Evaluation of 9-Layer Film Blowing Process by Using Variational Principles

Martin Zatloukal1,2, Roman Kolarik1

1 Centre of Polymer Systems, University Institute, Tomas Bata University in Zlin,

Nad Ovcirnou 3685, 760 01 Zlin, Czech Republic

2 Polymer Centre, Faculty of Technology, Tomas Bata University in Zlin,

TGM 275, 762 72 Zlin, Czech RepublicAbstract

In this work, coextrusion experiments utilizing an

industrial 9-layer Brampton Engineering coextrusion

film blowing line for LDPE/LDPE/tie/PA6/EVOH/PA6/

/tie/LDPE/LDPE film production has been performed

under different processing conditions (different air

cooling intensity and mass flow rate) in order to evaluate

variational principles based modeling approach for the

multi-layer film blowing process. It has been revealed

that the variational principle based model can describe

the bubble shape, temperature profile and predict internal

bubble pressure reasonably well for all applied

processing conditions even if the multi-layer film has

been viewed as the static elastic membrane characterized

only by one material parameter - bubble compliance J,

which was not allowed to vary along the multi-layer

bubble.

Introduction

Production of thin polymer films is mostly

introduced by the film blowing process. Although this

process is widely used, the single layer films do not

reach specific properties required especially in a food

packaging industry, such as barrier properties (low

permeability to oxygen or carbon dioxide), heat-seal

ability, high film strength, printability, adhesion and low

costs [1-2]. All these properties are easily and

economically achievable in multi-layer films produced

by coextrusion.

In coextrusion, two or more different polymer melts

(having various rheological properties and temperatures)

are extruded from individual extruders, through a

coextrusion die, to a continuous tube which is cooled by

an air ring and internal bubble cooling system, IBC,

axially stretched by the take-up force, F, and

circumferentially inflated by the internal bubble

pressure, Δp, to required bubble dimensions. Then,

above the freezeline height, the stable solidified bubble

is folded by the collapsing frames and consequently

drawn upward by the nip rolls to a wind-up roll. Then,

the final lay-flat coextruded multi-layer film, which

represents a combination of the best properties of each

used polymers, can be applied for example in food

packaging, medical and electronic industry. The most

frequently used materials in coextrusion are polar barrier

polymers, such as nylon (PA), ethylene vinyl alcohol

(EVOH), polyvinylidene chloride (PVDC), and nonpolar

polyolefines, i.e. polyethylene (PE), polypropylene

(PP), polystyrene (PS) [1-2].

In spite of a rapid growth of a blown film coextrusion

in the last decades, the number of experimental and

modeling studies of the multi-layer process is very

limited. In 1978, Han and Shetty [3] experimentally and

theoretically investigated blown film coextrusion of two

polymers in various combinations, i.e. low density

polyethylene (LDPE) with ethylene-vinyl acetate (EVA),

LDPE with high density polyethylene (HDPE), LDPE

with polypropylene (PP) and HDPE with EVA. Further,

they performed a theoretical study where the experiment

was theoretically analyzed by using a power-law nonNewtonian

model included in a computational procedure

predicting the number of layers, layer thickness and the

volumetric flow rate compared with the experiment.

Theoretical investigation of two-layer coextruded blown

film was also studied by Yoon and Park [4] in 1992. In

their work, considering isothermal processing

conditions, two film layers are described by a Newtonian

and an Upper-Convected Maxwell fluid (UCM). In order

to evaluate influence of viscous and viscoelastic forces

on the flow mechanics of the process, the various flow

rate ratio values of the fluids are applied for numerical

determination of the bubble radius and the film thickness

profiles. It was revealed, that in the case of the small

relaxation time the flow mechanics of UCM layer is

similar to a Newtonian single-layer. On the other hand,

increasing relaxation time supports the viscoelasticity

effect of the UCM layer leading to dominance of bubble

dynamics. In 2000, Yoon and Park [5] performed a

linear stability analysis of the above presented polymer

system. It was observed that the critical film thickness

decreases with increasing blow-up ratio which makes the

process unstable. In more detail, in case of a Newtonian

single-layer flow, there exists an upper unstable region where the bubble is unstable when the BUR is greater

than a certain critical value. On the other hand by the

presence of a thin viscoelastic layer this restriction can

be removed resulting in enhanced stable area at higher

values of BUR. In 2000, Stasiek [6] studied the heat

transfer between three-layer blown film and cooling

medium. In his work, mathematical model, estimating

length of a cooling path and taking into account

crystallization effect, was developed and used to

describe the relationship between the temperature

changes in each layer and the thermal energy. In 2005,

Elkoun et al. [7] investigated effect of composition and

layout of layers on end-use properties of a coextruded

LLDPE five-layer blown film. For coextruded structure,

a conventional Ziegler-Natta LLDPE gas phase butene

copolymer, an advanced Ziegler-Natta LLDPE solution

octene copolymer, and a single site LLDPE solution

octene copolymer were used and compared with monolayer

blended film. It was observed, that combination of

the LLDPE butene and the single site LLDPE in a fivelayer

coextruded film reveals improved tear resistance

due to a presence of interfacial transcrystalline layers.

Further, combination of coextruded single site LLDPE

and the Ziegler-Natta octane copolymers leads to

enhanced tear strength, too. Finally, significant haze

reduction, caused by placing the single site LLDPE on

the outside layers of the multi-layer films, was observed.

In 2005, Gamache et al. [8] performed experimental and

theoretical study evaluating stresses in a two-layer

coextruded blown film of LDPE, ultra low density

polyethylene (ULDPE), LDPE/ULDPE and

ULDPE/LDPE. Then, the axial and transverse stresses

were experimentally measured under various processing

conditions, which were then successfully compared with

theoretically calculated ones by the non-isothermal

Newtonian model. In 2007, Gururajan and Ogale [9]

studied effect of coextrusion on the orientation and

morphology of the coextruded films of PP and LDPE by

using Raman spectroscopy. In the case of multi-layer

films, no significant difference in overall molecular

orientation of PP and LDPE was found. On the other

hand, single-layer LDPE films indicated existence of

some row-nucleation of crystals which was not observed

in the LDPE layer in coextruded film. In 2009, a 2-D

model describing non-isothermal two-layer blown film

process was developed by Xu and McHugh [10]. This

model is based on the 1-D model of Henrichsen and

McHugh [11] taking to account viscoelasticity and flowenhanced

crystallinity. The 2-D model presents

numerical results showing influence of the rheological,

thermal and crystallization properties on the crystallinity

development and stresses in particular layers. It was

observed, that the individual layers of the same materials

contain significantly different stresses due to the

temperature difference. Further, different material

properties in a certain layer affect stresses and

crystallinity in its own layer as well as in another layer

through heat transfer. Finally, stresses and semicrystalline

phase orientation at the freezeline, i.e. final

film properties, are affected by the layer arrangement.

As can be seen from the literature overview, the

number of theoretical studies of the multi-layer film

blowing process is rather rare, considering maximally 3

layers and laboratorial processing conditions only due to

extremely high mathematical and rheological complexity

of the problem. Due to this, the multi-layer film blowing

process for high number of layers and industrial

processing conditions is not fully understood yet.

Recently, it has been found that utilization of the

variational principle based single-layer film blowing

process modeling leads to very stable numerical schemes

allowing qualitative as well as quantitative description of

the experimental reality [12-18]. The main goal of this

work is to investigate whether it is possible to utilize the

variational principles based modeling approach for the

multi-layer film blowing process. For the model

validation purposes, industrial 9 layer film blowing line

has been utilized to produce multi-layer bubbles under

different processing conditions.

Mathematical Modeling

Zatloukal-Vlcek Formulation

The variational principle based Zatloukal-Vlcek

formulation [12] describes a stable film blowing process

as a state when the bubble shape satisfies minimum

energy requirements (here the bubble energy is given by

the elastic strain energy increase due to take up force and

negative work done by the applied internal load). The

bubble shape is described by a set of simple analytical

equations (see Table 1) utilizing four physical

parameters: the freezeline height, L, the bubble

curvature, pJ (which is given by the membrane

compliance, J, and the internal load, p, representing the

internal force acting on the bubble length due to Δp – see

Eq. 6), the inner die radius, R

0 and the blow-up ratio,

BUR. It should be mentioned that the equations

describing the freezeline height (Eq. (7)) and the

temperature profile (Eq. (8)) have been derived in [13]

from the cross-sectionally averaged energy equation [19]

neglecting axial conduction, dissipation, radiation effects

and crystallization. The particular symbols with respect

to model equations summarized in Table 1 have the

following meaning: C

p represents the specific heat

capacity, HTC is the heat transfer coefficient, m is the

mass flow rate, T

melt(die) represent the die exit melt

temperature, T

solid is the solidification temperature and

T

air is the cooling air temperature. Parameter φ is defined

according to Table 2 where a parameter A is defined by

Eq. (4).

Experimental

In this work, coextrusion experiments were carried

out on an industrial 9-layer Brampton Engineering

coextrusion film blowing line (Figure 1) equipped with a

350 mm diameter flat spiral die (R0 = 0.1626 m) with a

die gap of 2.032 mm (H0 = 0.002032 m). During the

process, the bubble was cooled by an air ring as well as

by an internal bubble cooling system. The coextruded

structure was LDPE/LDPE/tie/PA6/EVOH/PA6/tie/

/LDPE/LDPE with following layer thicknesses: 17.5 %

for LDPE, 5% for tie, 5% for PA6 and 10% for EVOH.

In all experiments, the following parameters were kept to

be constant: die exit temperature, Tdie = 250°C, overall

film thickness (gauge), H1=100 μm, (which corresponds

to draw-down ratio DDR = 11.17), blow-up ratio, BUR =

1.8, and lay-flat film, 1000 mm. During the experimental

work, firstly, different bubble cooling intensity was

applied at the constant overall mass flow rate, 300 kg/h,

(i.e. constant line speed 25.9 m/min) and secondly,

overall mass flow rate was varied from 225 kg/h to 375

kg/h (i.e. from 19.4 m/min to 32.3 m/min for the line

speed) by keeping the bubble cooling intensity the same.

For given processing conditions, the bubble shape

was monitored by the EOS digital SLR photo camera

Canon EOS 450D model (Canon, Inc., Japan) with

resolution of 12.2 Mpx equipped with Canon lens EF-S

18-55mm f/3.5-5.6 IS whereas the average bubble

temperature was measured by the heat gun, model

camera: INFRACAM

TM using calibration site FLIR

SYSTEM, AB SWEDEN and corresponding software

(ThermaCAM QuickReport 1.0).

Results and Discussion¶

At the beginning, three unknown film blowing model

parameters L, BUR and pJ (for the known die radius

R0 = 0.1626 m) were determined through fitting of all

experimentally obtained bubble shapes by Eq. (8)

utilizing the least square minimization method and they

are summarized in Table 3. In order to calculate the takeup

force and the internal bubble pressure for given

processing conditions, p and J parameters were separated

from the particular pJ value in the same way as

described in [12] i.e. parameter J (which is viewed as

constant characterizing the bubble compliance) was

determined from pJ value for one reference processing

conditions for which the load p was chosen to get equal

predicted and measured internal bubble pressure. The

reference processing conditions are provided in the

second column of Table 3.

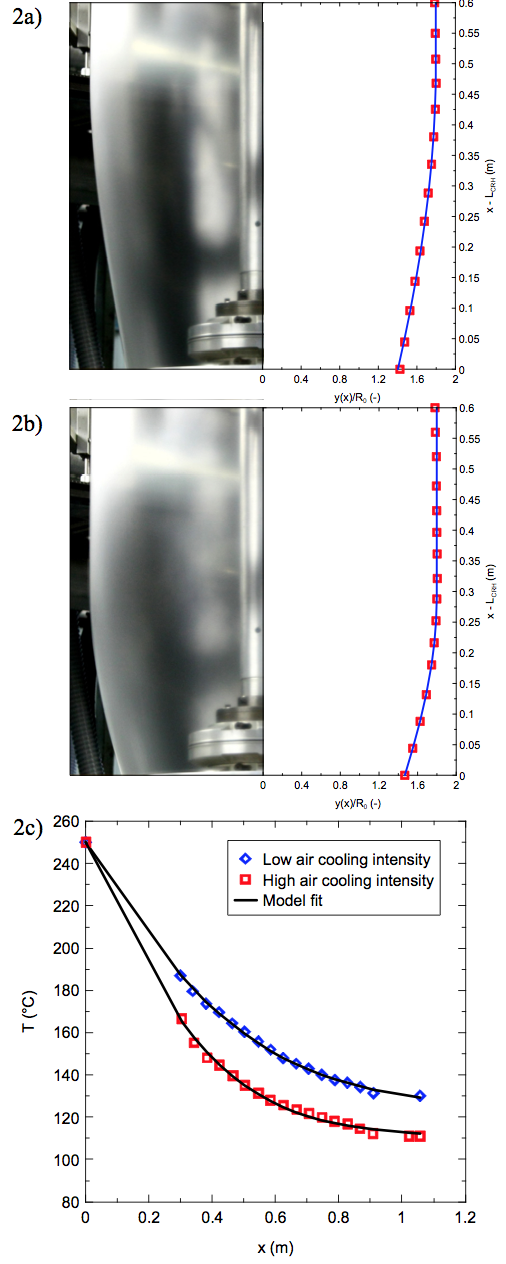

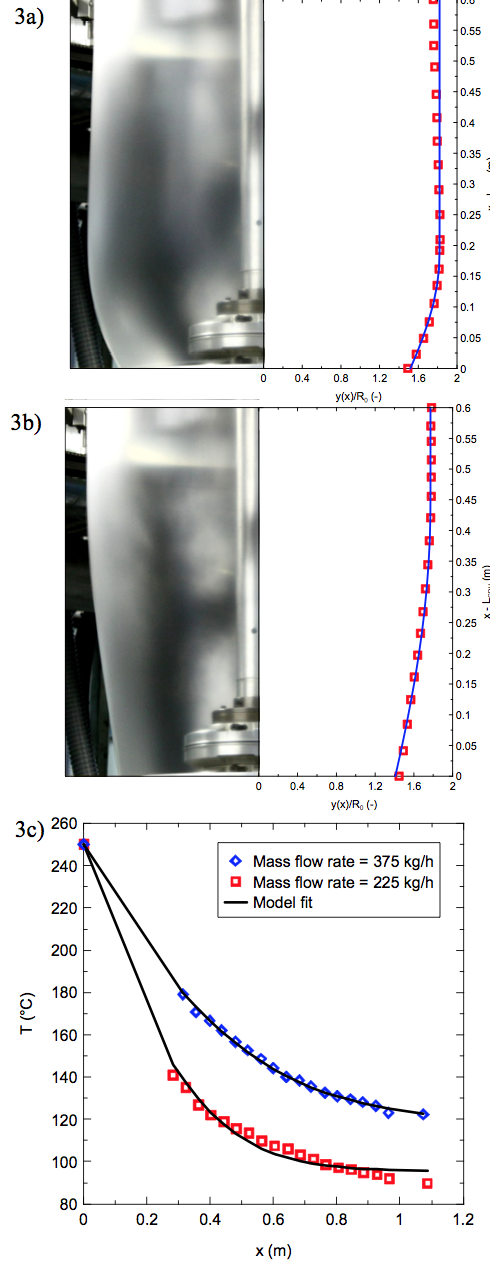

The comparison between the experimentally

determined bubble shape and internal bubble pressure

for all tested processing conditions are summarized in

Figures 2-3 and Table 3, respectively, and as it can be

seen, the agreement between the measured data and

model fits/predictions is very good. In more detail, the

model can describe the bubble shape as well as

temperature profile along the bubble and predict internal

bubble pressure reasonably well for both, decreased

freeze line height and the bubble curvature due to

increased air cooling intensity or decreased mass flow

rate under highly non-isothermal conditions, even if the

assumption about the constant bubble compliance J

along the multi-layer bubble has been used. The fact that

the single parameter J works could be explained by the

statement that the layers which freezes first in

coextrusion dictates the bubble shape [20-21]. This

suggests, that the variational principle based modeling

approach proposed in [12] can be used and explored for

the multi-layer film blowing process in the similar way

as shown in [12] for single-layer film blowing process.

Moreover, it is believed, that such theoretical approach

can be used to understand complex heat transfer and

crystallization effects occurring in multi-layer film

blowing process resulting in highly non-linear average

temperature profile along the multi-layer bubble,

depicted in Figures 2c and 3c for the studied

experimental conditions, which is not the case of the

single-layer film blowing process at which the average

temperature profile along the bubble is almost linear as

shown in [22-29].

Conclusion

In this work, coextrusion experiments utilizing an

industrial 9-layer Brampton Engineering coextrusion

film blowing line for

LDPE/LDPE/tie/PA6/EVOH/PA6/tie/ /LDPE/LDPE film

production has been performed under different

processing conditions (different air cooling intensity and

mass flow rate) in order to evaluate variational principles

based modeling approach for the multi-layer film

blowing process.

It has been revealed that the variational principle

based model can describe the bubble shape, temperature

profile and predict internal bubble pressure reasonably

well for both, decreased freeze line height and the bubble

curvature due to increased air cooling intensity or

decreased mass flow rate under highly non-isothermal

conditions even if the multi-layer film has been viewed

as the static elastic membrane characterized only by one

material parameter - bubble compliance J, which was not

allow to vary along the bubble. Thus, it is believed, that

the variational principle based modeling approach can be

used and explored for the multi-layer film blowing

process to understand complex rheological, heat transfer

and crystallization phenomena occurring in multi-layer

film blowing process with respect to process stability

and final film properties.

Acknowledgments

The authors wish to acknowledge the Grant Agency

of the Czech Republic (grant No. P108/10/1325) for the

financial support. This article was written with support

of Operational Program Research and Development for

Innovations co-funded by the European Regional

Development Fund (ERDF) and national budget of

Czech Republic, within the framework of project Centre

of Polymer Systems (reg. number:

CZ.1.05/2.1.00/03.0111).

The authors would also like to thank Brampton

Engineering Inc. which allowed us to perform all

experimental work on their complete commercial size 9-

layer AeroFrost air cooled blown film line.

References

1. Cantor, K. Blown Film Extrusion. Munich: Carl

Hanser Verlag, 2006. ISBN 3-446-22741-5.

2. Butler, T.I. Film Extrusion Manual: Process,

Materials, Properties. Atlanta: Tappi Press, 2005.

ISBN 1-59510-075-X.

3. Han, C.D., Shetty, R., Polym. Eng. Sci. 1978, vol.

18, no. 3, pp. 187-199.

4. Yoon, K.S., Park, C.W., Polym. Eng. Sci. 1992,

vol. 32, no. 23, pp. 1771-1777.

5. Yoon, K.S., Park, C.W., J. Non-Newtonian Fluid

Mech. 2000, vol. 89, no.1-2, pp. 97-116.

6. Stasiek, J., Prog. Rubber Plast. Recycl. Technol.

2000, vol. 16, no. 3, pp. 183-192.

7. Elkoun, S., Huneault, M.A., McCormick, K.,

Puterbaugh, F., Kale, L., Polym. Eng. Sci. 2005,

vol. 45, no. 9, pp. 1222-1230.

8. Gamache, E., Agassant, J.F., Demay, Y., Lafleur,

P.G., J. Plast. Film Sheeting 2005, vol. 21, no. 2,

pp. 127-144.

9. Gururajan, G., Ogale, A.A., J. Plast. Film Sheeting

2007, vol. 23, no. 1, pp. 37-49.

10. Xu, F., McHugh, A.J., Chem. Eng. Sci. 2009, vol.

64, no. 22, pp. 4787-4795.

11. Henrichsen, L.K., McHugh, A.J., Int. Polym. Proc.

2007, vol. 22, no. 2, pp. 179–189.

12. Zatloukal, M., Vlcek, J., J. Non-Newton. Fluid

Mech. 2004, vol. 123, no. 2-3, pp. 201-213.

13. Kolarik, R., Zatloukal, M., J. Appl. Polym. Sci.

2011, vol. 122, no. 4, pp. 2807-2820.

14. Kolarik, R., Zatloukal, M., AIP Conference

Proceedings 2009, vol. 1152, pp. 251-269.

15. Zatloukal, M., Kolarik, R., Annual Technical

Conference - ANTEC, Conference Proceedings

2009, vol. 3, pp. 1587-1595.

16. Zatloukal, M., Kolarik, R., Annual Technical

Conference - ANTEC, Conference Proceedings

2011, vol. 2, pp. 1317-1322.

17. Kolarik, R., Zatloukal, M., AIP Conference

Proceedings 2011, vol. 1375, pp. 56-74.

18. Kolarik, R., Zatloukal, M., Martyn, M.,

International Journal of Heat and Mass Transfer

2013, vol. 56, no. 1, pp. 694-708.

19. Doufas, A.K., McHugh, A.J, J. Rheol. 2001, vol.

45, no. 5, pp. 1085-1104.

20. Morris, B.A., Journal of Plastic Film and Sheeting,

1999, 15(1), 25-36.

21. Giriprasath, G., Ogale, A.A., Annual Technical

Conference – ANTEC, Conference Proceedings,

2006, 2, 830-834.

22. Wagner, M.H., Ph.D. Thesis, IKT Stuttgart, 1976.

23. Fisher, E., Ph.D. Thesis, IKT Stuttgart, 1983.

24. Cao, B., Sweeney, P., Campbell, G.A., J. Plast.

Film Sheeting 1990, vol. 6, no. 2, pp. 117-130.

25. Kanai, T., White, J.L., Polym. Eng. Sci. 1984, vol.

24, no. 15, pp. 1185-1201.

26. Ast, W., Ph.D. Thesis, IKT Stuttgart, 1976.

27. Muslet, I.A., Kamal, M.R., J. Rheol. 2004, vol. 48,

no. 3, pp. 525-550.

28. Beaulne, M., Mitsoulis, E., J. Appl. Polym. Sci.

2007, vol. 105, no. 4, pp. 2098-2112.

29. Sarafrazi, S. Sharif, F., Int. Polym. Proc. 2008, vol.

23, no. 1, pp. 30-37.

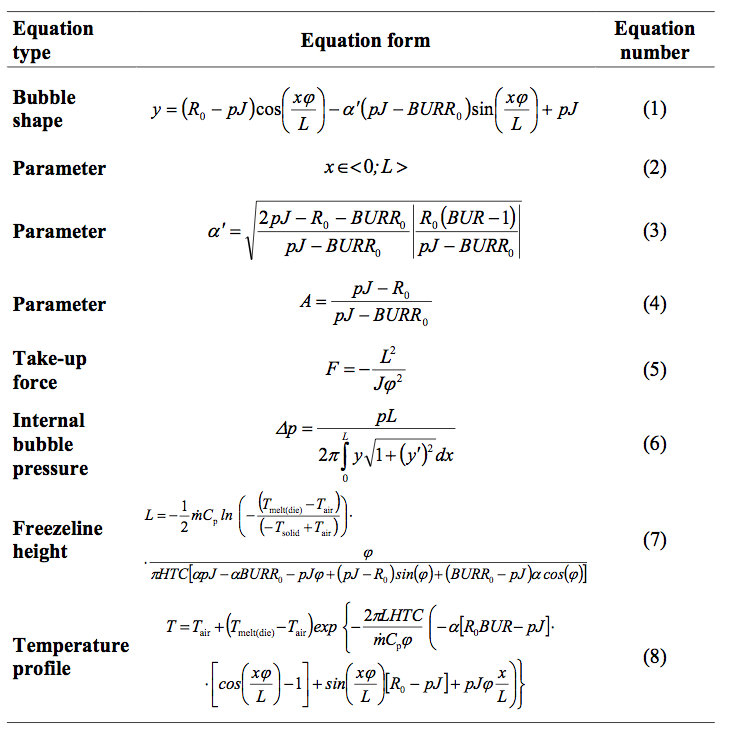

Table 1. Summary of the Zatloukal-Vlcek film blowing model equations [12-13].

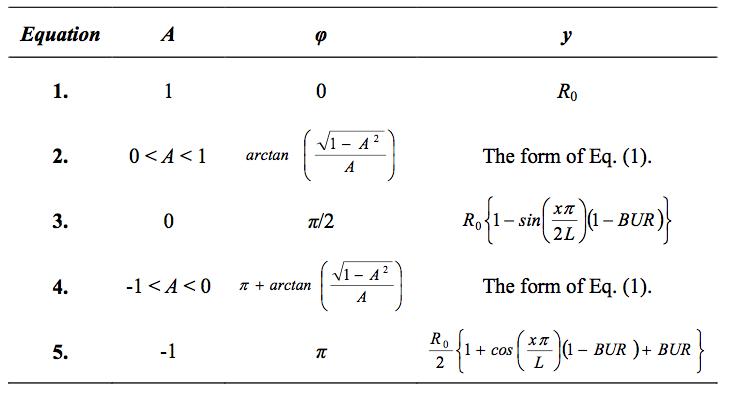

Table 2. Parameters A and φ for different bubble shapes (y) [12].

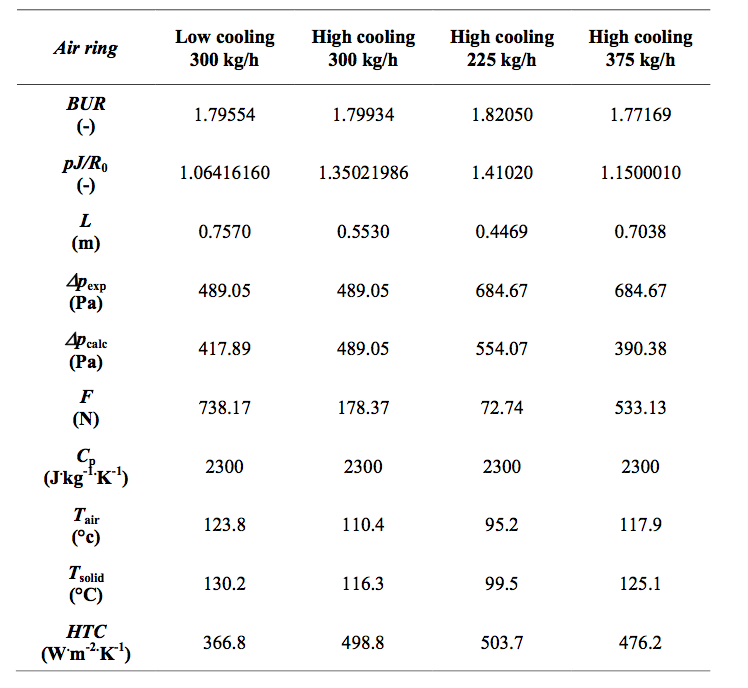

Table 3. Summarization of the model parameters and model predictions (by keeping the bubble compliance J the same for all the cases equal to 0.00028221 Pa-1) for all tested processing conditions including the measured value of the internal bubble pressure Δpe

xp.

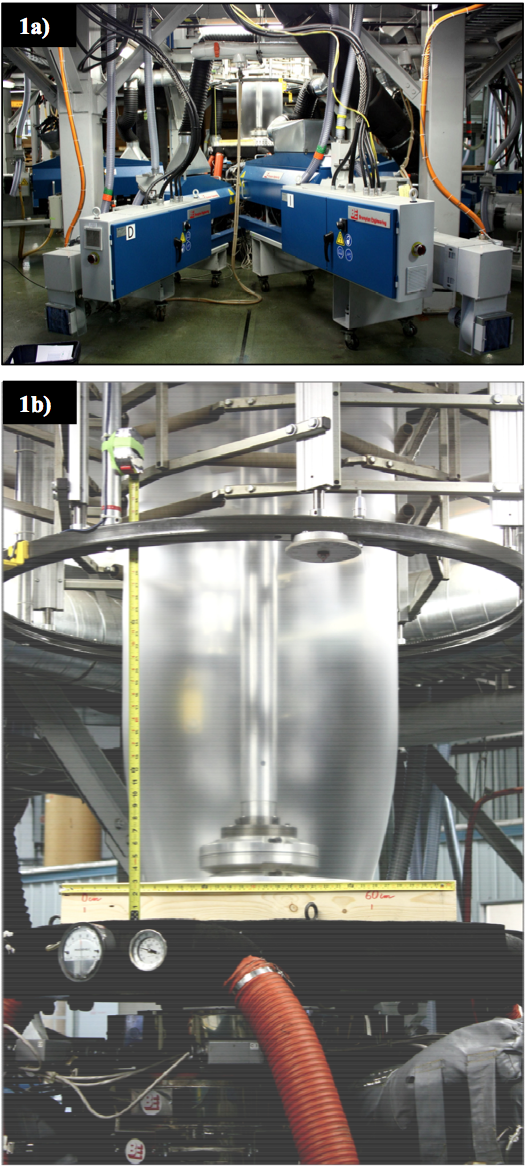

Figure 1. Brampton Engineering 9-layer air cooled blown film line. 1a) Side view. 1b) Detail view of the 9-layer film formation at multi-layer die exit region including the scale for precise bubble shape determination by using digital image analysis.

Figure 2. Comparison between experimentally determined multi-layer bubble shape and temperature profile (open symbols) and model fits (lines) for different air cooling intensity and fixed mass flow rate equal to 300 kg/h (cooling ring height, LCRH = 0.26 m). 2a) Bubble shape for low air cooling intensity. 2b) Bubble shape for high air cooling intensity. 2c) Temperature profiles for both applied air cooling intensities.

Figure 3. Comparison between experimentally determined multi-layer bubble shape and temperature profile (open symbols) and model fits (lines) for different mass flow rates and fixed air cooling intensity (cooling ring height, LCRH = 0.26 m). 3a) Bubble shape for mass flow rate equal to 225 kg/h. 3b) Bubble shape for mass flow rate equal to 375 kg/h. 3c) Temperature profiles for both applied mass flow rates.

Return to

Paper of the Month.