HSEI Twin Screw Extruders

Vol. 35 #1, Winter 2010

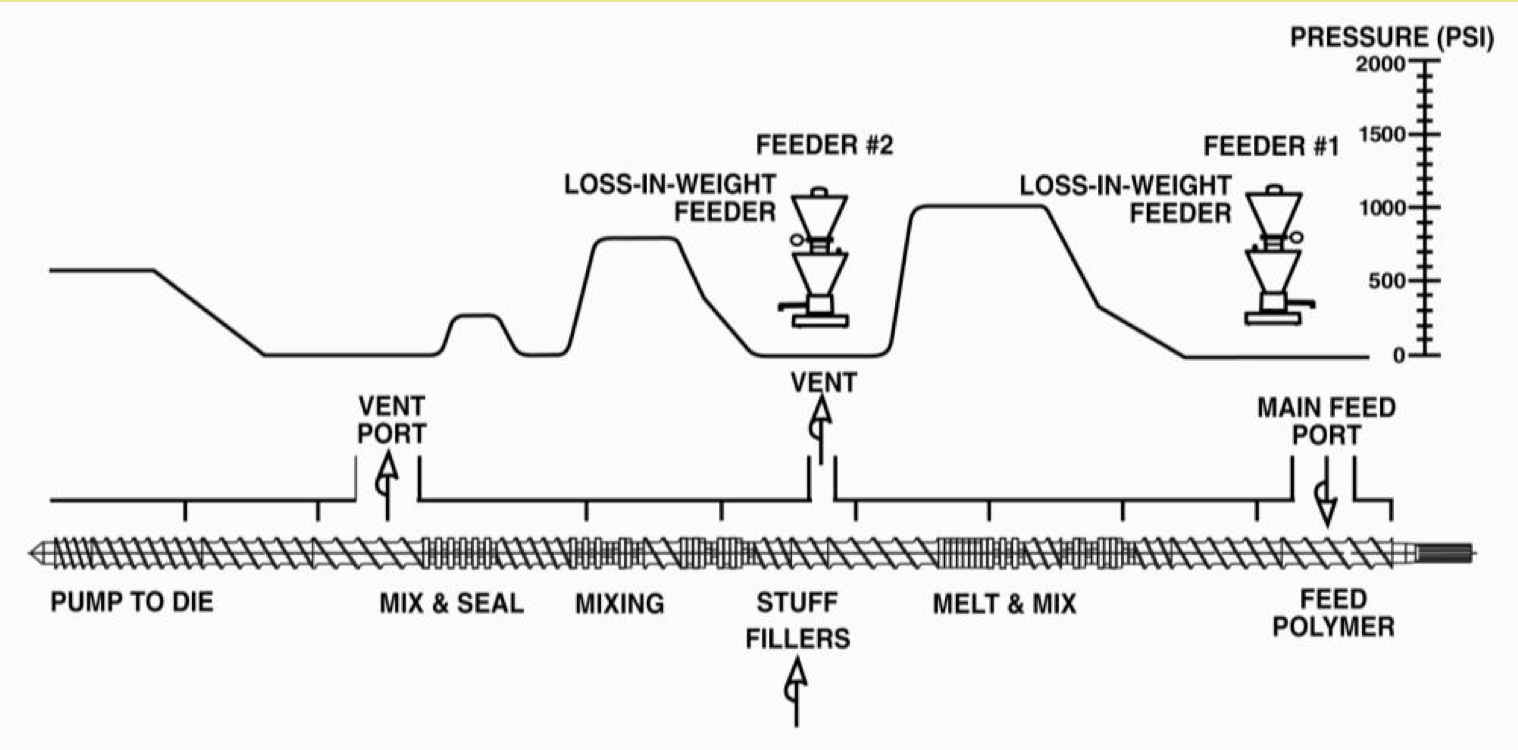

High speed, energy input (HSEI) twin screw extruders are starve fed with the output rate determined by the feeder(s). Feeders meter solids (pellets/fillers) and/or liquids into the HSEI twin screw extruder for compounding, devolatilization and REX. The extruder screw RPM is independent from the feed rate and is used to optimize mass transfer efficiencies. Because the pressure gradient is controlled, and zero for much of the process, materials can be introduced into downstream barrels sections, often by a twin screw side stuffer that “pushes” materials into the extruder screws. Downstream side stuffing can be beneficial to obtain high filler loadings, to decrease the abrasive wear in the extruder process section, and when processing shear sensitive materials. The controlled pressure profile also facilitates venting.

Fig. Example pressure profile in HSEI twin screw extruder.

- Charlie Martin, Leistriz

Return to

Extrusion Hints