Three Dimensional Simulation of Coextrusion in a Complex Profile Die

Mahesh Gupta

Michigan Technological University Plastic Flow, LLC

Houghton, MI 49931 Houghton, MI 49931

Abstract

Mesh partitioning technique is used to simulate bilayer coextrusion in a complex profile extrusion die. Mesh partitioning technique allows coextrusion simulation without changing the finite element mesh as the interface between the adjacent polymer layers is changed during a coextrusion simulation. Since the finite element mesh in the die remains fixed during the simulation, the mesh partitioning technique allows coextrusion simulation even in highly complicated profile dies. Effect of polymer viscosity on interface shape, velocity, pressure, shear rate, and residence time distribution in a profile coextrusion die is analyzed. It is found that polymer viscosity has significant effect on the interface shape, velocity, pressure, and shear rate, but only a minor effect on the residence time distribution in the die.

Introduction

Coextrusion, which involves simultaneous extrusion

of several different polymers through a die to form a

single multilayered product, combines the functionalities

and benefits of several polymers into a single product [1].

Despite this inherent advantage of coextrusion, growth of

coextrusion market has been slowed down by the

complexity of coextrusion die design. Depending upon the

rheology of polymers used for coextrusion, the polymers

in various layers may get redistributed as they flow

through the die such that the distribution of various

polymers at the inlet and at the exit of the die may be

quite different. Because of this redistribution of polymer

layers, finding a die geometry which will give the

required layer distribution in the final product can be

extremely difficult.

Coextrusion dies are currently designed using a “trial

and error” approach. This repetitive approach is not only

highly time-consuming and costly, but also requires

highly experienced engineers and rarely provides an

optimum die design. Therefore, a coextrusion simulation

software, which can accurately predict the shape of the

interface between different polymer layers, is an excellent

design-aide for a coextrusion die designer. A coextrusion

software not only tremendously simplifies the coextrusion

die design process, the software can also be exploited for

a proper selection of the material in different layers and

for optimization of the processing conditions.

Coextrusion Simulation Equations

For simulation of a multilayer flow of polymers

during coextrusion, the velocity and stresses are required

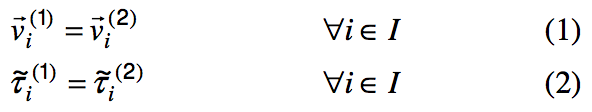

to be continuous across the interface between the adjacent polymer layers [2]. That is,

where I contains all finite elements nodes on the interface, v(vector)

i(1) and τ~

i(1) are the velocities and stresses on one side of the interface, with v(vector)

i(2) and τ~

i(2) being the velocities and stresses on the other side of the interface. Besides the continuity of velocity and stress, coextrusion simulation requires enforcement of the no-cross-flow condition at the interface. That is, the velocity component normal to the interface must be zero at all interface nodes:

where v(vector)

i is the velocity, and n(vector)

i is the unit vector perpendicular to the interface.

Mesh Partitioning Technique

In most three-dimensional simulations of coextrusion

reported in the literature, finite element mesh is modified

after each flow simulation iteration, such that the interelement

boundaries coincide with the interface between

adjacent layers of different polymers [2]. Such an

approach using an interface-matched finite element mesh

can only be employed for simulating a two-dimensional

system or a simple three-dimensional system such as a

rectangular die. For real-life coextrusion systems, with

complex three-dimensional die channel geometry,

repeated generation and modification of interface-matched

finite element meshes is impractical.

In the present work, polyXtrue software [3] was used

to simulate the flow in a bi-layer profile coextrusion die.

In this software a three-dimensional mesh of tetrahedral

finite elements is generated over the complete flow

domain in the die. This finite element mesh is not

modified or regenerated at any stage during coextrusion

simulation. Thereby, allowing simulation of even highly

complex coextrusion systems.

In the coextrusion software used in this work, the

interface between adjacent layers of different polymers is

represented by a surface mesh of linear triangular finite

elements. However, the surface mesh of triangular

elements on the interface and the three-dimensional mesh

of tetrahedral elements in the coextrusion die are

completely independent of each other. This decoupling

between the two finite-element meshes is possible because

in the mesh partitioning technique for coextrusion

simulation, the interface between adjacent polymer layers

is not required to match with the inter-element boundaries in the three-dimensional mesh of tetrahedral finite

elements. Instead, in the software used in this work, the

interface is allowed to pass through the interior of the

tetrahedral finite elements in the three-dimensional mesh.

In the mesh partitioning technique for coextrusion

simulation, the tetrahedral elements which are intersected

by the mesh of triangular elements on the interface are

partitioned into two three-dimensional finite elements.

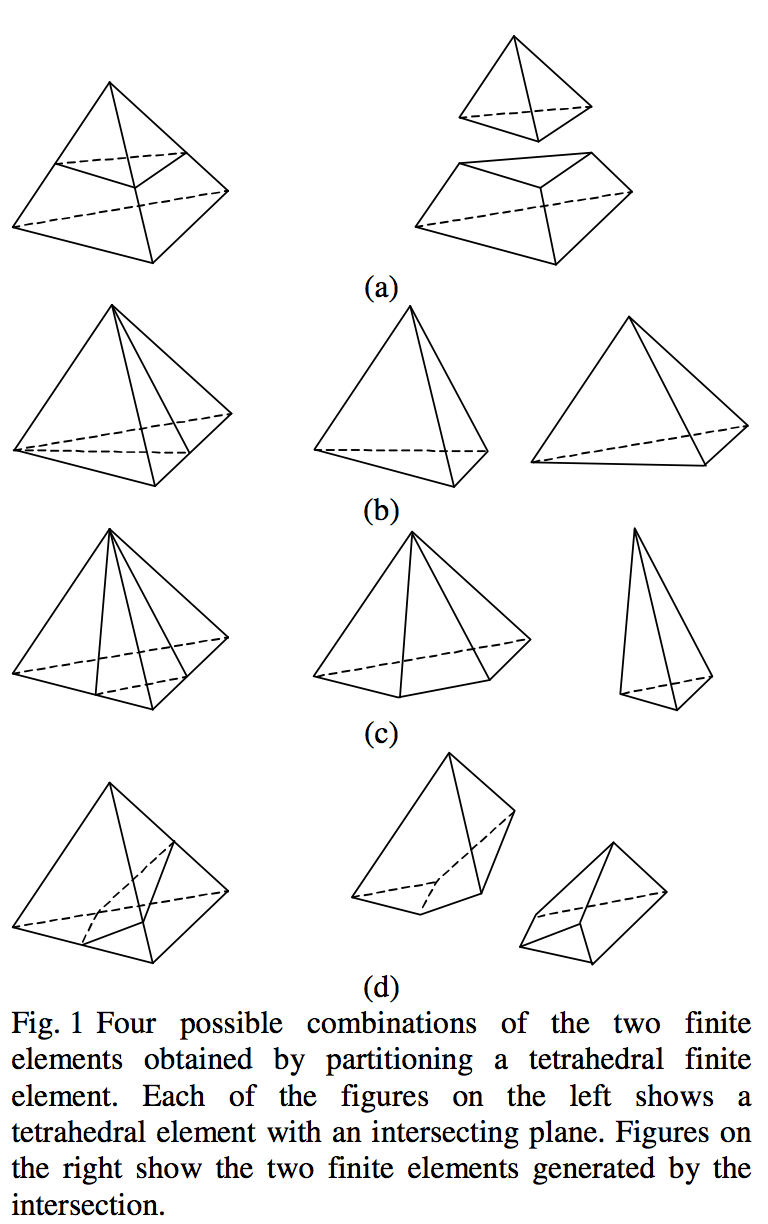

When a two-dimensional plane intersects a tetrahedral

finite element, it leads to one of the following

combinations of two finite elements.

o One tetrahedral and one prismatic element (Fig. 1 a),

o Two tetrahedral elements (Fig. 1 b),

o One pyramidal and one tetrahedral element (Fig. 1 c)

o Two prismatic elements (Fig. 1 d).

In the coextrusion software used, each of the tetrahedral

elements which are intersected by the interface between

adjacent polymer layers is replaced by one of these four

combinations of the two finite elements.

Prediction of Interface Shape

The shape of the interface between adjacent polymer

layers is defined by the no-cross-flow boundary condition

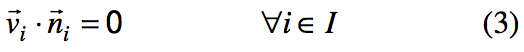

(Eqn. 3). In the coextrusion software used in this work, a

weighted residual form of Eqn. 3 is solved to predict the

interface shape [4].

where I

s is the space of weighting functions (same as the shape functions) on the interface and Γ denotes the interface surface.

In our earlier publication [5] on coextrusion

simulation for simpler extrudate shapes, an initial estimate

of the interface shape had to be specified as an input to the

coextrusion software. Starting with the initial estimate of

the interface shape, the earlier version of the software then

accurately predicted the interface shape between the

adjacent polymer layers. For complicated profile

coextrusion dies, such as the die analyzed in this work, it

is difficult to determine the initial estimate of the interface

between the adjacent polymer layers. Therefore, in the

current version of the polyXtrue software, using the

streamlines for the flow simulation in the previous

iteration, an initial estimate of the interface between the

adjacent polymer layers is automatically determined by

the software. This initial estimate of the interface shape

obtained from the streamlines for the previous flow

iteration is then updated according to the predictions from

the weighted residual form of the no-cross-flow condition

(Eqn. 4).

Resins

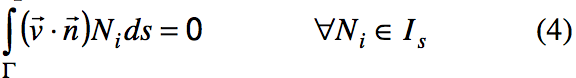

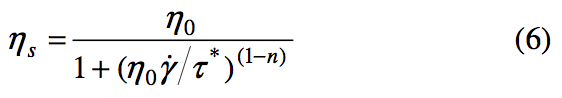

The generalized Newtonian formulation for an

inertialess, incompressible flow with shear-thinning

viscosity was used for the coextrusion simulations. To

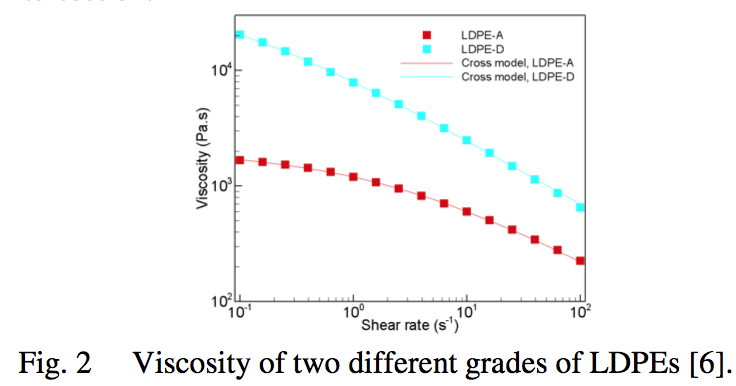

simulate a multilayer flow in coextrusion dies, two different grades of low-density polyethylene (LDPE) were

used in this work. The shear viscosity data at 200oC for

the two grades of LDPE is shown in Fig. 2. Experimental

data from reference [6] (Fig. 2) was used to obtain the

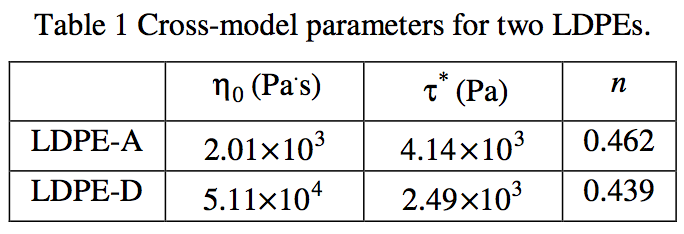

parameters for the Cross model (Table 1).

Fig. 2 also shows the viscosity curves based upon the

Cross model parameters given in Table 1.

Results and Discussion¶

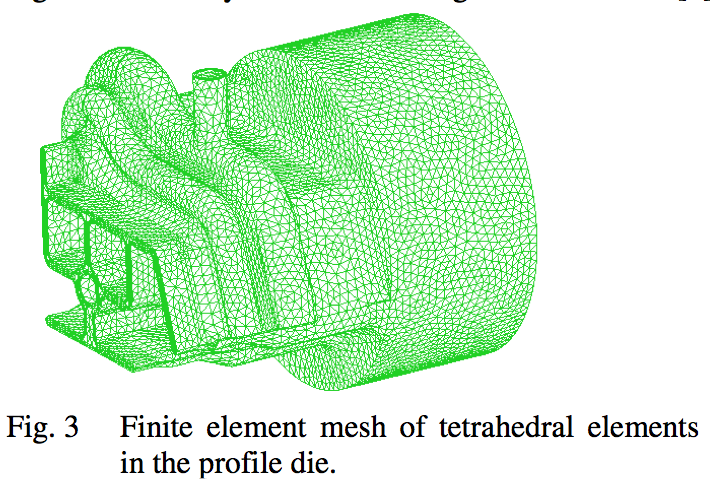

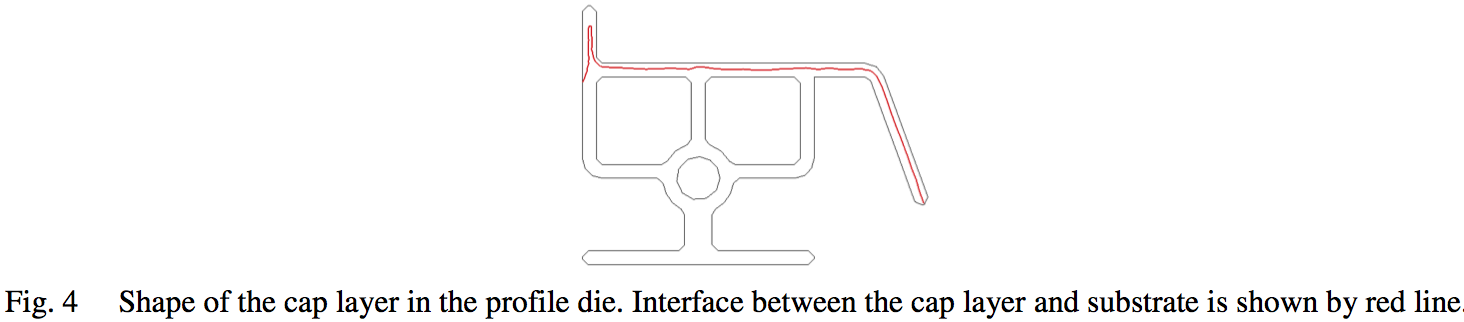

The geometry of the complex profile die analyzed,

and the mesh of tetrahedral elements used for coextrusion

simulation is shown in Fig. 3. Most of the extruded profile

(substrate) is made of one polymer, but it has a thin cap

layer on the top wall. As shown in Fig. 4, the cap layer

also wraps around the vertical tab on the left side of the

part. For substrate of the profile the polymer enters along

the axial direction into a circular channel which is

gradually transformed into the profile shape. The cap

layer enters through a circular channel on top, which is

perpendicular to the die axis. In order to distribute the

polymer from the circular channel to the thin cap layer,

the circular channel is followed by two distribution

channels. Both distribution channels have circular crosssections,

and are connected by a channel with uniform

narrow opening. Because of the narrow channel between

the two distribution channels, the polymer first flows

along the transverse direction and is distributed in the first

distribution channel before it enters into the second

distribution channel. The second distribution channel is

connected to the entrance of the cap layer in the die, again

by a narrow channel which further distributes the polymer

in the second distribution channel before the polymer

uniformly reaches the contact line where the cap layer

meets the substrate for the first time.

The flow in the bi-layer profile die was simulated for

the following three different combinations of LDPE-A

and LDPE-D in the substrate and the cap layer.

Substrate | Cap layer

LDPE-A | LDPE-A

LDPE-A | LDPE-D

LDPE-D | LDPE-A

For these three combinations of LDPE-A and LDPE-D,

the velocities at the circular entrances of the substrate and

cap layer were 0.1 cm/s and 1.5 cm/s, respectively. These

values of entrance velocities were used so that the

velocities of the two polymers are similar when the two

polymers come in contact inside the die. The bi-layer flow

in the die was also simulated for entrance velocity of 3.0

cm/s for the cap layer, while keeping the entrance velocity

for substrate to 0.1 cm/s

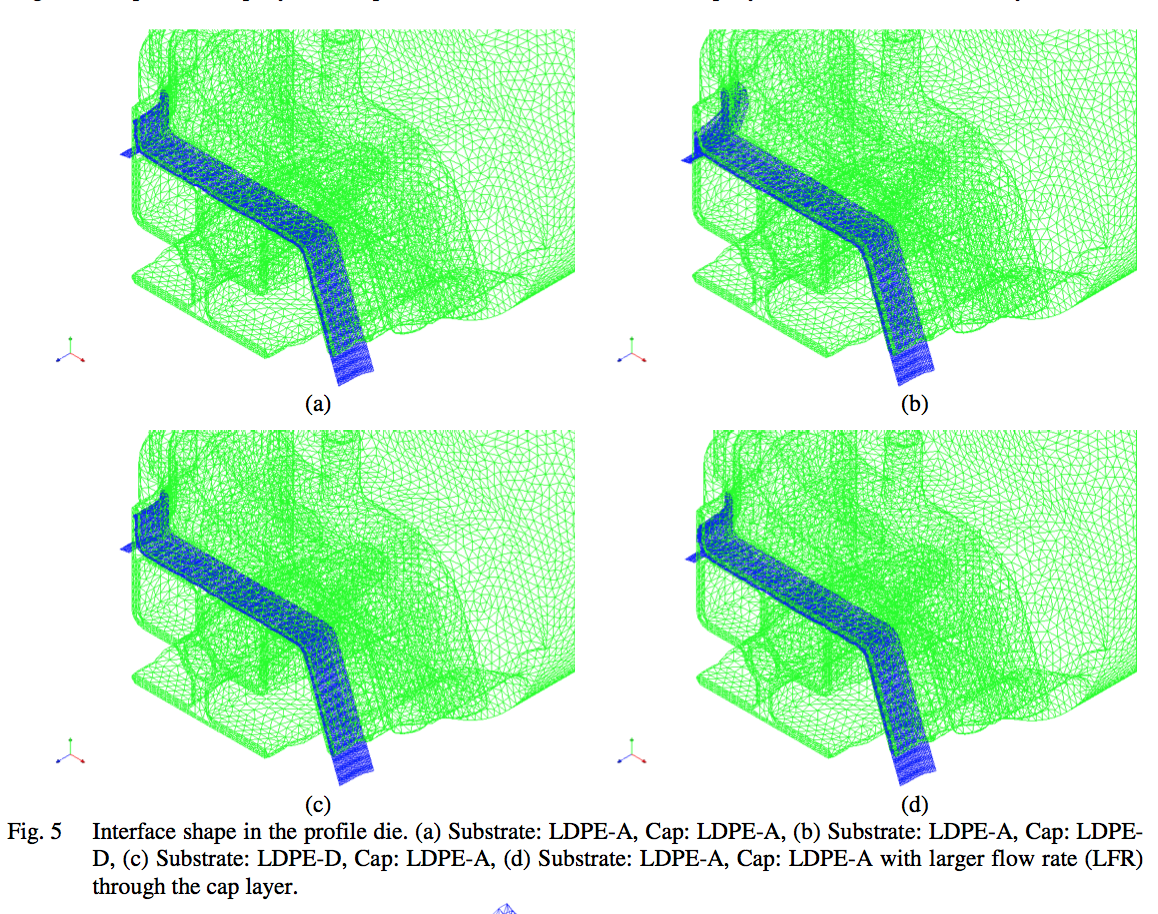

For the three different combinations of LDPE-A and

LDPE-D, as well as for the case with larger flow rate (LFR) through the cap layer, Fig. 5 shows the predicted

interface shape between the two layers. In Fig. 5, all four

interface profiles look very similar, except for the

interface shape in Fig. 5 (b). In Fig. 5 (b), the interface

shape near the contact line in the vertical tab on the left

where the cap layer wraps around the substrate is quite

different than the interface shape for the other three cases.

This difference in the interface shape for the case with

higher viscosity polymer (LDPE-D) in the cap layer and

lower viscosity polymer (LDPE-A) in the substrate is

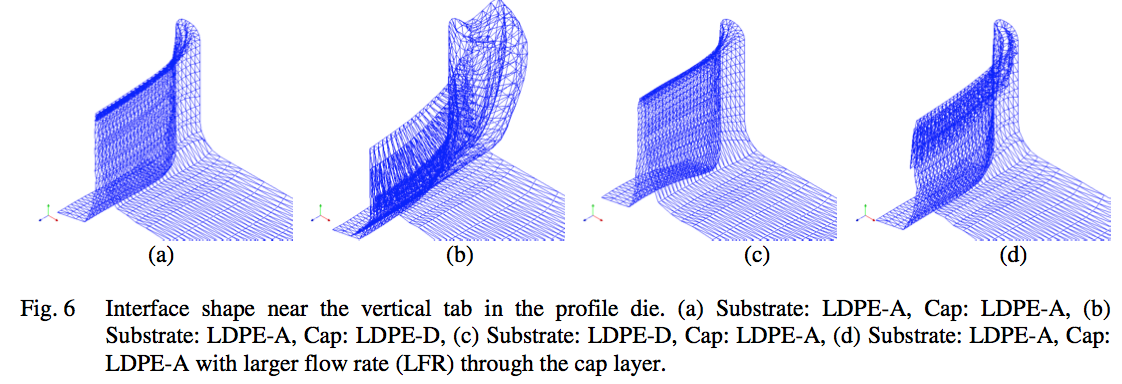

further clarified in Fig. 6. When the viscosity of the

polymer in the cap layer is the same (Fig. 6 a, d) or lower

(Fig. 6 c) than the viscosity for the polymer in the

substrate, after the two polymers come in contact at the

contact line, the interface between the two layers goes

towards the exit along the axial direction. However, for

the case with higher viscosity polymer in the cap layer

(Fig. 6 b), in the vertical tab on the left where the cap

layer wrap around the substrate, the interface first goes

toward the entrance before reversing back and starting to

move toward the exit. It was confirmed that for this case

with the higher viscosity polymer in the cap layer, the

polymer velocity in this region near the vertical tab is in

fact towards the entrance. Because of this initial

movement of the interface towards the entrance, for the

case with the higher viscosity polymer (LDPE-D) in the

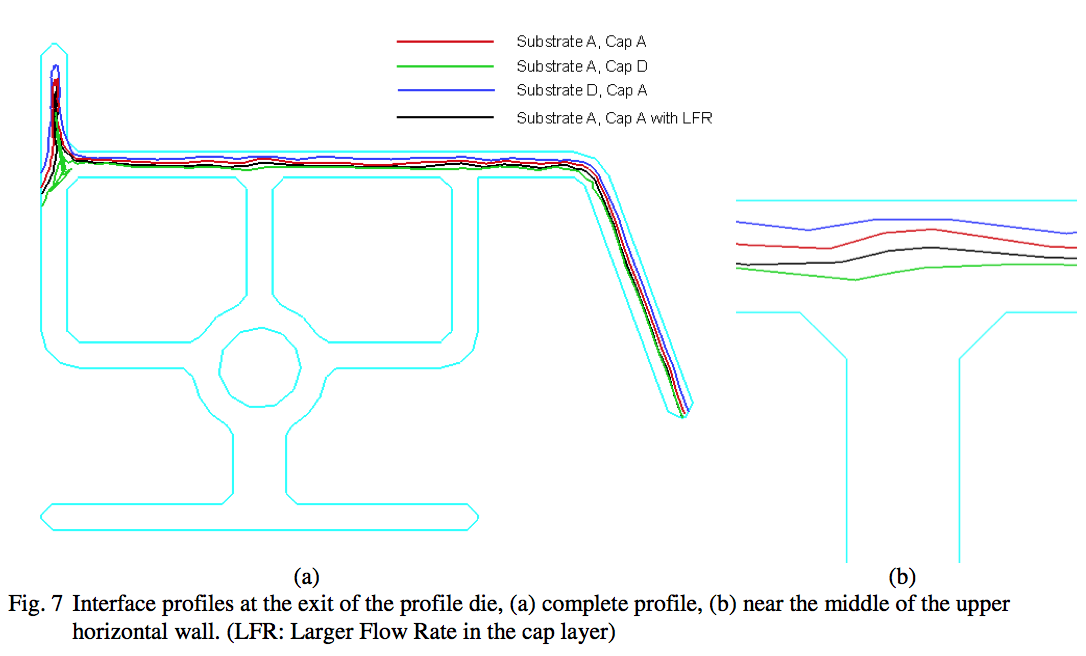

cap layer, the vertical tab on the left is almost completely

occupied by the higher viscosity polymer (green line in

Fig. 7). That is, for this case there is almost no substrate

polymer in the vertical tab. For the horizontal wall on top

of the extrudate profile, effect of the polymer viscosity on

the interface location at the die exit is shown in Fig. 7 (b).

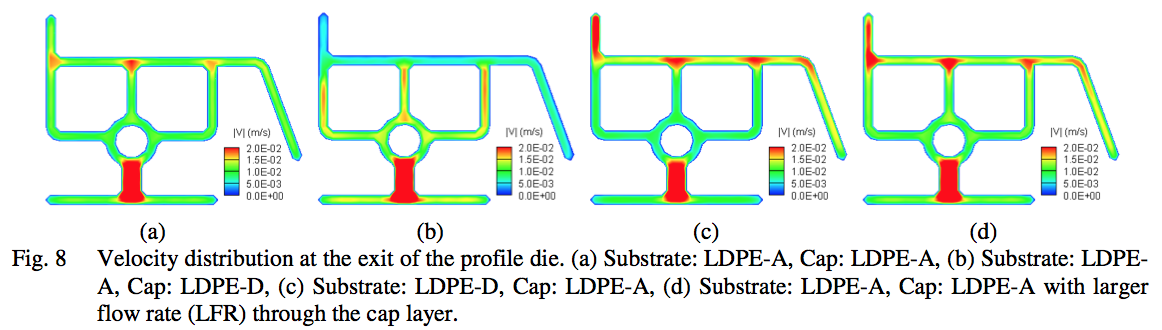

Effect of viscosity on the interface location in the

horizontal wall can be explained by examining the

velocity distributions shown in Fig. 8. In comparison to

the case with low viscosity polymer (LDPE-A) in the

substrate as well as the cap layer (Fig. 8 a), for the case

with higher viscosity polymer (LDPE-D) in the cap layer

(Fig. 8 b), the velocity of the polymer in the cap layer is

lower at the die exit. Therefore, in Fig. 7 (b) in order to

satisfy the mass balance, the interface in the horizontal

wall at the die exit is lower for this case (green line). In

contrast, for the case with higher viscosity polymer

(LDPE-D) in the substrate and the lower viscosity

polymer (LDPE-A) in the cap layer, as expected, the

velocity in Fig. 8 (c) is higher in the cap layer. Therefore,

in order to satisfy the mass balance, the interface for this

case is located at the highest position in Fig. 7 (b) (blue

line). That is, the cap layer is the thinnest for this case. It

is evident from Fig 7 (a) that the cap layer for this case

may be too thin in the region where the vertical tab on the

left connects with the horizontal wall. In this region where

the vertical tab is joined with the horizontal wall, for the

case with higher viscosity polymer (LDPE-D) in the

substrate, the interface is almost touching the die wall.

That is, for this case there may not be any cap layer in this region where the vertical tab connects with the horizontal

wall. For the last case with LDPE-A in the substrate as

well as the cap layer, but larger (double) flow rate in the

cap layer, (Fig. 8 d, and black line in Fig 7), as expected,

the interface is lower in comparison to the case with

smaller velocity in the cap layer and with LDPE-A in both

layers (red line in Fig. 7).

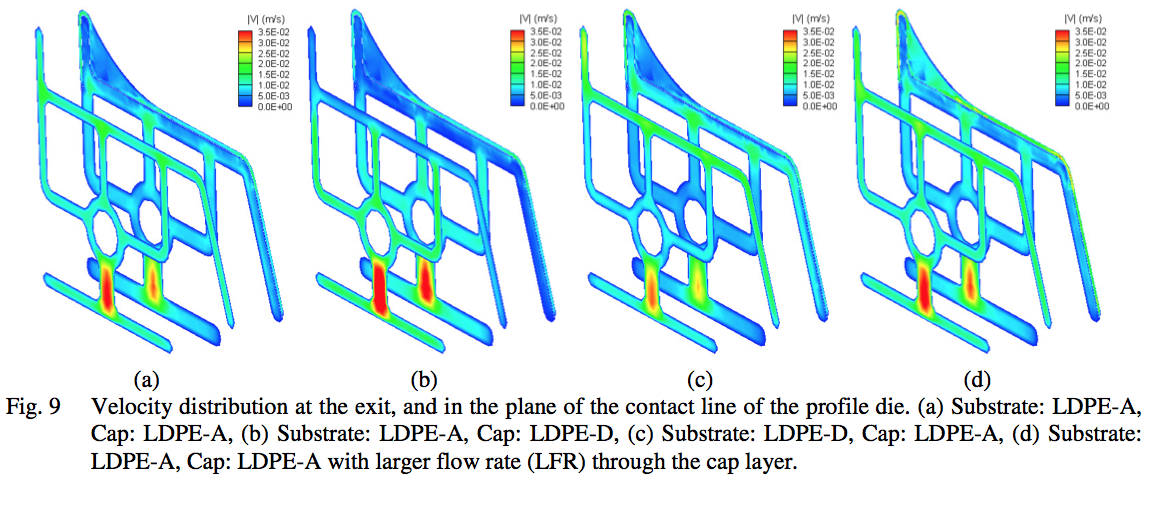

For the three cases with different polymer

combinations and the case with larger flow rate (LFR)

through the cap layer, the velocity distribution at the die

exit and the velocity distribution in the plane where the

cap layer first comes in contact with the substrate are

shown in Fig. 9. It should be noted that the range of scale

bars in Fig. 8 and Fig. 9 are different. For all four cases,

the flow in the substrate is not very well balanced. In

particular, the velocity is significantly higher in the

vertical wall connecting the circle in the middle with the

bottom horizontal wall. This higher velocity in the vertical

wall can be easily reduced, that is, the floor at the die exit

can be easily balanced, by reducing the opening in this

region in the die plates between the circular entrance and

the final die plate at the exit.

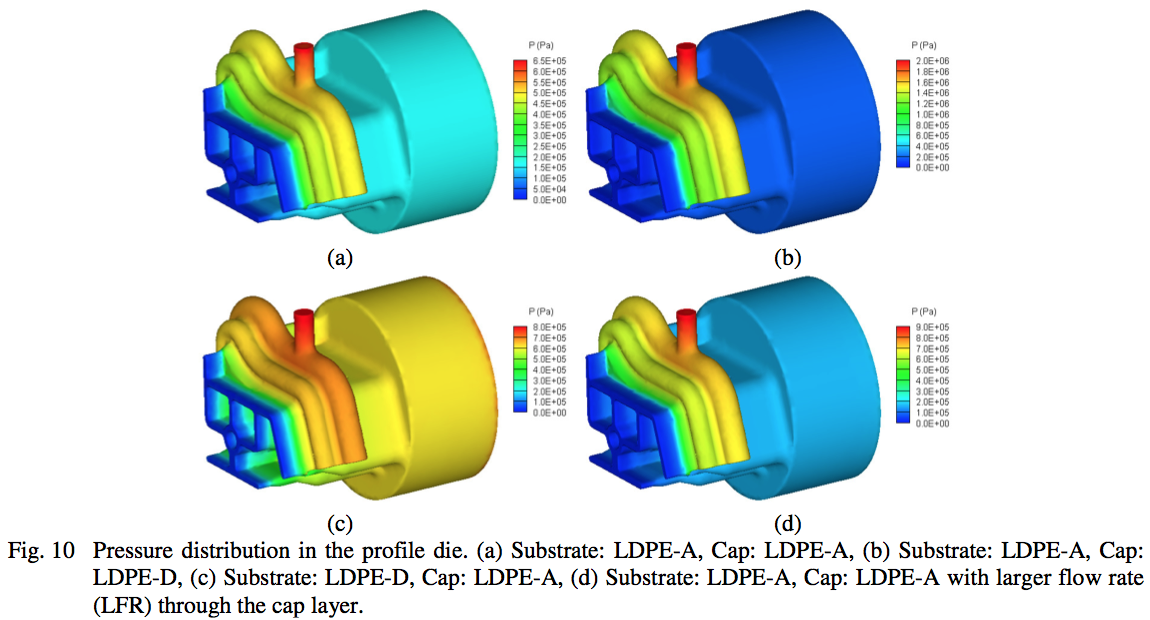

Fig. 10 shows the pressure distributions for the four

coextrusion simulations in the profile die. As expected,

the pressure is zero at the exit, and because of its smaller

cross-section and higher velocity, the pressure is the

highest in the circular channel at the entrance of the cap

layer. In comparison to the pressure for the case with

LDPE-A in both layers, the pressure in the die increases

when the higher viscosity polymer (LDPE-D) is used in

the substrate (Fig. 10 c) or in the cap layer (Fig. 10 b).

Also, the pressure in the two distribution channels and the

circular entrance channel increases for the case with larger

flow rate in the cap layer (Fig. 10 d).

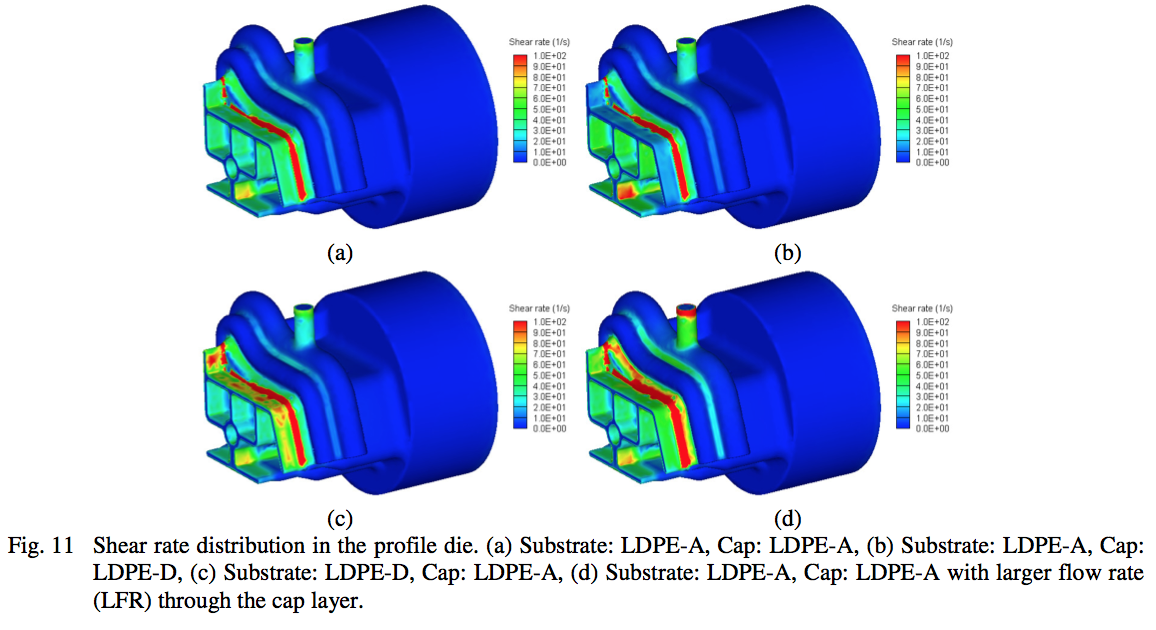

The shear rate on the die walls for the four

coextrusion simulations is shown in Fig. 11. For all four

cases the shear rate is the highest in the cap layer in the

plane where it meets the substrate for the first time. Also,

it is noted that after the two polymers meet, the shear rate

in the cap layer is higher for the case with the higher

viscosity polymer (LDPE-D) in the substrate (Fig. 11 c)

because after the two polymers meet the velocity in the

cap layer is higher for this case (see Fig. 8 c). For the case

with higher velocity through the cap layer (Fig. 11 d), as

expected, the shear rate is higher in the narrow channel

connecting the two distribution channels for the cap layer

and in the narrow channel connecting the second

distribution channel with the contact line where the two

polymers meet.

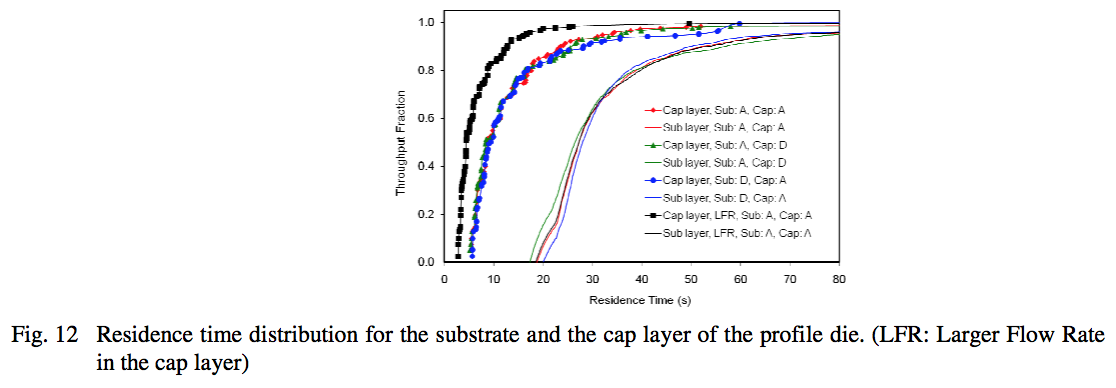

Fig. 12 shows the residence time distributions for the

polymers in the substrate and the cap layer. In Fig. 12, for

the four coextrusion simulations, the residence time for

the substrate is much larger than the residence time for the

cap layer. The larger residence time for the substrate is expected because the circular entrance channel for the

substrate has a larger cross-sectional area. Accordingly, a

smaller velocity (1 mm/s) was specified at the entrance of

the circular entrance channel for substrate, whereas a

much higher velocity (1.5 cm/s or 3.0 cm/s) was specified

at the entrance of the circular entrance channel for cap

layer. Also, as expected, the residence time for the cap

layer is smaller for the case with larger flow rate through

the cap layer (black line with square symbol in Fig. 12).

For the three cases with different polymer combinations in

the substrate and the cap layer, even though the residence

time distribution for the cap layer (and also for substrate)

are different for different polymer combinations, the

difference in the residence time for the cap layer (and also

for substrate) for the three cases is small, and is probably

within the accuracy of the predictions. That is, for the

three different polymer combinations, viscosities of the

polymers seem to have only a minor effect on the

residence time distribution.

Conclusions

Mesh partitioning technique was used for simulation

of a bi-layer coextrusion in a complex profile die. Since

the mesh partitioning technique does not require the

interface between different polymer layers to match with

the inter-element boundaries (instead, allowing the

interface to cut through the tetrahedral finite elements),

this technique could be used to simulate the flow in a

highly complex bi-layer coextrusion die. Effect of

polymer viscosity on interface shape, velocity, pressure,

shear rate, and residence time distribution was analyzed.

Viscosities of the two polymers were found to have

significant effect on the interface shape, velocity,

pressure, and shear rate in the die, but only a minor effect

on the residence time distributions of the two polymers.

References

1. C. Rauwendaal, “Polymer Extrusion”, Hanser Publishers, New York (1994).

2. A. Karagiannis, A. N. Hyrmak, and J. Vlachopoulos, Rheologica Acta, Vol. 29, 71 – 87 (1990).

3. PolyXtrue software, Plastic Flow, LLC, Houghton, MI, 49931.

4. J. Dheur and M. J.Crochet, Rheologica Acta, Vol. 26, 401 – 413 (1987).

5. M. Gupta, SPE ANTEC Technical Papers, Vol. 54, 217 – 222 (2008).

6. J. Dooley and L. Rudolph, Journal of Plastic Film and Sheeting, Vol. 19, 111 – 123 (2003).

Return to

Paper of the Month.