Flex Barrier Property Enhancement in Film Structures Using Microlayer Coextrusion Technology

Patrick C. Lee, Joseph Dooley, Jeff Robacki, Steve Jenkins, and Robert Wrisley

The Dow Chemical Company, Midland, MIAbstract

Microlayer coextrusion is a process in which two or

more polymers are extruded and joined together in a

feedblock or die to form a single structure with multiple

layers. This paper describes a multilayer coextrusion

process technology to maintain the gas barrier property of

Ethylene Vinyl Alcohol (EVOH) barrier films after

flexing.

Introduction

Coextrusion is a common method used for producing

multilayer cast and blown films. Coextrusion is a process

in which two or more polymers are extruded and joined

together in a feedblock or die to form a single structure

with multiple layers. This technique allows the processor

to combine the desirable properties of multiple polymers

into one structure with enhanced performance

characteristics. The coextrusion process has been widely

used to produce multilayer sheet, blown film, cast film,

tubing, wire coating, and profiles [1-6].

Currently films containing metal foil dominate the

barrier packaging market with over 15.4 billion dollars in

global laminate film sales. Despite the dominance of the

foil films which provide excellent unflexed barrier

performance at a low price, alternative packaging solutions

that maintain barrier performance after flexing, amenable

to microwave operation, transparent enough to view the

packaged contents inside, and offer sustainability and a

lower carbon footprint are highly desirable. Currently, no

clear polymer can offer the oxygen barrier performance of

foil, in a low carbon footprint, competitive cost solution.

Ethylene Vinyl Alcohol (EVOH) comes the closest to

matching the oxygen, clarity and cost parameters.

However, flex barrier properties of EVOH barrier films are

poor due to the brittle nature of EVOH. EVOH barrier

packaging products with an improved flex barrier property

may provide an alternative packaging solution in foil

dominating liquid packaging markets.

Background

Attempts to maintain flex barrier properties until now

have been focused on using metalized layer lamination,

coating and/or inorganic particle addition in multilayer

structures with seven or fewer layers [7-14]. Recently, G.

Medlock and M. Dolgovskij studied EVOH flex crack

resistance between conventional EVOH films vs.

microlayer EVOH films [15]. Their study demonstrated

that microlayer EVOH films yielded superior flex crack

resistance compared to films with a single EVOH layer. In

addition, they claimed that lower modulus polymers such

as PE based ties compared to Nylon resist crack

propagation from one EVOH microlayer to another. The

number of layers was varied from 7 to 21 layers and the

sample went though up to 1,000 Gelbo flexing cycles.

This study and G. Medlock and M. Dolgovskij’ study

using microlayer technology clearly have advantages over

previous art by (i) improving recyclability due to the use of

polymer-only systems (i.e., no inorganic/metallic

particles), (ii) avoiding an extra step such as lamination, or

coating, or chemical vapor deposition, (iii) maintaining

transparency, and (iv) allowing microwaving. Furthermore,

this study covers larger number of layers up to 35 layers

with statistical analysis to confirm the barrier property

enhancement with respect to the number of layers.

Experimental

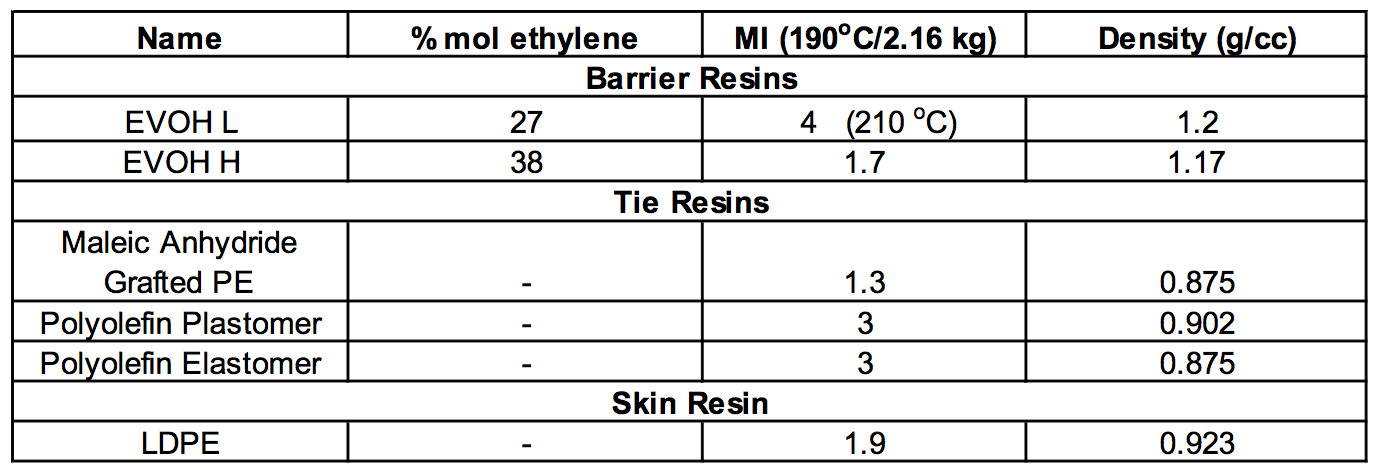

Barrier and tie materials used in this study are listed in

Table 1. The barrier resins of choice were EVAL L171 and

H171 grades from Kuraray America Inc. The % mol

ethylene content, Melt Flow Index, and density

information are listed in Table 1. Tie materials were blends

of Dow AMPLIFY (Trademark of The Dow Chemical

Company) and AFFINITY resins to vary the density from

0.875 to 0.9 g/cc. The skin material was Dow Low Density

Polyethylene (LDPE 503A) resin. This resin has a Melt

Flow Index of 1.9 g/10 min (190

oC/2.16 kg). The core to

skin ratio of the film structure was set to 20:80. The overall

film thickness was approximately 127 micrometers (5

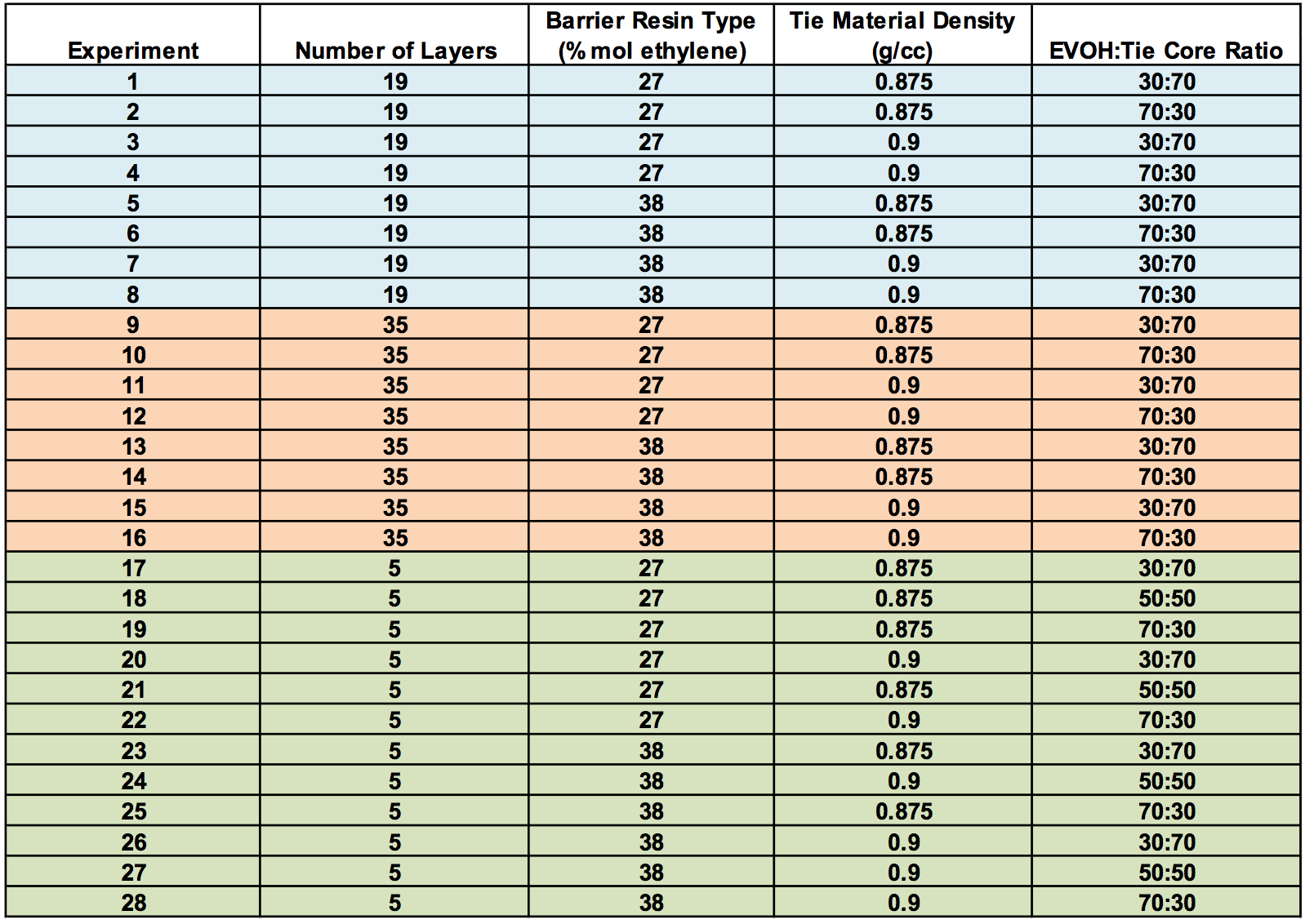

mils). The design of experiment (DOE) was created using

4 independent variables: number of layers, barrier resin

type (% mol ethylene), tie material density, and EVOH/Tie

ratio in the core. The detailed DOE is shown in Table 2.

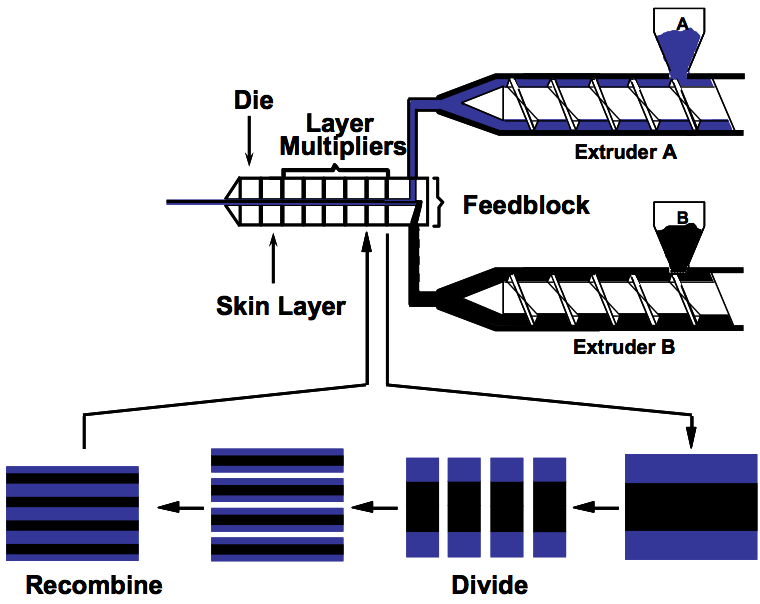

The coextrusion line used in this study consists of

three 38.1 mm (1.5 inch) diameter, 30:1 L/D or 24:1 L/D

single screw extruders. Extruders A and B feed a three

layer feedblock coupled with layer multipliers (see Figure

1). A 5 layer structure was created by operating all three

extruders without a multiplier (3 core layers+2 skin layers).

A four and a two channel multiplier were used to create 19

layer samples (17 core layers+2 skin layers). 17 core layers

were calculated by counting double layers as one layer

after multiplications. For example, initial 3 layers become

12 layers after flowing through a four channel multiplier.

However, 3 internal mating layers during re-stacking process are A-A double layers (Figures 1 and 2).

Therefore, actual flow structure has 9 A-B alternating

layers. After this flow goes through a two channel

multiplier, it has 17 alternating layers (9 x 2 – 1 double

layer = 17 alternating layers). In a same way, two four

channel layer multipliers were used to create 35 layer

samples (33 core layers+2 skin layers). 33 core layers are

calculated as follows: 3 X 4 = 12 layers – 3 double layers =

9 alternating layers; 9 X 4 = 36 layers – 3 double layers =

33 alternating core layers).

Figure 1. Coextrusion Line Set-up

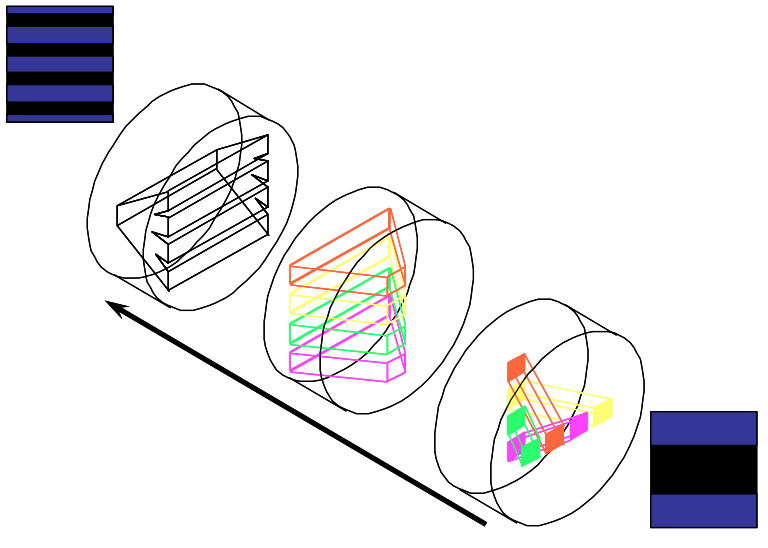

Figure 2 shows a schematic of the four channel layer multiplier. This multiplier creates 9 alternating layers from 3 layers as described earlier.

The multilayered structures are further sandwiched

with two skin layers by another extruder before entering a

304.8 mm (12 inch) coat hanger style die with a 0.559 mm

(0.022 inch) die lip gap.

The processing temperatures for all extruders,

feedblock, multipliers, and die were maintained at 210

oC

(410°F) except at the feeding zones of the extruders. The

microlayer samples were made of 20% of a core structure

containing the alternating microlayers, and 80% of a skin

structure equally divided between each side of the core.

The core material ratio was varied from 30 vol%/70 vol%

to 70 vol%/30 vol% in the core (see Table 2). The overall

flow rate was maintained at 27.2 kg/h (60 lb/h).

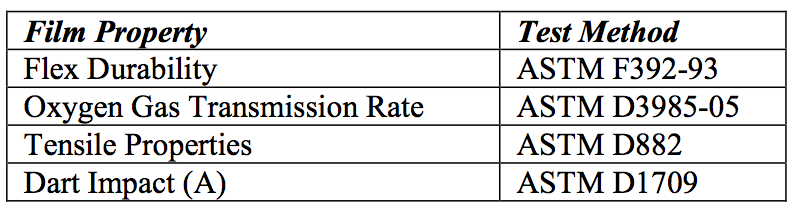

Film samples were tested for the following physical

properties using the ASTM standards listed in the Table 3.

Results

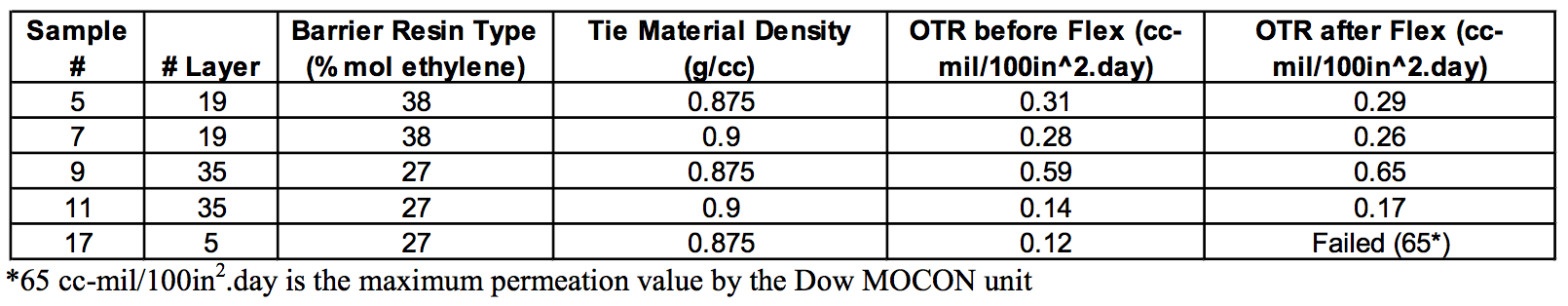

Effect of Flex Cycles on Oxygen Barrier Property

Oxygen transmission rate (OTR) was measured at

23

oC and 85% relative humidity before and after flexing

(400 Gelbo flex cycles) on the samples with fewer than 2

pin holes in the structure. The compositions and layer

numbers of these films are shown in Table 4.

OTR measurements for the sample 17 with 5 layers

before and after flexing were included to demonstrate the

detrimental effect of flex cycles on the samples with a

small number of layers (Table 4). After 400 flex cycles, the

5 layer sample failed the OTR test. The permeation value

of 65 cc-mil/100in

2.day is the maximum measureable

number by the Dow MOCON unit and is shown in

parentheses for the reference.

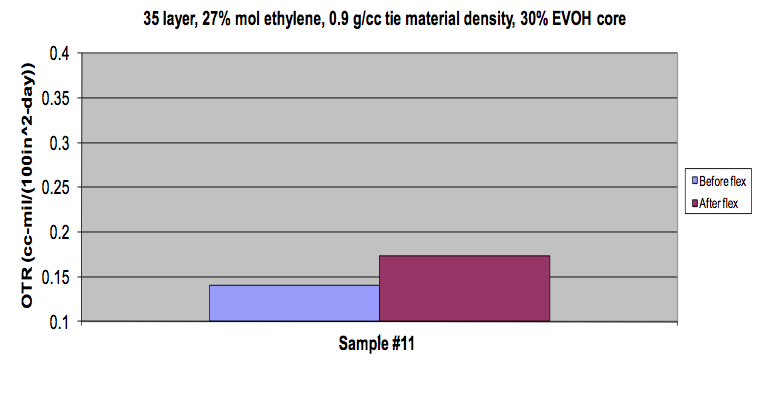

The OTR measurements on the four higher number of

layer samples (sample #: 5, 7, 9, & 11) demonstrate that

the flex barrier property was maintained after 400 Gelbo

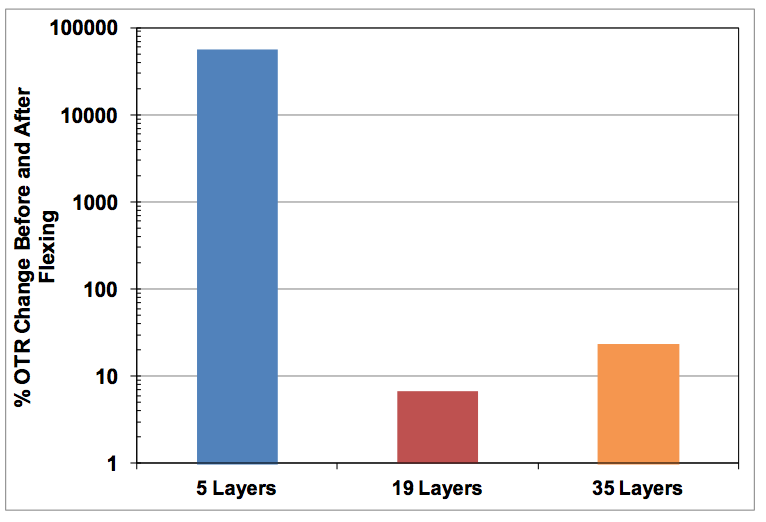

flexes (Table 3). % OTR change before and after flexing

with respect to the number of layers is shown in Figure 3.

The samples 5 and 11 data were used for 19 and 35 layer

cases, respectively, and the permeation value of 65 ccmil/100in

2.day was used to calculate % OTR change for

the 5 layer case. As depicted in Figure 3, the 19 and 35

layer samples maintained the flex barrier property after

flexing but the 5 layer sample lost the barrier property. The

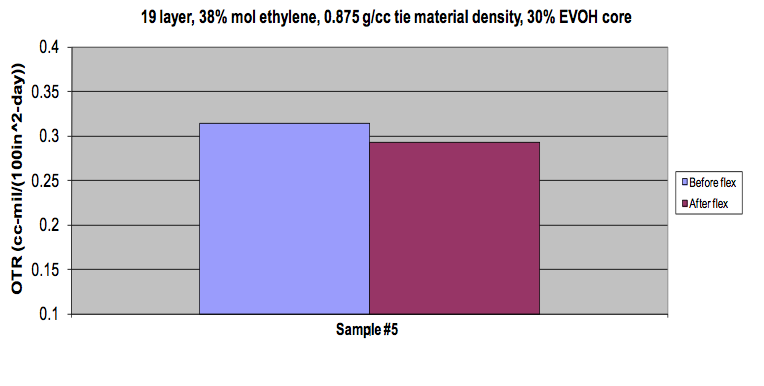

OTR measurement data on the samples 5 (19 layers) and

11 (35 layers) before and after flex cycles are shown in

Figures 4 and 5, respectively.

Figure 3. % OTR Change Before and After Flex

Figure 4. OTR Data of Sample 5 (19 layers) Before and After Flex Cycles: (a) Before and (b) After

Figure 5. OTR Data of Sample 11 (35 layers) Before and After Flex Cycles: (a) Before and (b) After Flex

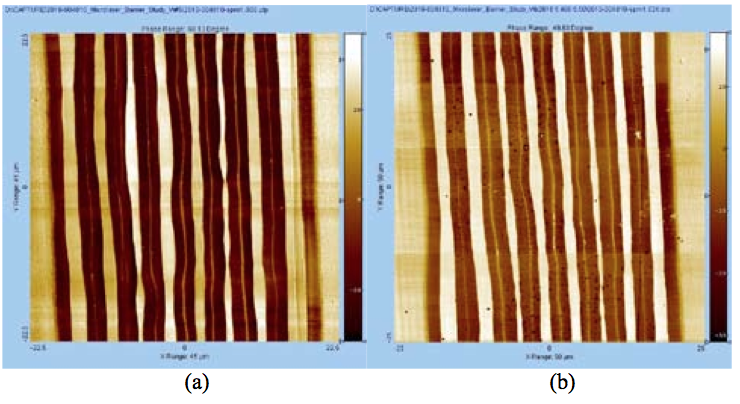

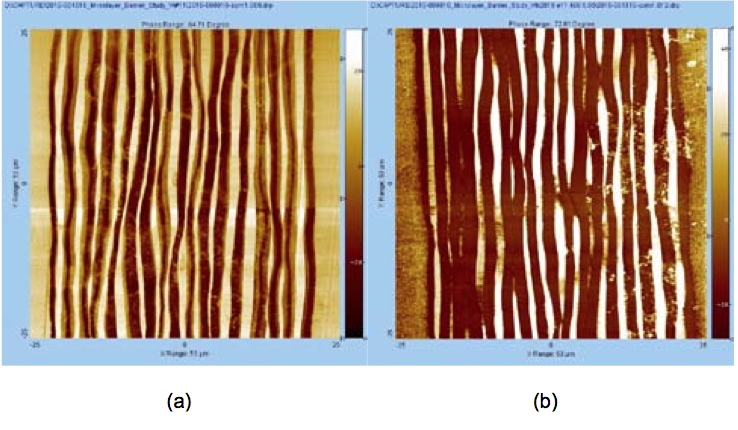

The AFM images before and after flex cycles, as

shown in Figures 6 and 7, were taken to demonstrate that

most of the EVOH (light layers) survived after flexing for

both 19 and 35 layer samples.

Figure 6. AFM Images of Sample 5 (19 layers) Before and After Flex Cycles: (a) Before and (b) After

Figure 7. AFM Images of Sample 11 (35 layers) Before and After Flex Cycles: (a) Before and (b) After Flex

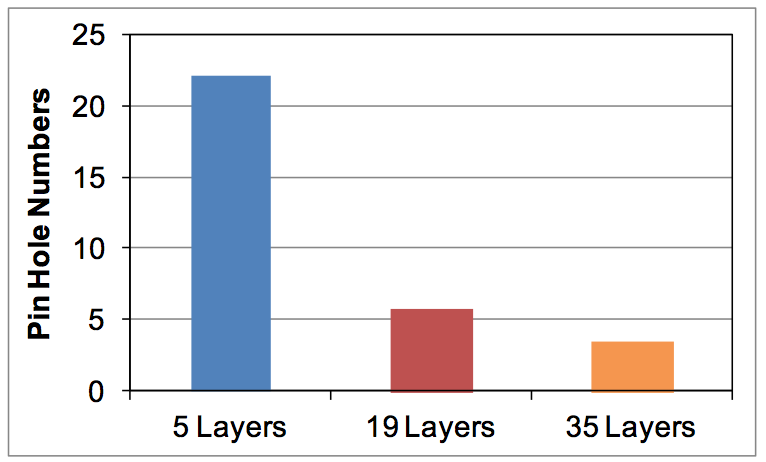

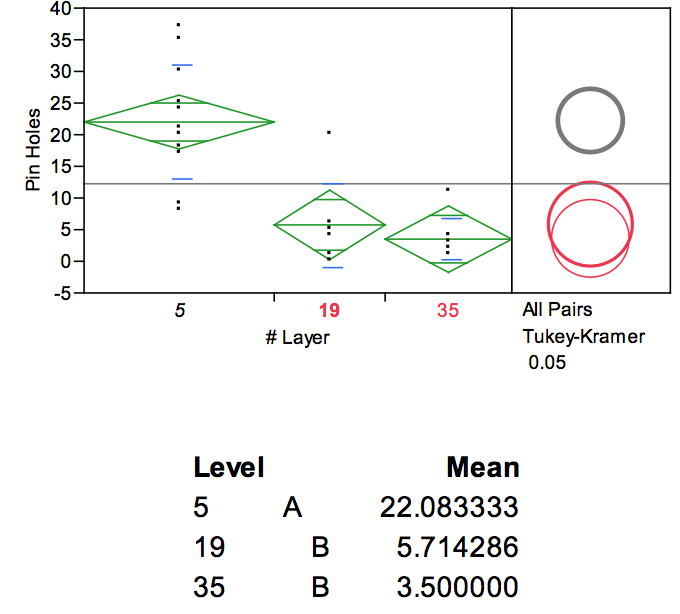

Effect of Layer Number on Pin Holes

Flex durability of our samples has been tested

according to ASTM F392-93. The flexing action consists

of a twisting motion followed by a horizontal motion, thus,

repeatedly twisting and crushing the film. After 400 cycles

of Gelbo flexes, physical holes through the structure were

measured by a color dye penetration method and the

average numbers of pin holes with respect to the number of

layers are shown in Figure 8.

Figure 8. Pin Hole Numbers with respect to Number of Layers

The data was analyzed with a commercially available

statistical software (JMP, SAS institute Inc.). Figure 9

clearly demonstrates that the pin hole numbers statistically

decrease with the number of layers (a Tukey-Kramer test

with confidence = 95%). This is possibly due to: (i) better

flexibility of a brittle EVOH barrier resin in thinner layers

[16], and (ii) longer tortuous path for the dye to travel

through even if some layers were broken in 19 and 35 layer

samples [17, 18].

The effect of individual layer thickness of

Polyethylene terephthalate (PET) and Polycarbonate (PC)

microlayer films on large strain deformation mechanism

was studied earlier [16]. As the thickness of individual

polymer layers decreases, a transition in deformation

mechanism from two-component behavior to onecomponent-like

behavior was observed. Therefore, it is

possible to improve the film toughness by decreasing

EVOH layer thickness in the EVOH/PE based tie material

microlayer system.

A Cussler-Fredrickson model for permeation of small

molecules through polymer films filled with impervious

particles or crystalline lamellae describes that high content

of impermeable particles or crystalline lamellae, high

aspect ratio, and high angle of particles/lamellae to the

permeation direction (i.e., more perpendicular to the

permeation direction) gives less overall permeation of gas

molecules. For the EVOH microlayer case, EVOH can be

viewed as particles/crystals in the model to decrease the

overall permeation due to longer tortuous path [17, 18].

Figure 9. Effect of Layer Number on Pin Hole Numbers

Effect of Barrier Resin Type and Content

The extensive statistical analysis was performed to see

the effect of barrier resin type (% mol ethylene) and

content on barrier and mechanical properties. The expected

trends were observed; better oxygen barrier property was

observed with the samples containing the 27% mol

ethylene content barrier resin. Increasing the barrier resin

content improved better the barrier property. Machine and

cross direction mechanical properties such as tensile

strength and yield stress increased with higher EVOH

contents in microlayer samples while ultimate elongation

decreased. The samples with the 27% mol ethylene

content barrier resin behaved stiffer compared to the ones

with 38% mol content.

Conclusions

This study describes a process technology to maintain

or improve gas barrier property of EVOH barrier films

after flexing. EVOH and MA-g-PE multi- and microlayer

samples with 5, 19, and 35 layers were produced in a

coextrusion line. Flexing was performed using a Gelbo

flexing tester (400 flexes). After flexing, pin hole tests

were performed on the film and only those with fewer than

2 pin holes were re-tested for OTR measurements. The

clear trend of pin hole numbers decreasing after 400 Gelbo

flexes was observed as the number of layers increased. The

OTR measurements on these films demonstrated that thin

EVOH barrier resin can improve flex crack resistance of

the film. This proves that for a given amount of barrier

resin, the flex barrier property can be increased

dramatically by microlayering. This flex barrier

improvement in microlayers is possibly due to: (i) better

flexibility of a brittle barrier resin in thinner layers, and (ii)

longer tortuous path for gas molecules to travel through the

structure even if there are some broken layers. In addition,

mechanical properties of these microlayer films were

measured and evaluated statistically to understand the

general trend.

References

1. L.M. Thomka and W.J. Schrenk, Modern Plastics, 49,

4, 62 (1972).

2. C.D. Han, J. Appl. Poly. Sci., 19, 7, 1875 (1975).

3. W.J. Schrenk, Plastics Engineering, 30, 3, 65 (1974).

4. J.A. Caton, British Plastics, 44, 3, 95 (1971).

5. L.M. Thomka, Plastics Engineering, 18, 2, 60 (1973).

6. C.R. Finch, Plastics Design Forum, 4, 6, 59 (1979).

7. T. D. Kendig, U.S. Patent 6,623,821 B1 (2003).

8. P. Frisk, U.S. Patent 5,916,685 A (1999).

9. K. Nakamura, U.S. Patent 20070160806 A1 (2007).

10. H. Umekawa and Y. Inui, U.S. Patent 20020197480

A1 (2002).

11. B. Bastion Bradle and R. Komro, U.S. Patent

20060046006 A1 (2006).

12. M. Yamazaki, H. Tanaka, and Y. Inaba, U.S. Patent

20070134476 A1 (2007).

13. K. Miharu, and H. Tachino, U.S. 6,011,115 A (2000).

14. K. P. Nelson and C. J. Harvey, U.S. Patent

20070031546 A1 (2007).

15. G. Medlock, and M. Dolgovskij, TAPPI PLACE

Conference (2012).

16. R. Adhikari, V. Seydewitz, K. Loeschner, G. H.

Michler, A. Hiltner, and E. Baer, Macromolecular

Symposia, 290, 156 (2010).

17. E.L. Cussler, S.E. Hughes, W.J. Ward, and R. Aris,

Journal of Membrane Science, 38, 161 (1998).

18. W.S. Jang, Ph.D. Dissertation, Mechanical

Engineering, Texas A&M (2008).

Table 1. Oxygen Barrier, Tie, and Skin Resin Properties

Table 2. DOE Table

Table 3. Film Property Tests and Methods

Table 4. OTR Measurements Before and After 400 Gelbo Flexes

Return to

Paper of the Month.