Lateral Stress and Density Measurements for PC, ABS, HIPS, and PP Bulk Resin Feed Stock¶

Stephen J. Derezinski, Extruder Tech, Inc., Penfield, NY 14526Abstract

A special test device [1-3] was used to make

laboratory measurements of the lateral stress and bulk

density of four resin feed polymers: polycarbonate (PS),

acrylonitrile butadiene styrene (ABS), high impact

polystyrene (HIPS), and polypropylene (PP). The data are

all presented as a function of primary compressive stress

on the bulk pellet resin feed stock. Data for lateral stress,

lateral stress ratio, and density are shown, and regression

functions are provided. Data for the bulk temperature rise

during compression are also provided.

Introduction

Lateral stress has been shown to be a factor in

solids conveying [2] as it is the driving force that creates

the frictional force on the barrel and screw that governs

solids conveying. The same frictional force is also key to

the onset of melting where higher lateral stress gives

higher rubbing friction on the barrel to initiate melting

sooner. More time (or extruder length) for melting results

in more complete melting which is key to stable flow and

pressure.

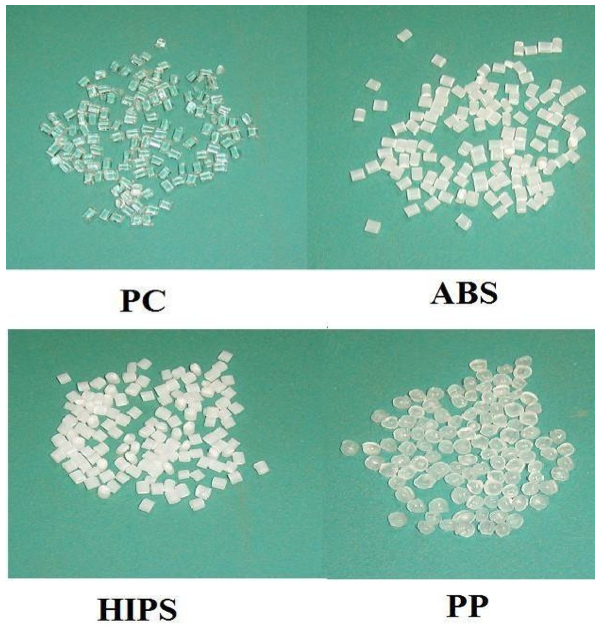

Materials

PC (DOW Icalibre 300-6), ABS (DOW Magnum

342EZ), HIPS (DOW Styron 1170), and PP (DOW

DX5E66) resin feed stocks in pellet form were analyzed.

Sample sizes of about 4 grams were used, and two samples

were tested for each resin. All temperatures were close to

27

oC. Figure 1 pictures the four resin feed stocks used for

this study.

Experimental Equipment

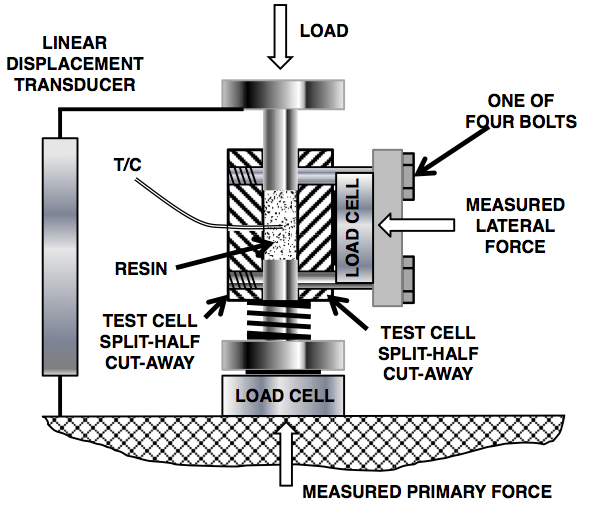

Figure 2 shows the test cell from previous

work [2,3] used to measure the stresses and bulk density of

the different resins. The instrumentation consists of two

load cells (primary load and lateral load), a linear

displacement transducer (specimen length), and a

thermocouple (resin bulk temperature). The dimensions

of the test chamber and the specimen length provide data

to calculate the bulk density of the sample as a function of

stress. The two load cells and the dimensions of the test

chamber give the needed data to calculate the axial and

lateral stresses developed during compression.

The experimental technique used here establishes

the starting point of compression by connecting the

displacement transducer directly to the top cylinder as shown in Figure 2. The ram of the press (not shown in

Figure 2) is not connected to the top cylinder. Therefore,

the origin of the data of each load cell data is precisely set

when the displacement transducer records compressive

strain as the press ram is lowered.

Temperature of the resin in the sample is

monitored during the test, and this has been added since

the last report [3]. A thermocouple made of 30 gauge wire

was made by twisting the wire pair to approximate the

bulk temperature. The thermocouple extended half of the

distance (~6 mm) across the diameter (~12 mm) of the cell

cavity. The small size of wire minimized the effect of its

presence on the compressive strain and had optimized

response time. The initial value and maximum values of

temperature are recorded. All resins had an initial bulk

temperature of about 27

oC.

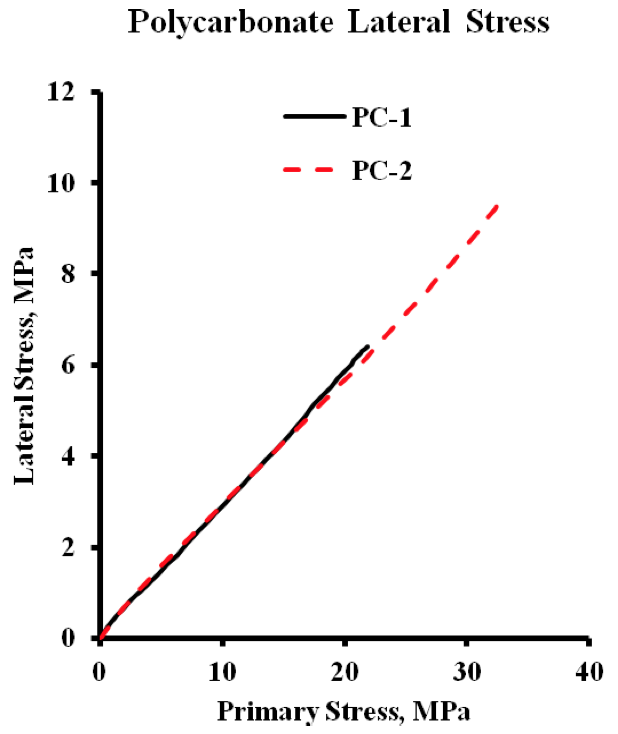

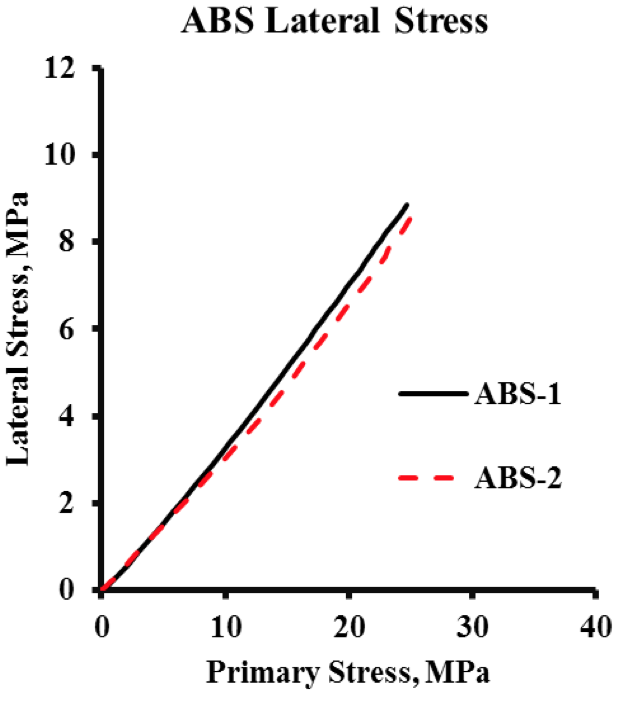

Lateral Stress vs. Primary Stress Data

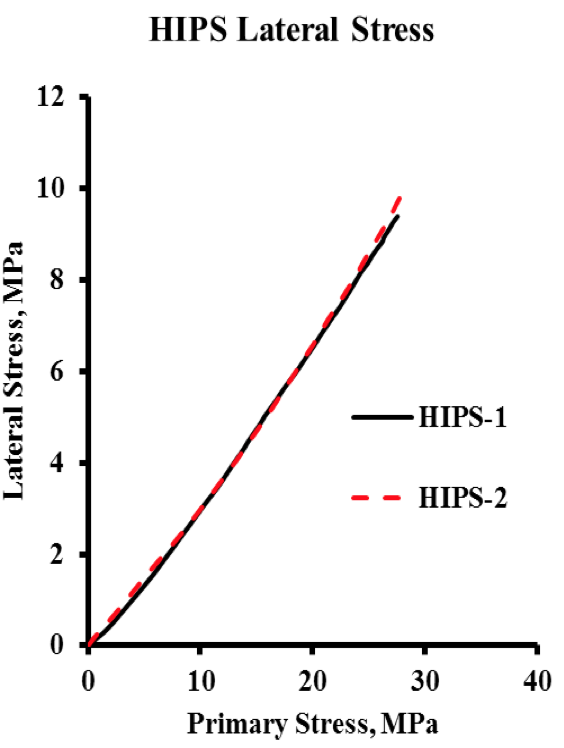

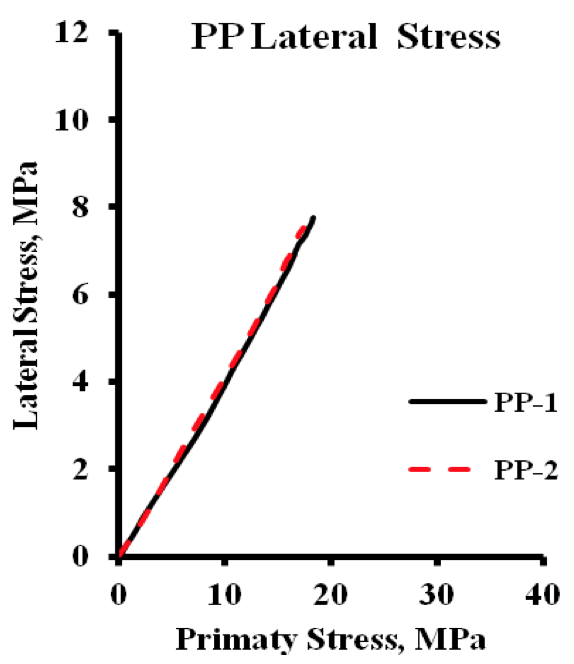

Figures 3-6 show the raw data for lateral stress

versus primary stress for the four polymers, PS, ABS,

HIPS, and PP. The data are repeated to provide two data

sets (1 and 2) for each polymer. As can be seen, the

variation in lateral stress versus primary stress is slight for

PC, HIPS, and PP, but is noticeable for ABS in Figure 4.

This suggests that the variation in lateral stress for ABS

may be unique to it.

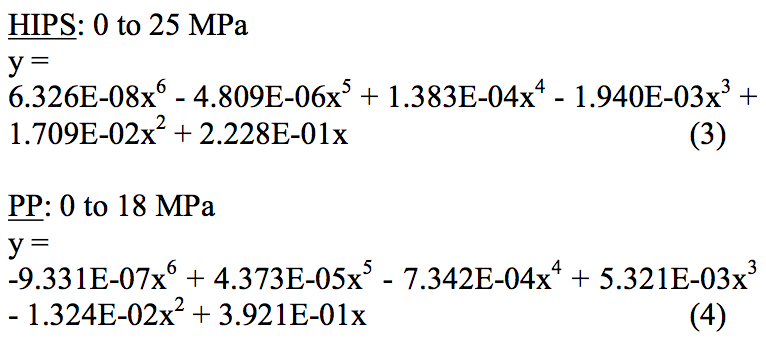

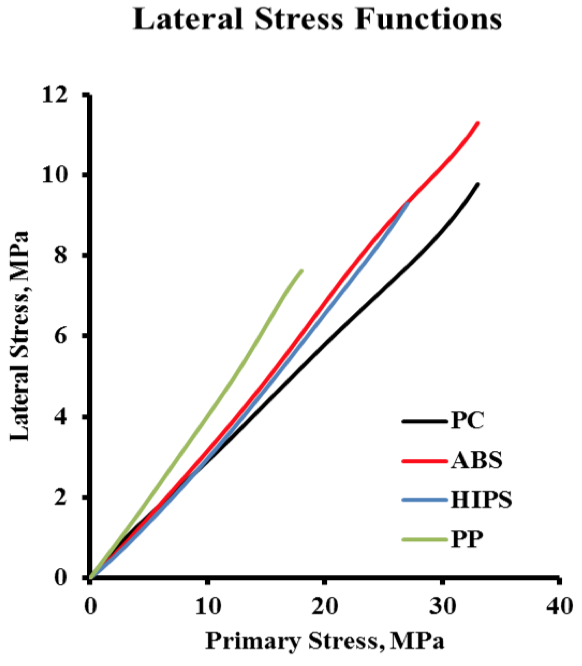

Lateral Stress Regression Functions

Regression curves for the data of lateral stress

versus primary stress shown in Figures 3-6 are given in

Figure 7. The data for each of the two sample runs of each

polymer shown in Figures 3-6 are combined and fitted

with the regression function (trend line). A (0,0) intercept

is assumed (zero primary stress = zero lateral stress). The

trend line consistently used is a 6

th order polynomial. Four

trend functions for lateral stress (y) versus primary stress

(x) are given below as follows:

Figure 7 clearly shows the relationship between

the lateral stresses for the four polymers. PP has the

greatest value of lateral stress while PC has the lowest

lateral stress function. ABS and HIPS appear to be very

comparable, which is logical since they are both styrene.

However, it is not generally the case that the same general

polymer has similar lateral stress as was shown for lateral

stress measurement of three polyethylene resins; LLDPE,

LDPE, and HDPE [2].

Equations 1-4 are only applicable within the

shown specified limits of primary stress. Extrapolation

above the upper limit will likely result in large error.

Limited extrapolation above the upper limit of primary

stress should be done with a linear trend line, if need be.

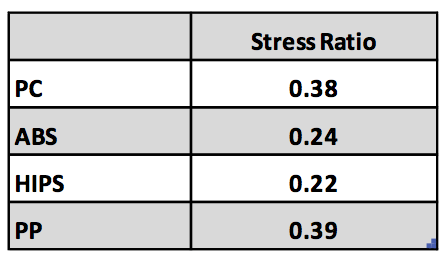

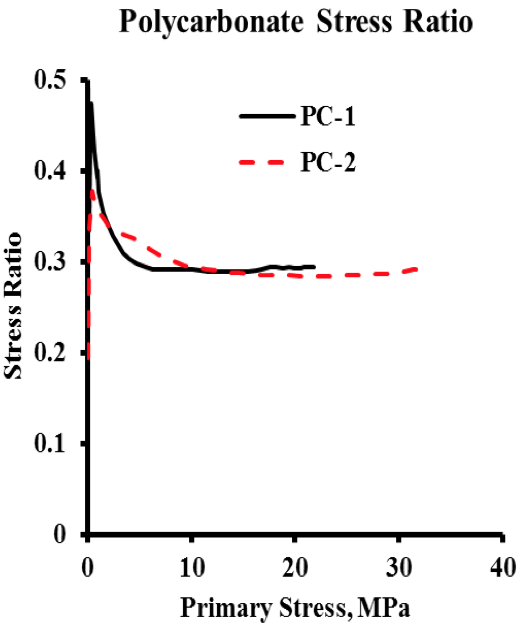

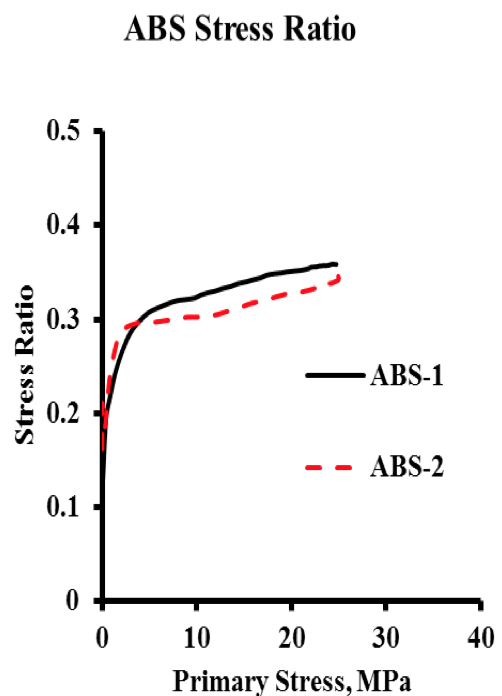

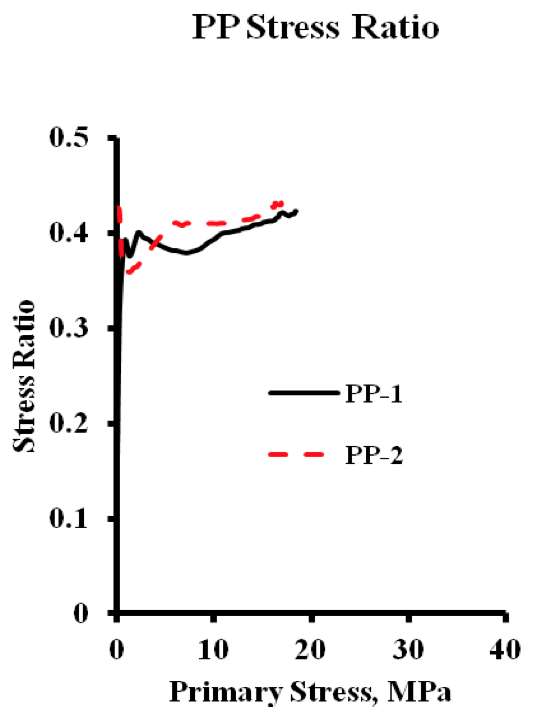

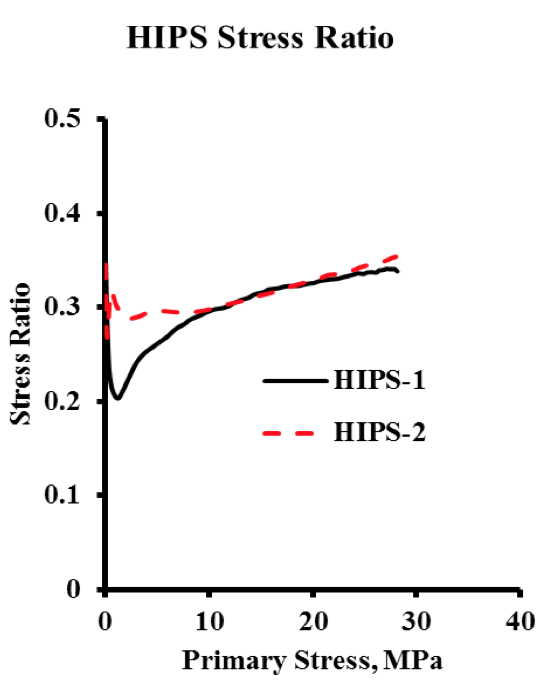

Lateral Stress Ratio Functions

The lateral stress ratio is defined as the ratio of

the lateral stress divided by the primary stress. The lateral

stress ratio function of primary stress is useful in modeling

solids conveying as it provides a convenient mathematical

method for including lateral stress as the product of stress

ratio and primary stress. The lateral stress ratio also

provides more detail about the lateral stress that is not

obvious from the lateral stress versus primary stress data

(Figures 3-6). This is particularly true at low stress levels

(inlet to solids conveying situation), so it is important to

the analysis of every solids conveying process. Figures 8-

11 show the lateral stress ratio functions calculated from

the raw data of lateral stress shown by Figures 3-6.

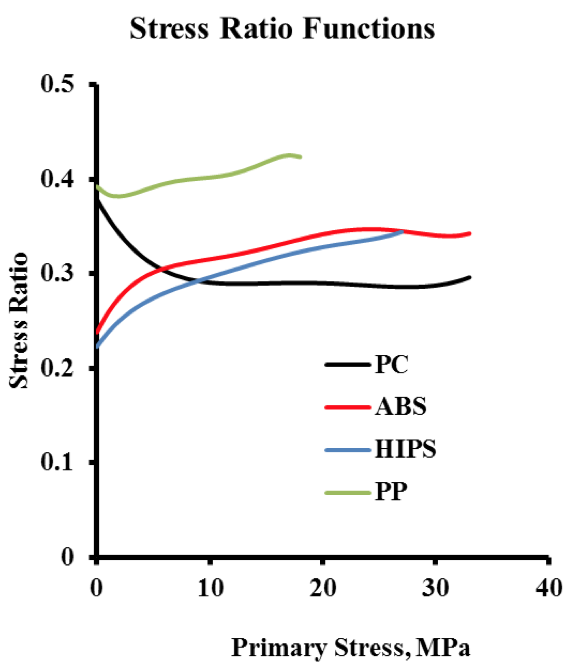

The resulting equations for stress ratio are the

same as Equations 1-4 but with the exponential power of

each term reduced by a value of one. Equations 1-4 are 6

th

order polynomials, so lateral stress ratio functions are then 5

th order polynomials. Figure 12 plots the resulting 5

th order equations for each of the four resins tested, and comparison to the raw data of Figures 7-10 shows that the 5

th order polynomial approximates the data well. Figure

12 demonstrates more detail about the lateral stress than

does the raw data of lateral stress in Figures 3-6.

The lateral stress ratio as defined cannot be

calculated from the raw data at zero primary stress (0/0 has

no mathematical result). This is obvious from Figures 8-

11 by the sporadic nature of the curves near zero primary

stress. However, the 5

th order function for lateral stress

ratio has a constant term that is the limit for lateral stress at zero primary stress. This limit provides a single value

unique for each resin that indicates lateral stress at the

entrance to solids conveying. Table 1 summarizes the

limit of stress ratio at zero primary stress.

Table 1 Stress Ratio Limit at Zero Primary Stress

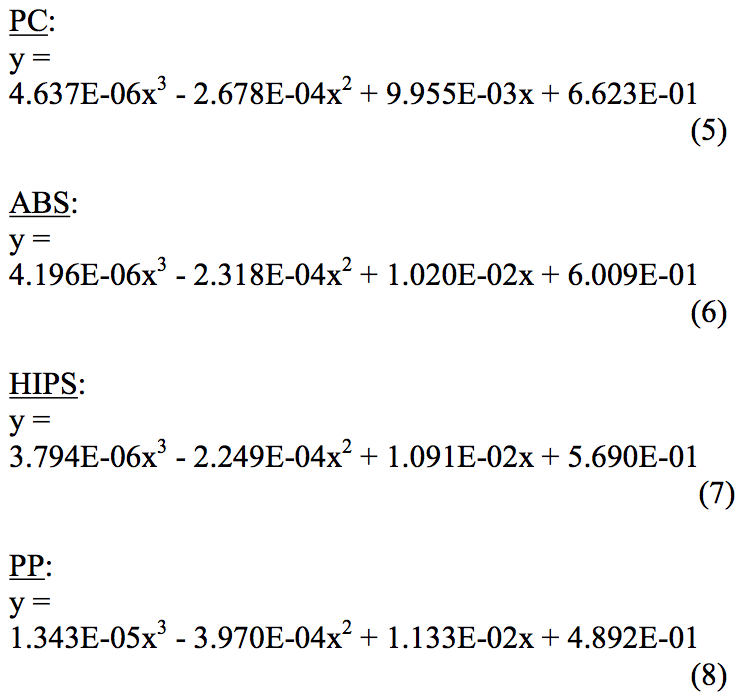

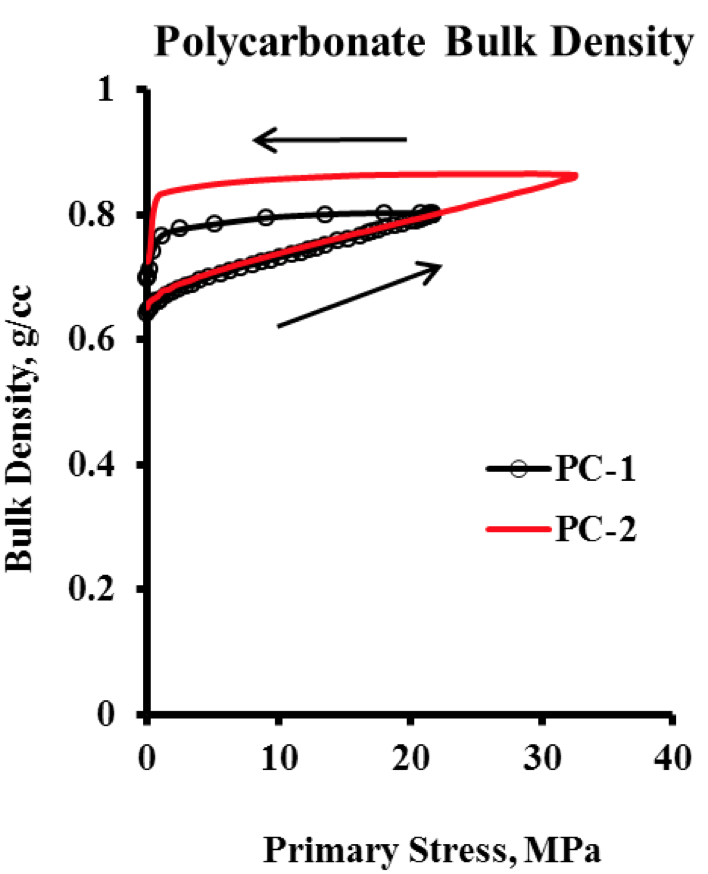

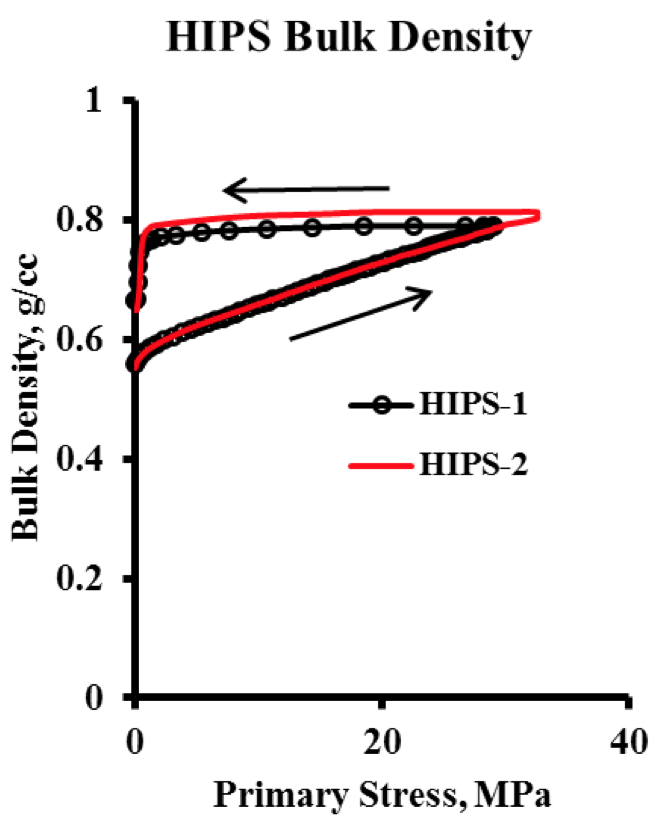

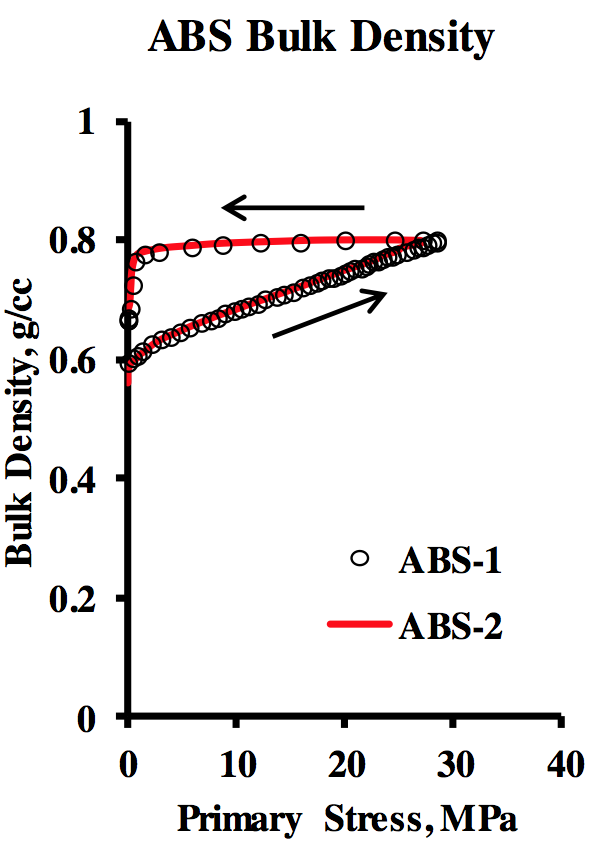

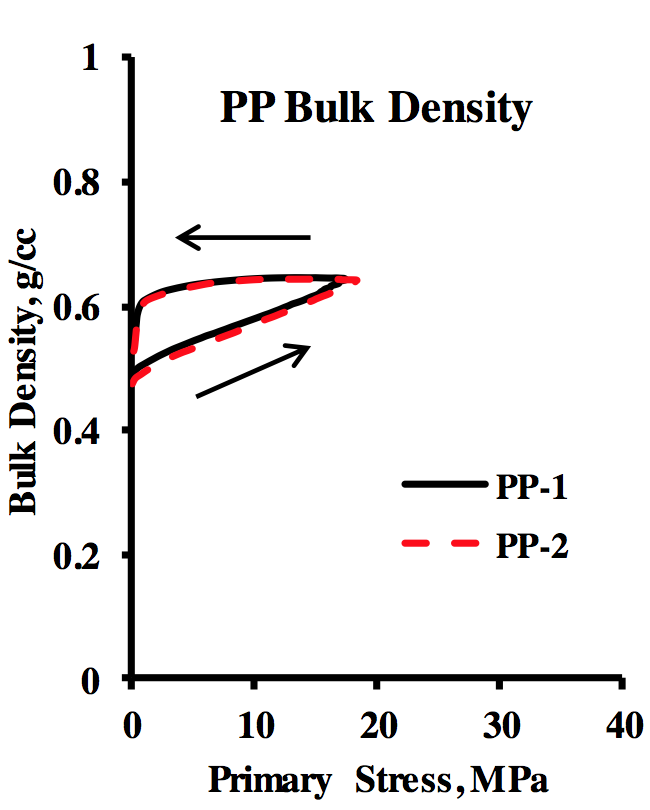

Bulk Density

Data: The bulk density of each of the four resins

was obtained from the measurement of compressive strain

and measured mass of the sample. Data for the bulk

density are plotted as a function of primary stress in

Figures 13-16. The data show the full cycle of

compression to the maximum value of primary stress and

then the reverse to zero primary stress. Excellent

agreement between each of the two trials of all four

samples is evident from the data of Figures 13-16.

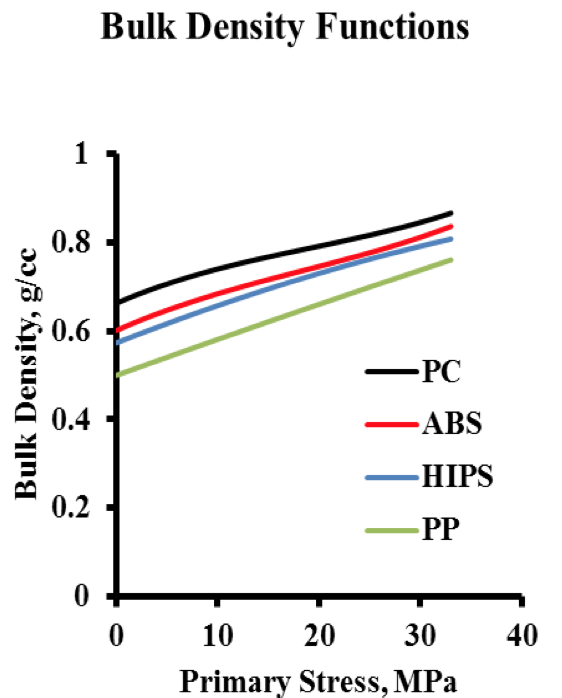

Regression of Density Data: Trend curves were

obtained for the bulk density data of Figures 13-16. The

trend curves are for only the compressive leg of the density

data. Figure 17 shows the regression curves so obtained,

and extrapolation to 30 MPa of primary stress is

illustrated. The regression equations for density (y) versus

primary stress (x) in Figure 16 are given as follows:

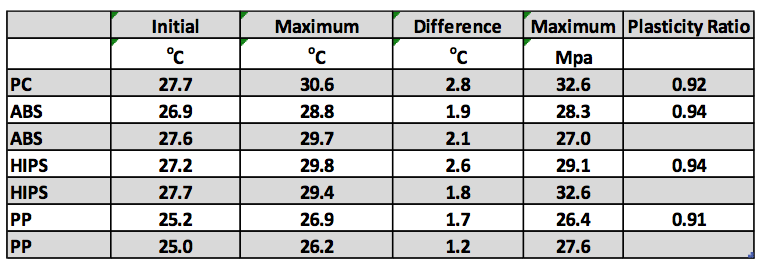

Energy Balance

Plastic Deformation: Mechanical energy used

for the compression of the resin sample by the test cell is

calculated by integration of the density versus primary

stress data shown in Figures 13-16 according to a method

previously given [1]. Integration for compression to

maximum stress provides the total energy. Integration

during the reverse of the load to zero provides elastic

energy of the specimen. The plastic energy is the total

energy less the elastic energy. The results shown in Table

2 give the ratio of plastic energy to total energy. This is

then used to characterize the ability of the polymer “solid

plug” to elastically expand during melting to maintain

solid contact (high rubbing friction) with the barrel for

efficient melting. The high plasticity (low elasticity)

calculated here is detrimental to maintaining solids contact

with the barrel when the solids plug is being eroded by the

removal of melt. Low plasticity (high elasticity) would

provide better conditions for efficient melting, and

extrusion process data for this effect were previously cited

[1]. Good screw design with proper compression section

length can alleviate this issue.

Table 2 Temperatures, Maximum Stress, and Plasticity Ratio

Heat Generation: Temperature measurement of

the polymer during the test was used to investigate the

temperature change that may accompany heat generation

during compression of the resin. A thermocouple was

located (see Figure 2) in the center of the polymer sample

to register the initial and maximum bulk temperature

during the test, and the results are shown in Table 2. The

temperature was found to increase, and the level of

increase was from about 1 to 3

oC for all four resins.

Summary

Lateral stress and bulk density were measured for

four feed resins, PC, ABS, HIPS, and PP. Data for

primary stress up to about 30 MPa show that the lateral

stress of the bulk feed does depend on the polymer. The

stress ratio is used as a function of primary stress to

provide details of the lateral stress and provide an efficient

mathematical method for incorporating lateral stress into

computational models. Regression equations are provided

for such use in computational applications.

The bulk density of the resins was accurately

measured, and regression equations for it are given. The

plasticity of the resin feed is calculated from the

compressive energy based on the density versus primary

stress data and shown to be over 90% for all resins tested.

Finally, the phenomenon of bulk temperature increase

during compression of the resin feed is measured to be up

to 3

oC for the resins tested here.

Conclusions

1. The lateral stress for PP was measured to be the

greatest. The lateral stress ratio was close to 0.4

over the entire primary stress range (0-20 MPa).

2. The lateral stress for the PC was the lowest, and the

lateral stress ratio was about 0.3 over most of its

range. However, it had a lateral stress ratio of up to

about 0.5 at initial primary stress levels. This

relatively high initial stress ratio was unique among

the four resins tested.

3. The lateral stress for ABS and HIPS (both styrene

resin) were measured to be very similar and

between that of PC and PP.

4. The lateral stress ratio for ABS and HIPS was just

above 0.3 over most of the measured range. Low

initial values of about 0.23 greatly differentiate

these resins from PC and PP with initial stress ratios

of about 0.4.

5. Heat is generated during the compression of bulk

resin feed stock as measured by an increase in bulk

temperature of 1 to 3

oC.

6. The energy of plastic deformation for all resins was

above 90% of the total energy of compression as

calculated by integration of the density versus

pressure data.

Acknowledgements

Very special thanks to son, Stephen J. Derezinski,

III of Platform Technology Ventures, Inc., for specifying

the temperature measurement equipment appropriate for

this experimental work.

References

1. S. J. Derezinski 2009. “Laboratory Measurements of

Resin Bulk Specific Gravity of PET and LDPE,”

ANTEC 2009-Proceedings of the 67th Annual

Conference & Exhibition, Chicago, IL, June 22-24,

2009, Society of Plastic Engineers, pp. 136-141.

2. S. J. Derezinski 2010. “Measurements of Biaxial

Stresses During the Compression of Bulk Resin

Feed,” ANTEC 2010-Proceedings of the 68th Annual

Conference & Exhibition, Orlando, Fl, May 16-20,

2010, Society of Plastic Engineers, pp. 617-622.

3. S. J. Derezinski, “Lateral Stress and Bulk Density of

PET Resin with Recycle”, ANTEC 2011-

Proceedings of the 69th Annual Conference and

Exhibition, Boston, Ma, May 1-3, 2011, Society of

Plastic Engineers, pp 100-100.

Key Words

Stress, bulk density, solids conveying, single screw,

extrusion, pellets, biaxial stress, plastic resin, bulk

properties

Figure 1. Four Resins Tested

Figure 2. The Test Cell for Measuring the Primary and Lateral Forces During Compression of Bulk Resin Feed as a function of bulk density [1,2]. Diameter of the cylinder is 12.7 mm. The linear displacement transducer records the height of the sample to establish the evolving bulk density value and lateral area of force. A thermocouple is centered in the resin to obtain the starting and maximum temperatures during compression.

Figure 3. Polycarbonate Lateral Stress versus Primary Stress Raw Data

Figure 4 Lateral Stress Raw Data for ABS Resin

Figure 5. Lateral Stress Raw Data for HIPS

Figure 6. Raw Data for Polypropylene Lateral Stress

Figure 7. Lateral Stess Function for Four Polymers. Curves obtained by regression analsysis of two data sets

for each of the four polymers (Figures 3-6).

Figure 8. Polycarbonate Stress Ratio Data versus Primary Stress. Curves calculated from data of Figure 3.

Figure 9. Stress Ratio for ABS Resin. Raw data of Figure 4 used to calculate the stress ratios.

Figure 10. Lateral Stress Ratio for HIPS. Curves calculated directly from raw data of Figure 5.

Figure 11. Stress Ratio for Polypropylene Curves calculated directly from raw data of Figure 6.

Figure 12. Lateral Stress Ratio Functions for Four Resins The curves are based on the regression equations, Equations 1-4, represented in Figure 7. The lateral stress ratio functions are obtained from Equations 1-4 by merely lowering the exponent in each term by a value of 1.

Figure 13. Raw Data for Polycarbonate Density versus Primary Stress. Two samples shown. Arrows indicate compression and release.

Figure 14. Raw Data for Density of Two ABS Samples. Arrows indicate compression and release.

Figure 15, Raw Density Data for HIPS Resin Density Arrows indicate compression and release.

Figure 16. Raw Data for Bulk Density of Polypropylene Arrows indicate compression and release.

Figure 17. Regression Curves for Bulk Density of Four Resins Only the density during the compression of each resin is shown See Equations 5 to 8.

Return to

Paper of the Month.