Troubleshooting Gear Pump Assisted Single-Screw Extrusion Processes

Mark A. Spalding and Wenyi Huang, The Dow Chemical Company, Midland, MI

Daniel Smith, Maag Automatik, Inc., Charlotte, NC

Gregory A. Campbell, Clarkson University/Castle Associates, Jonesport, MEAbstract

Gear pumps are often used in tandem with singlescrew

extruders to increase rate, decrease resin

consumption, improve process stability, and decrease the

extrudate temperature. When a process is unstable, it is

often not obvious if the extruder is unstable and the gear

pump is operating well, or the extruder is operating well

and the gear pump operation is unstable. This paper will

describe a few operations where gear pumps improved a

process, how they can be used in unstable processes, and

approaches to troubleshooting lines using gear pumps.

Introduction

Gear pumps are often positioned between smooth-bore

single-screw extruders and dies, providing several

processing advantages. These advantages include the

mitigation of pressure surges and thus flow surges from the

extruder, a decrease in the discharge temperature by

generating part of the pressure required for the die by the

pump instead of by the extruder, reducing resin

consumption, and for rate increases [1,2]. For example, if

the extruder is operating with a relatively small pressure

oscillation with time (or pressure surge) to the inlet of a

gear pump, the gear pump will provide a nearly constant

outlet pressure and flow rate to the downstream equipment

such as a die. Stable operations with a gear pump will

allow plant personnel to operate at the lower specification

limits for sheet or film and thus reduce the resin

consumption per unit of product. If a gear pump is

contributing to the generation of the discharge pressure for

the downstream equipment, the metering section will

operate with a higher specific rate as compared to a process

without a pump. Extruders that operate at a higher specific

rate will generally operate at a lower discharge temperature

[3]. A gear pump used with a two-stage, vented screw can

allow high operating rates at higher discharge pressures

while not causing material to flow into the vent.

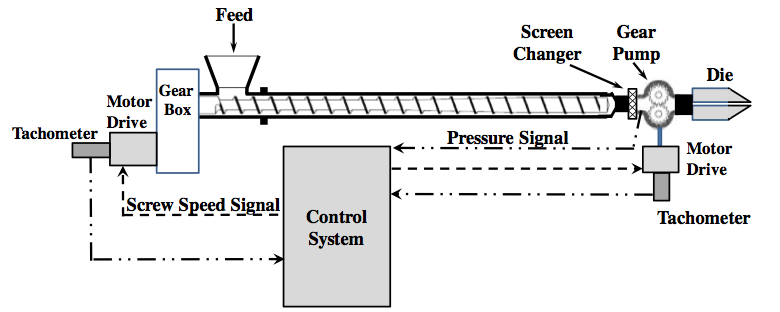

For gear pump assisted extrusion, the extruder control

algorithms are set to maintain a constant pressure to the

inlet side of the pump by the extruder. The pump is

operated at a constant rotational speed and thus it delivers

molten polymer at a very steady and controlled rate. A

schematic of a gear pump assisted extrusion process is

shown in Figure 1 for a single-stage extruder. If the

pressure to the inlet of the pump is less than the set point

value, then the control algorithm will increase the screw speed of the extruder. Conversely, if the inlet pressure is

too high the control system will decrease the screw speed.

For properly designed systems, the screw speed will only

have relatively small changes to compensate for slight

changes in the pump inlet pressure. But for extrusion

processes that are not operating properly and show severe

flow surging, the screw speed will have large variations.

Figure 1. Diagram of a typical gear pump installation for a single-stage extruder and a screen filtering system. The control schematic for extruder screw speed is included.

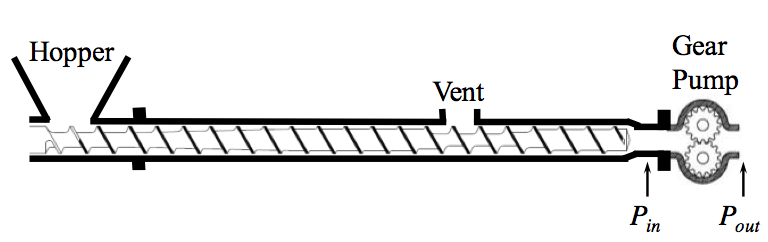

Figure 2. Schematic of a two-stage, vented extruder with a downstream gear pump.

Gear pumps allow higher rates and higher discharge

pressures for two-stage, vented extruders. A schematic of

this process is shown in Figure 2. Since the vent is at

atmospheric pressure or under vacuum, all pressure

required to operate the die for a system without a gear

pump must be generated in the second-stage metering

section of the screw. If the pressure required to operate the

die is higher than what the second stage metering channel

can develop, then molten resin will flow into the vent

opening. A gear pump, however, can allow higher rates

and higher discharge pressures while eliminating vent

flow. For this case, the metering section only needs to

generate enough pressure to operate safely the pump, a

pressure typically about 2 to 8 MPa. This pressure level is

high enough to keep the gear channels completely full of

resin and maintain lubrication in the bearings. The pump

will then increase the pressure to a higher level as required

by the downstream equipment. Moreover, if the gear pump

is generating most of the pressure required for the

downstream equipment, then the screw and extrusion

process can be optimized to a lower discharge temperature

[4].

The goal of this paper is to show the attributes of

positioning a gear pump in tandem with a single-screw

extruder, and provide troubleshooting methods for tandem

operation.

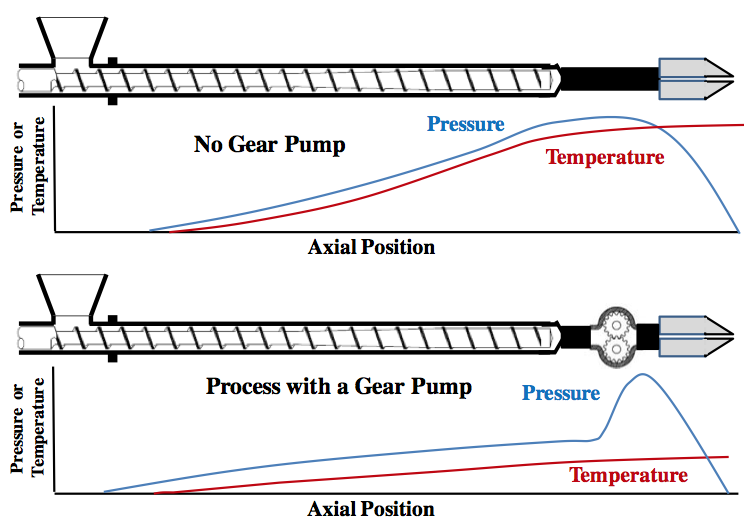

Temperature Reduction

A gear pump is a common method to decrease the

discharge pressure from the extruder, especially if the

discharge pressure required by the die is relatively high.

Decreasing the discharge pressure from the extruder will

cause the specific rate to increase and the discharge

temperature to decrease. A schematic for the axial pressure

and temperature for a single-stage process is shown in

Figure 3. Here the pump is generating the pressure rather

than the metering section of the screw, allowing the

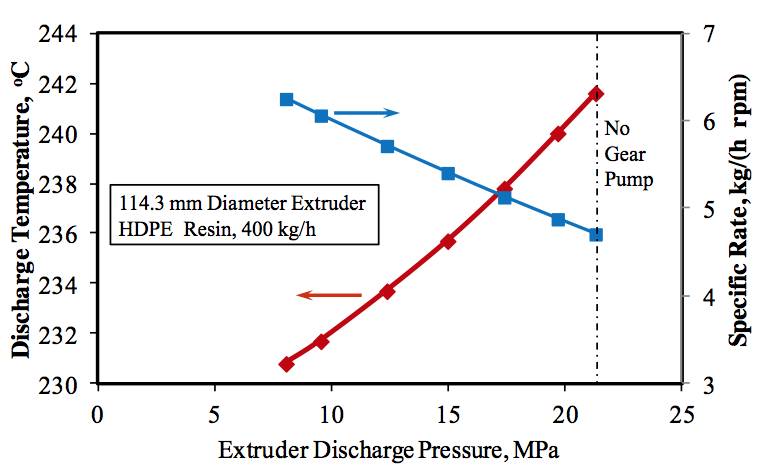

discharge temperature to decrease. For example, a process

and die required a pressure of 21 MPa for operation at a

rate of 400 kg/h for a high density polyethylene (HDPE)

resin with a melt index of 0.08 dg/min (190

oC, 2.16 kg). If

all of the pressure is provided by a single-stage 114.3 mm

diameter extruder (screw design fixed), the discharge

temperature will be about 242

oC, as shown by the

operating curve in Figure 4. Here the specific rate for

operation is 4.7 kg/(h rpm). But if a gear pump is

positioned between the extruder and the die such that a

portion of the required pressure is generated by the pump,

then the specific rate for the operation of the screw will

increase (causing the screw speed to decrease at a fixed

rate) and the discharge temperature will decrease. For

example, if the inlet pressure to the gear pump (discharge

pressure from the extruder) in this case was 8 MPa, the

extruder would discharge at 231

oC and operate at a specific

rate of 6.3 kg/(h rpm). Thus, the discharge temperature

could be decreased by 11oC and the specific rate increased

by 1.6 kg/(h rpm), as shown in Figure 4.

Some temperature increase will occur as the resin

passes through the gear pump. This temperature increase is

small compared to the decrease in temperature due to using

the pump to increase the line pressure. The actual extrudate

temperature will depend on the design and operation of the

screw, the shear viscosity of the resin, the pressure

contribution from the pump, and the design of the pump.

Surge Suppression

Flow surging is defined as the oscillatory change in

the rate of the extruder while maintaining constant set point conditions. Flow surging can originate from many

different sources including improper solids conveying,

melting instabilities, flow restrictions, and improper

control algorithms [3,4]. Gear pumps are very effective at

mitigating pressure surges originating from the extruder,

and thus they have the capability of minimizing the resin

consumption in the final product for a process with a mild

flow surge to maintaining a level of production for

processes with severe flow surging.

Figure 3. A schematic of the axial pressure and temperature for processes with and without a gear pump. The rates for both processes are the same, but the discharge temperature for the process with the gear pump is less than that for the standard process.

Figure 4. Operation of a 114.3 mm diameter extruder running a HDPE resin at 400 kg/h as a function of discharge pressure.

A severe and random flow surging problem limited the

production rate for a large-diameter, two-stage, vented

extruder [5]. If it were not for a gear pump positioned

between the extruder and die, this extrusion line would not

have been operable. The surging did, however, limit the

output of the line to about 70% of its potential rate. The

maximum potential rate is the rate that the extruder can run

at high screw speeds and with proper operation. The

extruder was 203.2 mm in diameter and had a 40 length-todiameter

(L/D) barrel. A schematic for the extruder and

gear pump arrangement are shown in Figure 2. The

extrusion system was used to make a sheet product.

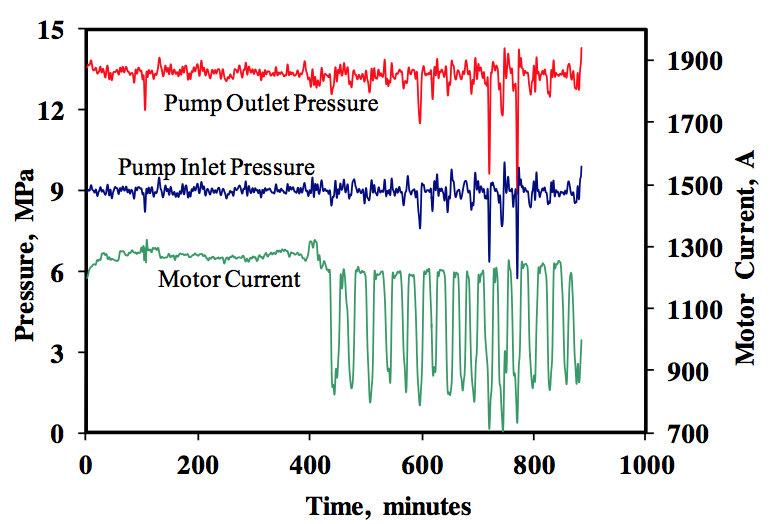

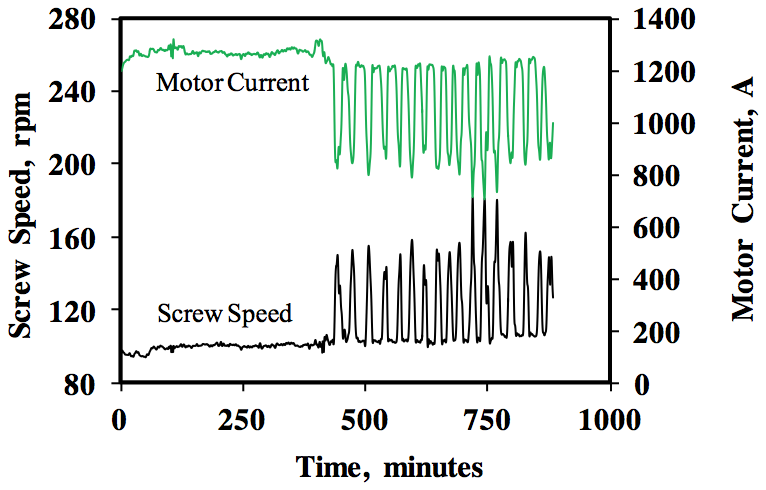

Steady-state operation of the extruder is shown by the

first 400 minutes in Figures 5 and 6. The data for these

figures were from the same production run. The extruder

was running a high-impact polystyrene (HIPS) resin at

2250 kg/h and a screw speed of 99 rpm for a specific rate

of 22.7 kg/(h rpm). This specific rate was about 14%

higher than the specific rotational flow rate calculated for

the first-stage metering section, indicating that a negative

pressure profile exists in the section. The negative pressure

gradient is expected for a first-stage metering section of a

vented screw that is operating properly; i.e., the first-stage

metering section was full of resin. To maintain the

stability, the extruder screw speed was reduced such that

extruder was operating at about 70% of its potential

maximum rate. That is, at screw speeds higher than 99 rpm

the extruder was more likely to transition from a stable to

an unstable operation.

Figure 5. Pump inlet (extruder discharge) and outlet pressures and motor current for stable and unstable extrusion for a large-diameter extruder running HIPS resin.

During this first 400 minutes, the inlet pressure to the

pump was relatively stable, and the discharge pressure to

the die was also acceptable, producing prime product. At

about 410 minutes into the run, the extruder started to

operate unstably, as indicated in Figures 5 and 6. The

processing change that caused the extruder to go from a

stable operation to an unstable one was not known, but it

could have been due to minor changes in the bulk density

of the feedstock or cooling water fluctuations to the screw.

The root cause for the event and technical solution were

provided earlier [3,5] and they are beyond the scope of this writing. As shown in Figure 6, the extruder screw speed

was oscillating between 100 and 180 rpm during the period

of the instability. During this unstable period, however, the

gear pump control allowed the pump inlet pressure to

oscillate at only a low level. The outlet pressure from the

pump (pressure to the die) had a similar level of oscillation

as in the inlet pressure, as shown in Figure 5. The

oscillation in the outlet pressure, however, was acceptable

for making prime product. Resin consumption was higher

than normal during unsteady operation because the product

was varying widely between the upper and lower control

limits for sheet thickness rather than operating close to the

lower control limit. If the pump would not have been on

this line, prime product could not have been produced

when the extruder was unstable. Although the pressure

oscillation observed here was unacceptable, the pump was

able to allow production during the time required to make

the process modification to mitigate the surge.

Figure 6. Screw speed and motor current for a large- diameter extruder running stable and unstable.

Gear Pump Pressure Control

A poor control algorithm for the pump can cause some

variation in the extruder screw speed, causing large

variations in the inlet pressure to the pump. This type of

control-induced surging can occur even though the process

as designed is inherently stable. To determine if the control

algorithm is inducing the surging, the screw speed of the

extruder should be operated in a manual mode and at a

constant speed. If the controller is inducing the surging,

placing the process in manual control mode will stabilize

the process.

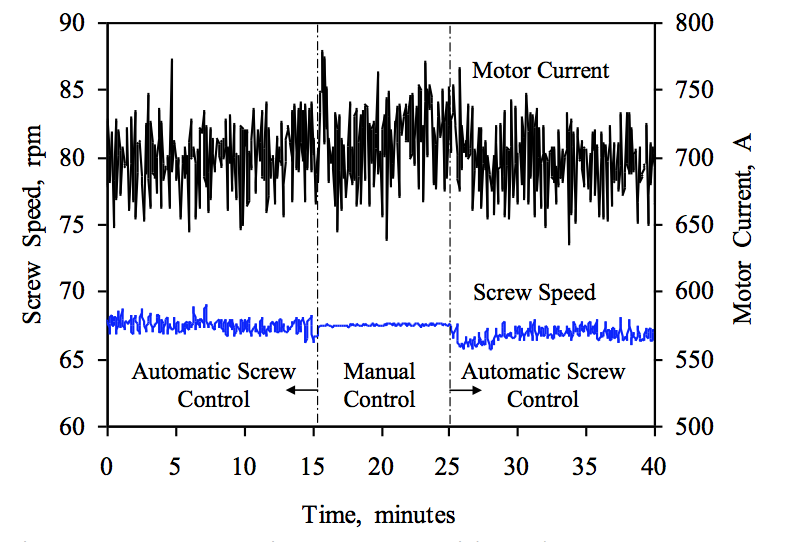

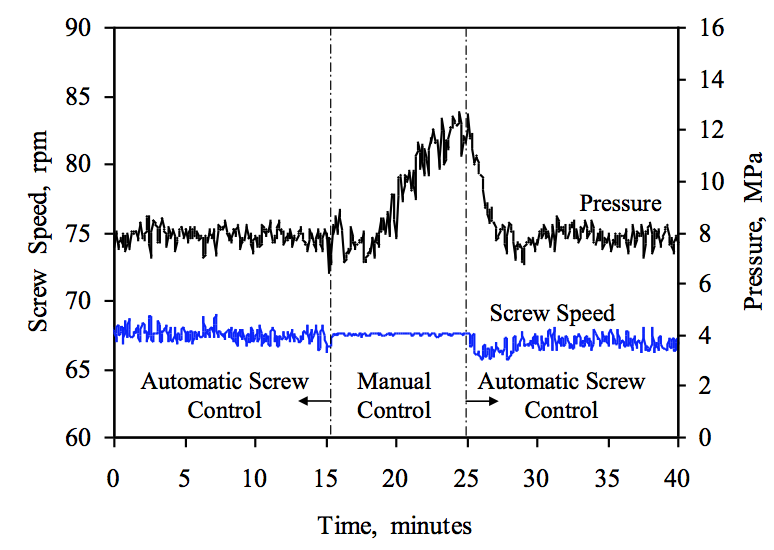

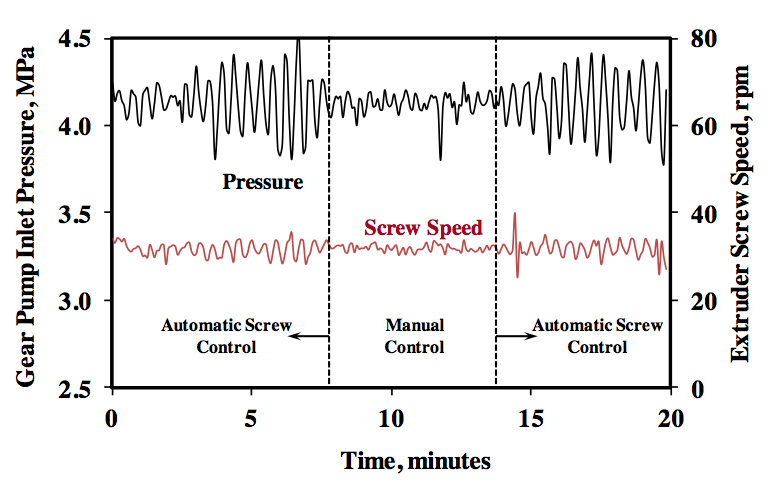

Transient process data were collected for an extruder

with a downstream gear pump, as shown in Figure 1. For

this case, the control algorithm was controlling the speed

of the screw such that the inlet pressure to the pump was

maintained at 8 MPa for a polycarbonate (PC) resin.

Although the variation in screw speed was not excessive at 67+1.5 rpm, the variation in motor current seemed quite

high at 540+90 A. At about 16 minutes into the run, the

extruder was switched from automatic to manual screw

control; i.e., the screw speed was held constant at 67 rpm.

As shown by the data in Figure 7, the motor current

variation was unchanged, indicating that the screw speed

control algorithm was not inducing the variation in the

motor current. During the period that the screw speed was

held constant, the pressure to the inlet of the pump slowly

increased, as shown in Figure 8. This pressure was

increasing because the screw was operating at a speed that

delivered a rate slightly higher than that needed by the

pump. When the control was placed back into the

automatic mode, the screw speed was decreased initially to

compensate for the higher than desired pump inlet

pressure.

Figure 7. An extrusion process with a downstream gear pump with the screw operating in inlet pressure control and followed by the screw in manual operation (constant screw speed).

Figure 8. Pressure at the inlet to the gear pump for the data presented in Figure 7. The pressure increased during manual control because the flow rate of the extruder was slightly higher than the rate of the pump.

The large level of variation in the motor current during

constant screw speed control suggests that the extrusion

process was unstable, and the control algorithm was not the

root cause for the variation in the motor current. The root

cause and technical solution for mitigating the surge are

provided elsewhere [3].

In another case, a single-stage extruder with a gear

pump running a low density polyethylene (LDPE) resin

was operating with a pressure oscillation at the discharge

of the extruder. Like the previous case, it was not known if

the extruder or the control algorithm for the gear pump was

causing the instability. The pressure oscillation during the

unstable period is shown in Figure 9 for the first 7 minutes

of data collection. Like before, the gear pump controller

was placed into manual mode such that the extruder screw

speed was held constant. As shown in Figure 9, the

pressure at the inlet to the gear pump was relatively stable

when the screw speed was in manual control. When the

control was turned back on, the pressure variations

resumed. These data indicate that the control algorithm

was causing the pressure surges to the inlet of the gear

pump. In this case the proportional gain of the controller

was set too high for the process. When the gain was

reduced, the process became very stable with the pump in

automatic control mode.

Figure 9. Process dynamics for a gear pump with a poorly designed control system.

Placing the screw speed controller in manual mode is

recommended when minor levels of flow surging are

observed with a process where the screw speed is

controlled from the inlet pressure of a gear pump. This

procedure will correctly guide the troubleshooting process

to focus on the extruder or the gear pump.

Gear Pump Seizing

A polystyrene (PS) sheet line was constructed using a

two-stage, vented extruder and a gear pump. On several occasions the bearings on a gear pump would seize. In both

cases, the gear pump was identified as the root cause of the

failure, and claims were placed against the manufacturer.

After the third pump seized, a full evaluation of the line

was performed. The analysis indicated that the first-stage

metering section of the extruder screw was not controlling

the specific rate of the process as designed. Instead the

specific rate was about 90% of the flow due just to

rotation; i.e., historically known as the drag flow rate. Here

the rate was controlled by a poorly designed solids

conveying section. During typical operation, the extruder

would operate with the first-stage metering channel at

essentially zero pressure, and the second stage metering

section would use only two diameters of filled length to

supply an inlet pressure of 6 MPa to the pump. On very

rare occasions, the solids conveying section would deliver

a large amount of material such that first stage metering

section was operating at 120% of the specific rotation rate.

This event would completely fill the second-stage metering

section such that a very high and nearly instantaneous

discharge pressure would occur. This pressure was

estimated at about 60 MPa. This high pressure coupled

with a low pump discharge pressure of 15 MPa created

enough differential force to deflect the rotors and overload

the gear pump bearings, leading to the seizing of the pump.

For a normal control scheme, the controller for the

screw speed would have decreased the screw speed to

match the 6 MPa inlet pump pressure set point. But

because the pressure surge happened extremely fast, the

controller could not respond fast enough when the high

pressure surge occurred, causing the catastrophic failure of

the pump.

The solids conveying section of the screw was

modified through screw design and process temperatures

such that the first-stage metering channel was always

operating full and under pressure at a specific rate of 110%

of the calculated rate due just to screw rotation. The pump

never seized again.

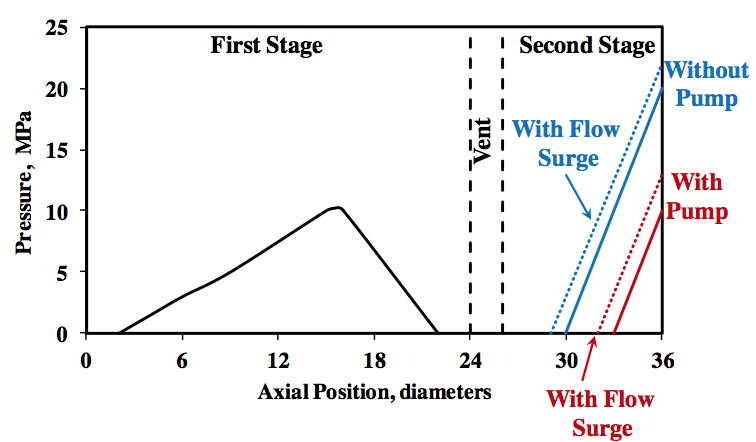

Improperly Designed Metering Section for a Two-Stage Screw

A gear pump system was added to an existing 114.3

mm diameter, two-stage, vented extruder on a PS sheet line

as detailed in Figure 2. The extruder discharge pressure

before the addition of the pump was about 20 MPa, and the

process was fairly stable and operated well. The screw

channels were previously optimized to a pre-specified rate

and a discharge pressure of 20 MPa. After the addition of

the pump, the extruder discharge pressure was reduced to

about 10 MPa. The line could not be operated at more than

70% of the potential rate due to the excessive oscillation in

the inlet pump pressure and consequently the fluctuation in

screw speed. The problem was analyzed and found that

solids conveying in the first stage of the screw was

performing as expected and that the flights were full and

pressurized in the first stage of the screw. Since the

discharge pressure of the second stage was decreased by

half, the length in the second stage that was required to

generate the discharge pressure was decreased

significantly, moving the position downstream where the

second-stage meter becomes first filled with resin. A

schematic of the axial pressure profile with and without the

pump is shown in Figure 10. For the line without the

pump, a typical pressure surge will cause the fill position

to start 1 diameter earlier and would cause the discharge

pressure to increase to 22 MPa or 10% as indicated by the

dotted blue line. When the line was configured with the

gear pump, the same surge would increase the extruder

discharge pressure to 12 MPa, or an increase of 20% as

indicated by the dotted red line. The higher percentage of

pressure increase caused the higher pressure oscillations at

the inlet to the gear pump and caused the controller to

oscillate the screw speed. When the pump was not

installed, the pressure fluctuation was about 10%.

Although this level of fluctuation is not acceptable, it did

allow the line to produce acceptable sheet.

Figure 10. Axial pressure profile for the PS sheet line with and without a gear pump. The blue dotted line is the expected pressure profile for a high pressure surge without the pump, and the red dotted line is the same surge with the pump.

With the gear pump installed, additional screen packs

were added to increase extruder discharge pressure to the

original 20 MPa. With these conditions, the screw speed

could be increased to full rate with the pressure relatively

stable at the inlet to the pump. Long term solutions were

found to be an adjustable melt restrictor valve installed

directly after the extruder to induce resistance and cause a

higher extruder discharge pressure, or the redesign of the

second stage of the screw for the expectation of reduced

extruder discharge pressure.

Although either solution will work, the preferable

course of action is to redesign the second-stage metering

section for the reduction in extruder discharge pressure,

allowing the processor to take advantage of lower energy

and discharge temperature afforded by the pump. For this

case, the second-stage metering channel was too deep

relative to the depth of the first-stage metering channel. As

expected, a similar problem occurs when the second stage

is not optimized with the first-stage metering section for

processes without gear pumps [6].

Discussion

Using a gear pump to control rate and to generate a

portion of the pressure required for the die is an excellent

method to allow a process to operate near the lower control

limit of the product thickness, reducing the consumption of

resin per unit area for a sheet line. For new installations,

the design of the extruder screw should be optimized for

the inlet pressure required by the pump. For the addition of

a gear pump to an existing extrusion line, the processor

should consider the process changes that will occur when

the discharge pressure from the extruder is reduced,

especially for two-stage, vented machines.

Gear pump rotors are positioned using specially

designed bearings. These bearings and rotor shafts are

lubricated with molten resin from the extruder. That is, a

very small portion of the resin flow from the high pressure

outlet side of the pump is flowed into the bearing annulus

and then into the low pressure inlet side of the pump. The

design of the bearing depends on several factors including

resin rheology, differential pressure, and rate. The

differential pressure is defined as the outlet pressure minus

the inlet pressure. If the differential pressure becomes too

low, resin flow to the bearings will be reduced or

interrupted, shortening the life of the bearings or causing

the pump bearings to seize.

Summary

Gear pumps positioned between single-screw

extruders and dies can provide advantages including

reducing the discharge temperature, reducing instabilities

from the extruder, and reducing the resin consumption to

make the final product. Reductions in extruder discharge

pressure can also extend the operation life of screws,

barrels, and thrust bearings while reducing energy

consumption. However, while applying this technology

processors must be aware in the change in dynamics of the

extrusion line for normal troubleshooting principles.

Troubleshooting process problems associated with this

type of process were presented.

References

1. D. Smith, P. Stoughton, C. Morgan, and G. Hovis,

“Auxiliary Systems” in “The SPE Guide on Extrusion

Technology and Troubleshooting,” Chapter 5, ed., J.

Vlachopoulos and J.R. Wagner, Society of Plastics

Engineers, 2001.

2. D. Smith, M.A. Spalding, and R.J. Gould, SPE

ANTEC Tech. Papers, 52, 814 (2006).

3. G.A. Campbell and M.A. Spalding, “Analyzing and

Troubleshooting Single-Screw Extruders,” Hanser,

Munich, 2013.

4. H.T. Pham and K.S. Hyun, Polym. Eng. Sci., 32, 488

(1992).

5. M.A. Spalding, J.R. Powers, P.A. Wagner, and K.S.

Hyun, SPE ANTEC Tech. Papers, 46, 254 (2000).

6. S.J. Derezinski, SPE ANTEC Tech. Papers, 48, 312

(2002).

Return to

Paper of the Month.