Distribution of Specific Energy in Twin-Screw Corotating Extruders Using One-Dimensional Process Simulation

Adam Dreiblatt, Century Extrusion, Traverse City, MI

Eduardo Canedo, PolyTech, Campina Grande, BrazilAbstract

Specific mechanical energy (SME) is a single

parameter that represents the energy transfer from the

main drive motor through frictional heating for melting,

mixing and die pressurization in the compounding

process. The calculation of SME is performed using the

extruder motor load (e.g. shaft torque), screw speed and

total throughput to provide energy input on a unit mass

basis. Use of one-dimensional computer simulation to

analyze the axial distribution of specific energy reveals

strategically where this energy is applied in fullyintermeshing,

co-rotating twin-screw extruders as a

function of screw design.

Introduction

Co-rotating intermeshing twin-screw compounding

extruders are the predominant machine in use today for

compounding polymers with additives, fillers, etc. The

compounding process is a complicated sequence of events

whereby polymer(s), impact modifiers and additives are

first melted to create a specific morphology. Particulate

fillers, pigments, etc. are typically introduced into a

downstream feeding port for dispersion into the melt,

followed by a second downstream feeding port for

addition of reinforcing fillers (e.g. glass fiber) or

additional particulate filler with subsequent

homogenization. Finally, volatiles are removed through

vacuum degassing port(s) and the compound is

pressurized through a die or melt filtration device.

For a given formulation, the resulting properties (e.g.

rheological, physical, etc.) are determined largely by the

mechanical energy input to the materials within the

residence time of the compounding extruder. If too much

mechanical energy is applied in homogenizing glass

fibers, for example, the mechanical properties will suffer.

Conversely, insufficient mechanical energy input can also

result in incomplete melting of polymer which will also

produce inferior properties. The interactions between raw

materials (and feeding position), screw design and

operating variables are captured within the single

parameter SME and can therefore be used to correlate

directly with compound quality.

The value of SME is derived from the extruder motor

load (using percent torque instrumentation or direct

measurement of power from the main drive) and represents the cumulative effect of energy input along the

entire screw axis.

This is a similar situation with measurement of

residence time. There are many citations correlating

mixing with residence time distribution (RTD). We can

measure the distribution of residence time using a tracer,

however, this information does not provide insight as to

the distribution of residence time in each element of the

extruder. The only means to obtain such information

would be to measure RTD for each segment of the

extruder. It is physically possible to assemble and operate

an extruder consisting only of the solids conveying

section and measure RTD. Then increase the length of the

extruder by adding a melting section and repeat the RTD

measurements. While a tedious and time-consuming

exercise, the information could be obtained using this

technique.

Similarly, the distribution of specific energy can

provide valuable insight as to where the energy is applied

within the compounding process. As mentioned above, it

would be possible (although time-consuming) to

physically measure the energy contribution of each part of

the screw design by assembling extruders with

incremental lengths.

An alternative to this method uses one-dimensional

(1D) simulation to analyze the mechanical energy

contribution for each part of the screw design. Such 1D

computer modeling programs have been commercially

available and have been validated to provide close

approximations to the actual compounding process

2,3,4.

Simulation provides the capability to measure differential

values along the screw axis for power, temperature,

residence time, etc. and is the basis for this investigation.

The overall energy balance in the processing chamber of

the extruder may be approximately formulated as:

where W is the power delivered to the material, QHT is the

rate of heat transfer between the polymer and the

processing chamber wall (usually the barrel internal wall,

as the screws are assumed adiabatic), ΔH and Δp are

specific enthalpy and pressure difference between output and input, G is mass throughput and v is the mean

specific volume.

For simple systems, ΔH can be easily estimated from the

thermodynamic properties (heat capacities of solid and

molten polymers and fillers, effective latent heat of fusion

of polymers, etc.) in terms of the feed and discharge

temperature and Δp is associated to the head pressure. The

power delivered by the motor may be computed from

measured motor torque and screw speed. Thus, Eq. (1)

may be used to estimate the heat transferred between the

extruder and the material.

Simulation by general purpose software using simplified

one-dimensional models allows the computation of the

power dissipated during compaction and melting of

polymer solids (by friction between the particulate solids

and the barrel wall and screw and between solid particles

themselves, by plastic deformation of the softened solid

particles, etc.) and during the transport and mixing and

pressurization of the molten material (essentially by

viscous dissipation). The heat transport between the

processing chamber and the barrel wall for a given barrel

temperature profile may also be computed (albeit with

greater uncertainty). All these calculations are performed

element by element along the extruder. Likewise,

simulation software computes the internal pressure

profile. Thus, simulation software allows the prediction of

the axial temperature profile, prediction that may be

verified against process data and the models adjusted

accordingly.

Once the simulation software has been validated, the

computation of the power profile along the extruder, or

the mechanical energy input profile (power per unit

throughput), is a powerful tool to investigate where power

is dissipated within the extruder, and how the specific

energy profile depends on screw design and operating

conditions (screw speed, feed rate, barrel temperature

profile, etc.)

With this approach, the individual contribution to

specific energy for each screw element type can be

quantified and optimized for melting and mixing

efficiency as well as for scale-up to larger screw

diameters.

Methodology

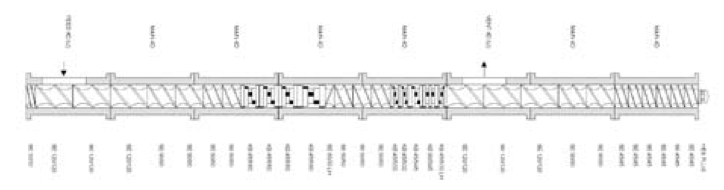

The one-dimensional computer simulation program

WinTXS™ from PolyTech was used for this analysis. The

simulations were performed using a polypropylene (PP)

resin with melt index = 5, 10 and 20 dg/min (230

oC, 2.16kg) and a 70 millimeter twin-screw extruder with

diameter ratio = 1.55, length/diameter ratio = 32. The

screw configuration used for simulation is shown in

Figure 1. Die pressure was maintained constant at 30 bar, feed rate was held constant at 1200 kg/hr and screw speed

varied between 400 rpm and 800 rpm.

The energy required to raise the temperature of a unit

mass of a polymeric material from the feed temperature T

1

to the discharge temperature T

2 may be computed,

approximately as:

where c

S and c

L are the average specific heats of the solid

and molten polymer, respectively, ΔH

m is the effective

heat of fusion of the polymer (which depends on the

material; for amorphous polymers ΔH

m, = 0), and T

m is

the melting or softening temperature.

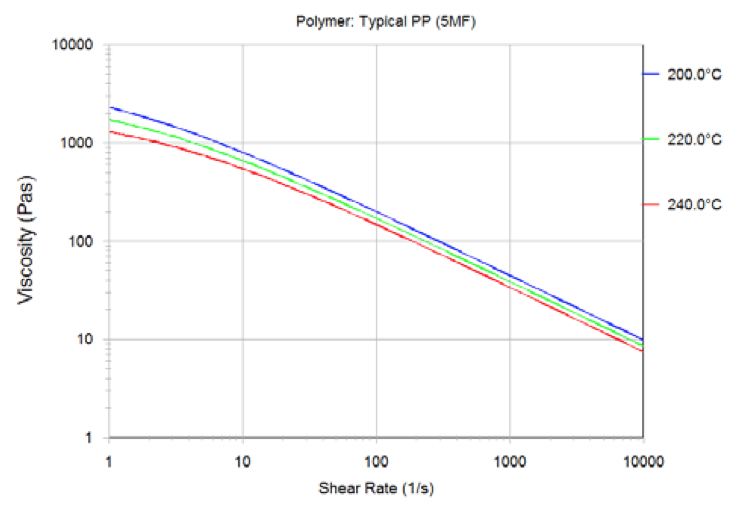

The melting temperature for PP was 170

oC and heat capacity 2.34 kJ/kg

oC (solid state) and 1.61 kJ/kg

oC (melt at 200

oC). Shear viscosity data for the MF=5 resin is

shown by Figure 2 using Carreau-Yasuda viscosity model.

Figure 1. Screw configuration used for 70mm simulation

Figure 2. Shear viscosity data for PP resin

Discussion

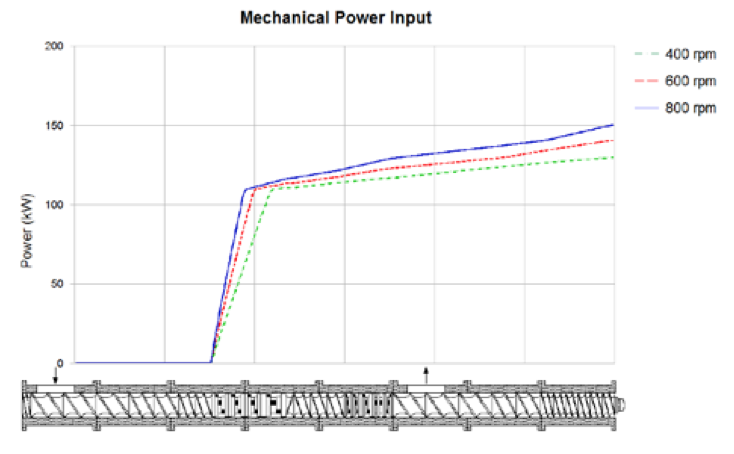

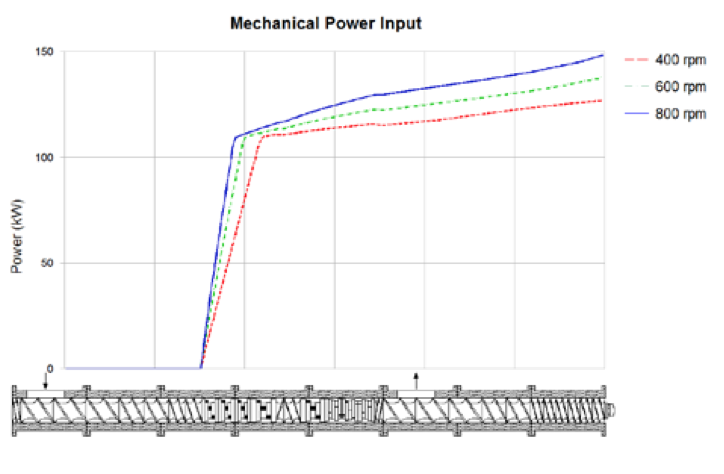

The net distribution of power along the screw axis is

shown in Figure 3. This curve represents the mechanical

energy input to the extruder and does not account for

energy removed through barrel cooling or the ‘no-load’

power required to turn the motor, gearbox and empty

screws. The contribution of power for each section of the

extruder reveals most of the energy is consumed in resin melting; an energy balance for this section of the extruder

can be used to corroborate the predicted melt

temperatures.

The theoretical energy requirement to raise the solid

polymer from ambient to melting temperature (170

oC) at 1200 kg/hr is 77.75 kW and the theoretical energy

requirement to melt the polymer at 1200 kg/hr is 20.0 kW.

Combining these two, the theoretical energy requirement

for polymer melting is 0.081 kWh/kg. Predicted SME

results for resin melting range from 0.092 kWh/kg at 400

rpm to 0.097 kWh/kg at 800 rpm.

The theoretical energy requirement to raise the

temperature of the melt to predicted discharge

temperature is 40.17 kW (221.5

oC @ 400 rpm), 42.9 kW

(225

oC @ 600 rpm) and 47.6 kW (231

oC @ 800 rpm).

The theoretical SME for the compounding process ranges

from 0.115 at 400 rpm to 0.121 kWh/kg at 800 rpm.

These values are compared to the simulation predictions

in Table 1.

Figure 3. Power consumption versus screw speed

The objective of this investigation is to determine

where this energy is applied along the screw axis.

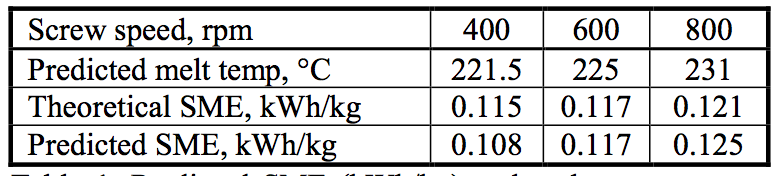

Table 1. Predicted SME (kWh/kg) and melt temperature (°C) versus screw speed.

Solids Conveying

Simulation results indicate zero power consumption

for the initial solids conveying. In reality, given the

available power for a given diameter extruder and the ‘no load’

power to rotate the drive motor, gearbox and screw

shafts, it is not an unreasonable estimate. Typical

industrial extruders do not have the resolution required to measure this small amount of energy. We do not expect

the energy requirement to be more than negligible for

most powders, pellets, flakes, etc. within the range of

most compounds. This situation changes, however, when

melt feeding a twin-screw extruder directly from a reactor

where the power required is for melt conveying (versus

solids conveying).

The process length (in terms of L/D) required for

initial solids conveying is usually in the range of 6D to

8D; increasing the length of the solids conveying section

would not increase the energy requirement. As there is

virtually no mechanical energy expended in this section,

any increase in material temperature is via thermal heat

transfer from barrel heating. Given the low degree-of-fill

of the screws in the solids conveying area and relatively

short residence time (less than 1.5 seconds for the material

to move from the feed barrel to the first kneading

element), the temperature of the solid polymer pellets is

far from its melting temperature.

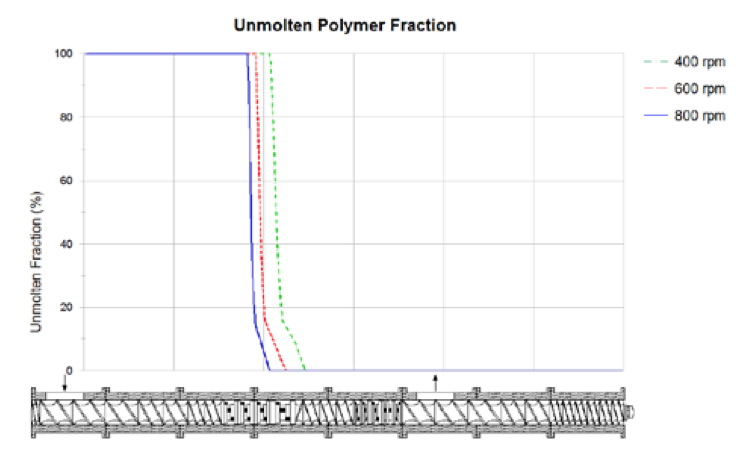

Polymer Melting

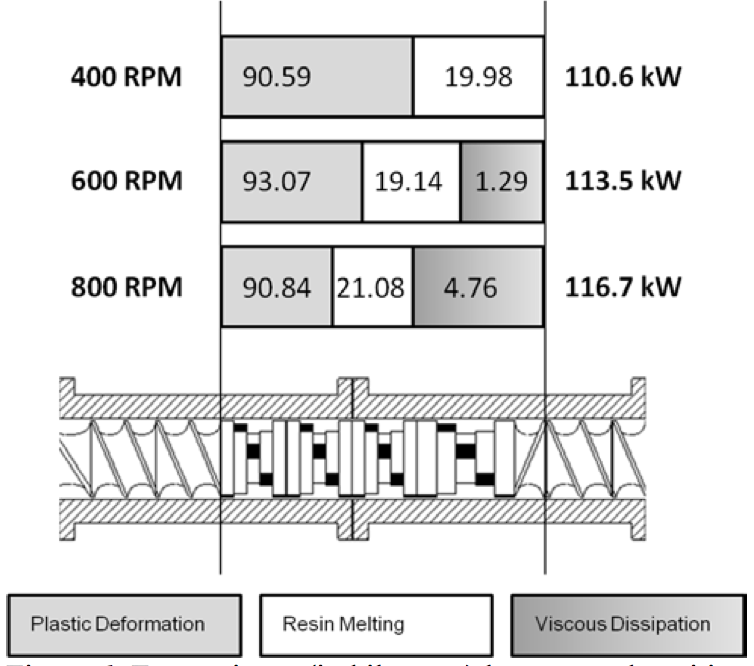

The distribution of mechanical energy within the

melting configuration is a function of screw speed and

feed rate. At high screw speed (i.e. high shear stress), the

plastic deformation of solids occurs within the first

kneading elements. This energy transfer is extended to the

following kneading elements at lower screw speed (i.e.

lower shear stress).

Figure 4. Position of resin melting versus screw speed

Note that the polymer is not yet melted, although

most of the mechanical energy is transferred to the

polymer. This energy is expended to deform and compress

the (solid) polymer resin and results in a rapid temperature

rise as illustrated in Figure 5. Melting (phase change)

occurs in the kneading elements that follow; the specific

kneading elements responsible for melting are determined

by screw speed and feed rate. At high screw speed,

polymer phase change occurs in the third kneading

element while the remaining kneading elements are required to accomplish this same task at lower screw

speed.

Once the polymer is molten, mechanical energy input

deteriorates rapidly in the following kneading elements as

viscous dissipation – this axial change in the rate of

energy transfer is shown as a rapid change in slope (i.e.

flattening) of the power distribution curve in Figure 3. In

this case, polymer melting is completed at the third

kneading element with high screw speed and the

remaining kneading elements are transferring mechanical

energy to the melt increasing the melt temperature. At the

lowest screw speed, there is no mechanical energy input

as viscous dissipation in this first kneading section.

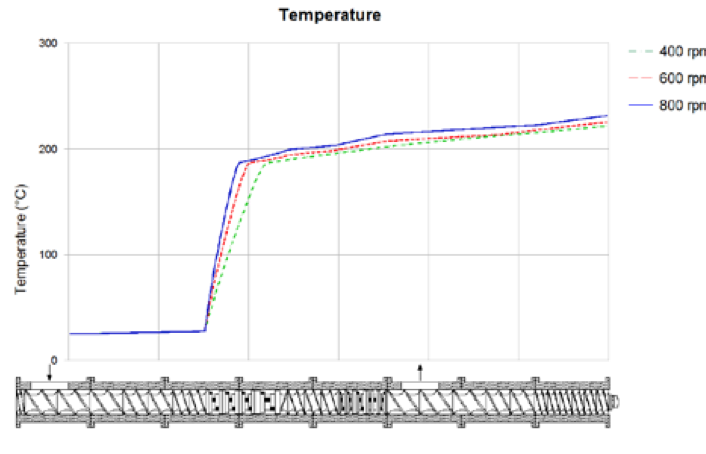

Figure 5. Axial temperature versus screw speed

Most of the energy contribution occurs prior to actual

melting where the temperature increases rapidly (less than

two seconds) as a result of plastic deformation of solids.

Figure 6. Energy input (in kilowatts) by type and position within the melting section as a function of screw speed

The distribution of mechanical energy within the melting

configuration is shown in Figure 6 where the simulation

predicts the exact position of solids melting as a function

of screw speed. The power distribution curve was used to

quantify the mechanical energy input within the melting

part of the screw configuration by energy type.

Intermediate Melt Conveying

Mechanical energy is applied to the molten polymer

in subsequent conveying sections of the extruder

increasing the melt temperature. Since the polymer

melting represents a substantial percentage of the total

energy requirement, the viscous dissipation of energy in

downstream conveying elements represents only a small

fraction of the total SME and is shown in Table 2. At

increasing values of SME (whether achieved by increased

screw speed, lower throughput or by screw design

changes) the additional mechanical energy is expended in

viscous dissipation since the energy required for polymer

melting is constant.

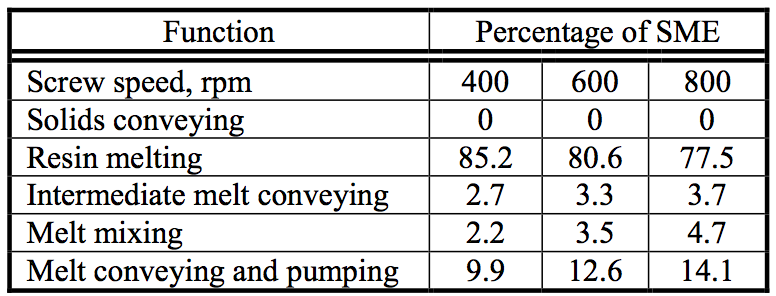

Table 2. Percentage contribution of SME by function versus screw speed (Melt Flow = 5.0).

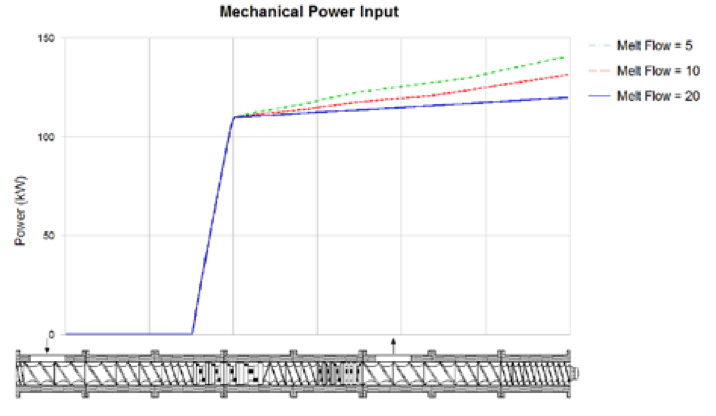

The rate of energy input in the downstream melt

conveying section is more depending on the melt viscosity

as shown in Figure 7. In this case, simulations were

performed using PP with different melt flow rates (MF =

5, 10, 20) at the same extruder conditions (1200 kg/hr,

600 rpm) to see the difference in the power distribution in

the downstream melt conveying section.

Figure 7. Power consumption (in kilowatts) versus polymer viscosity at 1200 kg/hr and 600 rpm screw speed.

Figure 7 also illustrates the mechanical energy

requirement to melt the PP polymer does not change with

melt flow, however, the resulting viscous dissipation is

strongly affected by polymer viscosity. The flattening of

the power distribution curves (in Figure 7) with decreased

polymer melt viscosity confirms reduced viscous heating.

Melt Mixing

Kneading elements are installed downstream of

polymer melting for dispersive and distributive mixing of

impact modifiers, pigments, additives. fillers, etc. which

may be introduced with the polymer in the main feed

opening or added through downstream feeding. In the case

of downstream feeding, the thermal cooling of the melt

from ambient solids entering the process is not considered

in this investigation (all solids are entering via the main

feed opening, downstream feeding is foreseen in future

work). The mechanical energy input from downstream

kneading elements, as a percentage of total SME, is not

much different than for melt conveying elements as

shown in Table 2.

A second screw design with additional downstream

mixing elements (Figure 8) does not contribute significant

SME as shown in Figure 9. Comparing the slope of the

power distribution curve in this region, there is little

change in viscous dissipation from the additional

kneading elements. The total SME does not change with

this alternate screw design.

Figure 8. Alternate screw design with additional downstream kneading elements.

Figure 9. Power consumption (in kilowatts) for alternate screw design with additional downstream kneading elements (PP melt flow = 5, 1200 kg/hr and 600 rpm).

The small increase in viscous energy input in this

downstream mixing section (thereby decreasing melt

viscosity) results in decreased viscous energy input in the

following melt conveying and die pressurization sections.

Die Pressurization

As shown in Table 2, the final melt conveying (e.g. in

vacuum degassing) and die pressurization sections add

between 10 and 15 percent of the total SME. Increasing

conveying length, melt viscosity and SME increases this

percentage. There is little difference, as seen in the slope

of the power distribution curve, in SME input for

conveying with and without pressure (all simulations were

conducted at 30 bar die pressure). The incremental energy

added via viscous heating translates to increased melt

temperature.

Conclusions

One-dimensional computer modeling of the

compounding process provides insight as to where and

how mechanical energy is transformed within the screw

design and enables twin-screw extruder screw designs to

be optimized for melting efficiency and minimizing melt

temperature.

The distribution of specific energy is concentrated in

the first kneading elements where mechanical energy is

applied to the solid polymer prior to actual melting. The

exact position and extent of this energy is dependent on

extruder operating conditions.

SME does not reflect how the energy is applied in

terms of mixing and/or homogenization. What is not

included within SME is the residence time over which the

energy is applied and the resulting shear stress within the

polymer.

Future work will validate some of these predicted

results and investigate SME distribution for downstream

feeding and different screw diameters to confirm scale-up

behavior.

References

1. S. Godavarti, M.V. Karwe, Determination of Specific

Mechanical Energy Distribution on a Twin-Screw

Extruder, J. Agricultural Engineering Research, 67, 4,

277-287 (1997).

2. H.Potente, J. Ansahl, B. Klarholz, Design of Tightly

Intermeshing Co-Rotating Twin Screw Extruders, Intl

Polymer Processing IX, 1, 11-25 (1994).

3. K. Kohlgrüber, Modeling: Possibilities and

Limitations, Co-Rotating Twin-Screw Extruders, Carl

Hanser, 114-117 (2008).

4. E. Canedo, Computer Simulation of Plastics

Compounding Operations in Twin-Screw Extruders,

SPE-ANTEC Tech Papers (1999).

Return to

Paper of the Month.