of the die to make room for more spiral

mandrel manifolds for each new layer. This tends to

limit the number of layers that can practically be

produced on this type of die because larger diameter

dies have longer residence times and more surface area

which can lead to degradation of the polymers being

processed in the die.

Figure 5. A multilayer spiral mandrel die.

Another style of spiral mandrel die has been

developed in which the spiral channels are cut on the

surface of a flat plate rather than on the surface of a

cylinder. In this type of die, there can be multiple

overlapping spirals cut into the same plate just as was

done in the previous cylindrical spiral mandrel dies.

By bolting two of these flat plates with matching

grooves together, a spiral flow channel is created.

Because of the dimensions of these large flat plates,

these dies are sometimes referred to as “pancake” style

dies.

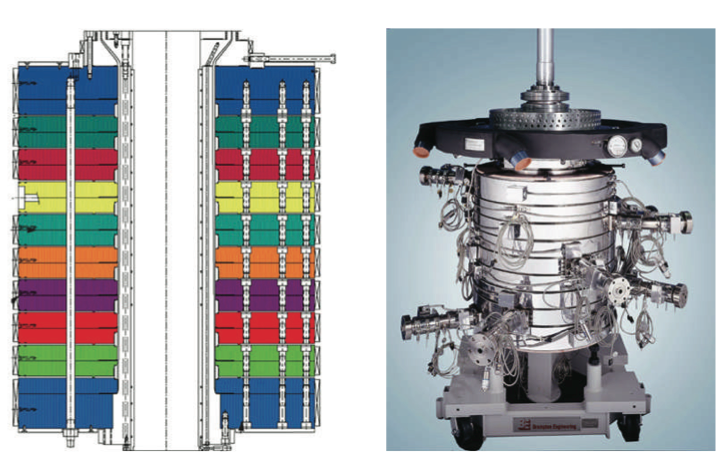

One advantage of using a flat plate die for

producing coextruded structures is the ability to stack

plates on top of each other. This is shown in Figure 6.

This figure shows a schematic diagram of multiple

stacked plates bolted together in which each set of

plates produces one layer. Each layer is added

sequentially to the previous layer as the structure flows

up the die towards the exit. This figure also shows a

photograph of a commercial stacked plate die used to produce coextruded films.

Figure 6. A multilayer stacked plate or “pancake” die.

This style of die is very versatile relative to

changing the number of layers in a structure. By

increasing or decreasing the number of plates stacked

together, it is relatively easy to change the number of

layers in the final film structure. Structures containing

up to 11 layers have been demonstrated using this type

of die design. However, stacking more die plates to

increase the number of layers beyond 11 layers

becomes difficult due to pressure drop considerations

and lack of space for more extruders.

Microlayer Blown Film Concept

As discussed in the previous section, making

multilayer blown films containing more than 11 layers

is currently not feasible using existing technology.

Technology has been developed by Schirmer [18, 19]

in which thin annular disks are stacked together to

form an annular structure with up to approximately 30

layers. This technology is similar to what is shown in

Figure 6 but the plates are very thin and use a specific

plate geometry and stacking to produce more layers.

Making the plates thinner allows more layers to be

added sequentially but a limit is reached when the

pressure drop through all of the die plates becomes too

large to process the structure. This process can also

produce non-uniform layer thicknesses in the film.

The new concept for producing microlayers in a

blown film is based on using a feedblock and layer

multipliers in combination with a unique film die.

This technique would overcome many of the pressure

drop and residence time issues seen with the existing

technology.

There are two main considerations to be taken

into account when feeding a microlayer structure into

a film die: (1) protecting the very thin microlayers as

they flow from the feedblock to and through the die,

and (2) the design of the geometry of the die to allow

the layers to flow smoothly through the die while

maintaining the microlayered structure.

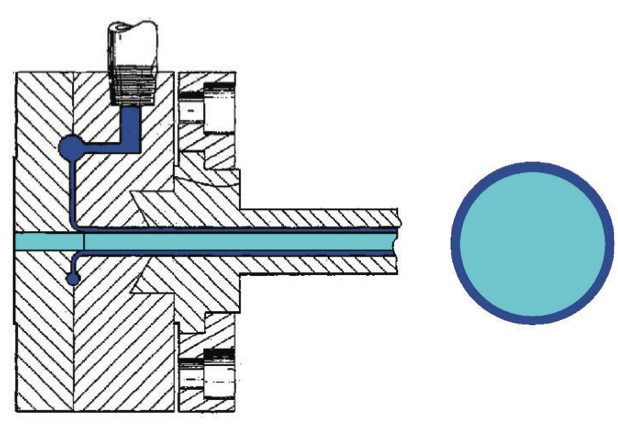

Protecting the microlayered structure as it flows

through the process can be done by encapsulating the

microlayers with another layer. This is shown

schematically in Figure 7. In this figure, an

encapsulation die is shown schematically on the left

producing a circular encapsulated structure on the

right. This diagram shows a single core material

being encapsulated by another layer but conceptually

the single core material could be replaced by a

microlayer structure.

Figure 7. A schematic drawing showing an encapsulation die on the left producing an encapsulated structure on the right.

The next consideration is the geometry of the die

to be used. As was discussed previously, a spiral

mandrel type die would tend to disrupt the layered

geometry fed to it and so this type of die geometry

probably cannot be used for a uniformly microlayered

structure.

Another type of die that could be used for this

process is a crosshead style die. In this type of die, the

flow is fed to the front side of the die where it is split

such that half of the material flows around one side of

the die while the other half flows around the other side

of the die. These two flows then join together on the

back side of the die forming a weld line region. Once

rejoined, the material then flows annularly around the

central mandrel.

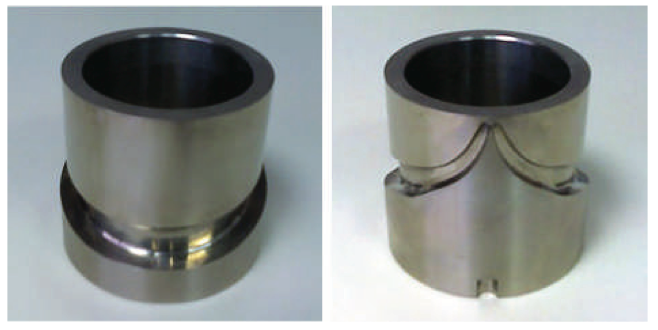

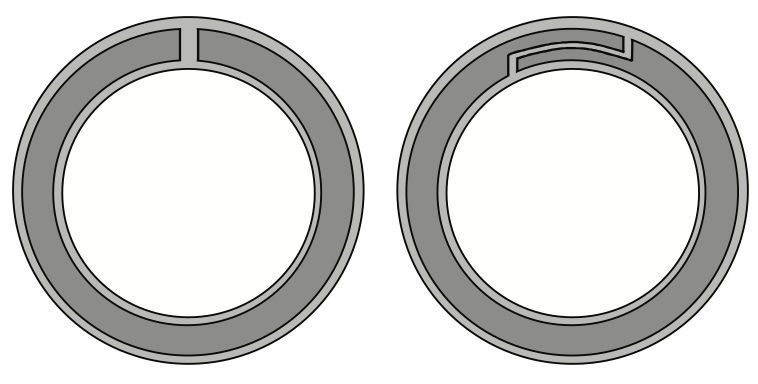

Figure 8 shows two photographs of the front and

back sides of a crosshead style die. The photograph

on the left shows the front where the flow is split into

two halves to flow around the central mandrel. The

photograph on the right shows the back of the die

where the two flow channels rejoin to form the annular

structure. Note that at the point that the two flows join

together, there is a place at which the two flows must

“weld” back together to form a single flow stream.

This area is sometimes referred to as the “weldline”

area.

Figure 8. Photographs showing the front (left) and back (right) geometries of a crosshead style die.

The difficulty encountered with feeding a

microlayer structure into a crosshead style die occurs

in the weldline area. When the microlayer structure

flows around the central mandrel and tries to rejoin in

the weldline area, the microlayers do not form a

continuous structure since there is a high probability

that each individual microlayer will not align perfectly

with the corresponding microlayer from the opposite

side of the die which leads to the discontinuity of

layers at the weldline. This difficulty can be overcome

by using technology developed and patented for

making coextruded blown barrier films [20-22].

The technology developed for making coextruded

blown barrier film consisted of encapsulating the

barrier polymer melt with a separate layer and then

processing that through a crosshead style die in which

the ends of the flow channels were overlapped. This

overlapping of the layers in the weldline area produced

a film structure with equivalent barrier properties in

the weldline area compared to other areas of the film

and eliminated the need to join the layers exactly

together in the weldline area. Dies containing this type

of technology are commercially available.

A diagram comparing an encapsulated melt in a

standard crosshead die and a die in which the ends of

the channels have been overlapped is shown in Figure

9. We have taken this technology and adapted it to

produce microlayer blown films. This diagram shows

a single core material being encapsulated by another

layer but the single core material can be replaced by a

microlayer structure and overlapped as well.

Figure 9. Comparison of an encapsulated melt in a standard crosshead die and a die in which the ends of the channels have been overlapped.

Proof of Concept for Microlayer Blown Film

In order to validate the concept of using a

feedblock, encapsulation, and a crosshead die with an

overlap geometry to produce a microlayer blown film,

a 7 inch diameter laboratory blown film line was

modified.

Microlayer Blown Films Containing 30+ LayersAs a first attempt to make a microlayer blown

film, a laboratory blown film line was modified by (1)

adding a feedblock to join together materials from two

extruders for a core layer, (2) adding a layer multiplier

to increase the number of core layers, and (3) adding

an encapsulation extruder and feedblock to

encapsulate the layered core structure. This equipment

modification produced a microlayer core structure

which was subsequently fed to a blown film die

containing a crosshead style manifold with an overlap With these line modifications in place, an

experiment was carried out to try to make a microlayer

blown film on this line. The first attempt consisted of

processing a low density polyethylene (LDPE) resin,

DOWTM LDPE 501 resin, manufactured by The Dow

Chemical Company, in all the extruders. The final

film structure would contain 27 layers from the

feedblock/layer multiplier combination, 2

encapsulation layers (top and bottom), and 5 additional

layers from the other 5 die manifolds for a total of 34

layers. A photograph of the film bubble with this

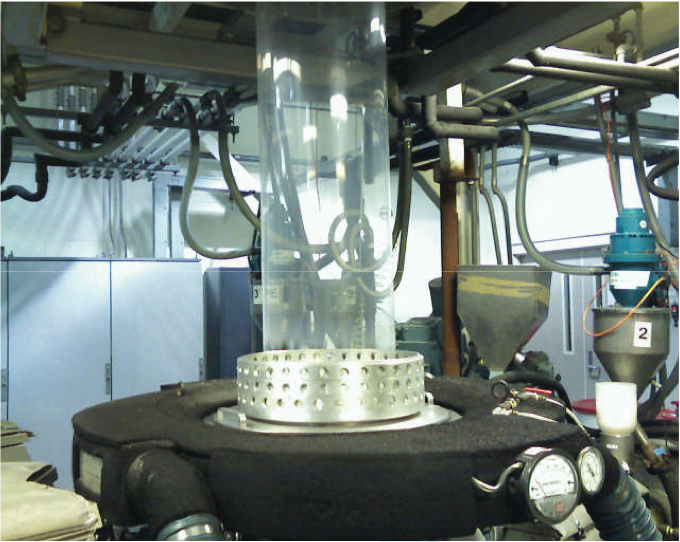

structure as it is being produced is shown in Figure 10.

This photograph is being taken from a vantage point

that shows the overlap side of the die. Note that the

film appears clear and uniform with no discernable

optical difference between the main part of the bubble

and the overlap area.

Figure 10. A microlayer blown film bubble containing 30+ layers.

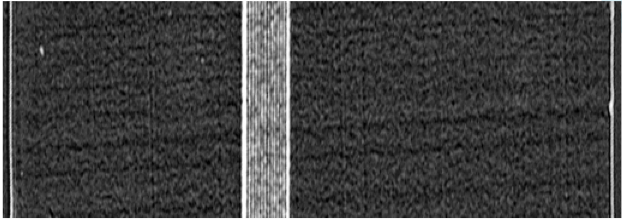

Figure 11 shows a photomicrograph of a crosssection

the microlayer blown film containing 30+

layers. The core microlayers are pigmented to make

them more visible during microscopy. This sample

showed that all of the microlayers were intact in the

structure.

Figure 11. A photomicrograph of a microlayer blown film containing 30+ layers.

This photomicrograph shows that the microlayer

core containing 27 layers was about 8% of the total

thickness of the 2 mil film. This makes each

microlayer approximately 0.006 mils or 0.15 microns

thick.

A second set of microlayer blown films were

produced with different materials in the core layers in

order to improve our ability to differentiate between

the layers during microscopy. These films had

microlayer cores composed of alternating layers of

DOW

TM LDPE 501 resin and AFFINITY

TM 1140

Polyolefin Plastomer resin, both manufactured by The

Dow Chemical Company. The density difference

between these resins allowed the use of Atomic Force

Microscopy (AFM) to produce images showing the

layered structure.

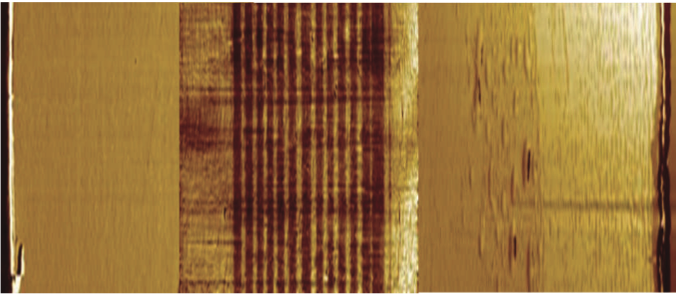

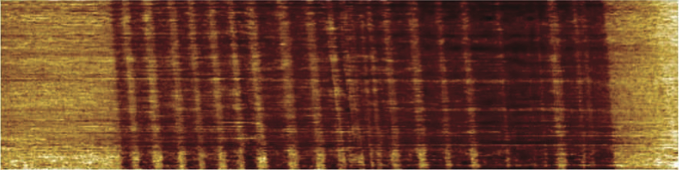

Figure 12 shows an AFM image of this microlayer

blown film containing the LDPE and polyolefin

plastomer resins with a thicker core. This core layer is

approximately 25% of the total thickness compared to

only 8% in the previous structure.

Figure 12. An AFM image of a microlayer blown film containing 30+ layers with a thicker microlayer core.

One important question that needed to be

answered in these blown film trials was whether the

microlayer structure would remain intact all the way

around the film tube and in the overlap area. AFM

images are shown in Figures 13 and 14 with expanded

views of the core microlayers near the die entry region

and near the die overlap for our microlayer film with a

core composed of alternating layers of LDPE and the

polyolefin plastomer resins. These images show the

layers are intact near the die entry and remain so in the

overlap area. Note in Figure 14 that the total number

of core layers has doubled since we are now

overlapping those layers on the back side of the die.

Figure 13. An AFM image showing an expanded view of the core microlayers near the die entry region in a microlayer blown film containing 30+ layers.

Figure 14. An AFM image showing an expanded view of the core microlayers near the die overlap region in a microlayer blown film containing 30+ layers.

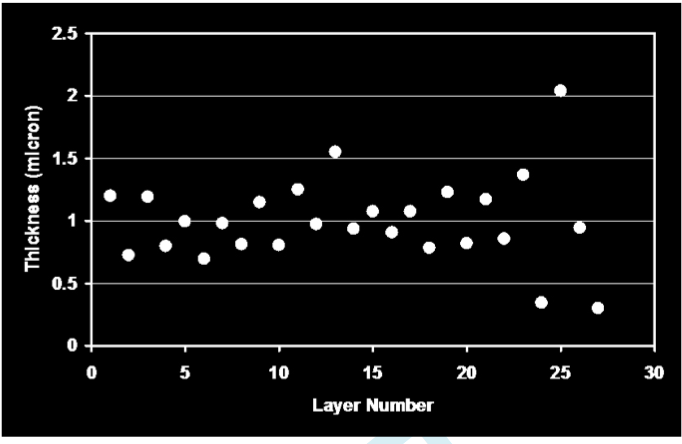

Figure 15 plots the thickness of the 27 microlayers

near the die entry in the core of the microlayer blown

film described previously, but with a total overall

thickness of 4 mils. Note that the thickness of the individual layers is fairly uniform and averages about 1

micron in thickness.

Figure 15. The layer thickness distribution for the core microlayers in a microlayer blown film containing 30+ layers.

Microlayer Blown Films Containing 100+ Layers

Our next target in making microlayer blown films

was to significantly increase the number of microlayers

in the core of the film.

Using the modified line set-up, the 27 layers

created previously were processed through a layer

multiplier to make 108 core layers. These 108 core

layers were then sent through the encapsulation die to

coat the outside of the microlayer core structure.

Figure 16 shows a sample taken from near the exit of

the encapsulation feedblock showing the encapsulated

108 layer structure before it enters the die. This

sample was taken to ensure that the layers were intact

prior to their entry into the die. Note the four bands of

black and white pigmented layers. These bands

correspond to the channels in the layer multiplier. The

surface layers in each band are white and so there are

two white layers between each band producing a white

layer with twice the thickness of the other layers.

Figure 16. A photograph showing the encapsulated microlayer structure prior to the die entry.

With these new line modifications in place, an

experiment was carried out to try to make a microlayer

blown film on this line. Once again our first

experiment consisted of processing low density

polyethylene resin in all the extruders. The final film

structure would contain 27 layers from the microlayer

feedblock multiplied four times by the layer multiplier

to produce 108 layers, 2 encapsulation layers (top and

bottom), and 4 additional layers from the other 4 die

manifolds for a total of 114 layers. A photograph of

the film bubble with this structure as it is being

produced is shown in Figure 17. This photograph is

being taken from a vantage point that shows the

overlap side of the die. Note that this 100+ layer film

appears clear and uniform with no discernable optical

difference between the main part of the bubble and the overlap area.

Figure 17. A microlayer blown film bubble containing 100+ layers.

Figure 18 shows an AFM image of a 100+

microlayer blown film containing LDPE and

AFFINITY

TM Polyolefin Plastomer resins. An

important question that needed to be answered was

whether the 100+ microlayer structure would remain

intact in the film. The AFM image shown in Figure 18

is an expanded view of the core microlayers near the

die entry region that shows the layers are intact near

the die entry.

Figure 18. An AFM image showing an expanded view of the core microlayers near the die entry region in a microlayer blown film containing 100+ layers.

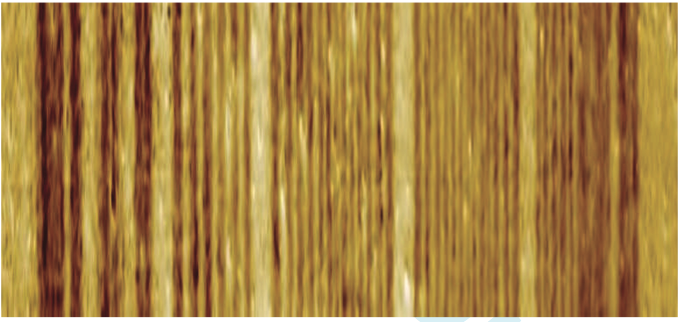

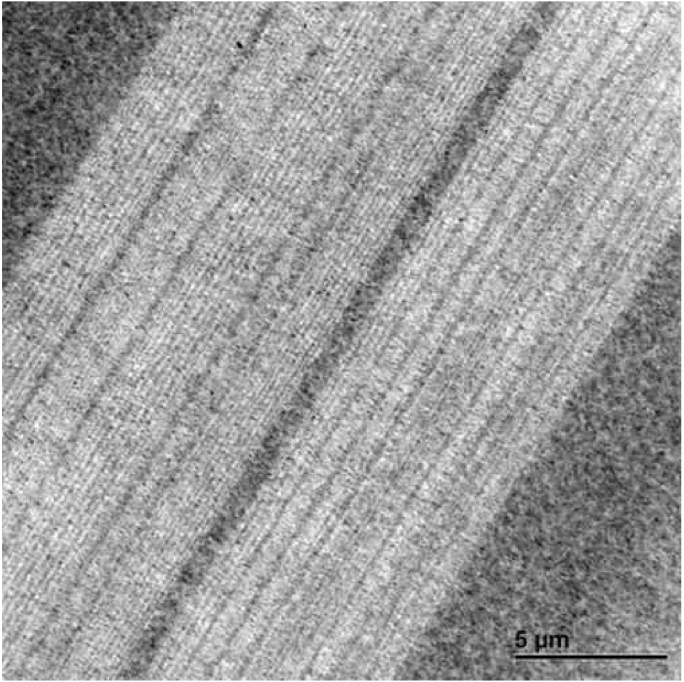

Just as Figure 18 shows an AFM image of the core

microlayers near the entry region of our microlayer

blown film containing 100+ layers, Figure 19 shows a

Transmission Electron Microscopy (TEM) image of

the core microlayers near the overlap region of the

microlayer blown film containing 100+ layers.

Figure 19. A TEM image showing an expanded view of the core microlayers near the overlap region in a microlayer blown film containing 100+ layers.

Figures 18 and 19 show the 100+ layers in our

microlayer blown film are intact near the die entry and

remain so in the overlap area. Note in Figure 19 that

the total number of core layers has doubled since we

are now overlapping those layers on the back side of

the die and so this figure actually shows more than 200

microlayers in the overlap area.

Conclusions

A new, unique microlayer coextruded blown film

technology has been developed in which a microlayer

structure is formed using feedblock and layer

multiplication technology and then processed through

a unique blown film die to produce an annular blown

film structure. This technology has been used to

produce microlayer blown films with over 100 layers.

A patent case has been filed covering this new

processing technology.

References

1. L.M. Thomka and W.J. Schrenk, Modern Plastics, (April 1972).

2. C.D. Han, J. Appl. Poly. Sci., 19 (1975).

3. W.J. Schrenk, Plastics Engineering, 30, 65, (March 1974).

4. J.A. Caton, British Plastics, 3, (1971).

5. L.M. Thomka, Plastics Engineering, 18, (Feb. 1973).

6. C.R. Finch, Plastics Design Forum, 59, (Nov./Dec. 1979).

7. J. M. Dealy and K. F. Wissbrun, Melt Rheology and Its Role in Plastics Processing, p. 537, Van Nostrand Reinhold, New York, 1990.

8. D. Chisholm and W.J. Schrenk, U.S. Patent 3,557,265 (January 19, 1971).

9. W.J. Schrenk, D.S. Chisholm, K.J. Cleereman, and T. Alfrey Jr., U.S. Patent 3,759,647 (September 18, 1973).

10. J. Im, and W. J. Schrenk, Coextruded Microlayer Film and Sheet, J. of Plast. Film & Sheeting,4,104, (April 1988).

11. T. Alfrey, Jr., and W. J. Schrenk, Multipolymer Systems, Science, 208, 813, (May 1980).

12. T. Alfrey, Jr., E. F. Gurnee, and W. J. Schrenk, Physical Optics of Iridescent Multilayered Plastic Films, Polym. Eng. and Sci., 9, 6, 400, (November 1969).

13. M. F. Weber, C. A. Stover, L. R. Gilbert, T. J. Nevitt, and A. J. Ouderkirk, Giant Birefringent Optics in Multilayer Polymer Mirrors, Science, 287, 2451, (March 2000).

14. W. J. Schrenk, U.S. Patent 3,884,606, (May 20,

1975).

15. W. J. Schrenk, R. K. Shastri, and R. E. Ayres,

U.S. Patent 5,094,788, (March 10, 1992).

16. W. J. Schrenk, R. K. Shastri, and R. E. Ayers,

U.S. Patent 5,094,793, (March 10, 1992).

17. H. Upmeier, U.S. Patent 3,689,192, (September 5, 1972).

18. H. G. Schirmer, U.S. Patent 5,762,971, (June 9, 1998).

19. H. G. Schirmer, U.S. Patent 6,413,595, (July 2, 2002).

20. U.S. Patent 6,685,872, (February 3, 2004).

21. J. Dooley, S. Jenkins, and J. Naumovitz, An Experimental Study of the Flow of an Encapsulated Polymer Melt Through a Unique Blown Film Die, SPE-ANTEC Technical Papers, 47, 386 (2001).

22. K. Xiao, S. Jenkins, and J. Dooley, Novel Methods to Process High Barrier PVDC, TAPPI, Polymers, Laminations, Adhesives, Coatings, & Extrusions Conference, Paper 3-1 (2008).

Key Words: Microlayer, Coextrusion, Blown Film,

Dies, Spiral Mandrel, Crosshead, Feedblock, Layer

Multiplication.

Return to

Paper of the Month.