Kinematic, Thermodynamic and Structural Factors Governing the Dispersion of Nanoclays in Polymer Melts¶

Mark D. Wetzel

DuPont, Wilmington, Delaware, 19880Abstract

Polymer nanocomposites offer a potential unique solution

to improve desired physical attributes while maintaining

other incompatible properties. For example,

increasing the mechanical stiffness and strength of ionomers

while preserving toughness and optical performance

may not be possible with conventional, micron-scale fillers.

In order to demonstrate significant property enhancements,

a well-controlled dispersion of nano-scale

fillers in a polymer matrix is required. Melt processing

represents the most economical and flexible route to producing

thermoplastic nanocomposites, but may not

achieve dispersion quality as has been demonstrated by

other methods. This paper describes melt compounding

experiments that help establish kinematic, thermodynamic

and structural factors that govern the dispersion of

layered silicates in ionomers. The results show that the

stress imparted during the melt blending influences dispersion.

Platelet size also influences the extent of exfoliation

in the extruder. However, the thermodynamic

compatibility between the filler surface, organic modifier

and matrix polymer plays a dominant role in the exfoliation

process.

Introduction

In order to demonstrate significant property enhancements,

a well-controlled dispersion of a nano-filler

into a polymer matrix is required. A good dispersion can

be characterized by a particle size distribution approaching

primary particle dimensions distributed uniformly

through the host polymer. For layered silicates, the

process must first break apart and wet large aggregates of

tactoids (cohesive platelet stacks) and then exfoliate

platelets (delaminate) from the tactoids. For a given

shaping and forming process (injection molding, blown

film, extruded film, etc.) an anisotropic nanocomposite

structure will be created with platelets and tactoids aligning

with a shear or extensional flow field. Physical properties

of interest depend on intrinsic matrix and filler

properties, interfacial adhesion between the filler, surface

modifier and polymer, the state of dispersion and particle

orientations induced by processing [1-3].

Melt processing represents an economical and flexible

route for producing thermoplastic nanocomposites.

However, conventional melt compounding systems usually

cannot create dispersions of the same quality as made

with solution or in-situ polymerization methods. Thus, a

conventional melt blending system may represent a tradeoff

between economics and dispersion quality. To date, few, if any academic or commercial publications have

achieved perfect exfoliation of layered silicates in thermoplastics

using conventional batch mixers or extruders.

In compounding experiments, organically modified

layered silicates were dispersed into ethylene copolymer

ionomers using a twin-screw extrusion process. The extent

of exfoliation was examined by microscopy and

through tensile property measurements of injection

molded samples. This work reproduces and extends research

on ionomer / clay nanocomposites conducted by

Paul and associates [4-6]. They investigated the effects

of counter-ion type (Li, Na, Zn) in Surlyn® ethylene copolymers

along with the type of quaternary ammonium

organic modifier on Montmorillonite (MMT) clay.

Kamal and his co-authors reported that the thermodynamic

interactions between the clay, modifier and polymer

have a significant effect on the cohesive force between

platelets by changing the van der Waals forces and the

inter-gallery spacing [1]. Furthermore, they quantified

the stress required in a polymer melt under simple shear

to promote delamination of platelets or separation of child

tactoids from parent particles.

Experimental

A ZSK-18mm intermeshing, co-rotating twin-screw

extruder (Coperion GmbH, Stuttgart, Germany) fitted

with 10 barrels was used to compound ethylene copolymer

ionomers with organically modified layered silicates.

A conventional compounding screw with a 41 L/D was

used with a melting zone followed by one mixing section

comprised of kneading blocks and reverse conveying

elements. DuPont Surlyn® (partially neutralized ethylene/methacrylic

acid copolymer) sodium 8945 (4.5 g/10

min at 190°C melt index) and zinc 9945 (4 g/10 min at

190°C melt index) ionomers were selected based on

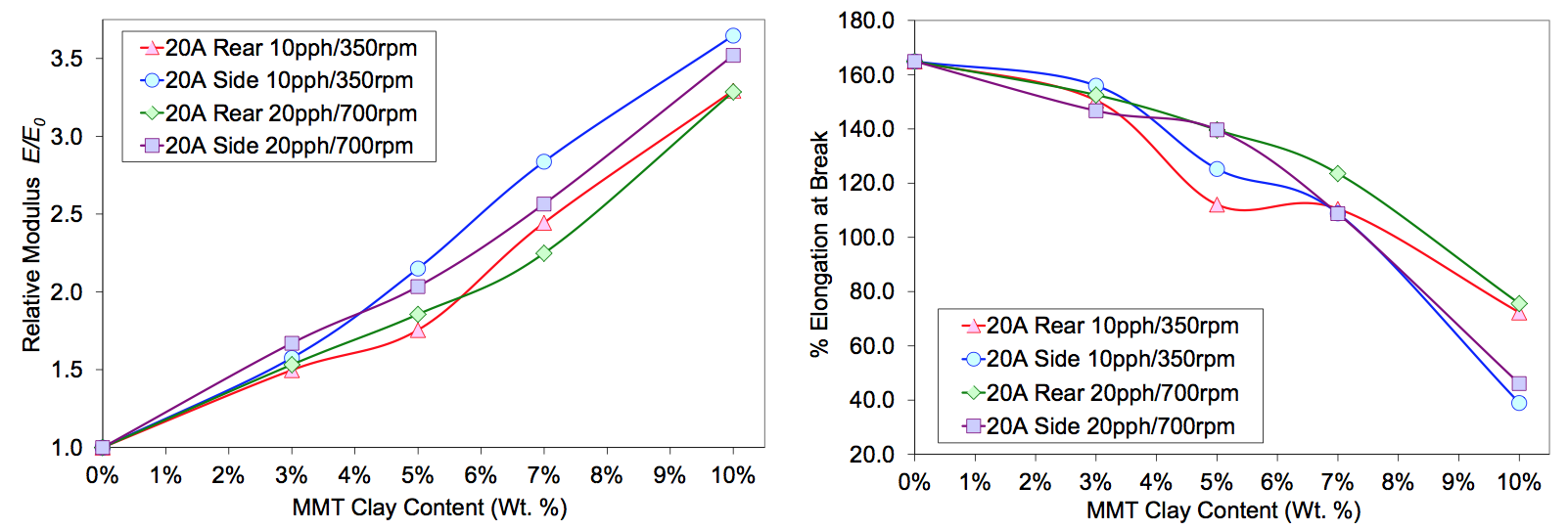

Paul’s work [4-6]. Several 2:1 layered silicates, including

organically modified Montmorillonite (MMT: Cloisite®

20A, 15A, 6A and 93A), unmodified MMT (Cloisite

Na+) and synthetic Hectorite (Laponite® RD and OG) and

fluorohectorite (Laponite B) were supplied by Southern

Clay Products, Gonzalez, Texas. Cloisite 93A uses a

more polar methyl, dihydrogenated tallow ammonium

surfactant (designated MH(HT)2 with one methyl group

replaced by one hydrogen) while all other clays were ion

exchanged with a dimethyl, dihydrogenated tallow, quaternary

ammonium moiety (designated M2(HT)2). Clay

types, modifier type, amount exchanged and inter-gallery

spacing measured by wide angle X-ray scattering

(WAXS) are listed in Table 1.

The ingredients were added using two loss-in-weight

feeders, with polymer pellets metered into the first feed

port and clay powders side-fed into barrel #4 into the

molten ionomer for most tests. Several tests fed both

materials in the rear feed port. The total feed rate was

varied from approximately 4.5 to 9 kg/hr (10 to 20 lb/hr)

with a range of powder concentrations from 3 to 10

weight percent clay content. The extruder screw speed

was fixed at 350 RPM for all states, with the exception of

a 9 kg/hr / 700RPM run. Barrel temperatures were fixed

between 160 to 220°C from inlet to the die. In several

tests, 25 wt. % Cloisite 20A masterbatches were prepared

with melt mixing zone barrel temperatures set to 160 and

210°C to emulate high and low stress states, respectively.

The concentrates were then let down to final compositions

in a second extrusion step. Pellet samples were collected,

dried and then molded into ASTM tensile bars

using an Arburg Allrounder 1.5oz injection molding machine

using standard Surlyn drying and operating conditions.

Tensile data were measured using ASTM standard

638D on dry as molded samples. Transmission Electron

Microscopy (TEM) micrographs were made with approximately

90nm thick microtomed cross-sections cut from

the center of the bars, perpendicular to the flow direction.

Discussion of Results

Process Kinematic Effects

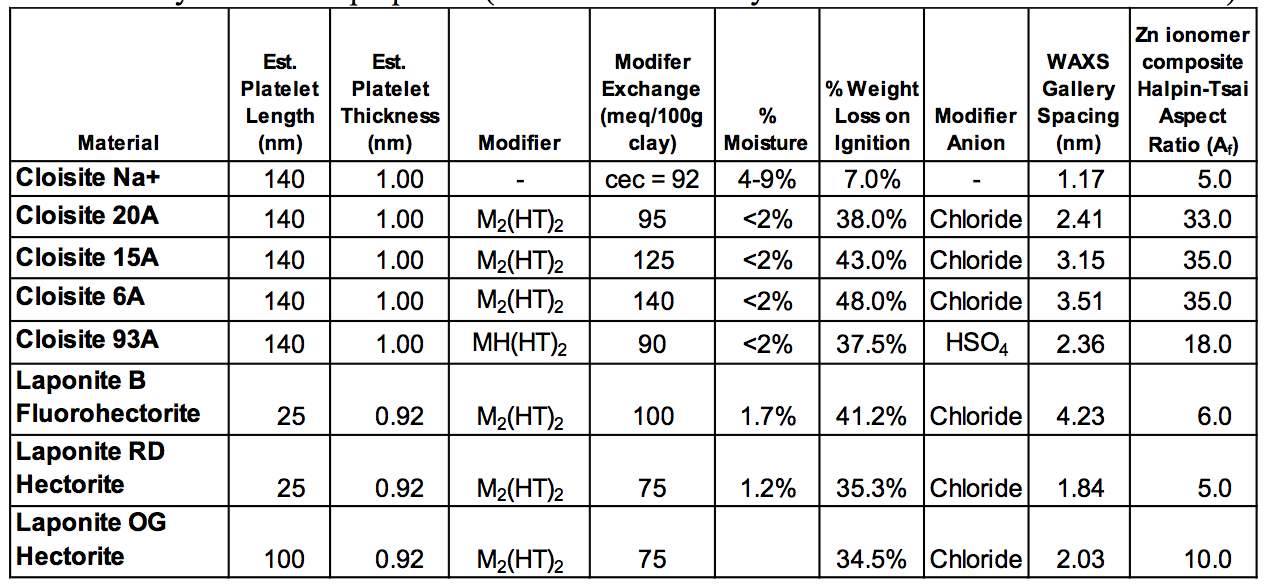

Figure 1 shows the shear stress for the sodium and

zinc ionomers plotted as a function of shear rate and temperature.

The curves are model predictions based on measurements

in a capillary rheometer. While the zinc

Surlyn has a higher viscosity than the sodium resin at

160°C, the viscosities are closely matched at higher temperatures

typically experienced in the melt mixing zones

of the extruder. The ZSK-18mm extruder has a high surface

area to free volume providing significant heat transfer

to control melt temperature. Masterbatches containing

25 wt. % MMT were prepared by melt compounding with

the melt mixing zone barrels set to 160 and 220°C to impose

high and low stress states on the sodium ionomer

clay mixtures. The concentrate pellets were then co-fed

with the sodium ionomer in a second extrusion operated

with barrels set to a conventional profile to produce 3, 5

and 7 wt. % MMT nanocomposites.

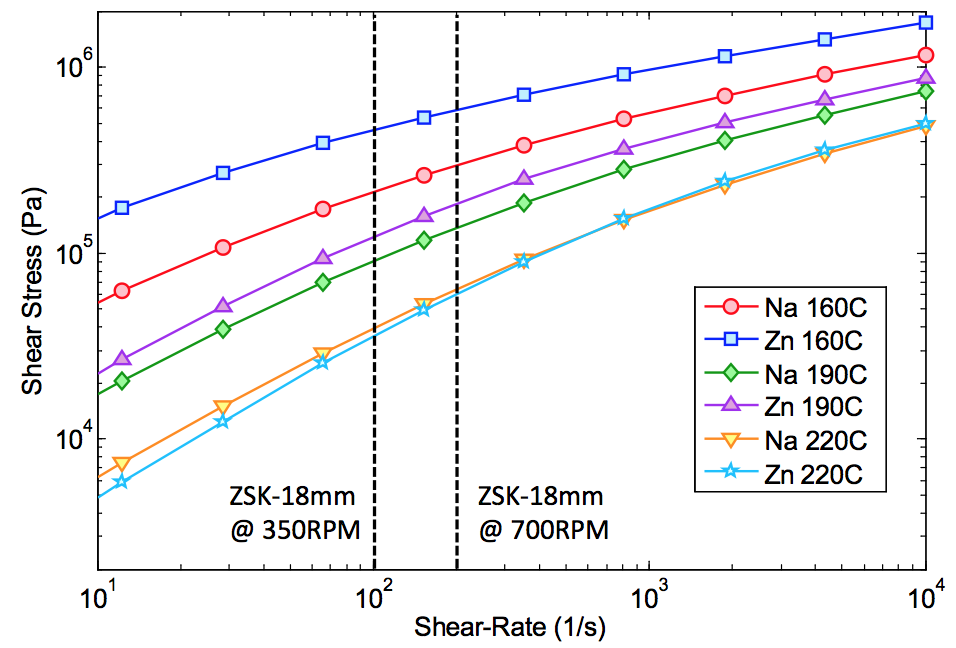

Figure 2 shows tensile properties of the letdown

compositions as a function of MMT loading and masterbatch

process barrel temperature. Paul showed that the

tensile modulus of MMT nanocomposites is influenced

by the extent of exfoliation as indicated by a measurement

or estimate of an effective aspect ratio [3-6]. The

low temperature states show a clear increase in modulus

over the high temperature states. From the rheology measurements,

the shear stress at the 160°C condition would

be significantly higher than at 210°C. It is likely that

more tactoids would experience the critical stress required

to overcome the cohesive force to exfoliate plate lets or split tactoid fragments. The elongation at break

also changed with masterbatch compounding barrel temperature.

The low temperature condition resulted in a

decrease in the strain at break with MMT loading. For

the high temperature state, the elongations were higher.

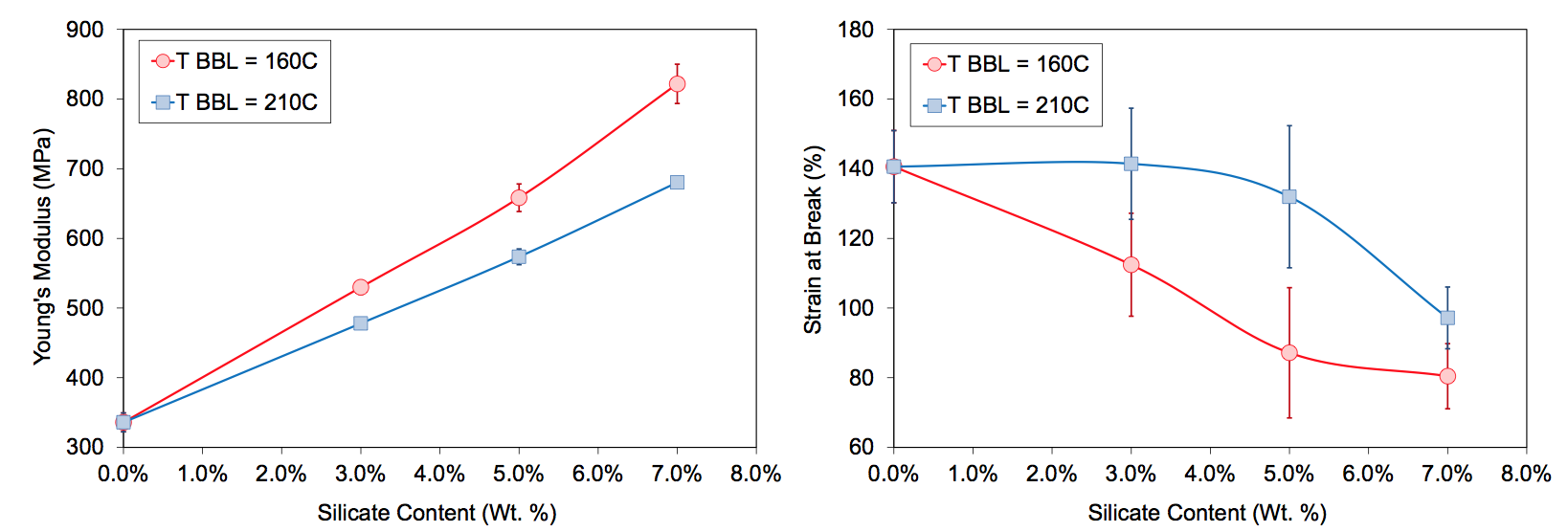

Another experiment was conducted to explore the effects

of throughput (Q) and screw speed (N) on MMT

dispersion in the sodium ionomer. Cloisite 20A was metered

into the first feed port or the side stuffer at 3, 5, 7

and 10 wt. % MMT content. Two constant Q/N conditions

were run. Tensile properties of injection molded

samples are shown in Figure 3. Clay fed in the rear of the

extruder experienced the high stress of the melting zone.

This likely changed the extent of exfoliation and the effective

aspect ratio as indicated by the tensile modulus.

For each feed method, the modulus and elongations for

almost all composition states were very similar at the

constant Q/N conditions.

From Figure 1, the shear stress at a screw speed of

700 RPM is slightly higher than at 350 RPM. The energy

dissipation, and hence the melt temperature are anticipated

to be higher at 700 RPM, reducing the average

stress in the channel. The mean residence time at 4.5

kg/hr (10 lb/hr) and 350 RPM is expected to be longer

than at the 9.2 kg/hr (20 lb/hr) and 700 RPM condition [7,

8]. It is likely that the dispersion quality was similar for

the two conditions with the same degree of fill. This result

indicates that a melt compounding process can be

operated in different regimes where a balance of residence

time, stress and melt temperature can be found to

produce the microstructures with similar physical properties.

Thermodynamic and Structural Effects

The choice of MMT surface modifier and the excess

amount of surfactant above the clay cation exchange capacity

(CEC) have significant effects on processing, dispersion

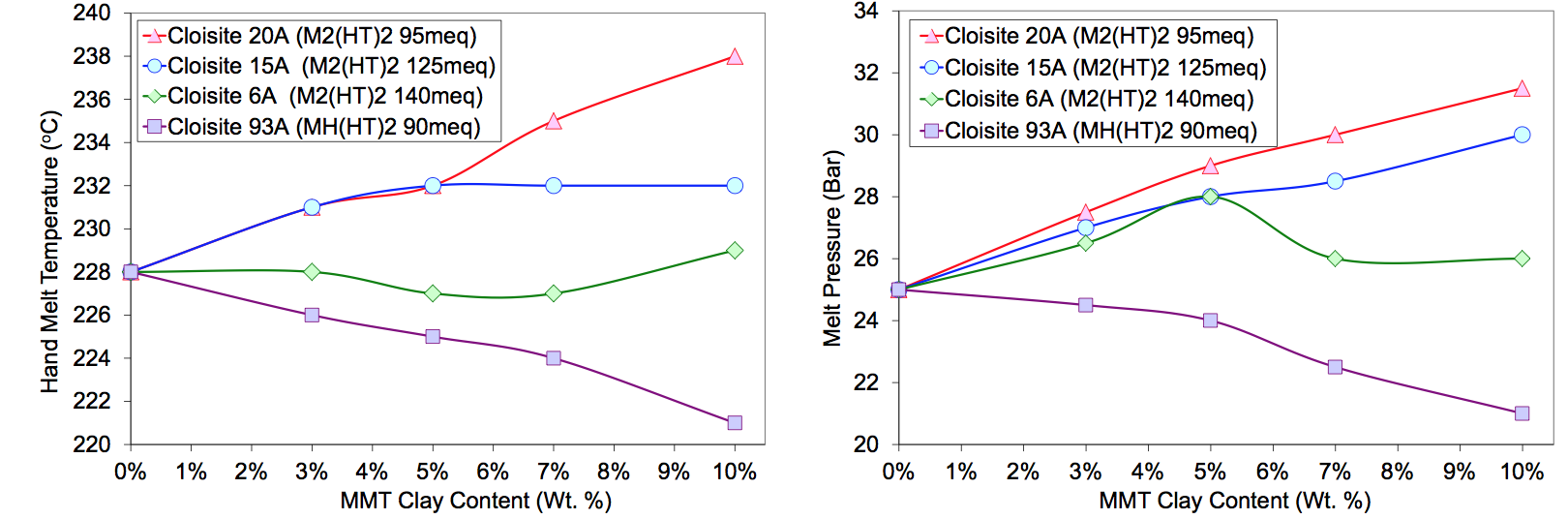

and physical properties. Figure 4 shows the die

hand melt temperature and exit pressure as a function

modifier type and MMT concentration at the 4.5 kg/hr

(10 lb/hr) and 350 RPM condition. Temperature and

pressure increased with loading for Cloisite 20A

[M

2(HT)

2 modifier, CEC 95 milli-equivalents/100gm clay

(meq)]. The temperate and pressure increase with filler

loading was reduced when excess surfactant was applied

(Cloisite 15A, CEC 125 meq, and 6A, CEC 140 meq).

This indicates that the excess modifier may act as a plasticizer.

Excess surfactant likely dispersed in the polymer,

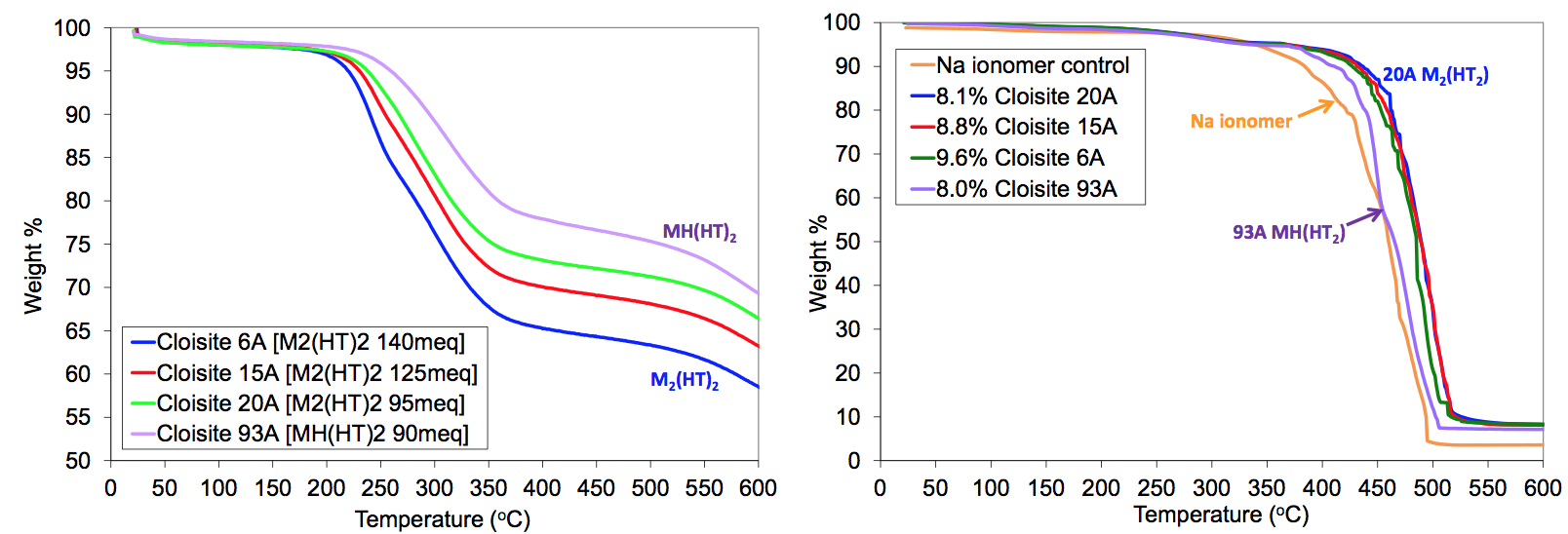

reducing melt viscosity. Thermogravimetric analysis

(TGA) tests on the organically modified MMT and sodium

ionomer nanocomposites are shown in Figure 15.

The TGA in air show that the clays and nanocomposites

are thermally stable up to the process temperatures experienced

in the extrusion tests (typically less than 240°C).

The Cloisite 15A and 6A did show more weight loss, due

to the free excess surfactant. Although is known that quaternary ammonium salts degrade through Hoffman

elimination beginning at 160 to 170°C, the potential degradation

products of the bound and excess surfactant did

not appear to be a primary cause of plasticization (or additional

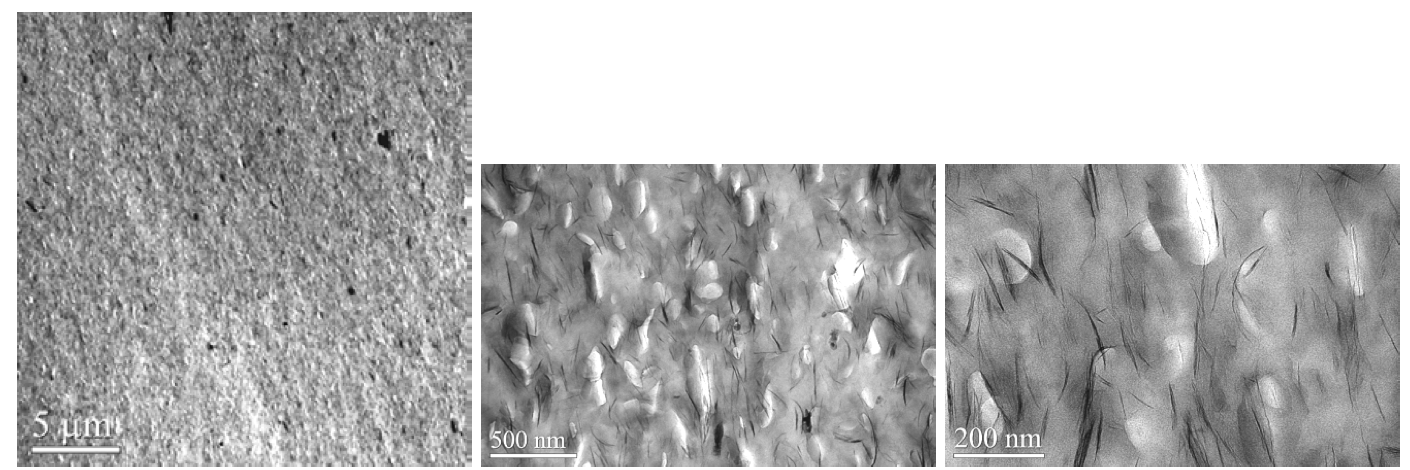

discoloration of the samples). TEM micrographs

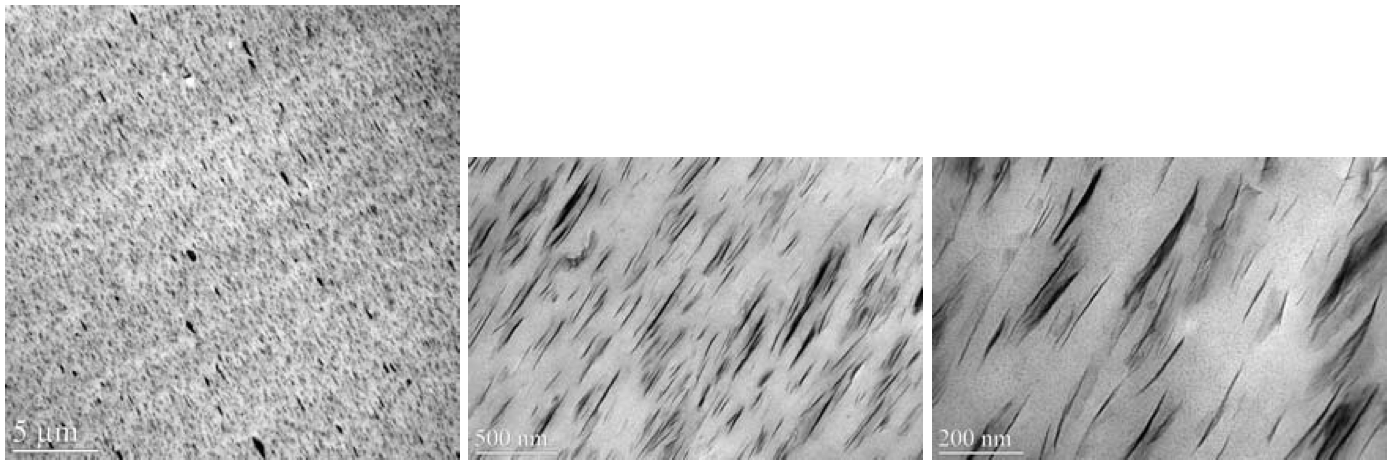

in Figure 8 and 9 show that the Cloisite 20A and 15A

composites with 5 wt. % MMT content had similar micro/nano-structures

consisting of individual exfoliated

platelets and a distribution of tactoids. For this experiment,

the excess surfactant in the 15A clay did not improve

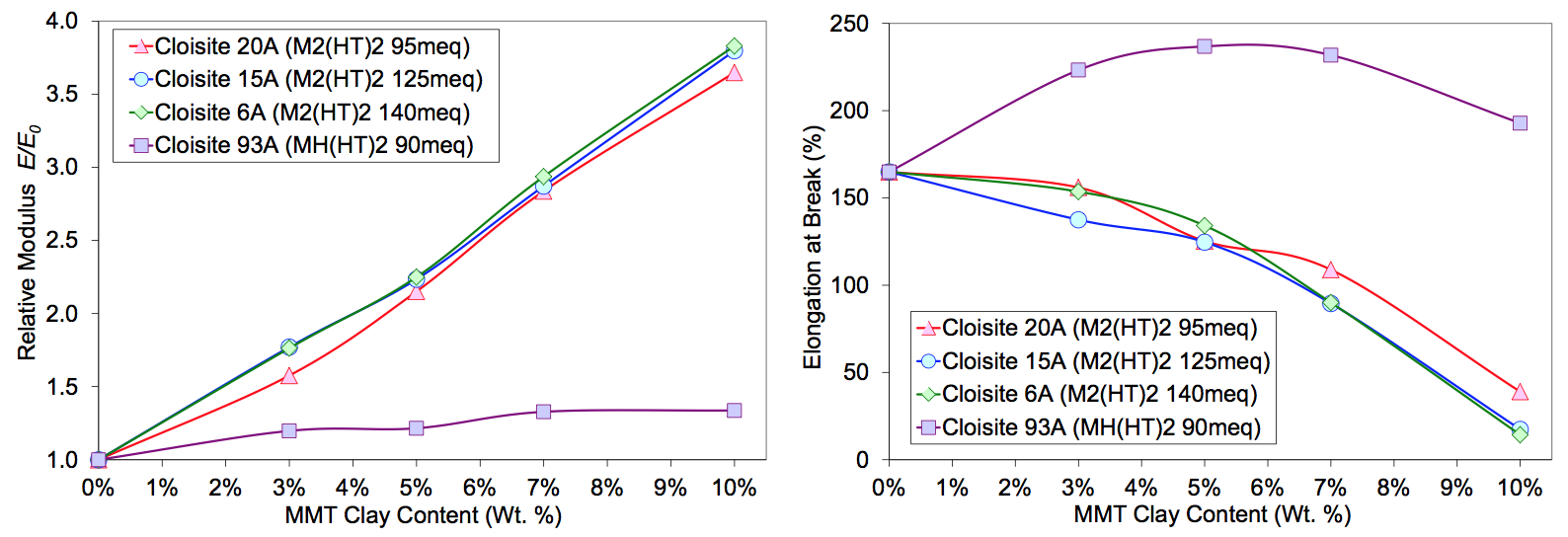

the dispersion quality measurably. The tensile

properties of the Cloisite 20A, 15A and 6A nanocomposites

are shown in Figure 5. The modulus and elongations

were very similar with MMT loading. The excess

M

2(HT)

2 modifier may have improved the extent of exfoliation

(visually less haze) and hence, the effective aspect

ratios slightly. Improved dispersion may have

compensated for the plasticizing effect, especially with

the Cloisite 6A (CEC 140 meq).

Cloisite 93A treated with a more polar modifier

[MH(HT)2, CEC 90 meq] appeared to be thermodynamically

incompatible with the sodium ionomer as indicated

by decreasing process melt temperatures and pressures

shown in Figure 4. Higher filler loading should have

increased melt viscosity. If the exfoliation process produced

a particle size distribution capable of forming a

rheologically percolating network, the melt viscosity

should have increased significantly [1]. The TGA data in

Figure 15 show that the Cloisite 93A clay and the nanocomposite

were thermally stable over the processing temperatures

experienced. The sodium ionomer / 93A

composite was more thermally stable than those using

MMT modified with M

2(HT)

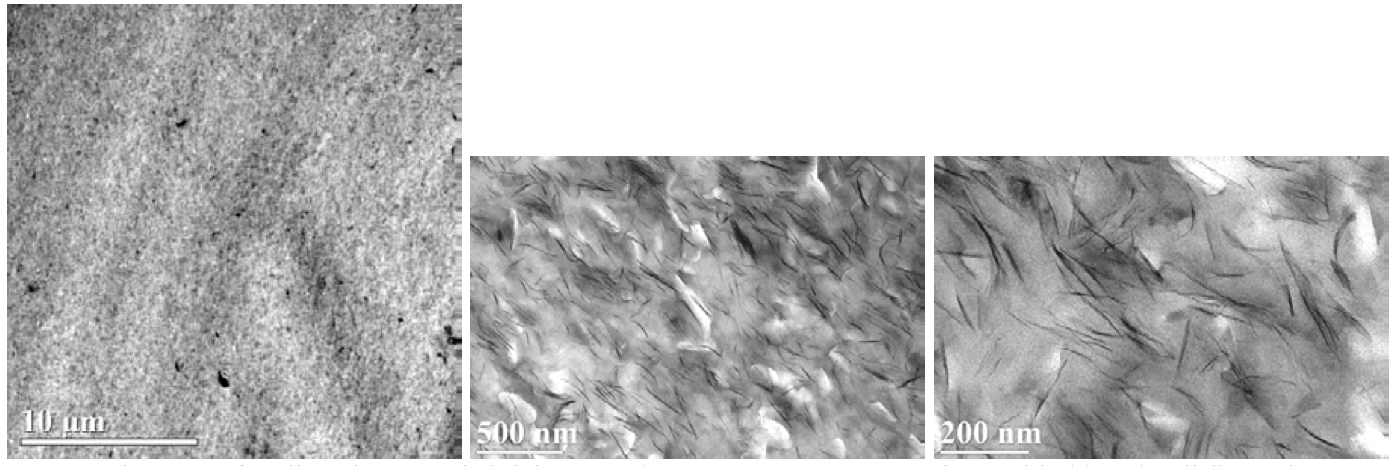

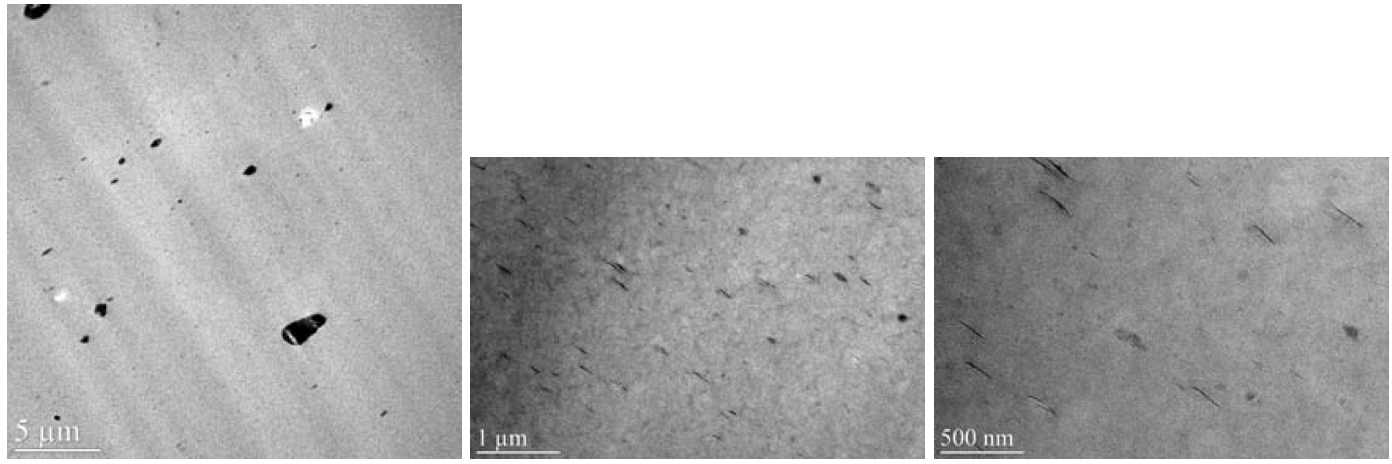

2. The TEM micrographs in

Figure 10 show that the melt process failed to produce a

good dispersion. The micro/nano-structure consisted of a

small number of exfoliated platelets and a dominant population

of large tactoids and agglomerates. This morphology

resulted in little increase in the Young’s modulus

shown in Figure 5. However, Cloisite 93A composites

had a significant increase in the elongation at break from

160 to 240%. Usually, a poor dispersion would not contribute

to a large increase in the elongation (large agglomerate

stress concentrators and flaw sites). This is strong

indication that the MH(HT)

2 modifier was incompatible

with the sodium Surlyn, resulting in poor interfacial adhesion

which, in part, increased the toughness. Furthermore,

the large tactoids could induce cavitation upon

fracture, dissipating energy that could also increase the

toughness [10]. This experiment shows that the thermodynamic

compatibility between filler-modifier-polymer

system components is critical in promoting good dispersion

in the melt blending process and providing sufficient

interfacial adhesion in the nanocomposites resulting in

significant reinforcement [1].

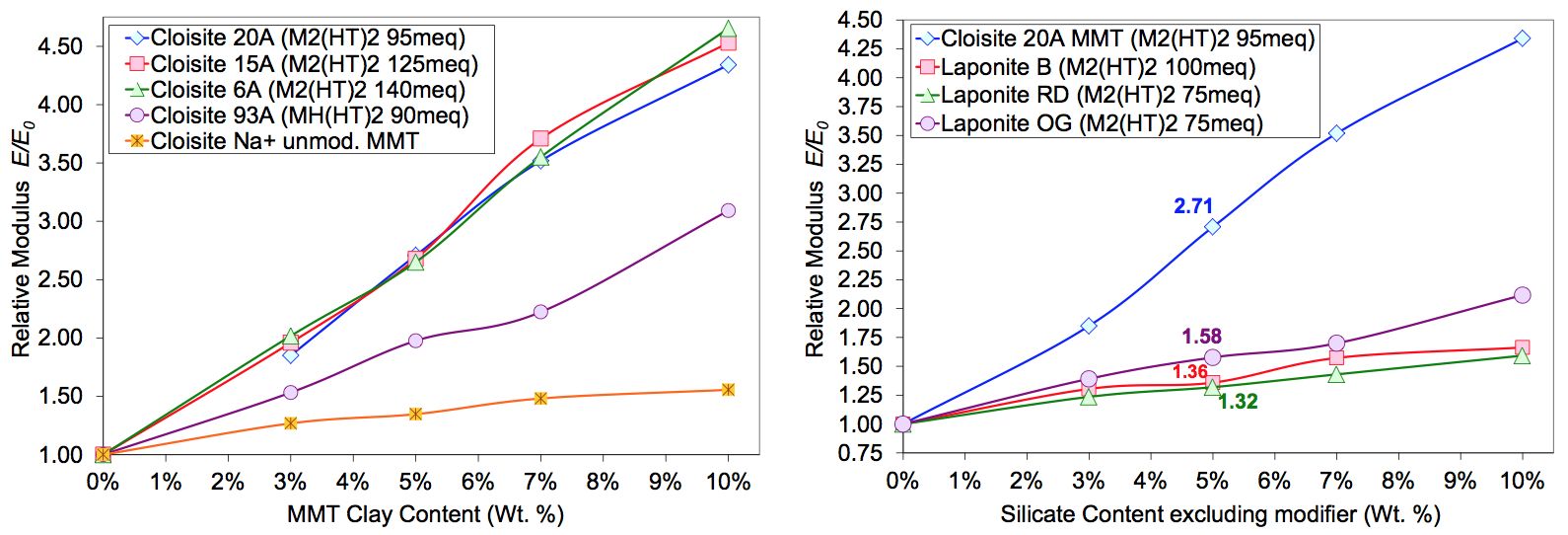

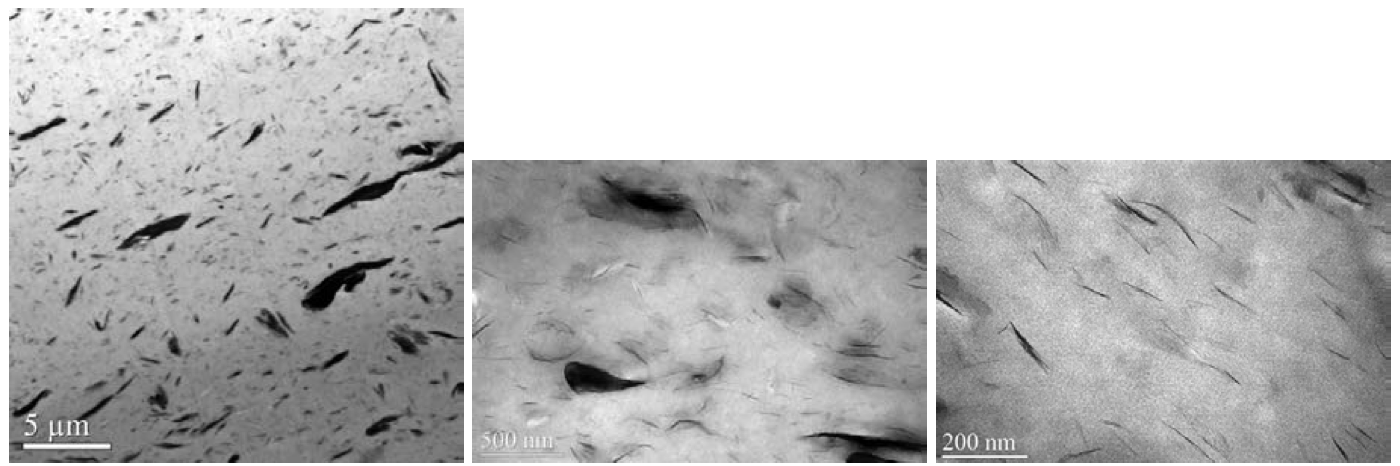

In the next experiment, the zinc ionomer was melt

compounded with the same set of MMT clays. Unmodified MMT (Cloisite Na+) was included in the composition

series. All clays were introduced into the extruder in

the side feed location. Figure 11 shows TEM micrographs

of the zinc ionomer/Cloisite 20A (5 wt. % MMT)

composite. While there is a small population of submicron

particles, the dispersion represents a significant improvement

in extent of exfoliation as compared with the

sodium ionomer. The tensile properties are shown in

Figure 6. The unmodified MMT control shows that without

any surface modifier, the hydrophilic clay is incompatible

with the ionomer resulting in a micron-scale

dispersion (opaque bars with visible particles) and almost

no reinforcement (very low effective aspect ratio). While

the modulus increase trends are similar to the sodium

ionomer system, the reinforcement was significantly

higher for all compositions. Since the melt viscosity of

the zinc and sodium ionomers have similar rheological

properties, the data indicate that the divalent zinc Surlyn

was more thermodynamic compatible with the M

2(HT)

2

modified clay, resulting in a superior morphology. This

finding is consistent with the results reported by Paul [4-

6]. As with the sodium ionomer, while the excess

M

2(HT)

2 modifier increased the inter-gallery spacing (to

reduce the cohesive force), it did not make a measurable

change to the tensile properties.

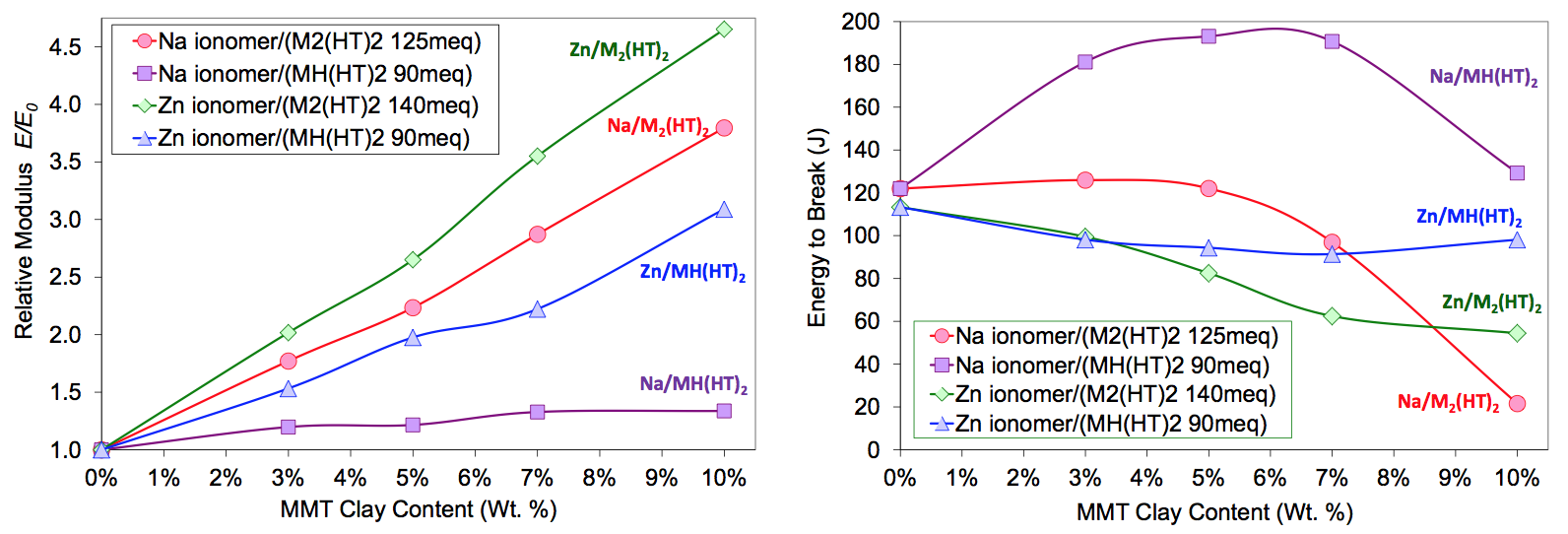

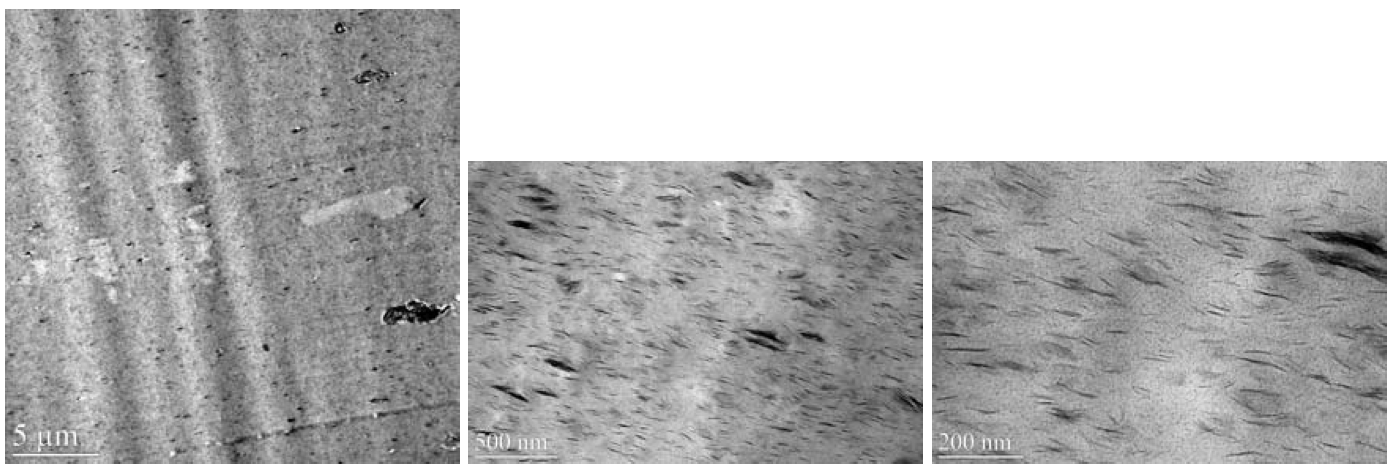

As shown in Figure 12, the more polar MH(HT)

2

modified Cloisite 93A produced a partially exfoliated

micro/nano structure that was inferior to that of the Cloisite

20A sample. However, the dispersion quality of the

zinc ionomer composite was far superior to that of the

sodium ionomer system. The tensile data for both sodium

and zinc ionomer nanocomposites are summarized in

Figures 7. Zinc ionomer nanocomposites had significantly

higher modulus over the entire composition space

tested, but had lower toughness (energy to break) for

most states. While it cannot yet be established why the

zinc system produced a marked improvement over the

sodium ionomer in dispersion and tensile properties, it is

postulated that the zinc ionomer matrix was thermodynamically

more compatible with both the M

2(HT)

2 and

MH(HT)

2 surface modifiers. The effects of the ions on

dispersion and surface interactions will be investigated in

future research.

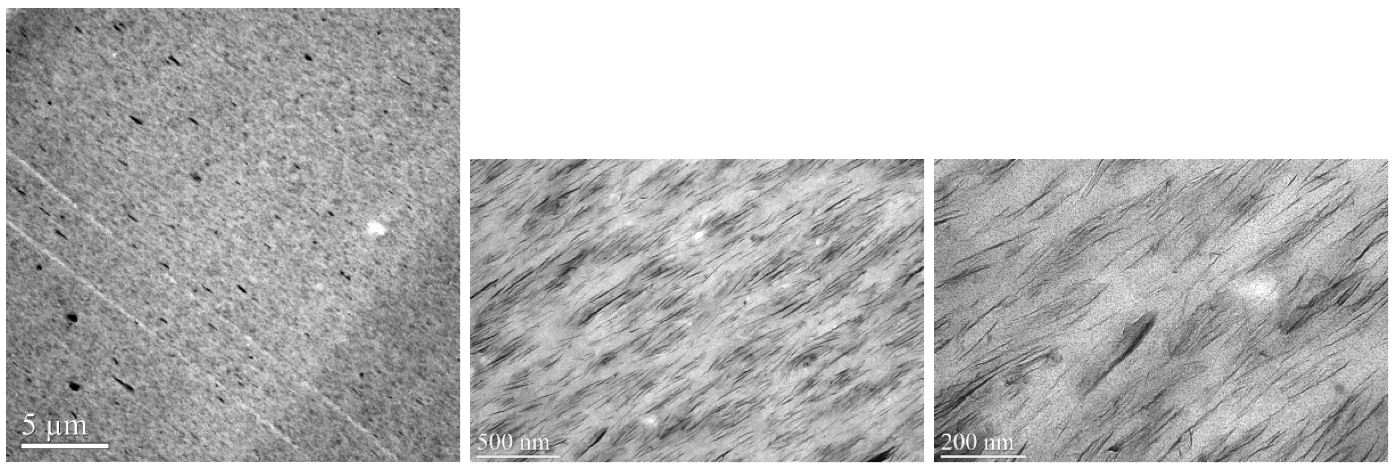

In the last experiment, several grades of M

2(HT)

2

modified Laponite synthetic Hectorite and Fluorohectorite

layered silicates provided by Southern Clay Products

were melt compounded into the zinc ionomer. Figure 13

shows TEM micrographs of a Laponite B Fluorohectorite

composite with 5 wt. % clay content. Southern Clay

Products claims that the platelet diameter is on the order

of 25nm with a cation exchange capacity of 100

meq/100gm clay. WAXS measurements showed that the

inter-gallery spacing was approximately 42Å, the largest

of all silicates tested. This spacing was expected to reduce

the platelet cohesive force substantially, increasing

the likelihood of delamination in a polymer melt [1].

However, the dispersion was very poor, with much of the

clay bound in large micron and sub-micron sized agglomerate

particles. There were very few platelets found in

the TEM micrographs and a sparse population of small

tactoids was observed. Laponite RD Hectorite (25nm

platelets, CEC of 75 meq) produced a very poor micronscale

agglomerate dispersion as well. The bad dispersion

made it difficult to produce useful TEM micrographs.

Modified Laponite OG Hectorite (80 to 100nm platelets,

CEC of 75meq) was compounded into the zinc ionomer

with a resulting micro/nano-structure shown in the TEM

micrographs of Figure 14. The TEM micrographs indicate

that the dispersion was much better than that of both

25nm Laponite grades, but it was not as good as the 140

to 160nm platelet (presumed average sizes) Cloisite

MMT composites.

The tensile properties of the Laponite composites are

shown in Figure 6. The reinforcement with clay type and

loading was consistent with the extent of exfoliation

achieved during compounding and the silicate platelet

size estimates. While the overall structure and surface

charge mechanisms are similar for Hectorite, Fluorohectorite

and MMT, slight surface charge distribution and

chemistry differences may have affected dispersion kinematics

and thermodynamic interactions. If one assumes

that the van der Waals and ionic interactions were

similar, then the test results indicate that platelet dimensions

influence melt compounding dispersion dynamics.

These results would confirm Kamal’s work showing how

large lateral dimensions of platelets reduce the hydrodynamic

stress required for breakup to occur in polymer

melts [1, 9].

The structure-property relationships for the zinc ionomer

nanocomposites were examined using composites

theory [3-6]. The Halpin-Tsai equations were used to

predict the Young’s modulus and estimate an effective

aspect ratio of the layered silicate dispersions as list in

Table 1. Assuming good interfacial adhesion between the

matrix and filler, the aspect ratios are consistent with the

structures shown in the TEM micrographs and the tensile

reinforcement. Unmodified MMT clay produced a micron-scale

dispersion providing little reinforcement with

an effective aspect ratio estimate, Af , of 5. The Cloisite

93A [MH(HT)

2] composites had an Af of 18, approximately

half that of the M

2(HT)

2 modified MMT samples.

Conclusions

Melt compounding experiments were conducted on a

twin screw extruder to disperse organically modified

layered silicates into sodium and zinc ionomers. The

results identified key factors that govern the exfoliation

process in a polymer melt under shear that create the

morphology and subsequently influence physical properties.

These key factors include:

1) For the Surlyn ionomers tested, an appropriate organic

modifier is required to provide thermodynamic compatibility in the melt state to promote a higher

extent of exfoliation or tactoid size reduction while

maximizing the effective aspect ratio of the particles.

2) Ethylene copolymers neutralized with different cations

(sodium and zinc in these experiments) can alter

the compatibility between the polymer and the

modifier, resulting in significant changes to the morphology

and tensile properties.

3) The stress generated during melt compounding does

affect exfoliation and tactoid size reduction. On a

laboratory extruder, barrel temperatures can be used

effectively to change the melt viscosity and move the

melt mixing zone from high to low stress states.

4) Layered silicate geometry (platelet size or aspect

ratio) impacts the extent of exfoliation and tactoid

size reduction. Layered silicates with large lateral

platelet dimensions, like Montmorillonite, may be

more easily dispersed in a polymer melt provided the

components have good thermodynamic compatibility.

Further research is required to develop an understanding

of the roles that the ionomer cations play in the thermodynamic

interactions between the filler, modifier and

polymer.

Acknowledgements

The author is grateful to Southern Clay Products

(SCP) who produced the organically modified clays. The

author acknowledges the advice and stimulating conversations

with Doug Hunter at SCP and Professor Don Paul

at the University of Texas at Austin.

References

1) S. N. Bhattacharya, R. K. Gupta, M. R. Kamal, “Polymeric

Nanocomposites, Theory and Practice,”

Hanser Gardner, Cincinnati, 2008, 35-104.

2) D. L. Hunter, K. W. Kamena, D. R. Paul, MRS Bulletin,

Volume 32, April 2007, 323-327.

3) T. D. Fornes, D. R. Paul, Polymer 44 (2003) 4993–

5013.

4) R. K. Shah, D. R. Paul, Polymer 46, 2005, 2646–

2662.

5) R. K. Shah, D. R. Paul, Macromolecules, 39, 2006,

3327-3336.

6) L. Cui, C. Troeltzsch, P. J. Yoon, D. R. Paul, Macromolecules,

March, 2009.

7) J. Gao, G. Walsh, D. Bigio, R. Briber, M. Wetzel,

AIChE Journal, 1999, 45, 2541-2549.

8) J. Gao, G. Walsh, D. Bigio, M. Wetzel, Polymer Engineering

and Science, 40, 2000, 227-237.

9) N. Borse, M. Kamal, Polymer Engineering and

Science, 49, 4, 2009, 641-650.

10) K. Wang, L. Chen, J. Wu, M. L. Toh, C. He, A. F. Yee, Macromolecules, 38, 2005, 788-800

Table 1. Layered silicate properties (source Southern Clay Products and WAXS measurements).

Figure 1. Sodium and zinc ionomer shear stress vs. shear rate curves at different operating temperature regimes.

Figure 2. Tensile properties of injection molded bars of letdown extrusions of Sodium ionomer / Cloisite 20A master- batches made under low and high temperature conditions (error bars are ± one standard deviation, 6 bars per state).

Figure 3. Tensile properties for constant Q/N samples run on a ZSK-18mm extruder with MMT fed in the rear or side ports.

Figure 4. Sodium ionomer / organically modified MMT extrusion melt temperature and pressure.

Figure 5. Sodium ionomer / organically modified MMT tensile properties.

Figure 6. Tensile modulus data for zinc ionomer / layered silicate composites.

Figure 7. Tensile data comparing zinc and sodium ionomer / Cloisite MMT nanocomposites.

Figure 8. TEM images of sodium ionomer/Cloisite 20A (5 wt. % MMT) composite molded bar (10 lb/hr and 350RPM).

Figure 9. TEM images of sodium ionomer/Cloisite 15A (5 wt. % MMT) composite molded bar (10 lb/hr and 350RPM).

Figure 10. TEM images of sodium ionomer/Cloisite 93A (5 wt. % MMT) composite molded bar (10 lb/hr and 350RPM).

Figure 11. TEM images of zinc ionomer / Cloisite 20A (5 wt. % MMT).

Figure 12. TEM images of zinc ionomer / Cloisite 93A (5 wt. % MMT).

Figure 13. Zinc ionomer / organically modified Laponite B Fluorohectorite composite (5 wt. % clay) TEM.

Figure 14. Zinc ionomer / organically modified Laponite OG composites (5 wt. % clay) TEM.

Figure 15. Thermogravimetric analysis (TGA) of organically modified MMT and sodium ionomer nanocomposites in air.

The advice contained herein is based upon tests and information believed to be reliable, but users should not rely upon it absolutely for specific applications since performance properties will vary with processing conditions. It is given and accepted at user’s risk and confirmation of its validity and suitability in particular cases should be obtained independently. The DuPont Company makes no guarantees of results and assumes no obligation or liability in connection with its advice. This publication is not to be taken as a license to operate under, or recommendation to infringe, any patents.

Return to

Paper of the Month.