Using Hypothesis Setting to Optimize the Troubleshooting Process for Single-Screw Plasticators

Mark A. Spalding, The Dow Chemical Company, Midland, MI

Gregory A. Campbell, Castle Research Associates, Jonesport, MEAbstract

The goal of all troubleshooting operations is to

restore the process to its original performance as quickly

as possible. This paper describes a process that is based

on developing hypotheses using verified data. Next, the

hypotheses are tested using properly developed

experiments. Once the root cause of the problem is

identified, the best technical solution is implemented.

Three case studies are presented.

Background

The goal of all troubleshooting operations is to

restore the process to its original performance as quickly

as possible. If the process is operational and producing a

high level of off specification product, then the

manufacturing costs can be very high. Restoring the line

to its original performance quickly will reduce costs by

eliminating some quality control operations and labor

wasted in making product that is not fit for use, reduction

in resin consumption, eliminating recycle due to off

specification product, and decreasing energy

consumption. Moreover if the line is inoperable due to the

defect, the downtime of the line can be extremely costly,

especially if the line is sold out. In this latter case, the

goal would be to bring the line back to production

operation as quickly as possible. Excellent overviews of

the troubleshooting process for extrusion systems were

provided by Gould [1] and Christie [2]. Procedures to

troubleshoot processes in general were outlined by Mager

[3] and Fogler and LeBlanc [4].

Troubleshooting a process can range from solving a

very simple problem such as replacing a malfunctioning

barrel heater to a very difficult flow problem that is very

complicated to diagnose. Collecting the proper

information on machine performance can minimize the

time required to restore the machine to its original

performance while reducing the cost of the

troubleshooting process. The machine owner will provide

details and information for the operation. Typically, the information will be a collection of facts, ideas on the root

cause, and data that are not relevant to the problem. The

troubleshooter must be able to listen to the information

provided and then sort the important facts from the nonrelevant

information. Often, several different solutions

will be possible. The best solution will be based on a

combination of the cost of lost production, the time and

cost to implement, machine owner acceptance, and the

risk associated with the modified process.

The first thing that a troubleshooter should do is talk

to the plant personnel and the process operators about the

defect. The operators in many cases witnessed the event

that caused the problem or they can provide the recent

history leading up to the failure. In some cases the

operator may have inadvertently caused the problem.

Interviewing the operator and having the operator assist

in the diagnosis of the problem can speed up the

troubleshooting process. After the interviews, the

troubleshooter must verify the accuracy of the

information. Verification of the information can be as

simple as viewing computer fault information on a control

panel to questioning events that are impossible to

reproduce or verify. The information that is verified will

become part of the basis for setting hypotheses on the

root cause of the problem.

The troubleshooter should obtain the performance

and modification history for the machine. This

information is typically available from electronic data

storage devices associated with the extruder, the machine

owner, maintenance personnel, and the operators. A

schematic for the screw is required for most

troubleshooting operations. Most screw vendors will

provide, as a courtesy, a diagram that shows the flow

channels of the screw. If these diagrams are not provided

during the original purchase, a diagram of the screw

should be made by plant personnel prior to installation.

Other required data include the rate, screw speed, motor

current, barrel temperature settings, and discharge

pressure and temperature. Additional sensor data are

occasionally available on some machines including

pressure measurements in the barrel, gear pump rate via

its rotation rate, and sensors specific to a process. The screw speed and motor current values displayed on the

control panel should be verified. For the screw speed,

counting the rotations of the screw at the back of the

gearbox for a time period must be performed to verify the

speed displayed on the panel. Most displays show the

screw speed within a 5% error, but for some processes the

screw speed display has been in error by a factor of 2.

Verifying the motor current is easily performed by an

electrician using a simple current meter. As a general

practice, all instruments and sensors should be verified

for accuracy.

All mechanical and electrical components should be

examined and verified that they are functioning properly.

These components include the solenoid valves for water

cooling systems, cooling water pumps, cooling fans,

electrical heaters, thermocouples and other temperature

sensors, pressure sensors, and gear pump operations.

Most extrusion processes measure the discharge

temperature using a thermocouple sensor positioned in

the transfer line downstream from the tip of the screw.

The thermocouple is often positioned into the polymer

stream about 1 cm past the inside wall of the transfer line.

This equipment configuration is the best for most

applications, but it can provide temperature measurements

that are considerably different from the actual resin

temperature [5]. The thermocouple measures the

temperature at the sensor junction, and this junction is

influenced by the temperature in its vicinity, including the

temperature of the resin, the temperature of the sensor

sheath, and the temperature of the transfer line. Since the

thermal conductivity for a metal is typically 300 times

higher than that for a polymer, thermal conduction is

more influenced by the surrounding metal than the

temperature of the resin in the transfer line. Thus, for a

transfer line that is controlled at a temperature less than

the bulk resin temperature, the thermocouple is going to

report a temperature that is less than the bulk temperature

of the resin. A better way to measure the discharge

temperature is by placing a hand-held thermocouple in the

resin discharging at the die opening. In order to mitigate

conduction of energy away from the junction, the

thermocouple sheath should be immersed in hot resin. If

the transfer line is relatively short with no significant

cooling or heating occurring in the line, then the

measured value should be close to the actual discharge

temperature from the extruder. For many systems where

the polymer flow is always inside lines, hand-held

measurements are not possible and the troubleshooter

must rely solely on the temperature measurement through

the transfer line. Hand-held temperature sensors that

measure the infrared (IR) radiation level from the resin

provide an excellent measure of relative temperatures, but

because of the difficulty in measuring the emissivity of

the polymer these devices are not as accurate as hand held thermocouple sensors.

Next, the troubleshooter should perform a basic

series of calculations for the screw and process. These

calculations include the rotational flow rate (or drag flow

rate) and pressure flow rate [6]. These calculations will

allow the troubleshooter to determine if the metering

section of the screw is the rate limiting section of the

process. The metering section of a flood-fed single-stage

screw or the first-stage metering section of a multi-stage

screw must control the rate for the process. If the

metering section is not rate controlling, then the extruder

will operate at reduced rates and has the potential to flow

surge and cause resin degradation products to occur in the

discharge [6,7]. For a multi-stage screw, if the first-stage

metering section does not control the rate then flow of

resin into a vent opening may occur. These calculations

are simple and will guide the troubleshooter to develop

appropriate hypotheses on the root cause of the process

defect. Other calculations that should be performed are

the compression rate and compression ratio. The

calculation of the compression ratio for a screw with a

constant lead length is as follows:

where C is the compression ratio, H is the channel depth

of the feed section, h is the depth of the metering channel.

The compression rate for the transition section of the

screw describes the rate that the channel depth changes as

the resin is transported through the section. The

compression rate is calculated as follows:

where R is the compression rate in the transition section,

M is the number of turns in the transition section, θ

b is the

helix angle at the barrel wall, L is the lead length, and Db

is the inside diameter of the barrel. The compression rate

and ratio should be within an acceptable range for the

resin processed.

To aid in the calculations and the relevance of their

application, the bulk density of the feedstock resin and

the shear viscosity should be measured. The shear

viscosity is needed for the pressure flow calculation while

the bulk density is needed to assess the compression ratio

and compression rate. For example, ground recycle

streams when added to pellets cause the bulk density of

the feedstock to decrease. If the bulk density of the feedstock is considerably less than just pellets, then the

compression ratio and compression rate should be

adjusted as follows:

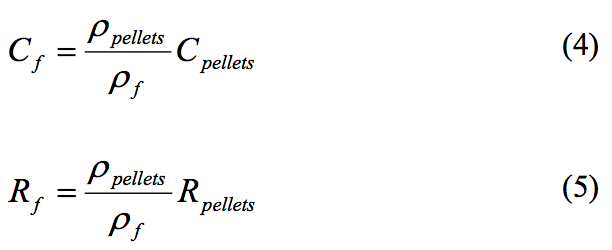

where Cpellets and Rpellets are the compression ratio and

compression rate used for a pellet feedstock, ρ

pellets is the

bulk density of the pellets at ambient conditions, ρ

f is the

bulk density of the feedstock mixture at ambient

conditions, and C

f and R

f are the compression ratio and

compression rate that should be used for the lower density

feedstock resin, respectively.

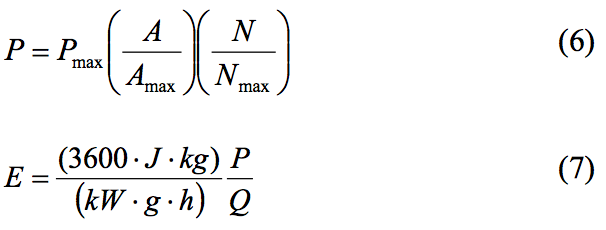

The specific energy inputted by the motor to the resin

should be calculated and compared to similar processes.

The power and specific energy inputted into the polymer

from the extruder screw are estimated using Equations (6)

and (7):

where P is the power that is dissipated in kW, P

max is the

nameplate power (kW) for the motor, A is the motor

current observed during the extrusion, A

max is the

nameplate motor current at full load, N is the screw speed

(rpm) during extrusion, and N

max is the maximum screw

speed (rpm) that the extruder is capable of running (with

full field voltage). After the power is computed, the

specific energy inputted to the resin from the screw, E, in

J/g is calculated using Equation (7) and the extrusion rate,

Q, in kg/h.

Often troubleshooting guides are provided by

equipment manufacturers for common problems. These

guides are helpful for many of the simpler problems

associated with the equipment. Some resin manufacturers

are an excellent resource for troubleshooting processing

problems that are specific to a resin. Subject matter

experts or extrusion consultants are also resources for

troubleshooting an extrusion process.

Spare parts for common components such as heaters

for barrels, transfer lines, and dies, thermocouples,

pressure transducers, drive belts, and fuses should be kept

in stock. Since the goal is to maintain the line operational at all times, keeping these low cost but necessary

components in stock can reduce the amount of downtime

due to simple failures. For operations where the resin is

abrasive or corrosive, a spare screw should be kept in

stock. As the screw wears in the extruder and the

performance decreases beyond an economic limit, then

the screw should be replaced with the spare screw and the

worn screw should be sent to a screw manufacturer for

refurbishment.

Hypothesis Setting and Problem Solving¶

With the plant interview information, verification of

the data, and the completion of the simple calculations, an

experienced troubleshooter will develop a set of

hypotheses for the root cause of the defect. After the

hypotheses are established a series of experiments need to

be developed that accept or reject the hypotheses. Once a

hypothesis is accepted via experimentation, then the next

step is to develop a technical solution to remove the

defect. Often more than one technical solution is possible.

The best technical solution will depend on the cost and

time to implement the solution, machine owner

acceptance, and the risk associated with the modified

process. An accepted hypothesis must drive the technical

solution. If a hypothesis is not accepted prior to

developing a technical solution, then the troubleshooter

may be working on the wrong problem and the defect

may not be eliminated from the process.

A hypothesis is a proposed explanation for an

observation. The hypothesis should be stated such that it

is clear and testable. For each hypothesis, an alternative

hypothesis should be stated that is accepted should the

original hypothesis be proven false. Developing

alternative hypotheses allows the troubleshooter to

quickly arrive at the defect while moving through a

complicated decision making process. The alternative

hypothesis provides a logical branch that directs the

troubleshooter to the root cause. Each troubleshooting

process should be developed with a set of alternative

hypotheses, design of experiments that exclude one or

more of the hypotheses, and then performing the

experiments such that definitive results occur [8]. At the

conclusion of this process, a new set of alternative

hypotheses may be required to continue the decision

making process.

As an example of an alternative hypothesis, a simple

case study is presented here. For this case, an extruder is

discharging degradation products into the product stream.

The hypothesis and alternative hypothesis statement is

“the metering section of the screw is not operating full

and not under pressure, creating regions where resin can

degrade, or the process is operating with the metering

section full and under pressure and the degradation products are coming in with the resin or generated in

some other section of the process.” This combination of

hypothesis is referred to here as the alternative hypothesis

since it allows for a decision to be made about where the

root cause occurs. Once an experiment is developed to

test the hypothesis, the troubleshooter can then focus the

next hypothesis and experiments looking at only one side

of the decision branch. Developing acceptable hypotheses

depends on validated information, a fundamental

knowledge of the process, and knowledge of the

properties of the resin.

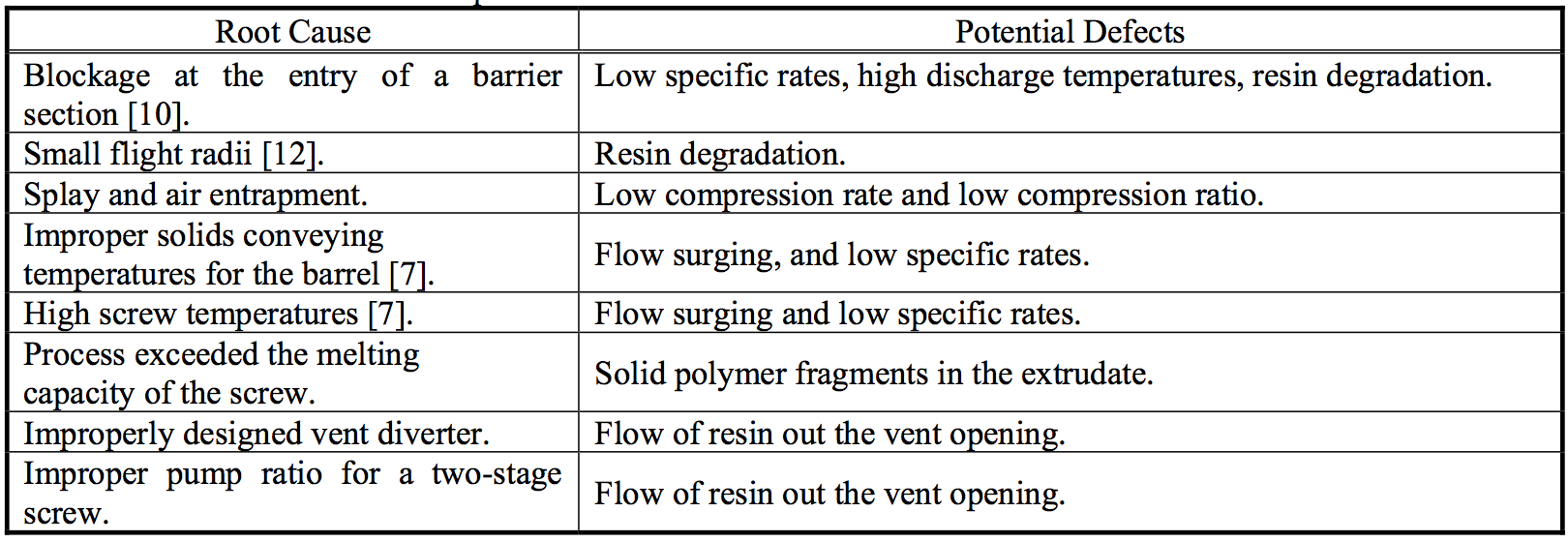

Some of the most common root causes along with the

defects that they create are provided in Table 1. As shown

in this table, several defects can occur from the same root

cause, and a particular defect can be produced by several

root causes.

Once the root cause has been properly identified as

the source of the defect, a technical solution must be

devised that eliminates the root cause from the process.

As previously discussed, often more than one solution

exists. The best solution will depend on many factors

including the economic conditions for the plant and

product line, the cost the defect is creating at the plant,

the cost and time for implementing the technical

solutions, and the risk associated with each solution. Plant

personnel will ultimately decide on the best technical

solution for their plant.

Three case studies are presented next that

demonstrate the approach to troubleshooting problems.

The first two cases were developed with poor hypotheses

while the last case study had a problem that was solved

quickly using strong hypotheses and a strong

experimental plan for verification.

Case Study for the Design of a New Resin

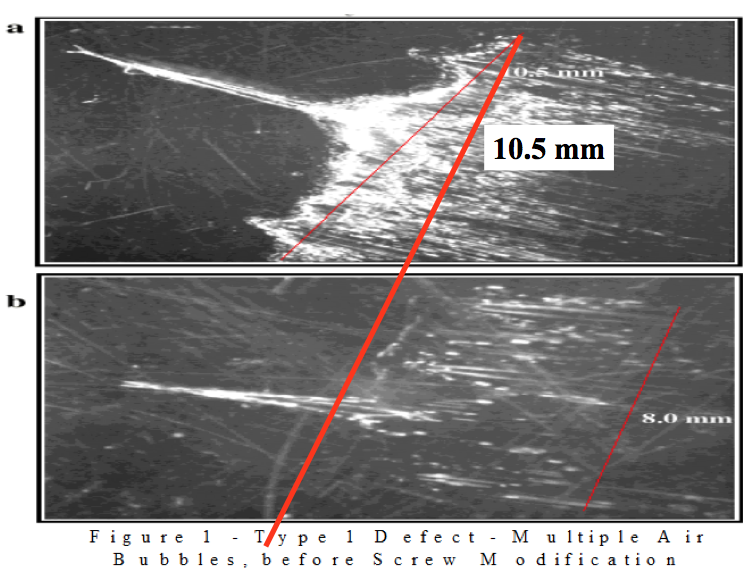

A new general purpose polystyrene (GPPS) resin was

trialed at a customer’s injection molding plant as an

improvement over an incumbent resin manufactured by a

competitor. The new resin performed well in the process

except that it created parts with a 5% rejection rate due to

a splay defect. A photograph of a part with splay is shown

in Figure 1. The competitive resin was reported to run

well but with a lower defect rate. The plant manager

asked that the new resin be redesigned such that it had a

defect rate comparable to the competitive resin. Here the

hypothesis was that the new resin had a poor performance

relative to the incumbent resin, and the technical problem

to be solved was that the new resin needed to be modified

such that it performed as well as the incumbent resin. As

will be shown later, this technical problem was the wrong

problem to be solved.

Performance information for the incumbent resin was

missing from the early parts of the decision making

process. The decision that the technical problem was the

performance of the new resin was based on anecdotal

information from plant personnel on the performance of

the incumbent resin. That is, the plant personnel believed

that the reject level for parts made from the incumbent

resin was less than 5%. A statistical analysis of the part

defect rates was not performed. This lack of information

early in the process allowed the plant manager to pose a

poor technical solution without understanding the root

cause for the defect. A statistical analysis of the defect

rate indicated that the incumbent resin had a defect rate

that was statistically equivalent to the new resin.

Figure 1. Microphotograph of the splay defect in a clear GPPS injection molded part. The flow direction was from the upper left to the lower right.

The primary and alternative hypotheses here are that

the injection molding machine process was creating the

defects in the parts, or the resin design was creating the

defects. The statistical analysis on the part defects molded

using the new and incumbent resins showed that the

resins were not the root cause for the defects. A small set

of exploratory experiments on the injection molding

machine allowed the development and acceptance of the

hypothesis that the screw design used in the plasticator

was not effective at melting the resin at high rates and

expelling entrained air out through the hopper. The new

technical problem to be solved was to increase the

melting capacity of the process and eliminate the

entrainment of air via process changes and screw

modifications. The technical details and the modifications

that were made to the screw were presented earlier [9].

When the modifications to the screw were finished, the

splay defects were eliminated and the capacity of the

plant was increased by about 14%.

This example clearly shows that developing and accepting a hypothesis based on accurate and complete

information is necessary for setting an acceptable

technical solution. If the plant manager could have

persuaded the resin manufacturer to develop a new resin

that was similar to the incumbent resin, then the defect

would still be there, the cost of the troubleshooting

process would have been extremely high, the supplier

would have incurred unnecessary development costs, and

a high level of defective parts would still have occurred

because the root cause would not have been removed.

Case Study for a Surface Blemish

A surface blemish on a specialty sheet product was

severely limiting the rate of the process. The blemish

appeared as a small (2 mm diameter) hemispherical pit or

crater in the surface. The level of surface defects could be

minimized but not totally eliminated by reducing the rate

of the process by 50%. A series of exploratory

experiments were performed and the defects could be

eliminated by decreasing the temperature of the last 6

barrel zones. The first 2 barrel zones were not adjusted so

as to not change the solids conveying behavior of the

resin. When large temperature changes (decreases in set

point temperatures of up to 50

oC) were made to these zones, the extrudate temperature was decreased by about 15

oC and the defects were totally eliminated. The hypothesis developed was that when the extrudate

temperature exceeded a specified value then surface

defects occurred. The technical solution was to develop a

process that discharged the resin at less than the specified

temperature and at high rate. The reason why the defects

occurred at higher discharge temperatures, however, was

unknown.

The resin was analyzed for moisture and other

volatiles that might cause a gas to be evolved at higher

temperatures. All analyses, however, did not indicate that

a gas was evolving or that the material was degrading.

These data are conflicting with the stated hypothesis. The

technical solution for this path was to design a screw with

a very deep metering section such that the extrudate is

discharged at as low a temperature as possible. Since the

material will discharge at increasing temperatures with

increasing screw speeds, the maximum rate will be

bounded when the extrudate exceeds the maximum

specified temperature.

In this case, the experiment developed to test the

hypothesis that high discharge temperatures create the

surface defects was flawed. The screw had a very low

compression ratio and compression rate. A better

hypothesis is that when the barrel zone temperatures are

decreased over the melting section, the temperature and

bulk density of the solid bed are decreased, allowing

entrained air to egress out through the hopper. To test this new hypothesis, the barrel zone temperatures over the

melting and metering sections were selectively changed

such that the melting zones were kept low while the

metering zones were increased. For these tests, the defects

in the sheet only appeared when the melting zone barrel

temperatures were high. The discharge temperature was

not a factor in controlling the defects. The new technical

solution was to design a screw with a high compression

rate and compression ratio such that entrained air can be

forced backward and out through the hopper.

A new screw was designed with a higher

compression rate and compression ratio. The new screw

was installed and the defects were totally eliminated. This

case study shows a poorly developed experiment that

incorrectly validated a poor hypothesis. If the second

experiment would have been performed first, the original

hypothesis of high discharge temperatures create surface

defects would have been invalidated. Clearly, the

experimental plan must be such that they definitively

validate or invalidate the hypothesis.

Case Study for a Profile Extrusion Process

A customer wanted to switch to a resin with a higher

modulus such that a large profile part could be made with

additional strength. The initial production trial was

performed and limited data were collected. The

information that came out of this trial was that the part

profile could not be maintained in specification, the

discharge temperature was higher than normal, and the

motor was operating at the maximum current load. Since

the trial did not last long, rate data were not collected.

The new resin was more viscous than the original resin.

Based on these very limited data, a second trial was

developed based on two hypotheses. The first hypothesis

was that the higher modulus of the new resin created a

blockage at the entry to a barrier melting section of the

screw. The blockage would cause the motor current to

increase dramatically and cause the specific rate for the

extruder to decrease. This type of screw defect was

presented previously [10]. The alternative hypothesis is

that a blockage did not occur and some other section of

the process other than the barrier section was the root

cause.

Preliminary work was performed prior to the trial and

included the measurement of the viscosities of both resins

around the discharge temperatures and the calculation of

the specific rotational flow rate for the metering channel

geometry. The specific rotational flow rate for the resins

were calculated at 11.3 kg/(h rpm). At the start of the

trial, the extruder and line were processing the original

resin at a specific rate of 11.0 kg/(h rpm), a value that is

consistent with the specific rotational rate. The part

profile was acceptable. Next the new resin with the higher modulus was added to the line. Within 30 minutes the

part profile dimensions were out of specification and the

motor was operating at near the maximum current limit. If

the first hypothesis is correct that a blockage is occurring

at the entry to the barrier melting section, then the

specific rate should be significantly less than the

calculated rotational rate of 11.3 kg/(h rpm). In this case,

the specific rate was measured at 11.1 kg/(h rpm), and

thus the first hypothesis that the barrier section was

causing a blockage was not valid. A second hypothesis

was developed that the higher viscosity of the new resin

caused too much energy to be dissipated, increasing the

motor load and the discharge temperature such that an

acceptable part profile could not be produced. To test this

hypothesis, the metering zone barrel temperatures were

slowly decreased in 10

oC increments [11] until the

cooling ability of the zones were at the maximum

capability. In order to maintain the motor torque at an

acceptable level, the temperature of the zones in the solids

conveying section were increased slightly. The extruder

was allowed to come to a steady-state operation. Within

45 minutes the part profile was on specification and the

extruder was operating at a specific rate of 11.0 kg/(h

rpm) and discharging at a temperature that was about

15

oC less than that at the start of the trial. The data

indicates that the second hypothesis is valid. The

technical solution for this case was to design a process

that discharges the new high-modulus resin at a lower

discharge temperature. In this case, plant personnel opted

for a new screw design with a deeper metering section to

decrease the energy dissipation level and decrease the

extrudate temperature.

This case study was developed with an alternative

hypothesis and then a second hypothesis, and the

experiments were designed properly to determine quickly

the root cause of the defect in the part profile. If the

hypotheses and experiments had not been developed

properly, the time required to troubleshoot the problem

would have increased or the project may have failed.

Conclusions

The time required to troubleshoot an extrusion

process or the plasticator on an injection molding

machine can be decreased by verifying operational data,

performing simple calculations, and developing strong

hypotheses. Next, the troubleshooter must develop

experiments that either validate or invalidate the

hypotheses. Once the root cause is determined, the best

technical solution will depend on many factors including

cost of lost production, the time and cost to implement,

machine owner acceptance, and the risk associated with

the modified process.

References

1. R.J. Gould, “Introduction – Basics of Extrusion

Troubleshooting,” in “The SPE Guide on Extrusion

Technology and Troubleshooting” Chapter I, Edited

by J. Vlachopoulos and J.R. Wagner, SPE, 2001.

2. A. Christie, “Troubleshooting the Extruder,” in “Film

Extrusion Manual,” Chapter 9, Edited by T.I. Butler

TAPPI Press, Atlanta, GA, 2005.

3. R.F. Mager, “Troubleshooting the Troubleshooting

Course or Debug D'Bugs,” Center for Effective

Performance, Atlanta, Georgia, 1983.

4. H.S. Fogler and S.E. LeBlanc, “Strategies for

Creative Problem Solving,” Prentice Hall PTR,

Upper Saddle River, New Jersey, 1995.

5. T.W. McCullough and M.A. Spalding, SPE-ANTEC

Tech. Papers, 42, 412 (1996).

6. M.A. Spalding, SPE-ANTEC Tech. Papers, 50, 329

(2004).

7. M.A. Spalding, J.R. Powers, P.A. Wagner, and K.S.

Hyun, SPE-ANTEC Tech. Papers, 46, 254 (2000).

8. J.R. Platt, Science, 146, 347 (1964).

9. M.A. Spalding and J.R. Powers, SPE-ANTEC Tech.

Papers, 55, 2463 (2009).

10. K.S. Hyun, M.A. Spalding, and J. Powers, SPEANTEC

Tech. Papers, 41, 293 (1995).

11. S.L. Crabtree, M.A. Spalding, and C.L. Pavlicek,

SPE-ANTEC Tech. Papers, 54, 1410 (2008).

12. Spalding, M.A., Dooley, J., and Hyun, K.S., SPEANTEC

Tech. Papers, 45, 190 (1999).

Key Words: Extrusion, Single-Screw, Troubleshooting,

Hypothesis Setting.

Table 1. Common root causes and potential defects.

Return to

Paper of the Month.