A Mechanism for Solid Bed Breakup in Single-Screw Extruders - Solid Bed Shape Change

Gregory A. Campbell, Clarkson University/Castle Associates, Jonesport, ME

Mark A. Spalding, The Dow Chemical Company, Midland, MIAbstract

It is well known that solid bed breakup in plasticating

single-screw extruders can lead to defects in the

downstream product, reduced rates, and process

instabilities. After a review of the mechanism of solid bed

melting an enhanced discussion will be presented

regarding a new concept for solid bed break up. The

literature generally attributes this breakup to pressure

gradients emanating from the beginning of the metering

section of the screw. In a previous paper [1] a new

mechanism was proposed that was developed as a result of

the physics of the melting mechanism and fluid flows

associated with screw rotation physics. During the

discussion after the presentation of this new mechanism at

ANTEC 2013, questions were raised as to the assumptions

made regarding the shape change of the solid bed during

melting which the authors proposed was a result of the

flow that occurs as a result of the new mechanism. In this

paper more data will be presented that will help define this

new concept.

Introduction

Solid bed breakup is a process that occurs in almost all

plasticating single-screw extruders, and in most cases the

process is undesirable since it can lead to solid polymer

fragments in the extrudate, process instabilities due to

solids plugging mixers, and thermal gradients [2]. Solid

fragments in the extrudate will almost always cause defects

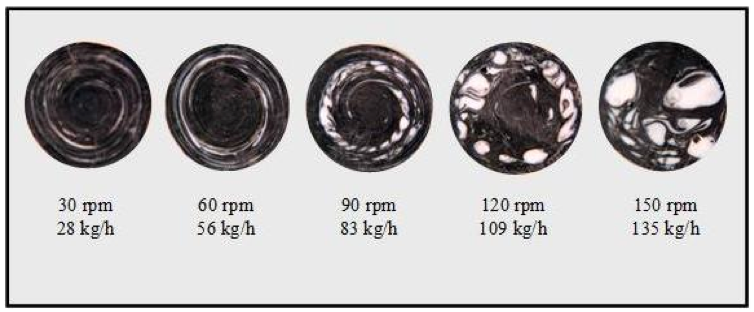

in the finished product. For example, a lab extruder was

operated with a mixture of 100 parts of white tinted

acrylonitile-butadiene-styrene (ABS) terpolymer pellets

with 1 part of black tinted ABS pellets. If the extruder

operates properly without solid bed breakup, the extrudates

are tinted black and are relatively uniform in color, as

indicated by the cross sections shown in Figure 1 at screw

speeds less than about 70 rpm. At higher screw speeds, the

solid bed broke up and caused solid polymer fragments to

flow downstream and into the extrudate, as indicated by

the white tinted fragments at screw speeds greater than 80

rpm.

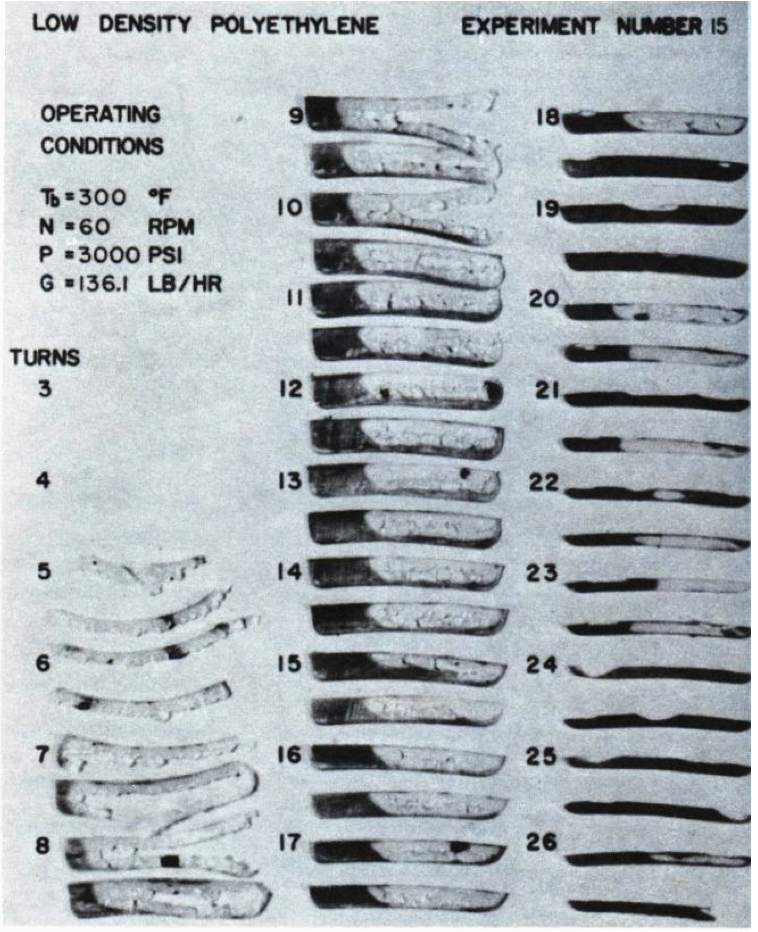

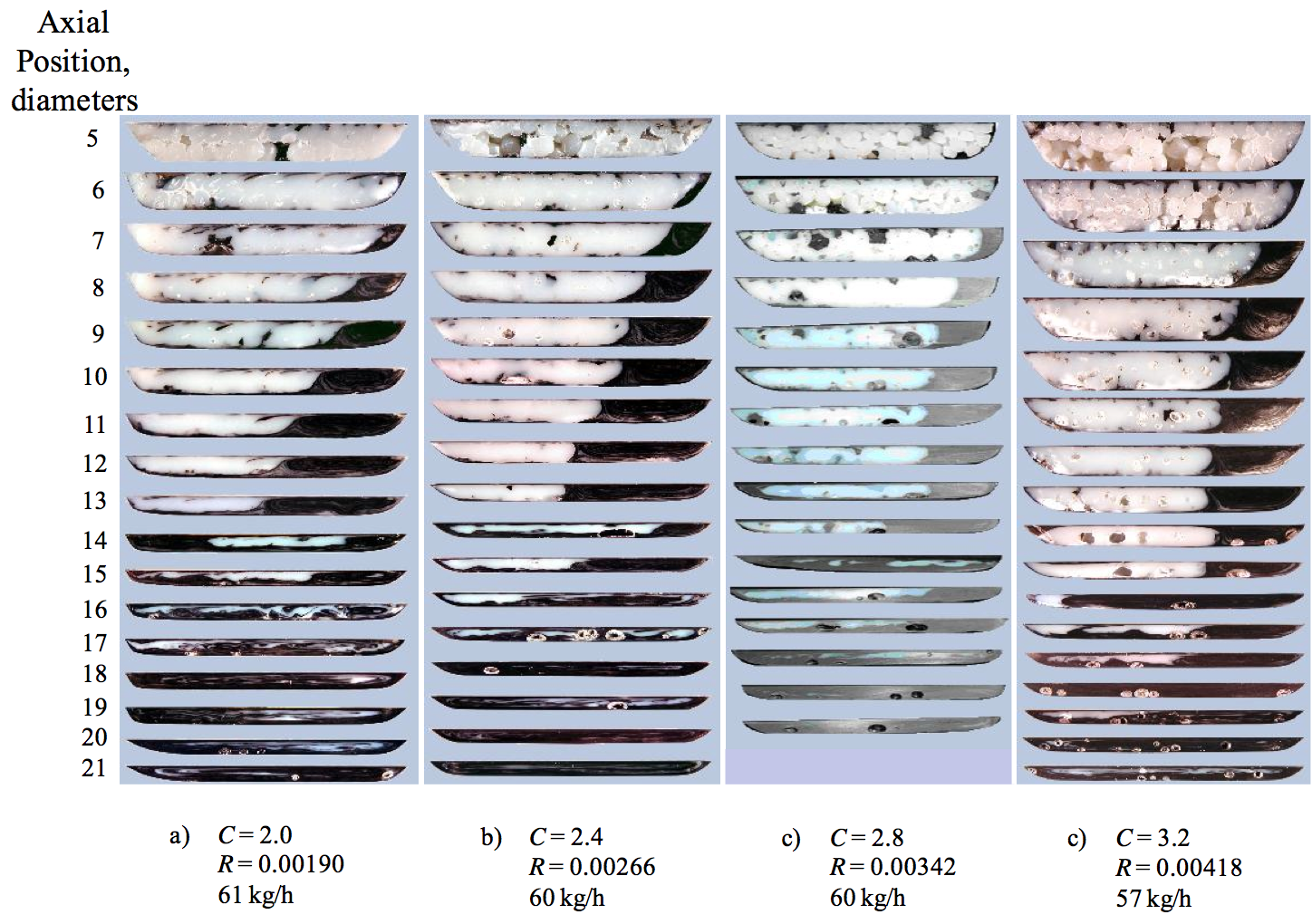

Solid bed breakup can be observed by performing a

Maddock solidification experiment [3], as indicated by the

photographs in Figure 2. Here the black tinted areas show

regions in the screw channels that were molten at the

moment of stopping screw rotation and solidifying the

resin. Areas that were tinted white show regions that contain resin in the solid form. Solid bed breakup is

evident in these cross sectional photographs since there are

regions were the molten resin is essentially across the

entire channel and solids are evident in downstream cross

sections. These types of views are typical in almost all

published Maddock solidification experiments.

Figure 1. Cross-sectional views of extrudate samples at a letdown ratio of 100 to 1 of a white pigmented ABS resin with a black color concentrate for a melting-mixing experiment.

Literature references discuss solid bed breakup as a

phenomenon where strong forces due to pressure gradients

breakup the low strength solid bed [4,5]. The source of the

pressure gradients, however, is not evident and in general

the pressure is higher at the end of the bed so this would

logically tend to push the particles back into the bed. Zhu

et al. constructed an extruder with glass inserts in the barrel

for viewing the internal processes during extrusion [6] and

injection molding [7]. Their observations indicated that

solid bed breakup was more likely to occur at high screw

speeds. For injection molding plasticators, bed breakup is

more likely to occur for long injection strokes, high

discharge pressure (back pressure), and long dwell times

[7]. They observed small cracks that occurred across the

solid bed and perpendicular to the flights in the later stages

of the melting process. These cracks would then increase in

width as they were filled with molten polymer. Their

observations are consistent with previous researchers. The

mechanism for the crack formation was not reported.

The current melting and conveying mechanisms using

barrel rotation physics do not provide an explanation for

solid bed breakup. Screw rotation physics, however,

provides a melting mechanism and a flow mechanism that

explains the solid bed breakup process in single-screw

extruders.

Melting Mechanism Literature

The key to understanding solid bed breakup is the

comprehension of the melting mechanism that occurs in

the extruder using the actual boundary conditions for screw

rotation physics. Therefore this relatively new melting

mechanism will be outlined and reviewed in this section.

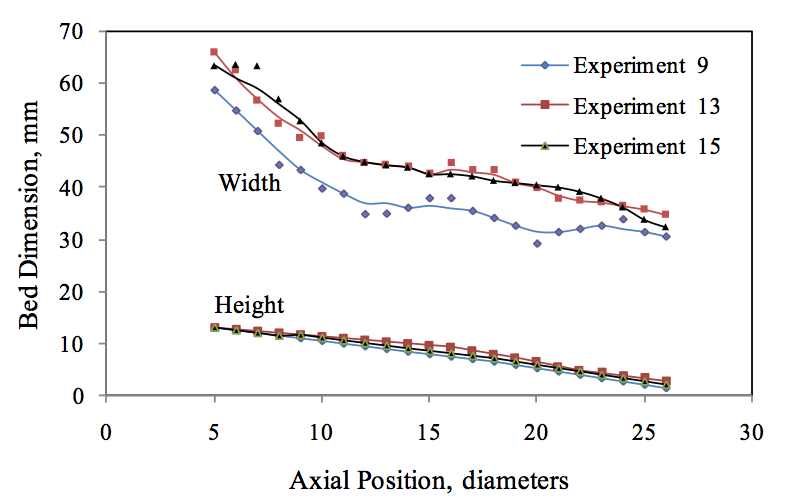

Recently the Polymer Processing Research group at

Clarkson University reexamined the melting data published

in Tadmor and Klein [4] and found that in essentially all

cases the material in a conventional screw transition

section disappeared in the height direction before the width

direction, as shown in the reanalysis of the data in Figure

3. This was in direct contrast from the melting theory

developed by Maddock [3] and the model developed by

Tadmor and Klein [4]. The Tadmor and Klein model had

the solid bed disappearing in the width direction only.

Lindt and his research group investigated and reported a

body of work trying to set up a series of complete

mathematical models for the melting process. Lindt [11]

developed a model by considering the solid bed in the

center of the cross-section in 1976 using barrel rotation

theory. Lindt focused his later work on the five-zone

melting model [12-15]. Lindt, Elbirli, Gottgatreu, and Baba

[12] set up a model by considering all situations that

previous people considered separately. Lindt and Elbirli

[13] considered the cross section circulation in the model

in 1985 where the screw was still considered to be

stationary. Also in 1985, Lindt claimed that "the

development of the melting theory based on the Maddock

mechanism has been virtually completed" [14].

Figure 3. Reevaluation of the melting data from Tadmor and Klein for PE resins [4] as analyzed by Tang [8] and Campbell et al. [9,10].

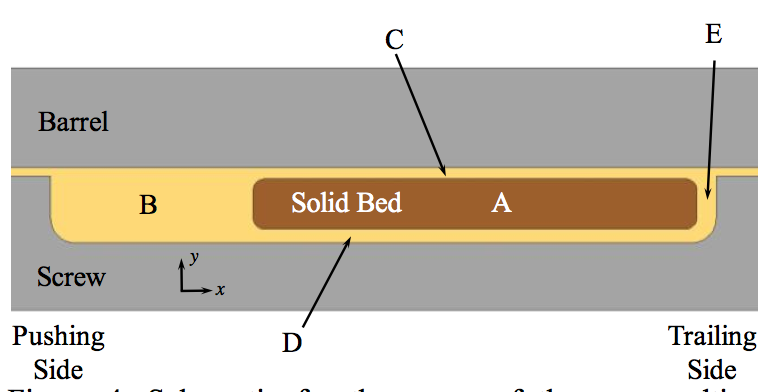

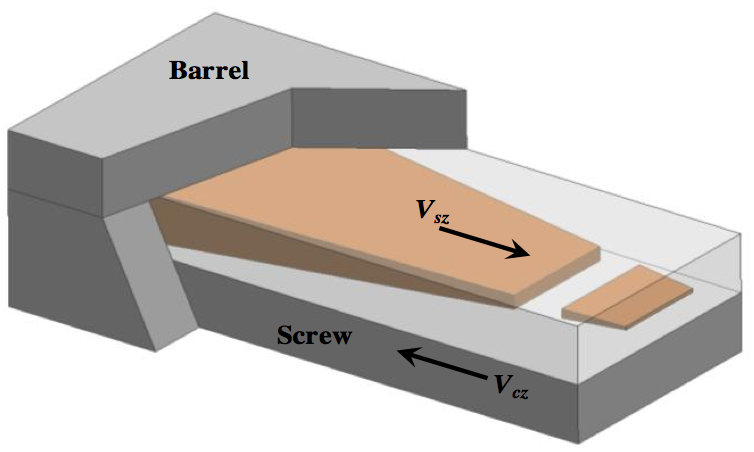

A new melting mechanism was developed using screw

rotation physics that is diagrammatically portrayed in

Figure 4. The rotation of the screw creates a velocity

gradient at the barrel-solid bed interface and the combination of the heat flux from the barrel and the

dissipation in Film C cause the solid to melt in the negative

y direction. The motion of the screw under the bed

contributed to the energy dissipation in Film D, causing the

bed to melt in the positive y direction. The same

mechanisms occur in Zones E and B to melt the solid bed

in the x directions. A major difference in this mechanism

compared to the historic literature analysis is that the bed

does not reorganize.

Figure 4. Schematic for the zones of the new melting concept: Zone B is the melt pool, Zone C is the melt film located between the solid bed and the barrel wall, Zone D is the melt film between the solid bed and the screw root, and Zone E is the melt film between the solid bed and the trailing flight. The cream color represents molten resin.

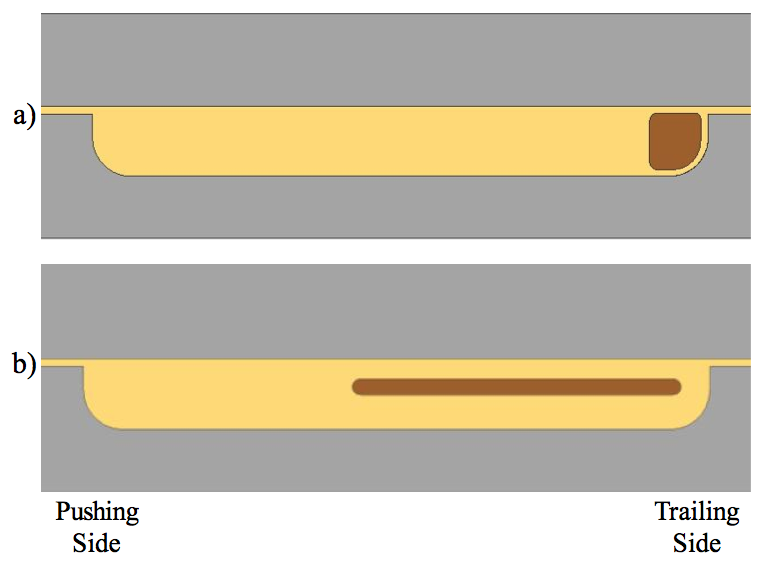

The Tadmor and Klein model [4] allows melting only

in the Zone C film located between the solid bed and the

barrel wall, as shown in Figure 4. The material melted is

then dragged by the motion of the barrel and collected in

the melt pool of Zone B. As melting progresses, the melt

pool increases in width and the solid bed decreases in

width. The solid bed is assumed to reorganize such that it

covers the full depth of the channel. Near the end of

melting, the Tadmor melting model and other literature

models have the last remaining portion of the solid bed

positioned at the trailing flight and across the full depth of

the channel, as shown by Figure 5a. These models are all

based on barrel rotation physics.

As previously mentioned, the Tadmor and Klein

model forces all melting to occur in Zone C. The melting

that occurs at the other zone interfaces with the solid bed is

ignored because the velocity gradients and thus energy

dissipations were believed to be very small. These

gradients are due to the solid bed moving at a velocity Vsz

calculated from a mass balance at the entry to the melting

section and a stationary screw; i.e., barrel rotation physics.

Recently Campbell, Spalding, and Tang [16,17] have

reexamined the assumptions in the literature models in

order to address the reanalysis of the classical melting data

discussed previously and shown in Figure 3. This concept

was developed based on recognizing that the rate limiting melting dynamics for solid bed consumption was in the

channel height and not the channel width direction. Here

the melting process occurs in all four of the melt films

surrounding the solid bed, as shown in Figure 4. The

boundary conditions were set to those for screw rotation

physics.

Figure 5. Schematics of the solid bed just prior to complete melting: a) the solid bed is pushed to the trailing flight with the Tadmor melting model and barrel rotation physics, and b) the solid bed is a thin plate and positioned as in the diagram (screw rotation and observation). The cream color represents molten resin.

To visualize the difference between screw rotation and

barrel rotation, a simple cardboard paper towel roller can

be used to model the screw core and a wood block to

model the solid plug. For barrel rotation, the roller is held

constant and the block is moved downstream at a velocity

of V

sz. Here the velocity difference between the block and

roller is simply V

sz. For screw rotation, the roller is rotated

counterclockwise while the block is moved downstream

with a velocity of V

sz. The observer will see that the core of

the screw is moving in the negative z (helical) direction at

a velocity of V

cz. The velocity difference for Zone D is as

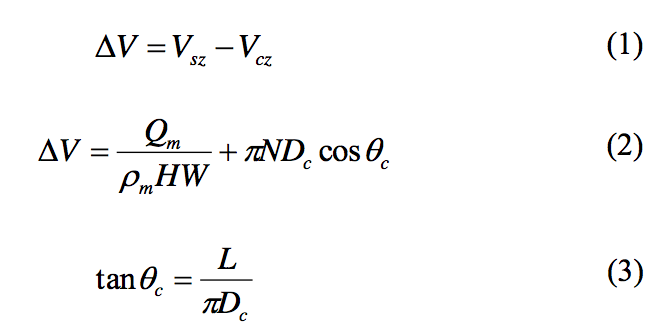

follows:

where ΔV is the velocity difference between the solid bed

and the root of the screw, Q

m is the mass flow rate, ρ

m is

the bulk density of the solids at the start of melting, H is

the channel depth at the start of melting, W is the average

channel width, N is the rotation rate of the screw (rev/s), D

c

is the diameter of the screw at the root (or core), θc is the

helix angle at the screw root, and L is the lead length. The

first term on the right side of Equation (2) is V

sz while the

second term is –V

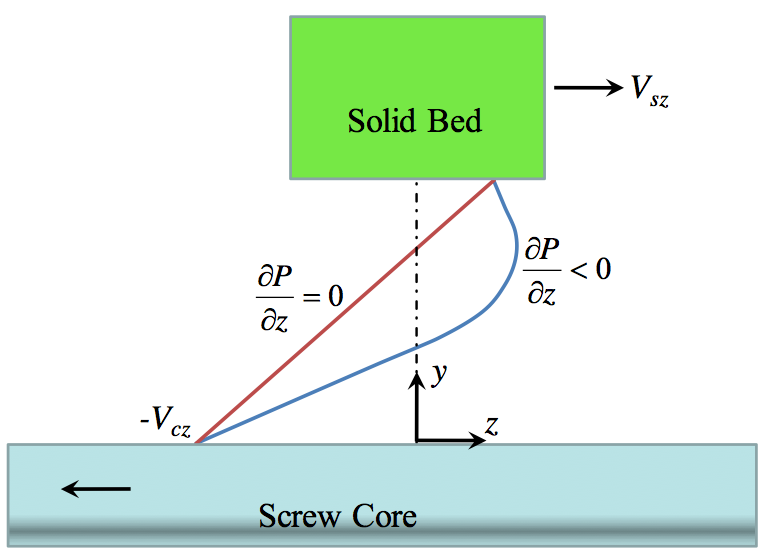

cz. A schematic of the velocity difference

is provided in Figure 7. This velocity difference is

considerably larger than that for barrel rotation physics.

The screw rotation model presented here includes the

dissipation and melting rates for all zones. The details may

be found in [2].

Developing a physical model for these melt zones,

leads to a description of the flow dynamics in the films that

exist in the screw channel from the beginning of the

melting of the solid bed through the transition section that

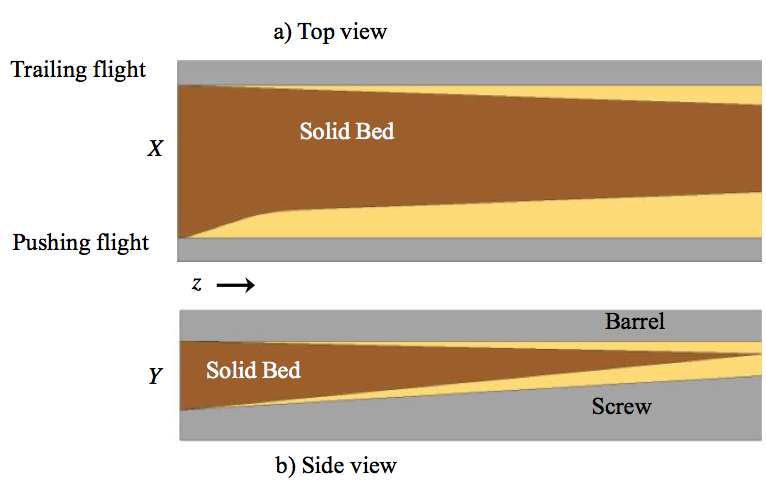

ends at the beginning of the metering section. A schematic

of a typical solid bed profile is provided in Figure 6 with

the solids profile near the end of melting shown in Figure

5b for screw rotation. The fluid velocity gradient in Film C

at the top of the solid bed is in the x direction which causes

fluid to be deposited into Zone B. The fluid velocity in

Film D between the screw root and the solid bed in Figure

4 is a more complex recirculation flow due to motion of

the screw surface in the opposite direction of the solid bed.

That is, the screw root motion drags fluid into the Film D

gap at the end of the transition section. Some of the fluid

that is dragged into Film D is thought to flow into Zone B

due to a higher pressure under the solid bed than in the

melt pool (Zone B). This pressure under the solid bed is a

key to the mechanism for solid bed breakup.

Figure 6. Qualitative shape of X and Y bed dimensions and

melt film thickness for melting in a conventional transition section; a) top view, and b) side view. The cream color represents molten resin. Here X and Y are the local width and thickness of the solid bed, respectively.

For most extrusion processes, the solid bed can

breakup near the completion of melting, that is in the

transition as it approaches the metering section. At this

point in the melting process the bed is relatively thin and

its cohesive strength is low. The strength of the bed is low

at this location since the solid bed temperature is

approaching the melting temperature or devitrification

temperature and thus the material modulus is low. Because

the bed is thin in the y direction there is little stability.

Evidence of solid bed breakup is apparent in photographs

of Figure 2. Moreover, solid bed breakup is evident in

almost all reported Maddock solidification experiments for

a conventional melting screw. The initiation of the breakup

may be the result of the physics discussed previously from

references [6,7].

The Mechanism for Solid Bed Breakup

As will be presented next, two processes are required

for solid bed breakup. These processes include the melting

mechanism presented above for screw rotation physics and

a flow mechanism for transporting molten resin between

the solid bed and the screw root.

It is obvious that the strength of the solid bed would be

low near the end of melting since the bed is very thin and

its temperature is approaching the melting or

devitrification temperature. Based on the historical melting

models using barrel rotation physics, the pressure gradients

postulated for breaking the bed are difficult to produce. In

general, the pressure gradient in the transition section is

positive such that one might speculate that this would

stabilize the bed by pushing the solids back toward the

thicker and more stable portion of the bed. However, screw

rotation theory leads to an alternative mechanism to those

based on barrel rotation theory. Screw rotation theory is

presented in great detail in [2,18-22] for the metering

section. For screw rotation analysis, the barrel has zero

velocity and the solid bed is moving in the positive z

direction at a velocity of V

sz. The screw has a velocity of

–V

c and a component in the z direction of -V

cz. Here, the

backward motion of the screw (ǀ-V

czǀ or V

cz) is larger than

Vsz, causing a negative pressure gradient (∂P/∂z) in Film D

between the solid bed and the screw root.

There has not been an extensive technical discussion

as to why the solid bed always is in close proximity to the

barrel. It is thought that centrifugal force is not the primary

mechanism because this phenomenon is prevalent even at

very low screw rotation speeds. The locally higher pressure

resulting from the rotation of the screw under the solid bed

in Film D of Figure 7 is postulated to force the solid bed up

against the barrel surface. This would explain the

consistent observation that the solid bed is always near the

barrel surface with only a thin film of fluid between the

barrel and the solid bed that results from melting at the

barrel-solid interface. There can be a substantial thickness

of melt in Zone D. The pressure in Film C has been

experimentally measured by many researchers. The local

pressure in Film C is always less than the pressure in the

melt pool. With the local pressure in Film C being less than

that in the melt pool and with the pressure in Film D higher

than the melt pool, it follows that the difference in the

pressures create a force that pushes the solid bed against

the barrel wall.

Figure 7. Schematic of the Vz velocity in the Film D between the screw core and the solid bed. The red and blue velocity lines are for pressure gradients that are zero and negative, respectively. The dotted vertical line is for Vz = 0.

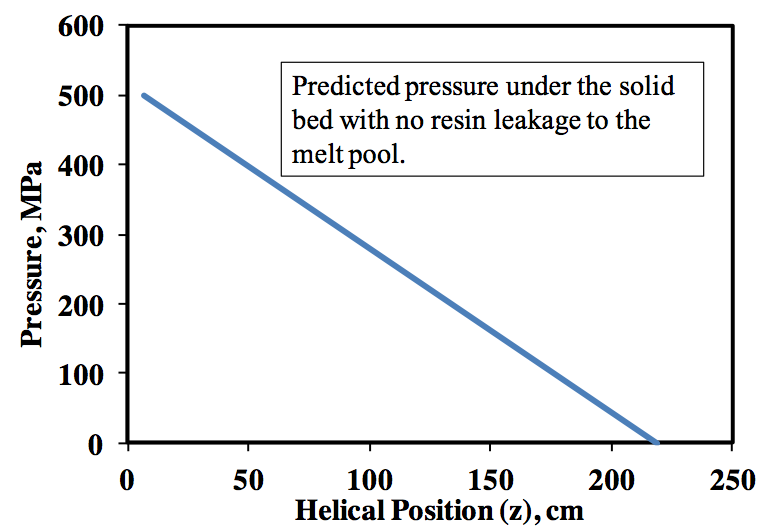

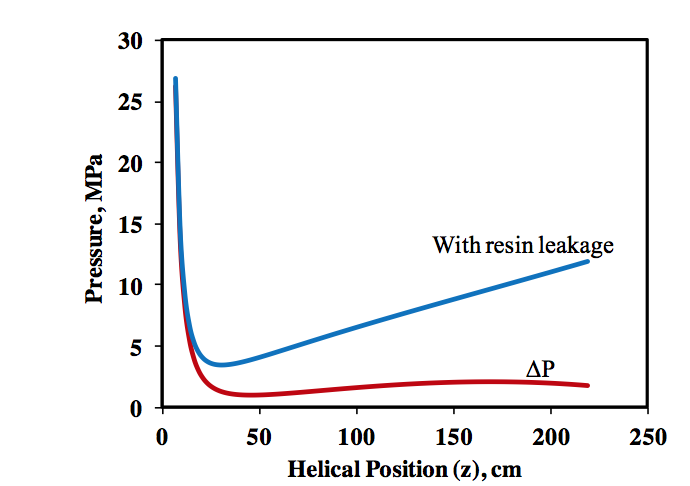

The existence of a fluid flow back toward the solid

feeding section is postulated as seen in Figure 7. For a

typical melting system the pressure under the bed was

calculated and is presented in Figure 8 if there were no

leakage flow from Film D to the melt pool. One observes

that the predicted pressure at the beginning of the melting

is extremely high and well above that which is measured.

The authors than went to the literature to determine if there

is any evidence during the melting process where there

may be flow from under the bed into the melt pool. Two

sets of melting dynamics copied from Tadmor are

presented in Figures 9 and 10.

Figure 8. Predicted pressure profile under the solid bed with no resin leakage to the melt pool.

Figure 9. Melting profiles for LDPE resin from Tadmor and Klein Figure 5.16 [4].

One observes in Figure 9 that that the solid bed profile

from section 7 to section 9 in contact with the melt pool is

essentially a vertical surface for a low density polyethylene

(LDPE) resin. However by section 17 the front of the

profile shows that the bottom of the front of the profile has

melted faster than the top, creating a curved interface and

changing the shape of the bed.

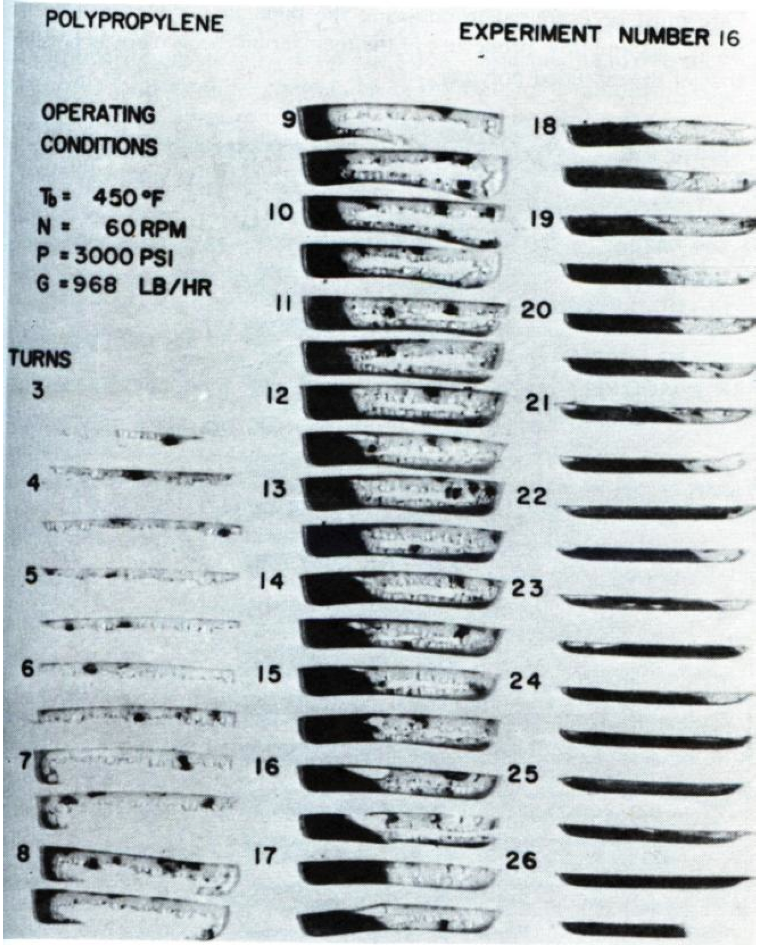

The same general observations are made regarding this

melting sequence for a polypropylene (PP) resin as shown

in Figure 10.

The locally high pressure underneath the solid bed and

the positive ∂P/∂x in Film D causes some flow of resin

from Film D to the melt pool. Thus, for a local Δz

increment for Film D, there is material entering the

element from the melting process and from the drag

motion of the screw core, and there is material leaving the

increment from the motion of the screw core and from the

flow of material into the melt pool due to a positive ∂P/∂x.

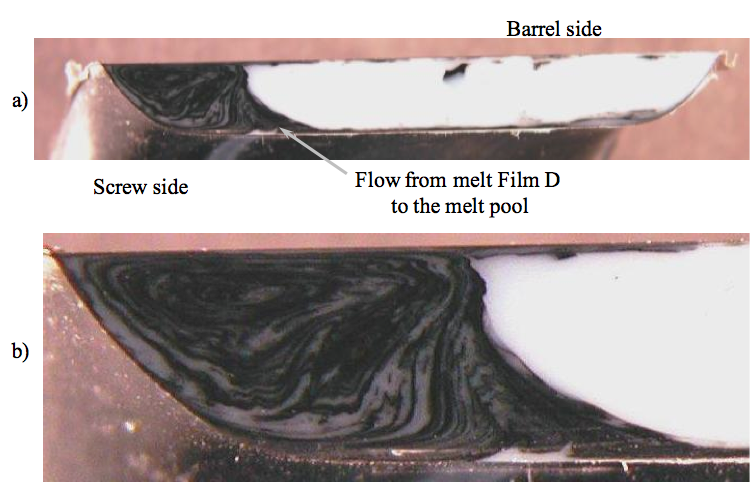

These complex flows are consistent with observations from

Maddock solidification experiments. This flow is shown in

detail for the Maddock solidification experiment shown in

Figure 11.

Figure 10. Melting of PP resin from Tadmor and Klein Figure 5.3 [4].

The flow from the film between the solid bed and the

screw root (Film D) can be observed in most Maddock

solidification experiments, as shown in Figure 11. The

section in this photograph was for a location early in the

melting process where the strength of the solid bed is high

and can withstand the pressure gradient created by the flow

induced by the backwards motion of the screw.

Figure 11 Photograph of resin solidified in the transition section after a Maddock solidification experiment for an ABS resin: a) the arrow is pointing at the flow lines created by the flow of material from Film D out to the melt pool, and b) an enlargement of the flow area.

The high strength of the bed prevents the bed from

breaking up. Flow lines due to poor mixing of the colorant

into the white resin show the flow from Film D into the

melt pool (Figure 11). The flow is substantial as it is

pushing and deforming the recirculating flow of the pool

away from the solid bed. The fluid flowing from under the

bed would be relatively hot due to shear heating as it flows

under the bed. This is postulated as the cause of the more

rapid melting at the base of the solid bed and causing the

shape change of the solid bed at this edge. These flow

patterns can be observed in Figure 2 as well with careful

observation, and the observed flow pattern is not consistent

with a barrel rotation model.

The qualitative expected velocities and pressure

gradient are shown in Figure 7. That is, the backwards

motion of the screw is dragging molten polymer backwards

at the screw root and generating a significant level of

pressure in Film D. When the strength of the solid bed is

relatively high, the high pressure in Film D causes material

to flow out to the melt pool B. If the strength of the solid

bed is relatively low, then the bed will form a small crack

due to the fluid flow induced stresses at the bottom

interface of the solid bed, and then the crack will fill with

fluid as observed by Zhu et al. [6,7]. Since the screw core

develops predominately recirculating flow under the bed,

the fluid would be expected to also flow under the solid

bed toward the metering section (see blue line in Figure 7).

This recirculating flow would cause a shear stress on the

bottom of the solid bed. The upstream velocity in

conjunction with the bed low cohesive energy and cracks

would tend to cause fragments to break off of the bed. The

surface shear stress from the recirculating fluid would thus

drag the solid bed fragments away from the solid bed and

into the metering section. The solid bed breakup process is

qualitatively described in Figure 12.

Figure 12. Schematic for solid bed breakup.

Figure 12 qualitatively describes the solid bed breakup

process. For this process, the solid is moving in the V

sz

direction. The motion of the screw drags fluid into Film D between the screw root and solid bed, creating a relatively

high pressure in the film. When the strength of the solid

bed is high, the high pressure induces flow out of the film

into the melt pool. The flow out of Film D into the melt

pool is observed in Figure 11. When the strength of the

solid bed becomes low near the end of the melting process,

the pressure produces a crack as shown in Figure 12, and

then the crack fills with fluid as observed by Zhu et al.

[6,7].

The predicted pressure under the bed with leakage

flow from Film D to the melt pool is presented in Figure

13. The very high pressure as the bed approaches the 0

distance is of course not completely accurate since the

liquid under the bed approaches 0 thickness at this point

and there is likely a static volume where there is little or no

flow

Figure 13. Predicted pressure under the solid bed.

The predicted pressure change between Film D and

the melt pool, ΔP (the red line of Figure 13), decreases

quickly leading to a predicted pressure profile which will

provide leakage flow into the melt pool.

Discussion

The melting model based on screw rotation physics

and the flow due to the negative V

cz velocity provides the

mechanism for solid bed breakup. This paper provides

more detail than originally presented in 2013 [1] on the

mechanism of solid bed breakup. Barrel rotation physics

and models have been unable to explain adequately solid

bed breakup. The mechanism provided here is consistent

with flows observed during Maddock solidification

experiments and the observations by Zhu et al. [6,7].

The flow of resin from Film D to the melt pool causes

some of the solid bed to melt at the interface near Film D.

This melting is very obvious from the photos provided by

Tadmor and Klein [4]. The melting is obvious due to the

extremely small flight radii on the screws used in their

experiments. Thus as melting progresses, the solid bed edge adjacent to the melt pool changes shape as melting

occurs faster at the edge near the root relative to that near

the barrel surface. That is, the edge changed shape from a

vertical surface to a curved surface. Since the flight radii

for the screws used for the experiments in Figure 2 were

considerably larger, this melting at the corner of the bed is

not obvious.

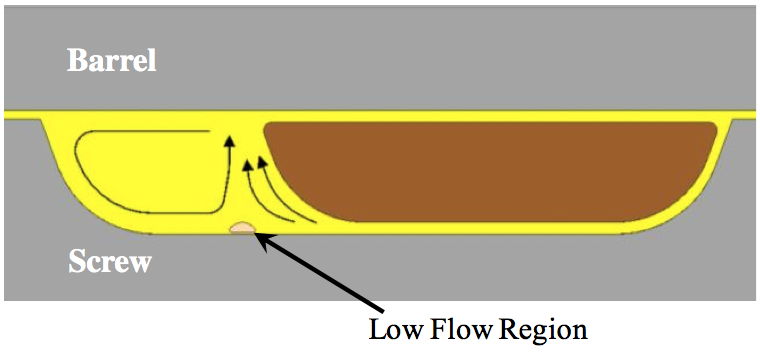

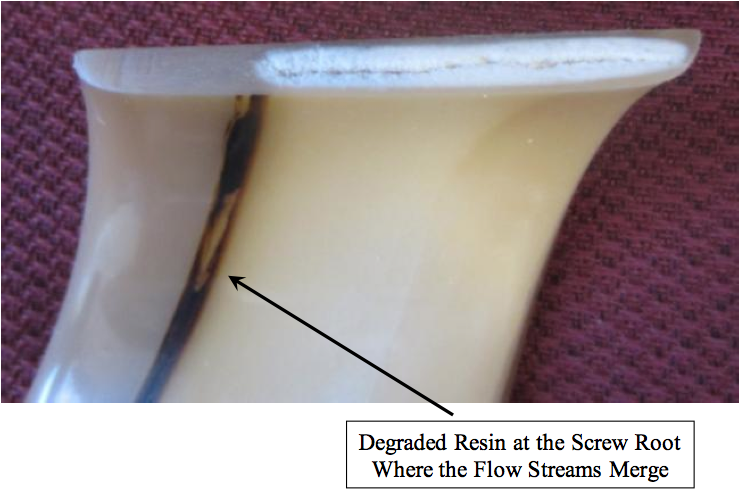

The recirculating flow in the melt pool and the flow

entering the pool from Film D create a region at the screw

root where the flows are likely very low or form eddies.

This low flow region where the recirculating and entering

flow merge is shown in Figure 14. For most extrusion

processes, this low flow region is not a problem and likely

very difficult to detect. For thermally sensitive materials

such as polyvinylidene chloride (PVDC) resin, the long

residence time of the region can cause a ribbon of degraded

material to form on the root of the screw where the flows

merge. This ribbon typically starts when the melt pool first

forms and ends when the melting process is about 70%

complete. A photograph of this type of degradation is

shown in Figure 15. Processing changes can mitigate this

type of degradation [23].

Figure 14. Schematic showing the recirculating flow in the melt pool and the flow entering the melt pool from Film D.

A low flow region exists where the flow streams merge.

The degradation ribbon at the merge of the flows

occurs because of the low flow region created between

cross channel flow of material from Zone D and the

recirculation flow in the melt pool. As shown by Figure 11,

this flow from Zone D is relatively large. As previously

stated, the flow occurs because of pressure induced flow

and the dragging of fresh material under the solid bed by

the backwards motion of the screw root. This process is

consistent with the physics presented for screw rotation.

The flow fields developed for a barrel rotation system

would not create the low flow region such as shown in

Figure 15.

For processes with relatively low compression rates

such that the air entrained between the pellets is not readily

pushed back out the hopper, solid bed breakup will eliminate a pathway for the air back to the hopper. In this

case the entrained air will discharge with the extrudate and

often create defects in the product.

Figure 15. Photograph of a segment from a Maddock solidification experiment for a PVDC resin extrusion. The dark band is degraded resin due to a long residence time at the location.

Solid bed breakup can be mitigated using screw design

and process conditions for a conventional screw design.

For example, the largest single contributor to bed breakup

is high screw speeds. For a particular screw, the extrudates

were relatively free of solid polymer fragments at low

screw speeds. But at screw speeds above about 75 rpm,

solid bed breakup is occurring and high levels of solids are

discharged with the extrudates. Although not desirable for

a commercial process, decreasing the rate of the line is

often a short term fix to eliminating solids in the discharge.

Placing a finer screen in the screen pack is also an

acceptable short term remedy. The best long term fix is to

add an acceptable dispersive mixer to the screw or to

install a high-performance screw.

Several high-performance screws actually take

advantage of solid bed breakup by using the small solid

fragments as a cooling method for the extrudate. For these

designs, the solid polymer fragments are reduced in size

using dispersive type dams. The small fragments are then

melted primarily by heat conduction from the hot molten

resin to the cooler solid fragments, decreasing the

temperature of the molten stream. Common commercially

available high-performance screws that employ this

technology include Wave screws [24,25], Energy Transfer

screws [26,27], Fusion screws [28], and DM

2 screws [29].

Summary

The process of solid bed breakup is described and

demonstrated using photographs from Maddock

solidification experiments. A new theoretical hypothesis is developed based on screw rotation theory that proposes

that the bed breakup is due to the melting process and the

backward flow of material under the solid bed, creating a

high pressure in this gap. If this pressure is high enough to

break the solid bed, solid bed breakup will occur. Flow of

material from under the solid bed to the melt pool has the

ability to change the shape of the edge of the solid bed that

is in contact with the melt pool.

Acknowledgements

The authors are grateful to many colleagues and

students that worked to develop these techniques.

References

1. G.A. Campbell and M.A. Spalding, SPE ANTEC Tech.

Papers, 59, 1087 (2013).

2. G.A. Campbell and M.A. Spalding, “Analyzing and

Troubleshooting Single-Screw Extruders,” Hanser

Publications, Munich, 2013.

3. B.H. Maddock, SPE J., 15, 383 (1959).

4. Z. Tadmor and I. Klein, “Engineering Principles of

Plasticating Extrusion,” Van Nostrand Reinhold

Company, New York, 1970.

5. C.I. Chung, “Extrusion of Polymers, Theory and

Practice,” second edition, Hanser Publications,

Munich, 2011.

6. F. Zhu, A.C.-Y. Wong, R. Liu, and T. Liu, Plastics,

Rubber and Composites Processing and Applications,

26, 8, 343 (1997).

7. Z. Jin, F. Gao, and F. Zhu, Polym. Eng. Sci., 44, 1313

(2004).

8. Z. Tang, MS Thesis, Clarkson University, Potsdam,

NY, Chemical Engineering Department (1999).

9. G.A. Campbell, Z. Tang, C. Wang, and M.

Bullwinkel, SPE ANTEC Tech. Papers, 49, 213

(2003).

10. G.A. Campbell and Z. Tang, SPE ANTEC Tech.

Papers, 50, 162 (2004).

11. J.T. Lindt, Polym. Eng. Sci., 16, 284 (1976).

12. B. Elbirli, J.T. Lindt, S.R. Gottgetreu, and S.M. Baba,

Polym. Eng. Sci., 24, 988 (1984).

13. J.T. Lindt and B. Elbirli, Polym. Eng. Sci., 25, 412

(1985).

14. J.T. Lindt, Polym. Eng. Sci., 25, 585 (1985).

15. J.T. Lindt, Polym. Eng. Sci., 21, 1162 (1981).

16. G.A. Campbell, M.A. Spalding, and Z. Tang, SPE

ANTEC Tech. Papers, 55, 147 (2009).

17. G.A. Campbell and M.A. Spalding, SPE ANTEC Tech.

Papers, 56, 418 (2010).

18. G.A. Campbell, P.A. Sweeney, and J.N. Felton,

Polym. Eng. Sci., 32, 1765 (1992).

19. G.A. Campbell, P.A. Sweeney, and J.N. Felton, Intern.

Polym. Proc., 7, 320 (1992).

20. G.A. Campbell, P.A. Sweeney, N. Dontula, and C.

Wang, Intern. Polym. Proc., 11, 199 (1996).

21. G.A. Campbell, H. Cheng, C. Wang, M. Bullwinkel,

and M.A. te-Riele, SPE-ANTEC Tech. Papers, 47, 152

(2001).

22. G.A. Campbell, C. Wang, H. Cheng, M. Bullwinkel,

M.A. te-Riele, Intern. Polym. Proc., 16, 323 (2001).

23. S.R. Jenkins, J.R. Powers, K.S. Hyun, and J.A.

Naumovitz, J. Plast. Film & Sheet, 6, 90 (1990).

24. G.A. Kruder, US Patent 4,173,417 (1979).

25. G.A. Kruder and W.N. Calland, SPE ANTEC Tech.

Papers, 36, 74 (1990).

26. C.I. Chung and R.A. Barr, U.S. Patent 4,405,239

(1983).

27. C.I. Chung and R.A. Barr, SPE ANTEC Tech. Papers,

29, 168 (1983).

28. T.W. Womer, E.J. Buck, and B.J. Hudak Jr., US

Patent 6,672,753 (2004).

29. M.A. Spalding, J.A. Kuhman, D. Larson, J. Kuhman,

and H.L. Prettyman, SPE ANTEC Tech. Papers, 50,

599 (2004).

Figure 2. Melting profiles for a 63.5 mm diameter extruder running an ABS resin at 60 rpm for screws with a 3.18 mm deep metering channel, 6 diameters of feed section, 8 diameters of transition, and 7 diameters of metering section: a) compression ratio of 2.0, b) compression ratio of 2.4, c) compression ratio of 2.8, and d) compression ratio of 3.2. The pushing flights are on the right side of the section photographs. The void marks on c) at diameters 16 through 20 were caused by the resin shrinking slightly as it cooled. Compression ratio (C) and compression rate (R) defined in reference [2].

Return to

Paper of the Month.