Examination of the Performance of a High Speed Single Screw Extruder for Several Different Extrusion Applications

John P Christiano

Davis Standard LLC, Pawcatuck, CTAbstract

This study investigates the extrusion characteristics of a

High Speed Single Screw Extruder, (HSSSE), to

determine suitability for use in several different extrusion

applications including Sheet, Fiber and Extrusion Coating.

Three different material types were evaluated including a

Polypropylene, PP, and High Impact Polystyrene, HIPS,

for sheet extrusion, a PP fiber grade and Low Density

Polyethylene, LDPE, extrusion coating grade. The

extruder used for the study was a highly instrumented

63.5mm, (2.5 inch), 40:1 L/D extruder equipped with a

375KW, (500 HP) motor. Screw speeds up to 1200 rpm

were evaluated.

The study demonstrated that a properly designed

HSSSE could greatly improve the processing capability of

a small diameter single screw extruder for a wide range of

applications.

Introduction

One way of increasing the throughput capability of a

single screw extruder is to simply increase the screw

RPM. This is easier said then done. Depending on the

extrusion process, certain extruder sizes have been chosen

to meet the melt quality requirements of a given extrusion

process. The typical limitations for a given process at

high screw speed are poor melt quality caused by

exceeding the melting capacity of the screw design and

degradation caused by high melt temperature.

Use of a smaller diameter extruder of less than 90mm

diameter, (3.5 inch), can offer several advantages to

achieve a higher throughput at higher screw speed. One

important advantage of a smaller diameter extruder is

better heat transfer characteristics. The heat transfer area

to volume output ratio of a smaller diameter machine

offers a wider and more flexible processing window when

compared to a larger extruder. The heat transfer area to

volume ratio declines rapidly with increasing extruder

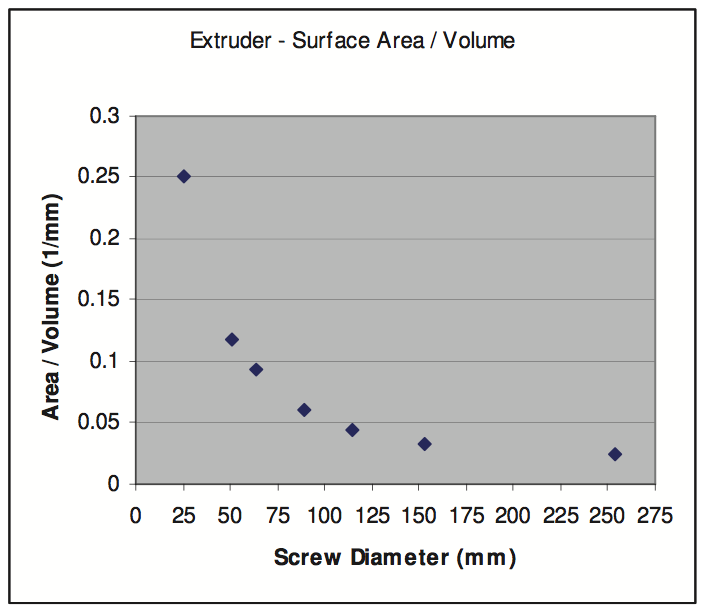

size. See the Figure 1 below. A higher ratio for a smaller

diameter extruder will lead to improved melting efficiency

and better control of melt temperature.

Figure 1. Extruder Surface to Volume ratio vs. Extruder Diameter

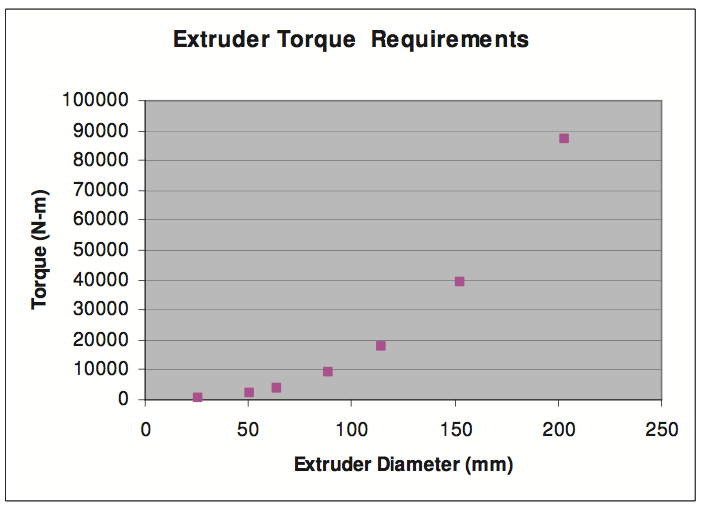

The torque requirement to rotate a Single Screw

Extruder, (SSE), screw increases exponentially as the

extruder diameter is increased for a given extrusion

process. See Figure 2. A small diameter single screw

extruder below 90mm diameter, (3.5 in), offers the

advantage of a lower torque requirement. In this range, a

Direct Drive extruder design can be implemented utilizing

a Permanent Magnet Synchronous or A/C motor without

the use of a gear reducer to further improve energy

efficiency. [1]

Figure 2. Torque requirements for Single Screw Extruders

Using a smaller diameter extruder to provide the same

output of a much larger extruder also has the practical

benefit of requiring less material to construct the extruder.

This improves the economics of the design and results in a

smaller footprint for a given output.

A HSSSE application is characterized by a screw

circumferential speed of greater than 1 m/sec. This

translates to a screw speed of greater than 300 RPM for a

63.5mm extruder. Most extrusion applications today

utilize screw speeds much lower than this with the

exception of extrusion coating. The screw speed range

examined in this study was in the range of 400 to 1200

RPM. This corresponds to a circumferential screw speed

of 1.3 m/s to 4 m/s.

In the 1990’s, high-speed extrusion was successfully

demonstrated for compounding applications using a corotating

twin-screw extruder. Most co-rotating twin-screw

extruders are constructed from a flexible design platform

consisting of segmented barrels and screws. It can easily

be manipulated to optimize the processing section of the

extruder. A typical maximum screw speed in the range of

600 RPM was commonly used in the mid – 1990’s, the

new technology demonstrated a 1200 RPM capability.

The co-rotating twin screw is operated in a starve feed

mode so feed rate is independent of screw speed. This

creates a flexible operating window for the process. The

authors demonstrated that the high-speed process could

dramatically improve throughput and maintain material

properties even with higher processing temperature. [2]

Unlike Twin Screw Extruders, SSEs are constructed

from a one-piece barrel and a one-piece screw. The

extruder is typically flood fed so the throughput of the

extruder is dependent on screw speed. This greatly

narrows the operating window of this process. It is also

much more difficult to optimize, compared to the corotating

twin screw, because of the one-piece construction

of the barrel and screw. HPM Corporation conducted

studies in 1997 on a high-speed extruder using a two-stage

triple wave single screw design. The paper focused on

processing various materials for a compounding

application. The paper concluded that an appropriate

screw design would be very critical in achieving

acceptable performance. [3]

The University of Paderborn recently published work on

processing a range of LDPEs for a high temperature

extrusion coating application using a HSSSE. The highspeed

process exhibited problems with air entrapment and

poor melt quality above 400 RPM and was not able to

achieve the desired melt temperature range. The study

demonstrated the importance of screw design in HSSSE

applications. They also proposed the possibly of using a longer extruder L/D to increase both dissipative energy

and residence time. [4]

This study investigates the extrusion characteristics of a

HSSSE to determine suitability for use in several different

extrusion applications including Sheet, Fiber and

Extrusion Coating. Three different material types were

evaluated included a PP and HIPS for sheet extrusion, a

PP fiber grade and LDPE extrusion coating grade.

The extruder used for the study was a highly

instrumented 63.5mm, (2.5 inch), 40:1 L/D extruder

equipped with a 375KW, (500 HP) motor. The screw

speed range examined in the study was from 400 to 1200

RPM. This corresponds to a circumferential screw speed

of 1.3 m/s to 4 m/s.

Experimental

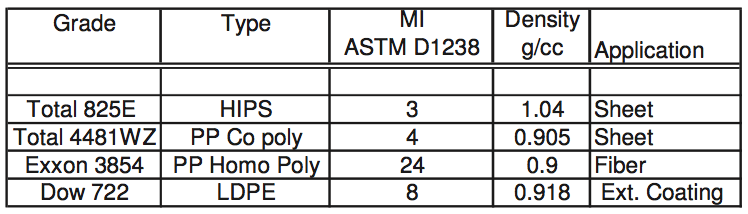

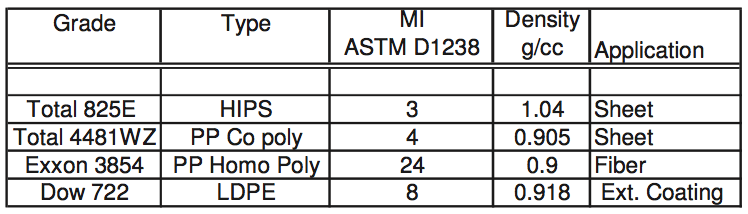

The study examined four different materials. See Table

1. The materials included an extrusion grade of PP and

HIPS suitable for a sheet thermoforming application, an

Extrusion Coating grade of LDPE and a PP fiber grade.

Table 1. Resin Specifications

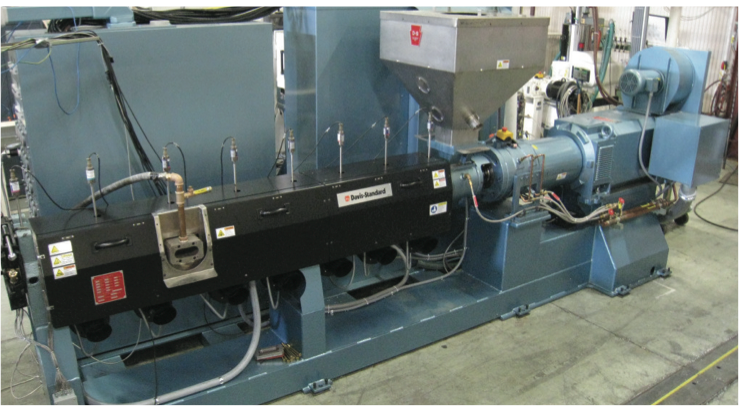

Experiments were conducted on a highly instrumented

63.5mm 40:1 L/D Davis-Standard extruder equipped with

seven electrically heated/air cooled barrel zones. See

figure 3. A Thermatic® Temperature Control system was

used to control the barrel temperatures and measure the

heat flux in each zone of the extruder. Eight pressure

transducers were located along the axial length of the

barrel at approximately 5 L/D increments, to measure the

axial pressure generation along the screw. A pressure

transducer and exposed junction melt thermocouple were

located in the discharge adapter of the extruder in order to

evaluate the output and thermal process stability of the

melt. A valved adapter and a 762cm, (30 in), wide coathanger

sheet die with a 1.27 mm, (0.050 in) die gap was

utilized for all of the trials. A 4 L/D Static mixer was

installed between the valved adapter and the die for the

sheet extrusion evaluations.

Figure 3. – 63.5mm 40:1 L/D, Instrumented extruder

The study investigated three experimental screw

designs. A two-stage moderate to high intensity screw

design was used for processing the sheet grade PP and

HIPS. A lower intensity two-stage screw was used to test

the Fiber grade PP. The Extrusion coating grade LDPE

was tested on a single stage very high intensity mixing

screw design.

The data recorded at each operating condition included

the extruder output, melt temperature measured with an

exposed junction thermocouple in the melt stream at the

entrance to the die, motor power consumption, and

pressure at the discharge of the extruder. The pressure

readings were recorded with a data acquisition system at a

rate of 50 Hz. The processing stability was evaluated for

each material by monitoring pressure variation and melt

temperature variation vs. time at the discharge of the

extruder. The melt quality of the extrudate was inspected

visually as it exited the 762 mm wide extrusion die. The

screw speeds examined ranged from 400 to 1200 RPM for

each of the materials. The operating conditions and

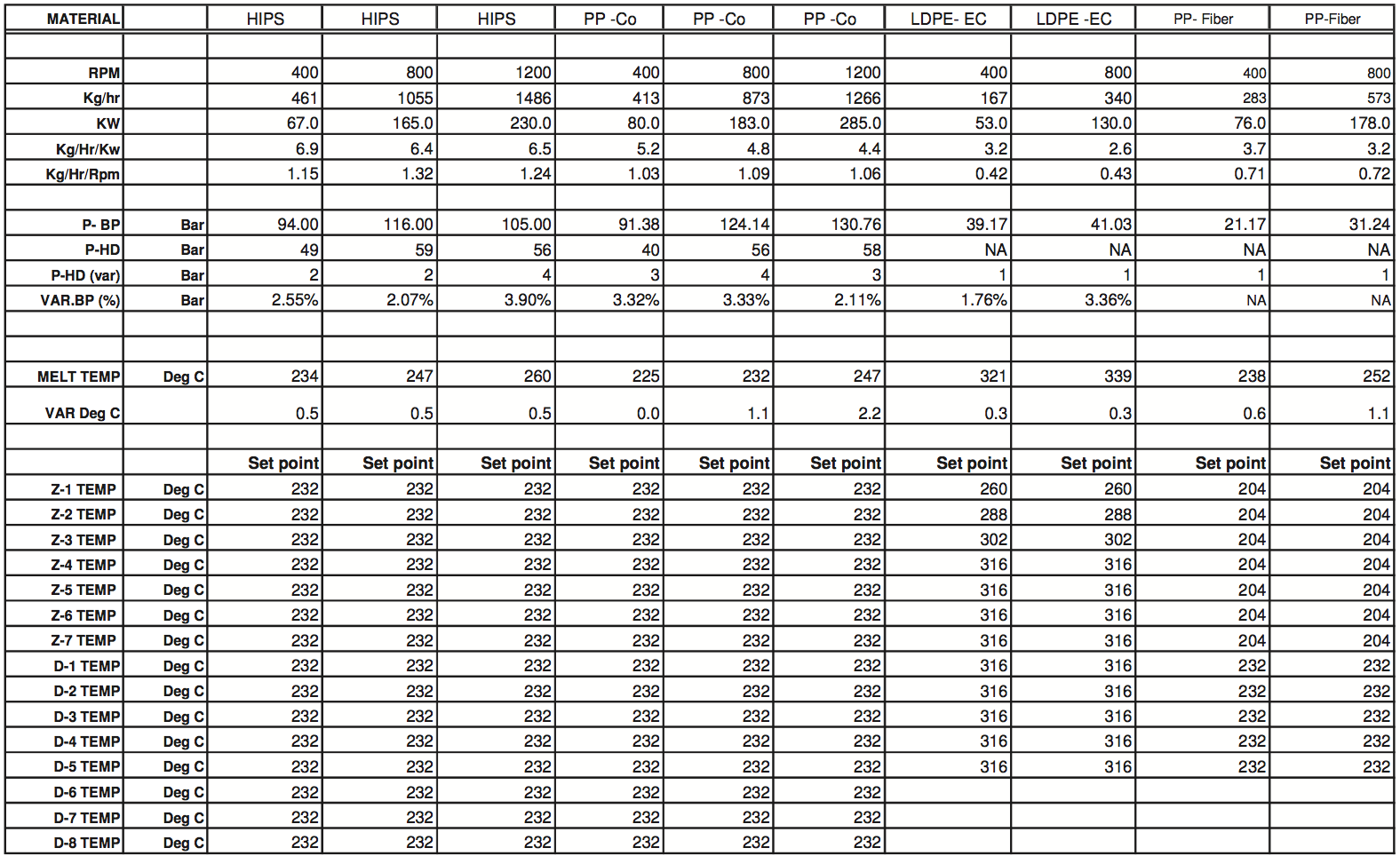

extrusion data for each of the tests is summarized in Table

3.

Discussion of Results

The object of this paper is to investigate the extrusion

characteristics of a HSSSE and determine the suitability

for use in several different extrusion applications

including Sheet, Fiber and Extrusion Coating. The

suitability of the HSSSE for each application was judged

by comparing the performance against a pre-defined set of

parameters that are commonly used in industry for each

application. The process parameters examined included,

feeding consistency vs. screw speed or linearity of specific

output, (kg/hr-rpm), vs. screw speed, acceptable melt

temperature range and required process stability. The

process stability was evaluated by monitoring pressure

variation, as an indication of output consistency, and melt

temperature variation in time, as an indication of thermal

homogeneity. Melt quality was inspected visually for defects exiting the die. The desired process parameters

for each application are listed in the table below.

Table 2. Acceptable Process Parameters

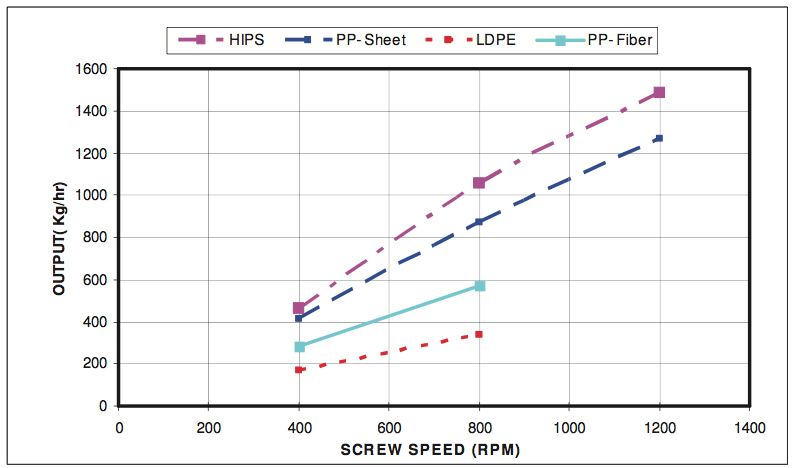

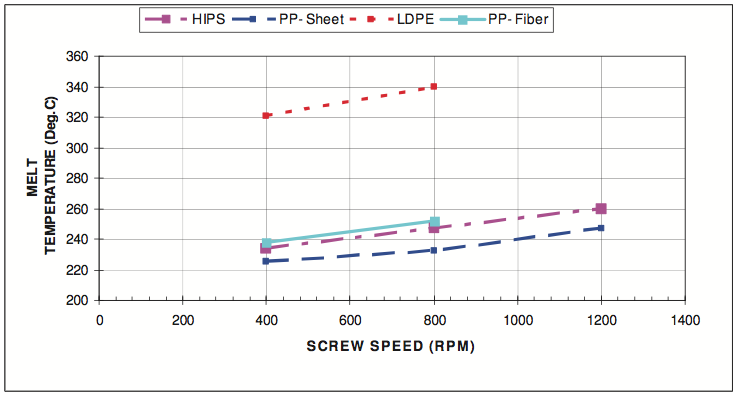

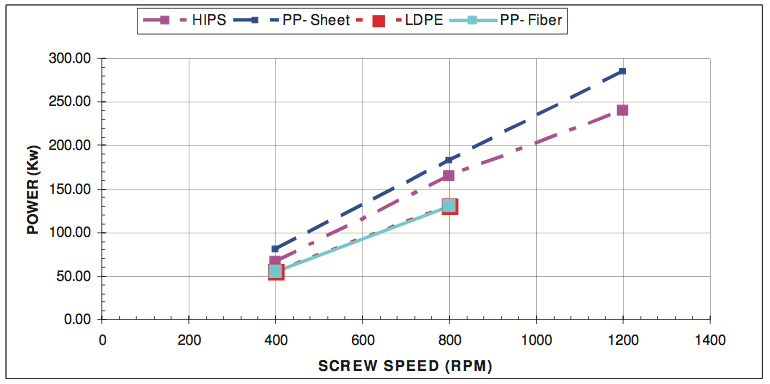

The output rate, melt temperature and power

consumption are plotted vs. screw speed for each of the

materials tested in Figures 4, 5, and 6, respectfully. The

graphical presentation of the data will be used in the

discussion of results below.

The output rate vs. screw speed for each of the materials

is shown below in figure 4.

Figure 4. Output rate vs. Screw Speed

The melt temperature vs. screw speed for each of the

materials tested is shown below in Figures 5.

Figure 5. Melt Temperature vs. Screw speed

The motor power consumption vs. screw speed for each

of the materials tested is shown below in Figure 6.

Figure 6. Drive Power vs. Screw Speed

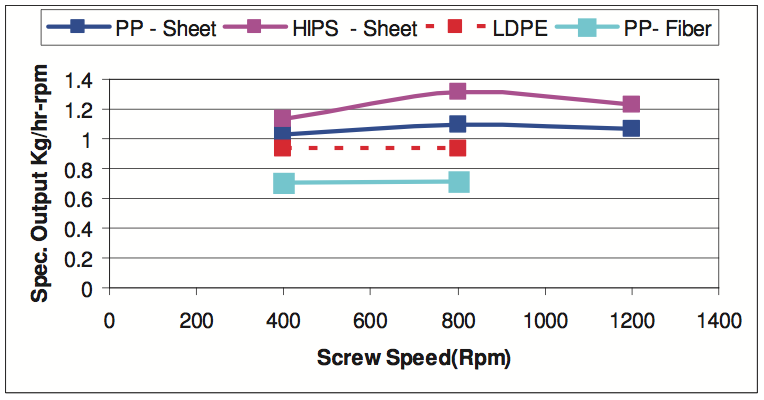

The Specific output kg/hr- rpm vs. screw speed for each

of the materials is shown in Figure 7. This figure examines

the linearity or feeding consistency of the through put vs.

screw speed and can help identify the point at which

process limitations due to solids conveying or melting

capacity occur.

Figure 7. Specific output vs. Screw Speed

The experimental data for each of the materials tested

will be compared below to the process requirements

shown in Table 2.

PP Sheet Extrusion

The output vs. screw speed for the PP sheet extrusion

grade material is shown in Figure 4. This figure shows

that the rate increased linearly with screw speed. Figure 7

shows the specific output rate, kg/hr-rpm, defined as the

output rate divided by the screw RPM. This figure shows

a slight increase at 800 RPM however, at 400 and 1200

RPM the value was constant. The relatively constant

specific output throughout the processing range, indicates

that solids conveying zone of the screw was operating

efficiently. The variation in specific output of less that 1.8

% over the desired processing range is well below the

required feed rate consistency criteria.

The melt temperature vs. screw speed is shown in

Figure 5. The melt temperature increased with increasing

rpm, but remained in an acceptable range when compared to the processing criteria listed in Table 2. The melt

temperature increased from 225 Deg C, at 400RPM, to a

maximum of 247 Deg C at 1200 RPM.

The thermal process stability remained in the desired

range up to the 800 RPM operating condition. At the

1200 RPM operating condition, the melt temperature

fluctuations in time increased to 2.2 Deg C.

The variations in pressure at the extruder exit, P-BP,

were in the range of +/- 2% target set in the processing

criteria. Most sheet extrusion systems have extruders

equipped with melt pumps to handle this level of pressure

variation.

Visual inspection of the melt curtain at the 400 and 800

RPM conditions showed excellent melt quality. The

visual melt quality of the extrudate declined at the 1200

RPM condition. A melt disturbance was observed in the

sheet exiting the die.

Overall, the performance of the HSSSE for processing a

sheet grade of PP was acceptable up to a screw speed of

800 RPM. To ensure consistent output and reduce the

thermal gradient in the melt stream exiting the extruder, a

melt pump and static mixer are recommended for this

application.

HIPS Sheet extrusion grade

The output vs. screw speed for the HIPS sheet extrusion

grade material is shown in Figure 4. The specific rate,

shown in Figure 7, was lowest at 400 RPM and reached a

maximum at 800 RPM. The peak specific output at 800

RPM was 10% above and the 400 RPM condition was

10% below the average specific output. These conditions

exceeded the upper limit defined in Table 2.

The melt temperature vs. screw speed is shown in

Figure 5. The melt temperature increased with increasing

RPM. The upper limit of the melt temperature was

reached at the 800 RPM operating condition. The melt

temperature increased from 234 Deg C, at 400RPM, to

247 Deg C at 800 RPM. This exceeded the maximum

temperature limit by 2 Deg C.

The thermal process stability remained in the desired

range. The melt temperature fluctuations in time remained

below 0.5 Deg C over the entire processing range. This

indicates good thermal homogeneity.

The variation in pressure at the exit of the extruder, PBP,

remained in an acceptable range for all of the

operating conditions.

Visual inspection of the melt curtain at the 400, 800

and 1200 RPM conditions showed excellent melt quality.

Overall, the performance of the HSSSE for processing

the sheet grade of HIPS was acceptable up to a screw

speed of 800 RPM. The maximum melt temperature was

exceeded above this screw speed. To ensure consistent

output and reduce the thermal gradient in the melt stream

exiting the extruder, a melt pump and static mixer is

recommended. A lower intensity screw design is required

to control the melt temperature above 800 RPM. Further

optimization of the barrel temperature in the solids

conveying zone could help to reduce the variation in

specific output at the different screw speeds.

LDPE Extrusion Coating grade

The output vs. screw speed for the LDPE extrusion

coating grade material is shown in Figure 4. This figure

shows that the output rate increased linearly with screw

speed. The specific rate shown in Figure 7 remains

constant between 400 and 800 RPM. The constant

specific output indicates that solids conveying remained

efficient over this processing range. The specific output

increased slightly between 400 and 800 RPM but

remained within the desired processing range criteria.

The melt temperature vs. screw speed is shown in

Figure 5. The melt temperature increased with increasing

rpm and exceeded the target specifications between 400

and 800 RPM. The 1200 RPM condition was not tested

due to the high melt temperature. The elevated melt

temperature indicates that the screw design is imparting

excessive mechanical energy into the material. A lower

intensity screw design is required in order process this

material above 400 RPM.

The thermal process stability of this design was

excellent. The melt temperature fluctuations in time were

less than 0.5 Deg C at both screw speeds. This is a good

indication that the intensity of the screw design can be

decrease to control the melt temperature.

The variations in pressure at the exit of the extruder, PBP,

were negligible and were under +/- 1 bar for both

operating conditions.

Visual inspection of the melt curtain at the 400 and 800

RPM conditions showed excellent melt quality.

Based on the results of the trial, a lower intensity screw

design is required in order to operate above the 400 RPM

operating condition and reduce the melt temperature to

within an acceptable range.

PP – Fiber grade

A short test was conducted under high-speed conditions

to examine the extrusion performance of a fiber grade PP

on the moderate intensity two-stage screw design. The output vs. screw speed for the PP Fiber extrusion grade

material is shown in Figure 4. This figure shows that the

rate increased linearly with screw speed. The specific

output rate, kg/hr-rpm, remained constant over the screw

speed range from 400 – 800 RPM. This is well within the

processing range required. See Figure 7.

The melt temperature vs. screw speed is shown in

Figure 5. The melt temperature increased with increasing

RPM. The upper limit of the melt temperature was

reached at the 800 RPM operating condition. The melt

temperature increased from 238 Deg C, at 400 RPM, to a

maximum of 252 Deg C at 800 RPM.

The thermal process stability remained in the desired

range. The melt temperature fluctuations in time remained

below 1.1 Deg C over the entire processing range. This

indicates good thermal homogeneity.

The variations in pressure at the exit of the extruder, PBP,

were in the range of +/- 2% target set in the

processing criteria for both operating conditions. Most

fiber extrusion systems have extruders equipped with melt

pumps to handle this level of pressure variation.

Visual inspection of the melt curtain at the 400 and 800

RPM conditions showed excellent melt quality.

Overall, the performance of the HSSSE for processing a

fiber grade PP was acceptable up to a screw speed of 800

RPM. The melt temperature exceeded the target limits at

800 RPM. The two stage screw design used for this short

test imparted excessive mechanical energy into the

material causing the melt temperature to exceed the

maximum allowable temperature at 800 RPM. An

optimized single stage screw design with a lower level of

intensity is required for this process.

Conclusion

The study demonstrated that a properly designed

HSSSE could greatly improve the processing capability of

a small diameter single screw extruder for a wide range of

applications.

The direct drive 63.5 mm, (2.5 in), HSSSE successfully

processed the PP sheet grade within the defined

processing limits up to a throughput rate of 1000 kg/hr.

This is approximately 9 times larger that the output of a

conventionally designed extruder used today. The HIPS

sheet grade was processed within the design parameters up

to 1100 kg/hr. With further screw design optimization to

improve melting and mixing capability higher output rates

are achievable. The LDPE extrusion coating screw

processed the material up to a screw speed of 400 RPM.

Further optimization by decreasing the intensity of the

screw design will widen the operating window.

Further optimization of the screw designs for each

application will help to increase overall performance.

Future work will focus on understanding solids conveying,

melting and mixing within the HSSSE under high-speed

extrusion conditions.

Reference

1. J. Baird and J. P Christiano, “An Evaluation of the

Performance of Drive System Configurations in

Single Screw Extuders,” SPE-ANTEC Tech. Papers,

56, Pg, (2010).

2. P. Andersen, E. Haring, K. Kapfer, “Understanding

High Rate and High RPM Compounding on

CoRotating Twin Screw Extruders,” SPE-ANTEC

Tech. Papers, 43, 238 (1997).

3. H.R. Sheth, “High Speed Extrusion, Ultra High Speed

Extrusion of Various Polymers,” SPE-ANTEC Tech.

Papers, 45, 140 (1999).

4. V. Schöppner, R. Weddige, H. Hörmann,” High

Speed Extrusion for Applications requiring High Melt

Temperature,” Kunststofftechnik Paderborn (KTP),

Universität Paderborn, Warburger Str, 100 33098

Paderborn, Germany.

KeyWords: High Speed Single Screw Extrusion,

High output rate, sheet, fiber, extrusion coating

Table 3. Operating Conditions P-BP pressure reading at the tip of the screw P-HD pressure reading at the inlet to the die

Return to

Paper of the Month.